Table of Contents

The Importance of PCB Prototyping: Why You Need It

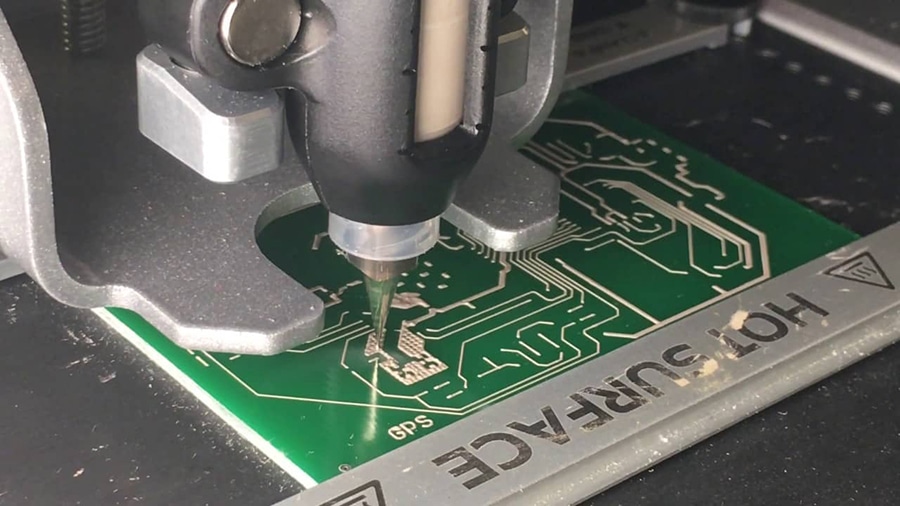

Prototyping is an essential step in the development process of any electronic product. Whether you’re a hobbyist or a professional electronics designer, PCB prototypes play a crucial role in bringing your designs to life.

Creating a PCB prototype allows you to physically validate and test your circuit design, rather than relying solely on simulations. No matter how advanced the simulation software is, it can never fully predict all the potential issues and interferences that may arise in the real world. A physical prototype enables you to identify and address design flaws that could have been overlooked.

Moreover, having a tangible and touchable PCB prototype makes it easier to communicate your design concepts to colleagues, investors, or customers. It transforms abstract ideas into concrete, understandable forms, facilitating better comprehension and feedback. In fact, many major companies release prototypes before launching new products to gather valuable insights.

Whether you’re pursuing a personal learning experience, a hobby project, or a commercial application, PCB prototyping is an indispensable part of the product development journey. Don’t underestimate the power of prototypes – they can help you avoid costly modifications down the line and ultimately create a superior final product.

Key Factors Affecting PCB Prototype Cost

When it comes to PCB prototyping, understanding the various cost factors is crucial for budgeting and making informed decisions. While the overall cost may seem straightforward, the truth is that numerous elements can influence the final price tag. In this section, we’ll delve into the key factors that play a significant role in determining the cost of your PCB prototype. By gaining insights into these cost drivers, you’ll be better equipped to optimize your design, select appropriate options, and ensure a cost-effective prototyping experience.

From the physical attributes of the PCB, such as board size and layer count, to the choice of materials and surface finishes, each aspect contributes to the overall expense. Additionally, factors like production quantity, specialized requirements, and turnaround time can further impact the pricing. By exploring these elements in detail, you’ll develop a comprehensive understanding of the variables at play, enabling you to make well-informed choices that align with your project’s budget and specifications.

So, let’s dive into the key factors affecting PCB prototype cost and uncover the knowledge you need to navigate this crucial phase of product development successfully.

Board size and layer count

One of the primary factors influencing the cost of your PCB prototype is the board size and layer count. The larger the board dimensions and higher the layer count, the more materials and manufacturing processes are required, driving up the overall costs significantly.

Regarding board size, most PCB manufacturers offer pricing tiers based on the board area. For instance, at JHYPCB, a 2-layer 5cm x 5cm PCB prototype costs around $5, while a larger 10cm x 10cm board of the same specification would cost around $10. As the size increases to 20cm x 20cm, the cost can reach $40 or more.

The number of layers in your PCB design is another crucial determinant of the prototype cost. Single-layer and double-layer PCBs are generally the most economical options, with prices starting as low as $5 for simple designs. However, as you move to 4-layer boards, the costs can double or even triple depending on the complexity. For instance, a 10cm x 10cm 4-layer board may cost around $20-$30.

It’s essential to carefully consider your board size and layer requirements during the design phase. While a larger board or higher layer count may seem beneficial for future-proofing, it’s crucial to balance your current needs and the associated costs, especially when prototyping on a budget. Optimizing your design for the minimum required board size and layers can help keep your PCB prototype cost low without compromising functionality. Industry data suggests that buyers can save up to 50% on prototyping costs by optimizing their designs.

Remember, prototyping aims to validate your design concept efficiently and cost-effectively. By being mindful of board size and layer count, and referring to manufacturer pricing tiers, you can ensure that you’re not overspending on unnecessary features, allowing you to allocate your resources wisely.

PCB materials and finishes

Another key factor that can significantly impact the cost of your PCB prototype is the choice of materials and finishes. PCBs are available in various materials, each with its own properties, durability, and price point.

The most common and cost-effective material for prototyping is FR-4, a glass-reinforced epoxy laminate. FR-4 boards offer a good balance of performance and affordability, making them suitable for various applications. Prices for FR-4 PCB prototypes can start as low as a few dollars for simple designs.

However, if your project demands higher thermal resistance, better electrical insulation, or improved high-frequency performance, you may need to consider more advanced materials like Rogers or Polyimide. These specialized materials can cost substantially more than FR-4, sometimes doubling or tripling the prototype price.

In addition to the base material, the type of surface finish you choose can also affect the overall cost. Common options include:

- Lead-free HASL (Hot Air Solder Leveling): An economical choice, ideal for basic prototypes.

- Immersion Silver: Provides better solderability and shelf life, slightly more expensive.

- ENIG (Electroless Nickel Immersion Gold): Offers superior planarity and oxidation resistance, but at a higher cost.

- Additional options: Consider other surface finishes like OSP (Organic Solderability Preservatives) and ENEPIG (Electroless Nickel / Electroless Palladium / Immersion Gold) for specific needs, each with its own cost implications.

Regarding materials beyond FR-4, some projects may benefit from alternative options such as Aluminum PCBs or Metal Core PCBs. Aluminum PCBs offer excellent thermal conductivity, making them suitable for high-power LED applications or other heat-sensitive designs. Metal Core PCBs, on the other hand, provide enhanced mechanical strength and can dissipate heat more efficiently than standard FR-4 boards. While these materials offer distinct advantages, they typically come at a higher cost than FR-4.

Other factors like the requirement for solder mask, silk screen, or impedance control can further increase the prototype pricing.

It’s crucial to carefully evaluate your project’s material and finish requirements during the design stage. While premium materials and finishes may offer performance benefits, they can significantly increase costs, especially for prototyping. Starting with more cost-effective options like FR-4 and HASL can help you validate your design concept without breaking the bank.

Remember, the key to keeping your PCB prototype cost low is to strike the right balance between performance needs and budget constraints. By understanding the pricing implications of different materials and finishes, you can make informed decisions and optimize your prototype for both functionality and affordability.

Production quantity (low vs high volume

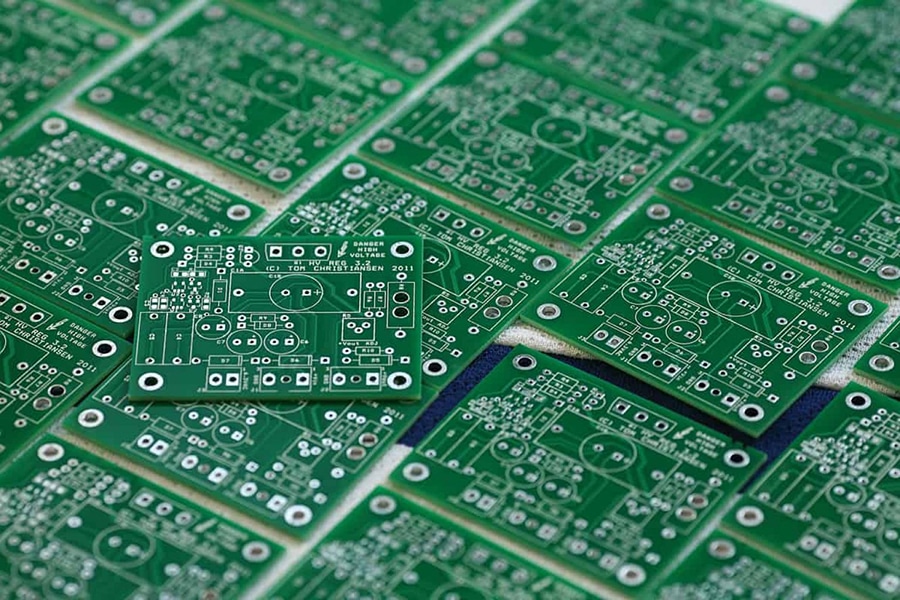

The production quantity you require for your PCB prototype can significantly influence the overall cost per unit. Generally, low-volume or prototype orders tend to be more expensive on a per-unit basis compared to high-volume production runs.

When it comes to prototyping, most PCB manufacturers offer various pricing tiers based on the order quantity. For instance, at JHYPCB, the cost for a single 10cm x 10cm, 2-layer PCB prototype with basic specifications can be around $10-$15. However, if you order 10 pieces of the same design, the cost per unit can drop to around $5-$8, effectively reducing the overall expenditure.

This pricing model is primarily due to the setup costs associated with PCB manufacturing. Regardless of the order quantity, manufacturers incur fixed expenses for tasks like tooling, programming, and panel preparation. With larger production volumes, these fixed costs can be spread across more units, resulting in lower per-unit prices.

It’s important to note that while ordering multiple prototypes may seem more expensive upfront, it can actually save you money in the long run. Having multiple units allows for more comprehensive testing, enabling you to identify and address potential issues more effectively. This can help you avoid costly design revisions and subsequent re-orders, ultimately leading to cost savings.

When planning your PCB prototype order, it’s advisable to carefully consider your testing and validation requirements. While a single prototype may be sufficient for basic functionality checks, ordering a small batch can provide more opportunities for thorough evaluation and debugging, ensuring a robust final design.

Moreover, consider the impact of lead time on cost, as higher volume orders may have longer lead times due to increased manufacturing complexity. Additionally, be mindful of minimum order quantities (MOQs) imposed by manufacturers, as reaching certain order quantity thresholds may unlock lower per-unit prices.

Understanding the concept of economies of scale is crucial, as larger production volumes allow manufacturers to optimize processes and achieve further cost reductions. Ensure you work with manufacturers who offer flexibility in production quantities and scalability as your project progresses from prototyping to mass production.

Remember, the key is to strike the right balance between your immediate prototyping needs and potential future savings. By understanding the volume-based pricing models offered by PCB manufacturers and considering factors like lead time, MOQs, and economies of scale, you can optimize your order quantity to achieve the best value for your PCB prototype project.

Special requirements (impedance control, blind/buried vias, etc.

While basic PCB prototypes cater to most standard designs, certain projects may require specialized features or processes that can impact the overall cost. These include impedance control, blind/buried vias, heavy copper layers, and other advanced manufacturing techniques.

Impedance control is crucial for high-speed and radio frequency applications, ensuring signal integrity and minimizing electromagnetic interference. To achieve precise impedance values, PCB manufacturers must follow strict design rules and use specialized materials, which can increase the prototype cost by 20-30% or more, depending on the complexity. For example, implementing impedance control in a high-frequency RF application may require specific substrate materials and tight tolerance manufacturing processes, significantly impacting the overall cost.

Blind and buried vias are via holes that do not extend through all layers of the PCB. These are commonly used in high-density designs to improve routing efficiency and save space. However, they require additional manufacturing steps and specialized equipment, leading to higher costs compared to standard through-hole vias. For instance, implementing blind and buried vias in a compact IoT device may increase manufacturing complexity and require precise drilling and plating processes, resulting in higher prototype costs.

Another factor that can drive up the cost is the requirement for heavy copper layers. These thicker copper layers are necessary for applications that demand high current-carrying capacity, such as power distribution or motor control circuits. The additional copper usage and processing steps can add 10-15% or more to the overall prototype cost. For example, designing a motor control PCB with heavy copper layers to handle high current loads may require specialized fabrication techniques and increased material costs, contributing to higher prototype expenses.

Other special requirements may include specific solder mask or silk screen colors, complex board shapes, or specialized testing and inspection processes. Each of these additional features or processes can contribute to an increase in the final prototype cost.

It’s essential to carefully evaluate your design requirements and communicate them clearly to your PCB manufacturer during the quoting process. Many manufacturers offer specialized services or pricing tiers for advanced features, allowing you to accurately assess the cost implications before placing your order.

While these specialized requirements can increase the upfront cost of your PCB prototype, they are often necessary to ensure the proper functionality and performance of your final product. By understanding and accounting for these additional costs during the prototyping phase, you can avoid unexpected expenses and ensure a smooth transition to full-scale production.

Turnaround time

The turnaround time, or lead time, for your PCB prototype order can also play a role in determining the overall cost. Faster delivery timeframes often come with a premium price tag, while longer lead times may allow for more cost-effective options.

In the world of PCB prototyping, speed is sometimes of the essence. If you need your prototypes quickly for testing, validation, or demonstration purposes, you may need to opt for expedited services offered by the manufacturer. These rush orders typically incur additional fees, ranging from 10% to 50% or more, depending on the requested turnaround time.

For instance, at JHYPCB, the standard lead time for a basic 2-layer PCB prototype might be 5-7 business days. However, if you need the prototype within 24-48 hours, you can expect to pay a significant premium for this express service. The premium for a 24-hour turnaround time might be considerably higher than that for a 48-hour turnaround time, and so on.

On the other hand, if your project timeline allows for a more relaxed schedule, you may be able to take advantage of economic shipping options or batch production runs. Many PCB manufacturers offer discounted rates for non-rush orders, as they can better optimize their production capacity and resources.

It’s essential to carefully evaluate your project’s time constraints and weigh the trade-off between turnaround time and cost. If you have a flexible timeline, opting for a longer lead time can help you save a considerable amount on your PCB prototype without compromising on quality.

However, if time is of the essence, be prepared to factor in the additional costs associated with expedited services. In some cases, it may be worth the premium to receive your prototypes quickly, especially if it enables you to meet critical deadlines or beat competitors to market.

By understanding the pricing implications of different turnaround times, you can make informed decisions and optimize your PCB prototype order to align with your project’s priorities, whether it’s speed or cost-effectiveness.

How to Get an Accurate PCB Prototype Quote

Getting an accurate quote for your PCB prototype is crucial to ensure you stay within your budget and avoid unexpected costs. Here are some tips to help you obtain a precise quote from your PCB manufacturer:

Provide Detailed Design Specifications: The more information you can provide about your PCB design, including board dimensions, layer count, material requirements, finishes, and design complexity, the better. Clear and complete specifications enable the manufacturer to provide an accurate quote without making assumptions that could lead to pricing discrepancies.

Specify Quantity and Delivery Requirements: Indicate the exact number of prototypes you require and any specific delivery timelines or turnaround times. Additionally, communicate any validation requirements, such as electrical testing or inspection, to ensure accurate quoting.

Request Quotes from Multiple Suppliers: Don’t rely on a single quote – request quotes from several reputable PCB manufacturers. Comparing pricing, lead times, and services offered by different suppliers will give you a better understanding of market rates and help you make informed decisions.

Clarify Pricing Components: Understand what is included in the price by asking the manufacturer to break down costs for materials, labor, setup fees, and additional services. Consider value-added services like design optimization or DFM reviews and their impact on the quote.

Communicate Clearly: Maintain open communication with the manufacturer throughout the quoting process. Ask questions, seek clarification on unclear aspects of the quote, and discuss quality assurance measures to ensure a smooth and cost-effective prototyping experience.

Negotiate Smartly: When negotiating with PCB manufacturers, consider factors such as volume discounts, payment terms, and long-term partnerships to ensure competitive pricing while maintaining quality standards.

By following these tips, you can increase the likelihood of receiving an accurate and transparent PCB prototype quote, allowing you to make informed decisions and effectively manage your project’s budget.

Cost-Saving Tips for PCB Prototyping

While PCB prototyping is an essential step in product development, the costs can quickly add up, especially for those working on a tight budget. Fortunately, there are several strategies you can employ to keep your PCB prototype costs in check without compromising on quality or functionality.

- Optimize Your Design

One of the most effective ways to reduce costs is to optimize your PCB design from the outset. As discussed earlier, factors like board size, layer count, and material selection can significantly impact the overall cost. By minimizing the board dimensions, limiting the number of layers, and opting for cost-effective materials like FR-4, you can potentially save a substantial amount on your prototype. - Order in Small Batches

While ordering multiple prototypes may seem more expensive initially, it can actually save you money in the long run. Most PCB manufacturers offer volume discounts, so ordering a small batch (e.g., 5-10 pieces) instead of a single prototype can reduce the per-unit cost. Additionally, having multiple units allows for more comprehensive testing, potentially preventing costly design revisions and re-orders. - Consider Chinese Manufacturers

Many reputable Chinese PCB manufacturers offer highly competitive pricing, especially for prototyping and low-volume orders. While quality should always be a priority, exploring these cost-effective options can help you save significantly without compromising on performance or reliability. Just be sure to thoroughly vet potential suppliers and request samples before placing a larger order. - Utilize Shared PCB Services

Some manufacturers offer shared PCB services, where your design is combined with others onto a single panel for production. This approach can significantly reduce costs, as the setup and material expenses are shared among multiple customers. While lead times may be slightly longer, this can be an excellent option for budget-conscious projects. - Leverage Online Quotes and Discounts

Many PCB manufacturers provide online quoting tools and occasionally offer discounts or promotions. Taking the time to explore these options can help you identify the most cost-effective solution for your specific requirements. Additionally, some manufacturers may offer discounts for first-time customers or students, so it’s always worth inquiring.

Remember, the key to cost-effective PCB prototyping is to strike the right balance between your project’s requirements and budget constraints. By implementing these cost-saving strategies and being willing to explore alternative options, you can maximize your resources and ensure a successful prototyping experience without breaking the bank.

Why Choose JHYPCB for Your PCB Prototyping Needs?

When it comes to PCB prototyping, choosing the right manufacturing partner can make all the difference in ensuring a smooth, cost-effective, and successful experience. JHYPCB, a leading PCB manufacturer based in China, offers a compelling combination of quality, affordability, and exceptional service that makes us an ideal choice for your prototyping needs.

- Competitive Pricing

As a Chinese manufacturer, we can leverage our economies of scale and streamlined processes to offer highly competitive pricing on PCB prototypes. Whether you require a single prototype or a small batch, our cost-effective solutions can help you stay within your budget without sacrificing quality or performance. - Quick Turnaround Times

We understand the importance of speed in the prototyping phase. That’s why we offer rapid turnaround times, with the option for expedited services if your project demands it. Our efficient production processes and dedicated team ensure that your prototypes are delivered promptly, allowing you to move forward with testing and validation without unnecessary delays. - High-Quality Standards

Despite our affordability, we never compromise on quality. JHYPCB adheres to strict quality control measures and utilizes advanced manufacturing techniques to ensure your PCB prototypes meet the highest industry standards. Our team of experienced professionals is dedicated to delivering exceptional results, ensuring your designs are brought to life with precision and reliability. - Comprehensive Services

From standard PCB prototyping to more advanced requirements like impedance control, heavy copper layers, or specialized finishes, we offer a comprehensive range of services to cater to your specific needs. Our knowledgeable staff will work closely with you to understand your project’s requirements and provide tailored solutions that meet your design specifications. - Customer-Centric Approach

At JHYPCB, we prioritize customer satisfaction above all else. Our team is committed to providing exceptional support and guidance throughout the prototyping process, from initial design consultations to final delivery. We strive to build long-lasting relationships with our clients, ensuring a seamless and hassle-free experience every step of the way.

When you choose JHYPCB for your PCB prototyping needs, you can rest assured that you are partnering with a reliable, experienced, and customer-focused manufacturer dedicated to delivering high-quality results at an affordable cost. Let us help bring your designs to life and take your project to the next level.

FAQs: Your PCB Prototyping Cost Questions Answered

The board size and layer count have the most substantial impact on the overall cost of your PCB prototype. Larger boards and higher layer counts require more materials and manufacturing processes, driving up the expenses.

FR-4 is the most economical base material for PCB prototypes, offering good performance at an affordable price. For surface finishes, HASL (Hot Air Solder Leveling) is the most budget-friendly option, suitable for basic prototypes.

Optimize your design by minimizing board size and layer count, order in small batches to take advantage of volume discounts, consider cost-effective Chinese manufacturers, and explore shared PCB services.

Yes, ordering a small batch (e.g., 5-10 pieces) instead of a single prototype can reduce the per-unit cost due to volume discounts offered by most PCB manufacturers.

Yes, PCB manufacturers often have minimum order quantities (MOQs) or non-recurring engineering (NRE) costs, which can increase the per-unit price for low-volume or prototype orders.

Rush orders or expedited delivery services typically come with premium fees, sometimes ranging from 10% to 50% or more, depending on the requested turnaround time.

Specialized requirements such as impedance control, blind/buried vias, or heavy copper layers can increase the prototype cost by 10-30% or more, depending on the complexity.

Provide detailed design specifications, indicate exact quantities and delivery requirements, request quotes from multiple reputable suppliers, clarify pricing components, and maintain clear communication.

Chinese PCB manufacturers can often offer highly competitive pricing, especially for prototyping and low-volume orders, due to their economies of scale and streamlined processes.

Compare quotes from multiple suppliers, consider their reputation and quality standards, and ensure transparency in pricing components. Industry benchmarks and reviews can also help assess the reasonableness of a manufacturer’s pricing.

Related Posts

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- What Is Prototype PCB Assembly?

- Introduction to Rapid PCB Prototyping Services

- How to Make Low-Cost PCB Prototypes

- Gerber Files for PCB Prototyping – A Comprehensive Guide

- Key Differences Between Prototype and Production PCBs Explained

- Choosing the Right PCB Material for Your Prototype: A Comprehensive Guide

- Why Should You Consider PCB Prototyping for Your Next Project?

- The Ultimate Guide to PCB Prototype Manufacturing: Everything You Need to Know

- Exploring the Benefits and Challenges of China PCB Prototype Manufacturing

- Internal Flow of PCB Prototype Assembly

- Why Do You Need a PCB Prototype?

- What Are The Requirements To PCB Prototype Manufacturing?

- Prototype PCB Fabrication Service Price in China

- Important Things to Consider While Ordering PCB Prototype Service