A complete guide to single-sided flex Circuits

JHYPCB is a flexible PCB manufacturer with advanced flexible PCB production technology and equipment. We can provide customers with flexible printed circuit boards with various technologies, from simple single-sided flexible PCBs to complex multilayer flexible PCBs. We can provide you with fast flexible PCB prototype manufacturing service within 24 hours.

Home » PCB Manufacturing » Flexible PCB » Single Layer Flexible PCB

This article will introduce what a single-sided PCB is, focusing on its definition, structure, characteristics, application, price, and how to order a single-sided flexible PCB.

Single-Sided Flexible Circuits

What Is Single-layer PCB?

Single-layer PCB, also called single-sided PCB, means that only one side of the printed circuit board is “printed” with electronic circuits with conductive materials. Single-layer PCB first appeared in 1950, and it is still used in a large number of applications.

Single-layer PCB is the most straightforward kind of printed circuit board. Single-sided circuit boards made of glass fiber reinforced epoxy resin and copper foil are called single-sided rigid PCBs; single-sided circuit boards made of polyimide (PI) copper clad laminates are called single-sided flexible PCBs.

The manufacturing cost of a single-sided flexible PCB is higher than that of a single-sided rigid PCB.

Further Reading

- What is double sided PCB?

- What is multilayer PCB?

- What is a 4 layer PCB?

- What is a 6 layer PCB?

- Single-Sided Vs. Double-Sided PCB: how to choose?

- Find Out Now, What Should You Do For Fast PCB Classification?

- What is a Multilayer PCB and What are the Advantages?

- Rigid PCB vs Flex PCB: What Is The Difference?

What Is A Flexible PCB?

Flexible PCB, or flexible electronics, or FPC for short, is a highly reliable and excellent flexible printed circuit made of flexible insulating substrates such as polyimide and polyester film. Flexible circuits provide PCB designers and engineers with more choices. Since the flexible PCB can provide excellent electrical performance for electronic products and meet the design needs of miniaturization and high-density mounting of electronic products, it has been widely used.

According to the number of circuit layers, flexible circuits, like rigid PCBs, can be divided into single-sided flexible circuit boards, double-sided flexible circuit boards, and multilayer flexible circuit boards.

What Is A Single-sided Flexible PCB?

Single-layer flexible PCB, using single-sided PI copper clad laminate, generally rolled copper foil, chemically etched conductive patterns, and then covered with a layer of covering film after the circuit is completed (strictly speaking, single-sided flexible PCB can be manufactured with or without With a cover layer or other protective coating. The cover layer or protective layer plays the role of protecting the circuit, usually located on the “top layer” of the flexible circuit), forming a flexible circuit board with only a single layer of conductors.

Since the single-sided flexible circuit board can only access the component termination function from one side, it can design through holes in the base film to allow the pins of electronic components to pass through and realize electrical interconnection in the form of welding.

The insulating substrate for making single-sided flexible PCB can be polyimide, polyethylene terephthalate, aramid cellulose ester, and polyvinyl chloride.

To increase the rigidity of the single-sided flexible circuit, reinforcement ribs can also be introduced in areas that require rigidity.

Single-sided flexible PCB is the simplest and lowest manufacturing cost among flexible circuit boards. When single-sided wiring, single-sided flexible PCB should be selected.

Therefore, a single-sided flexible PCB has huge cost-effectiveness.

What Is The Difference Between Single-sided Flexible PCB And Single-sided Rigid PCB?

- Different manufacturing materials: single-sided rigid PCB is made of rigid materials such as FR4; single-sided flexible PCB is made of flexible materials such as PI;

- Different mechanical properties: single-sided rigid PCB cannot be bent and wound, while single-sided flexible PCB can be assembled in three-dimensional space.

- The production cost is different: the production cost of a single-sided rigid PCB is lower than that of a single-sided flexible PCB.

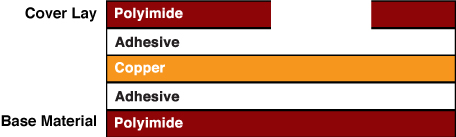

What Is The Structure Of A Single-sided Flexible PCB?

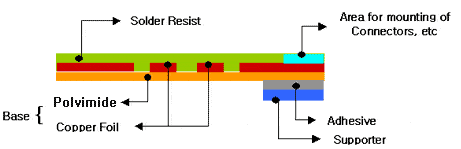

The single-sided flexible PCB comprises the Polyidime layer, copper layer, and adhesive layer.

1. Polyimide film is used as the substrate or cover layer in single-sided flexible PCB; the cover layer is located on both sides of the single-sided circuit board;

2. The copper is chemically etched to produce the required circuit pattern as the circuit layer, the copper layer (the circuit layer is located in the middle of the single-sided circuit board)

3. The adhesive is used to bond the copper layer and the polyimide film together;

4. Rigid PCB uses solder mask to protect the circuit; flexible PCB uses polyimide as a cover layer to replace the solder mask of rigid PCB.

5. Sometimes, it is necessary to apply reinforcing ribs in flexible circuit boards to harden the circuit board area assembled by SMT or through-hole assembly. The reinforcement ribs of the flexible PCB are usually made of FR4/polyimide, aluminum sheet, or steel sheet. They are combined with the flexible circuit through thermal bonding or pressure-sensitive adhesive (PSA). The primary function of the stiffener is to strengthen the solder joints, increase the wear resistance of the circuit board, reduce strain and heat dissipation.

Single-sided Flexible PCB Stack Up Example

What Are The Materials Of Single-sided Flexible PCB?

The following table details the materials used to manufacture single-sided flexible PCBs and their specifications. To learn more about flexible PCB materials, please click here.

Further Reading

What Are The Applications Of Single-sided Flexible PCB?

As mentioned in the previous article, the design and manufacture of single-layer flexible PCBs are effortless and have potent functions and huge cost-effectiveness. Therefore, they are still used in a large number of complex electronic devices, such as:

- mobile phone

- Intelligent wearable device

- Digital camera

- Copiers and printers

- vending machine

- Medical equipment (hearing aid, pulse generator, etc.)

- Relays used in automotive and power industries

- Household appliances such as coffee machine

- Microwave Oven

- LED lighting

- sensor

- Security monitor

- Digital and analog power supplies

Learn more about flexible PCB appliacations, please click here.

What Are The Advantages Of Single-sided Flexible PCB?

- The single-sided flexible circuit replaces the wire harness, which shortens the assembly time and reduces the assembly cost;

- The design is simple and can be completed in a short time;

- Maximum cost-effectiveness;

- Higher durability;

- The flexible circuit can be bent and wound freely and can be moved and stretched arbitrarily in three-dimensional space according to the needs of the spatial layout to achieve the integration of component assembly and wire connection;

- The use of flexible PCBs can significantly reduce the volume and weight of electronic products and cater to the public’s needs for miniaturization, portability, and high-density installation of electronic products.

- The flexible circuit also has good heat dissipation and solderability.

- Stronger and more stable signal quality;

- Improve the impedance control ability of the circuit.

- Significantly reduce wiring errors.

- Easier to use in harsh environments

- High tensile strength can be warped or deformed without breaking

How To Make A Single Layer Flexible PCB?

Single layer flexible PCB manufacturing process:

Cutting → Drilling → Dry Film Lamination → Position and Exposure → Develop → Etching → Remove Dry Film → Surface Finish → Coverlay Lamination →Lamination → Curing → Surface Finish → Immersion Gold → Silkscreen → V-cutting/scoring → Electrical Test → Punching → FQC → Packaging → Shipment

Further Reading

- Knowledge of Plating on Flexible Circuit Board Surface

- Knowledge of Flexible Printed Circuit Board Processing Technology

- The terms you have to know related to the manufacture of Flexible PCB

- Key Process Flow of Rigid-Fled PCB Production

- Double-Sided PCB Manufacturing Process

- Introduction to aluminum PCB manufacturing process

- How To Select The Right Flexible PCB Manufacturer For Your Product: A 6-Step Guide

- Flexible PCB Manufacturing: A Guide To Fabrication And Assembly

How To Assemble Single-sided Flexible PCBs?

Single-sided flexible PCB uses SMT surface mount technology to improve electronic circuits’ assembly density and performance.

Electronic products are becoming more and more miniaturized. Miniaturized electronic components can improve the packaging capacity on a small flexible PCB—the advantages of packaging density increase exponentially.

To learn more about the assembly process of flexible circuit boards, please click here.

Why Choose JHYPCB As Your Flexible PCB Manufacturer?

JHYPCB always insists on providing customers with high-quality, high-reliability flexible PCB products.

- More than 10 years of flexible circuit manufacturing experience;

- We can provide you with one-stop flexible PCB manufacturing, component procurement, assembly, and testing services;

- 100% quality inspection before shipment;

- UL, ISO9001, ISO14001, and ISO/TS16949 certificates;

- The product complies with Rohs and WEEE lead-free environmental protection standards and requirements;

- There is no minimum order quantity requirement;

- Fast single-sided flexible PCB prototype manufacturing service, shipping within 24 hours at the fastest.

| Single-Layer Flexible PCB Process Capability | ||

| Item | Process Capability | R & D capabilities |

| Layers | 1-16 | 18-22 |

| Max. size (mm) | 490*1800, 240*4000 | 490*4000 |

| Base copper thickness (oz) | 1/3oz-2oz, 6oz | 1/4oz-10oz |

| Board thickness | 0.04-2.5 | 0.03-4 |

| Drilling hole diameter (minimum/aperture tolerance) (mm) | 0.05/±0.02 | 0.025/±0.01 |

| Hole plating aspect ratio | 8:1 | 10:1 |

| Min. trace width/spacing (mm) | 0.035/0.035 | 0.02/0.02 |

| Min. solder mask bridge (mm) | 0.075 | 0.05 |

| Surface Finish | ENIG/Immersed Nickel Palladium, Electroplated Gold, OSP, Immersion Tin | / |

| Pitch(mm) | 0.1 | 0.075 |

| Minimum tolerance of external dimensions (mm) | ±0.03 | ±0.025 |

| Solder Mask | Yellow, white, black, green, red | / |

| Single-layer Flexible PCB Assembly Capability | |||

| Item | Process Capability | Methods | |

| Minimum processing size | 50*50 | / | |

| Maximum processing size | 500*500 | / | |

| Finished board thickness | 0.2-4 | / | |

| SMT | Component size | 0201(Option) 75mm connector | / |

| Pitch(mm) | 0.15 | / | |

| Repeatability (mm) | ±0.01 | / | |

| AOI | FOV(mm) | 610*450 | Online |

| Testing speed (mm²/Sec) | 9150 | / | |

| 3D | Degrees | 0-45 | Online |

| X-ray | Position repeatability | ±0.5 | Online |

How To Order Single-sided Flexible PCBs For Your Project?

1. Send your Gerber to sales@pcbjhy.com by email, or order online.

2. Please list your manufacturing specifications and requirements in the email to obtain an accurate and timely quotation.

3. Single-sided flexible PCB surface finish includes OSP, plating, electroless gold plating, or nickel. We recommend using ENIG as the surface finish process to obtain the best results.