Have you ever made a list of grocery items before going to a store?

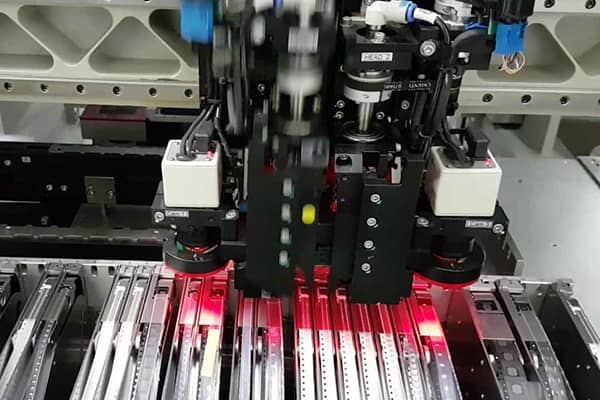

Your answer would probably be yes. It’s widespread, and almost everyone makes a list. The list can be on paper or your mobile. We often create lists to keep everything in mind. We make the list of materials that we need, and we buy everything on that basis. It helps a lot to keep everything organized. The same is the case with the printed circuit board; we make a comprehensive list of PCB materials known as BOM. A BOM file is essential for PCB manufacturing/assembling; therefore, we will discuss it in detail. Today, we will see the contents of a BOM file and how you can create it. Let’s start the discussion.

What is the Bill of Materials?

A Bill of materials is a detailed list that contains the materials or components required to make the PCBA. It is commonly abbreviated as BOM. It also includes essential information about the parts so that the manufacturer can gather all the relevant components. It’s an organized way that helps in buying the required component and placing them correctly on the board. It provides complete information to the PCBA manufacturer about the needs and requirements of the customer.

The buyer creates a BOM file of the PCB and provides it to the manufacturer/assembler. Based on the BOM file, the manufacturer gives a quote and creates the PCBA. Thus, BOM has a lot of importance. Any error in the BOM can result in a considerable loss. It would help if you created an error-free BOM before providing it to the PCB manufacturer. The more information you provide in the file, the better it is, but some essential things should be in the BOM. If you are unsure about the BOM file, you can also get a BOM template from the PCB manufacturer. It would be more helpful for you.

Why is the BOM so important?

Because the BOM lists all the materials required for manufacturing products, including raw materials, assembly parts, and the quantity, price, manufacturer, model, etc. of each component.

A perfect BOM will play a critical role in our successful PCB assembly:

- Make the procurement of raw materials more orderly;

- Estimate the material cost in advance;

- Timely adjust inventory information;

- Track and plan material requirements;

- Ensure the accuracy of purchase and inventory information

- Ensure that there are no errors in the supply chain and reduce waste.

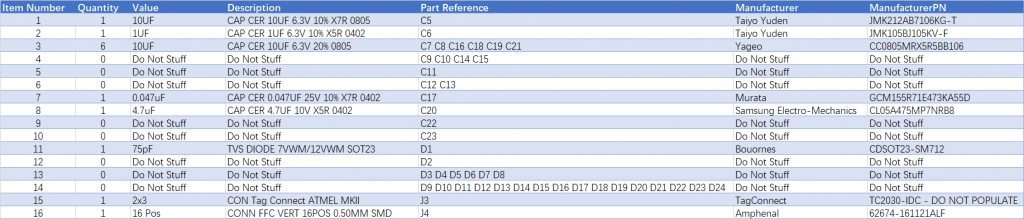

What Should Be Included in a BOM?

Before creating a BOM, you need to know what you need to include in it. It would help if you organized everything accurately. There can be a lot of information in a BOM file, but a few things are essential. Let’s discuss what you should include in your BOM file.

- Manufacturer Part Number (Essential)

The manufacturer part number (MPN) is a unique number that is provided to the product. This unique number helps to identify the suitable component without any confusion. MPN consists of several numbers and alphabets. It is essential to provide MPN so that the PCBA manufacturer can get the elements you need. You can also offer alternate part numbers if you know that the alternative component will work the same.

- Manufacturer’s Name

The manufacturer’s name is not essential, but it’s better to write the manufacturer’s name. The PCB assembler can get the right product from the proper manufacturer. But make sure to confirm that the component is available. Otherwise, it will create problems and waste your time. You can also provide an alternate name of the manufacturer if there is any flexibility.

- Value

The value of components is better to provide. For example, if it’s a capacitor, you can write its capacitance value. It’s not essential because you can easily find the value through the part number, but you should report it for the ease of the PCBA manufacturer.

- Description

The description tells the additional information about the component or part. You can show the voltage, tolerance, current, power, or any other information according to the element. You can also mention the package type in the description, such as 1206, 0403, SOT, BGA, and SOIC. The package type/reference can also be in a separate row.

- Quantity (Essential)

The quantity of the part or component required must be mentioned. It shows the minimum number of components necessary to complete the PCBA. It helps purchase the required components in bulk.

- Reference Designator (Essential)

You might have seen labels on the PCB. This labeling (silkscreen) shows the component designation. It shows the correct placement of the component. It would help if you mentioned the designator in BOM. For instance, if a capacitor is used at five places, you can write its identifiers as C1, C5, C7, C14, C20.

How Do You Create a BOM?

It’s easy to create a BOM. Mainly Microsoft Excel is used to make it, but you can also use dedicated software. You can mention everything in a spreadsheet and forward it to the PCBA manufacturer. Keep in mind that BOM cannot be created at the start. First, you need to finalize the schematic of your PCB, and then you can create its BOM. Let’s look at the steps of making a BOM.

- Open Excel and create a new spreadsheet. To distinguish between different BOMs, you can write the project name and some information at the top. It’s not necessary, but it can organize everything in a better way.

- Write the headings in columns to describe the information of rows. You can write “Item Number,” “Quantity,” “Description,” “MPN,” “Manufacturer Name,” “Designator,” or anything that you want to include.

- Now start writing the information under each column. Fill in the required information of every component.

Once you include all the information of every component on the PCB, your BOM is complete. But make sure there is no error. You can double-check the file before sending it to the PCBA manufacturer. Include as much information as you can so that the PCBA manufacturer can provide the required PCBA.

Final Words

Bill of Materials (BOM) is an important file that contains comprehensive information on the components/parts required in the PCB. This file is a must whether you need a quote from the manufacturer or a complete PCBA. We have discussed the complete information related to the BOM. We have described what you need to include in it. You can easily create a BOM after finalizing the schematic. You can use an Excel spreadsheet to create BOM.

JHYPCB is a leading PCB and PCBA manufacturing company that has been providing its services since 2011. We have an ISO 9001:2008 certified quality management system. We provide quality PCBs without any restriction of minimum orders. Moreover, we are capable of manufacturing small-medium volume PCBs. Our 24-hour online customer service is always available for you. For more information, feel free to contact us.

Related Reading:

Video introduction to what is BOM

BOM Basics – What is a Bill of Material? What does it contain and why is it important?

Creating a well organized BOM (Bill of Materials)

Bill of Materials Excel Template Step-by-Step Video Tutorial by Simple Sheets