Quick Turn PCB Assembly Services

JHYPCB has been engaged in quick turn PCB manufacturing and quick turn PCB assembly services for 11 years; our quick turn PCB assembly factory is located in China. Our customers are all over the United States, Canada, Australia, Europe, etc.; we have become the most popular quick turn PCB assembly manufacturer and supplier.

Home » PCB Assembly » Quick Turn PCB Assembly

Quick Turn PCB Manufacturer

Best Quick Turn PCB Assembly Manufacturer

As the market becomes more competitive, more and more OEMs are increasingly looking to get their products to market as quickly as possible. JHYPCB has become the first choice of many customers for quick turn PCB assembly services because we can help customers shorten the product development cycle. Our quick turn PCB assembly capability lets us provide you with quick turn PCB assembly service with competitive prices and high-quality service. We can guarantee the delivery of highly reliable quick turn PCB assembly. We have become one of the leading and popular quick turn PCB assembly service suppliers in China, the United States, Australia, Canada and Europe.

Quick Turn Electronic Assembly

What Is Quick Turn PCB Assembly Service?

Quick turn PCB is a type of PCB that enables manufacturers to complete projects or fulfill requests quicker than ever before. It has made it easier for users to meet the most demanding deadlines and pressing schedules.

Circuit board manufacturers tend to produce PCBs in the most timely manner. The process is all about combining both numbers and time. In other words, the companies are not only manufacturing printed circuit boards in large numbers. Also, such a process is being carried out in the timeliest manner. It is basically about meeting the deadlines of their customers. Due to the growth which the electronics market is experiencing, many companies are beginning to explore the option of Quick Turn PCB Assembly services.

Another way to view this form of service is that the manufacturing of PCBs will be done within a very short time. For instance, a manufacturer may decide that under normal circumstances, 5-7 days are required for circuit boards to be manufactured and assembled. However, the days can be reduced to 1 or even 2 at most. You should understand that this isn’t a set-in-stone rule because things may likely change. For instance, when the board to be built requires complex components, such service can take around 5-7days or even more.

It also depends on whether changes required are minimal or if there is already a design template available. In any of these cases, there is a very high possibility that your circuit board will be manufactured within the expected timeframe. In most cases, it is possible for China Quick Turn PCB Assembly companies to be sure about some factors or variables. These could be:

- Ideal mounting technique

- Lamination

- Number of layers

- Accuracy of the design

When it comes to quick turn assembly of circuit boards, the keyword is “time”. Without such, it can be said that a quick turn PCB supplier hasn’t delivered.

The Benefits of Quick Turn PCB Assembly Service

Why Do You Need Quick Turn PCB Assembly Service?

Quick turn PCB assembly has been widely used in all walks of life, such as instrumentation, medical treatment, semiconductor, robot, aerospace, military, and national defence. If you are a person in the following industries, you may need quick turn PCB assembly services:

- Electronic designers who need quick turn PCB assembly service

- Designers who need rapid prototyping PCB assembly to check the design and feasibility

- Companies that need products to enter the market quickly

- Students, researchers, etc

- Startups that need to show investors the prototype of new products

- Companies that need to participate in bidding in a very short time and need prototype products

- It is necessary to make prototype products to participate in the exhibition in a very short time.

- Need to catch up with the project progress and need to turn PCB assembly quickly.

The Advantages of Quick Turn PCB Assembly?

There are numerous benefits that a Quick Turn PCB Supplier can enable you to experience. These will be highlighted and briefly explained below.

It Is Fast

This is one of the reasons why many electronic manufacturers today prefer quick turn PCB assembly services. It ensures that PCBs are designed and manufactured in record time. Imagine being the first to stumble upon an idea or innovation. This means you will have an edge over competitors. Gone are those days when you have to wait for weeks or even months for your circuit boards to be completed by a supplier or manufacturer. Today, all of these have changed significantly. This is because such can be manufactured within a few hours or days. Simply put, such a service will ensure there is a reduction in manufacturing as well as assembly delays.

Reduced Cost

Are you looking for how to manufacture circuit boards at budget-friendly prices? Do you know that a Quick Turn PCB Company is the best option to explore? This is because their services can help reduce the cost. The lesser the time required to manufacture circuit boards, that is how the overall cost will also reduce significantly.

Easy Identifying of Defects

Quick turn is all about manufacturing and assembling prototypes. This makes it possible for manufacturing defects to be identified and fixed. In the same vein, it is possible more features & functionalities to be added to a circuit board without hassle. It is basically all about doing the same thing in all the boards.

Durability and Reliability

To many people, quick turn PCBs which have been assembled aren’t reliable. They are of the opinion that these boards are likely to disappoint at any time. This is not true in any way as they are always reliable. They are characterized by improved heat dissipation and high tensile strength.

Fast Turn PCB Assembly Services

How To Achieve Quick Turnaround PCB Assembly?

Just because a Quick Turn PCB Company promises to get your circuit boards assembled in record time doesn’t necessary mean such can go according to plans. In other words, there are some important steps you must take to enable your PCBs to be manufactured and assembled in few hours or days. A successful and Cheap Quick Turn PCB Assembly will require the following steps.

Regular Communication

This is a very crucial step that you must take. Poor communication which a company that is into PCB manufacturing and assembly can bring about possible delays. For instance, failure to communicate with a manufacturer can make your PCB designs to be put on hold. This is why you need to send messages or make phone calls to get an idea about the lead time, manufacturer’s capabilities and other factors. Failure to get the right information about factors like these can bring about redesigns and unnecessary delays.

Understanding Your Assembler

Again, you need to know your assembler including the design choices it can accommodate. Choices here could be silkscreen placement, solder mask thickness, and usage of thermal reliefs. You need to understand that there are some design status which manufacturers may not respond to in terms of bidding. Try to ask questions about the capacity and capabilities of your preferred assembler. Understanding your manufacturer will ensure potential design problems are avoided. This will in turn lead to decreased turnaround time.

Knowing What Your Manufacturer Can Handle

Being guilty of giving a PCB manufacturer too much to handle can lead to an increase in turnaround time. In other words, ensure that your order size matches its production capacity.

Specifying of Testing Requirements

For this to be achieved, you need to make use of Gerber data. With such test, NRE (Non-recurring engineering) charge can be increased. The end result is that errors will be easily detected and rectified on time.

Why Choose Us For Your Quick Turn PCB Assembly?

In order to experience all of the benefits that have been stated above, there is something you must know. This is having to hire the right Quick Turn PCB Company. Anything short of this could mean disaster. The good part is that there is no need racking your brains on how to find the best Quick Turn PCB Supplier around. This is because we can help you out today. Below are the reasons why you should choose us for Quick Turn PCB Assembly.

JHYPCB's Quick Turn PCB Assembly Capability

| Capability | Options |

| Types of quick turn PCB assembly | Surface Mount Technology (SMT) |

| Through-Hole Technology (THT) | |

| Mixed Technology (SMT & THT) | |

| Double-sided PCB assembly | |

| Single or double-sided mixed Technology | |

| Ball Grid Array(BGA) | |

| Micro Ball Grid Array(UBAG) | |

| Capacity | Prototype PCB assembly |

| Low-volume PCB assembly | |

| High-volume PCB assembly | |

| Types of PCB board | Fr4 Rigid PCB boards |

| Flex PCB boards | |

| Rigid-flex PCB boards | |

| All the above PCBs are available in single-sided, double-sided, and multilayer. | |

| Quick turn PCB assembly service mode | Turnkey PCB assembly service |

| Partial turnkey PCB assembly service | |

| Consigned PCB assembly service | |

| Soldering Types | lead-free and leaded solder for reflow soldering/wave soldering/ selective soldering/manual soldering |

| PCB surface finishes | Organic Solderability Preservatives (OSP) |

| Hot Air Solder Leveling (HASL) | |

| Lead-free HASL | |

| Immersion Gold (ENIG) | |

| Immersion Tin | |

| Immersion Silver | |

| Testing and Inspection for quick turn assembly | X-ray Inspection |

| Visual Inspection | |

| In-circuit Testing | |

| AOI Testing | |

| Functional Testing |

Turnkey PCB Assembly Service

One-stop Fast Turnaround PCB Assembly Services

Quick Turn PCB Prototype Assembly Service

Get standard quick-turn PCB assembly services suitable for basic circuits with minimal turnaround time. We also provide custom PCB manufacturing services that can provide comprehensive prototypes. If you are looking for the finest and performance-oriented comprehensive PCB prototypes, you’re at the right place!

Quick Turn Low-to-high Volume PCB Assembly Service

JHY is a leading PCB manufacturing company, and we offer low-volume and high-mix quick-turn PCB Assembly services consistent with your specified requirements. We have the capacity and multiple assembly lines to meet your low-volume assembly & high-mix assembly requirements without compromising on quality and pricing.

Full Turnkey or Partial PCB Assembly Service

Our core competencies lie in a one-stop turnkey PCB assembly service based on strong support from our technical team and a financially solid supply base. Whether you need a turnkey or consigned kit, we are right here to provide you with a wide range of services.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

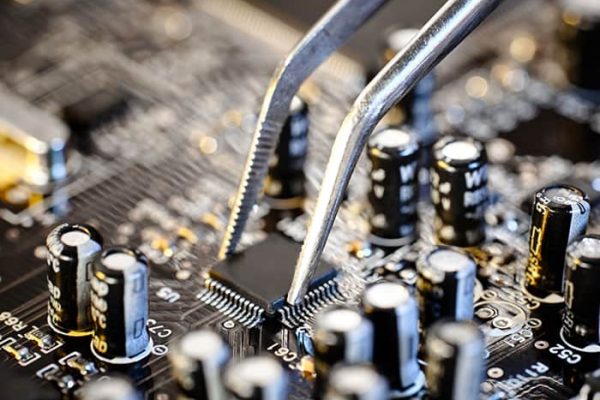

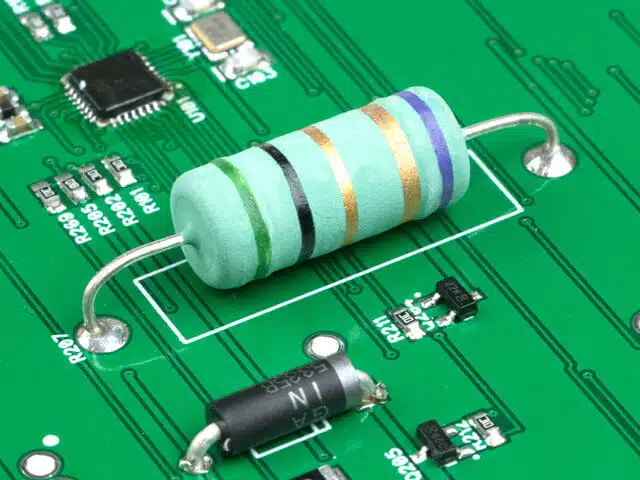

Through Hole PCB Assembly Service

JHY has extensive experience in high-quality through-hole PCB assembly services and manufacturing. We use manual and automated through-hole assembly methods to place radial and axial components efficiently.

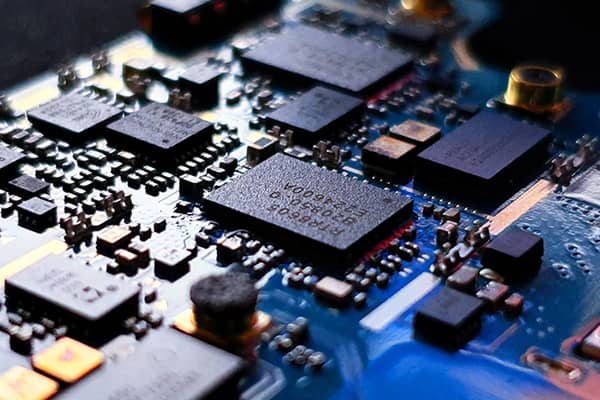

Surface Mount Technology Assembly Service

We have the absolute right to speak in surface mount technology, through-hole assembly technology, and hybrid assembly technology. Of course, from a cost perspective, we recommend you design with surface mount technology.

Professionalism

We are true professionals when it comes to carrying out PCB assembly within the expected timeframe. Even if you want us to source for parts, our experts are up to the task. If you want unused parts shipped over to you or stored for future orders, such will be done as instructed.

Affordable Services

We render Cheap Quick Turn PCB Assembly. This means that even with a limited budget, you have a fair chance of getting access to high PCBs that have been assembled by the best hands. We have managed to ensure that our service is available to all and sundry.

Full Compliance

Hiring a company that renders services related to PCB assembly in the shortest possible time is one thing. PCBs assembled by our experts are compliant will all the relevant government bodies. This means the stipulated procedures have been strictly followed.

Quick Turn Prototype PCB Fabrication

JHYPCB has strong PCB manufacturing capabilities and can provide customers with fast-turn PCB production services such as single-sided PCB, double-sided PCB, 4 layer PCB, 6 layer PCB, etc. We support any PCB expedited production service, such as aluminium PCB, flexible PCB, rigid-flex PCB, etc.

Quick Turn Components Sourcing

JHY has established a solid long-term cooperative relationship with world-renowned component agents and distributors such as Digi-Key. We can ensure that high-quality original components are ready at the best price and quickly. In addition, we have many components in stock to ensure fast delivery.

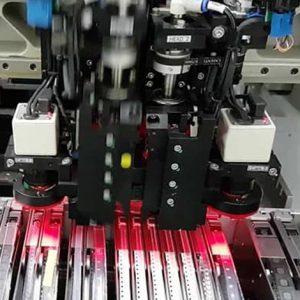

Quick Turn Assembly Services

As a quick turn PCB assembly supplier, we have advanced SMT machines and skilled workers. We can quickly assemble different kinds of PCBs. For each order, we have a dedicated person to follow up on the progress and record it in real-time, reporting to customers at any time.

Quick Turnaround PCB Assembly Quote

How to get your quick turn PCB assembly service?

You can quickly obtain quick turn PCB assembly service through the following steps:

Step 1: Click the call to action button on this webpage to submit online or send your completed PCB assembly requirements package to us by email;

Step 2: Our sales team and process engineer team will review your information and ask any questions;

Step 3: After all questions are answered, we will send you the official quick turn PCB assembly pricelist;

Step 4: After receiving your PO and payment, we will review and confirm the final delivery date again.

Step 5: Quick turn PCB assembly officially begins. In the meantime, please keep us in touch and communicate to resolve any issues that may arise during the PCB assembly process.

Step 6: Quality Inspection and Testing. We will strictly implement quality control procedures and test the PCBA according to your requirements.

Step 7: Shipping. We will use safe and secure packaging to ensure that the PCBA you receive is flawless.

FAQs

Most frequent questions and answers

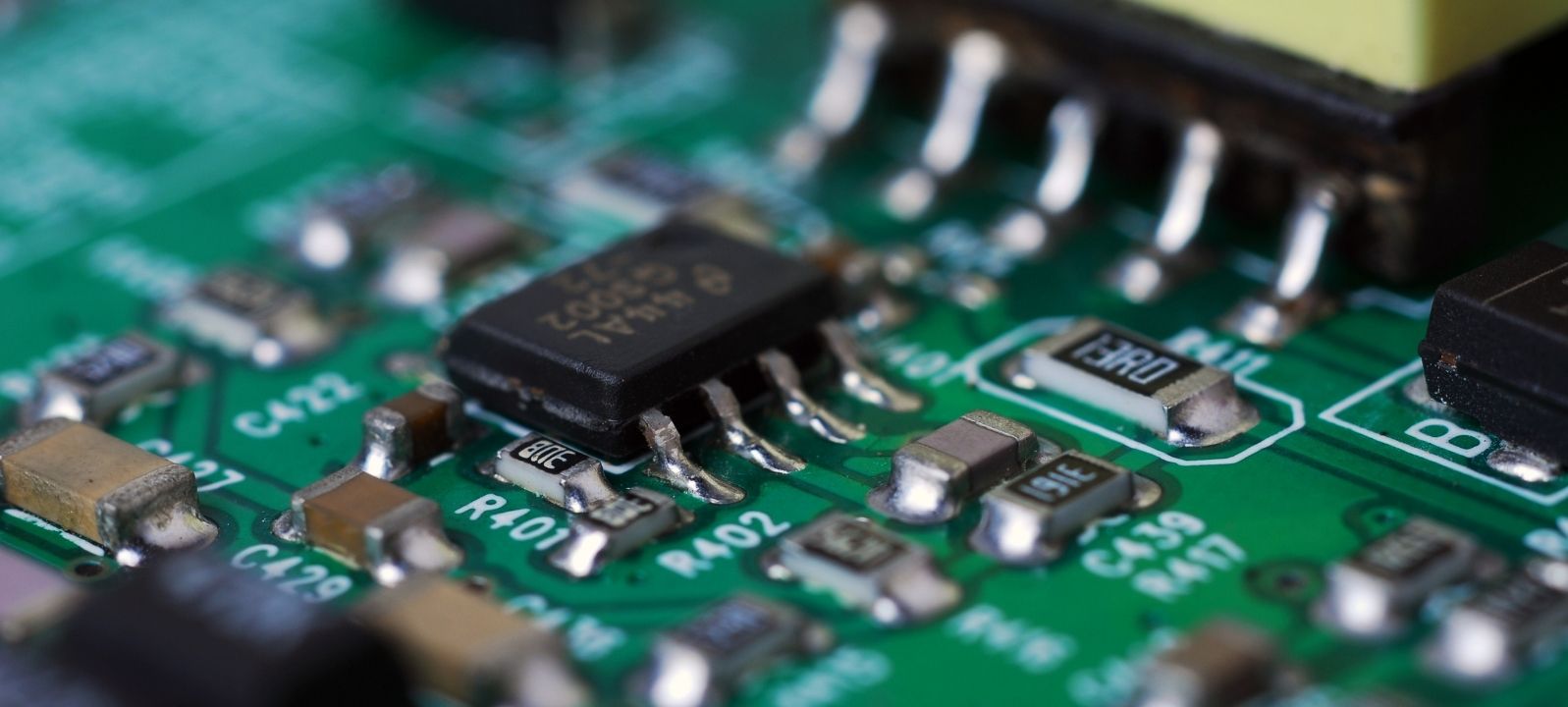

PCB assembly, PCBA or PCB’A is a part of electronic production. It is soldering electronic components such as chips, capacitors and resistors to the bare PCB board through SMT reflow soldering, wave soldering, selective soldering or manual soldering to achieve specific electrical functions.

PCB or PCBA is everywhere; you can see it in any electronic product. The importance of high-quality PCB assembly is reflected in the following points:

a. Reduce production costs

b. Improve production efficiency

d. Reduce the failure rate

c. Reduce product size

d. The test is fast and convenient

Surface mounting technology, referred to as SMT, is a popular technical process in the electronic assembly industry. The SMT process is to first transfer the solder paste, flux, etc., to the bare PCB pads accurately through the PCB stencil and then use the placement machine to place the electronic components on the PCB pads solder them through a reflow oven.

Turnkey PCB assembly service is one of the services provided by PCB assembly manufacturers, and you can also choose a partial PCB assembly service. Turnkey PCB assembly service includes one-stop services such as PCB manufacturing, component procurement, PCB assembly, and testing.

Yes. You can enjoy our low-cost PCB fabrication and quick turn PCB manufacturing services.

Yes, we will return the remaining unused components to the customer. But if you want, we will keep your components safe for you until your next order.

Usually, we provide 48 hours, 72 hours of quick-turn prototype PCB assembly service. The final lead time will depend on the quantity and complexity of the PCB Assembly you need. You can contact our sales team for turnaround times.

Yes, we can provide you with leaded and lead-free solder types.

We can handle rigid PCB, flexible PCB, rigid-flex PCB, and multi-layer PCB quick turn assembly services.

Please provide the following information for quick turn PCB assembly:

- Bill of Materials (BOM)

- Gerber

- Centroid file

- Assembly Drawings

- Special Requirements

Before requesting a quick turn PCB assembly quote, you’ll undoubtedly want to know the factors that can influence the cost. The most significant cost drivers include the following:

- Cost of labor

- Quick turn PCB assembly type

- Number of PCB layers

- Component placement (Single or Double-Sided Assembly)

- Packaging and shipping

- Turnaround time

PCB Manufacturers use several quick-turn PCB assembly technologies, the most popular being Surface Mount Technology (SMT) and Through-Hole Technology Assembly (THT). Depending on the nature of the work, the PCB assembly manufacturer can use both SMT and THT. Expect the cost to differ between these assembling technologies.

Although you have many quick-turn PCB assembly manufacturers to choose from, choosing the right one is the most important thing. Because the PCB assembly manufacturer you choose to work with on your project will greatly impact your satisfaction.

Here are some of the factors to consider:

- Manufacturer’s Experience

- Assembly speed

- Quality

- Equipment

- Manufacturing price

- Custom PCB

Printed Circuit Board Assembly Service

ready to reach new heights? Let's get there, together.

Based on the above, it is clear that quick turn assembly of PCBs is very beneficial in many ways. It is all about choosing the right China Quick Turn PCB Assembly that can meet your needs and expectations. The best part is that we are here to help out.