High-Quality PCB Manufacturing and Assembly Services for Servers and Data Storage

Home » Industries Served » Server and data storage PCBs

Servers and data storage systems are critical infrastructure powering today’s data-driven world. As a premier PCB manufacturer catering to this industry for over a decade, JHYPCB provides specialized PCB fabrication and assembly services tailored for high-performance computing, networking, and storage equipment used in enterprise and hyperscale data centers.

Leveraging strengths such as technical expertise, quality assurance, reliable supply chain, and strong customer support, we deliver complex multilayer boards, HDI PCBs, High TG PCBs, Flexible PCBs, Impedance Control PCBs, and Rigid-Flexible PCBs used in servers and storage systems which meet the stringent electrical, mechanical and thermal requirements of these applications.

By partnering with JHYPCB for tailored PCB manufacturing and assembly catered specifically for the server and data storage industry, OEMs can accelerate product development cycles and reduce time-to-market in order to stay competitive.

Get Ready to Start?

Types of PCBs Suitable for Server and Data Storage Manufacturing

As an experienced PCB manufacturer catering to the server and data storage industry, we can fabricate and assemble various types of printed circuit boards for these mission-critical applications. Our offerings include:

- Rigid PCBs – We manufacture high-layer count multilayer boards using FR4 and high-Tg FR4 base materials compatible with lead-free assembly processes. These sturdy PCBs can integrate complex circuitry for server motherboards and storage controller boards.

- HDI PCBs – Utilizing advanced interconnect technologies like blind/buried vias and microvias, we enable highly dense routing suited for compact server CPU cards and network interface cards.

With capabilities to deliver complex, high-layer count PCBs manufactured to tight tolerances using cutting-edge technological processes, we are an ideal PCB fabrication and assembly manufacturer for companies looking to design and manufacture high-performance servers and reliable data storage systems.

Our expertise in this niche application area differentiates us as a reliable PCB manufacturing partner for OEMs catering to the data center and storage industry.

Key Requirements for Server and Storage PCBs

The server and data storage industry imposes stringent requirements on PCBs to ensure high performance, reliability, and efficiency. These requirements stem from the need to handle massive data volumes, enable high-speed communication, and provide uninterrupted services. Here are some of the key requirements for PCBs in the server and storage sector:

High Speed and Bandwidth With the increasing demand for data-intensive applications and high-speed communication protocols, PCBs must support high data rates and wide bandwidth. Techniques such as controlled impedance, careful signal routing, and advanced materials are employed to minimize signal degradation and ensure data integrity.

Thermal Management Servers and storage systems generate significant amounts of heat during operation, which can lead to performance degradation or component failure if not managed effectively. PCBs must incorporate thermal management solutions, such as thermal vias, heat sinks, and specialized thermal interface materials, to dissipate heat efficiently.

Power Integrity Proper power distribution and management are critical for server and storage PCBs. These boards must ensure clean and stable power delivery to various components, minimizing noise and ensuring reliable operation. Power distribution networks, decoupling capacitors, and advanced power integrity design techniques are employed to achieve this.

Signal Integrity High-speed signals and dense component integration can lead to signal integrity issues, such as crosstalk, reflections, and electromagnetic interference (EMI). PCBs for servers and storage must be designed with signal integrity in mind, incorporating techniques like controlled impedance, ground planes, and shielding to maintain signal quality.

Electromagnetic Compatibility (EMC) Server and storage systems must comply with EMC regulations to prevent interference with other electronic devices and ensure safe operation. PCBs play a crucial role in EMC compliance by incorporating shielding, grounding, and filtering techniques to minimize electromagnetic emissions and improve immunity to external interference.

High Reliability and Extended Life Server and storage PCBs are expected to operate continuously and reliably for extended periods, often in demanding environments. These PCBs must be designed and manufactured to withstand harsh conditions, such as extreme temperatures, vibration, and humidity.

By meeting these stringent requirements, PCBs can support the high-performance, data-intensive, and mission-critical nature of server and data storage systems, enabling organizations to process and store data securely and efficiently.

Advanced PCB Technologies for Servers and Storage

The ever-increasing demands for high performance, reliability, and data throughput in the server and data storage industry have driven the development of advanced PCB technologies. These technologies enable PCBs to meet the stringent requirements of modern server and storage systems, offering improved signal integrity, superior thermal management, and enhanced electromagnetic compatibility. Here are some of the key advanced PCB technologies employed in this sector:

- High-Density Routing and Microvias

High-density interconnect technology enables the fabrication of PCBs with extremely fine lines, high component density, and microvias (tiny plated through-holes). This technology is crucial for miniaturization and high-density packaging, allowing server and storage PCBs to integrate more functionality within a compact footprint. - Advanced Materials

The selection of specialized materials is crucial for server and storage PCBs. Low-loss dielectric materials, such as Megtron and polyimide, are often used to minimize signal attenuation and improve high-frequency performance. These materials also offer excellent thermal stability and resistance to harsh environments, ensuring long-term reliability. - Controlled Impedance and Signal Integrity Design

High-speed signals and dense routing in server and storage PCBs can lead to signal integrity issues. Controlled impedance design techniques, such as differential pair routing, ground plane shaping, and advanced simulations, are employed to maintain signal quality and minimize reflections, crosstalk, and electromagnetic interference. - Power Distribution Networks

Efficient power distribution is critical for server and storage systems, which often incorporate numerous high-power components. Advanced power distribution networks, including dedicated power planes, decoupling capacitors, and specialized power integrity design techniques, ensure clean and stable power delivery, minimizing noise and voltage drops. - Thermal Management Solutions

Effective thermal management is essential for server and storage PCBs, which must dissipate heat generated by high-performance components. Advanced thermal management solutions, such as thermal vias, heat sinks, and thermally conductive materials like insulated metal substrates (IMS), are employed to maintain optimal operating temperatures and prevent overheating. - Electromagnetic Compatibility Compliance

Server and storage systems must comply with strict EMC regulations to prevent electromagnetic interference with other electronic devices. PCBs incorporate shielding techniques, such as ground planes, via stitching, and shielding cans, to contain and redirect electromagnetic radiation, ensuring proper equipment operation and preventing interference.

These advanced PCB technologies, combined with rigorous design practices and manufacturing processes, enable the server and data storage industry to develop high-performance, reliable, and scalable systems capable of meeting the ever-increasing demands of data-intensive applications and mission-critical operations.

Our PCB Manufacturing Capabilities for Server and Data Storage Applications

We provide specialized PCB manufacturing services catered to the unique requirements of high-performance server and data storage systems used in enterprise and hyperscale data centers. Our manufacturing capabilities are aligned to produce complex and high-layer count PCBs meeting stringent tolerances and quality requirements of this industry:

Manufacturing Infrastructure

Our facility houses advanced PCB fabrication equipment consisting of high-accuracy photolithographic printers, AOI and state-of-the-art drilling/routing machines that can manufacture PCBs with up to 32 layers. For controlled impedance boards, we also have impedance tuning equipment to optimize electrical performance.

Quality Control

We have a robust quality management system backed by ISO 9001 certification to ensure consistent product quality and reliable performance. Statistical process controls, comprehensive inspection procedures and strict quality benchmarks enable us to achieve over 98% yield rates for server and data center PCBs.

Volume Production

Our production capacity is over 500,000 square feet per month which can be flexibly allocated depending on customer requirements. We maintain scalable workflows, organized material sourcing, demand-driven inventory and efficient supply chain to ensure timely fulfillment of orders ranging from prototypes to mass production orders comprising thousands of PCBs.

By leveraging these substantial manufacturing capabilities, including advanced fabrication technology, stringent quality control and high-volume capacity, we deliver exceptional value as a manufacturing partner providing reliable and tailor-made PCB solutions for demanding server and data storage applications.

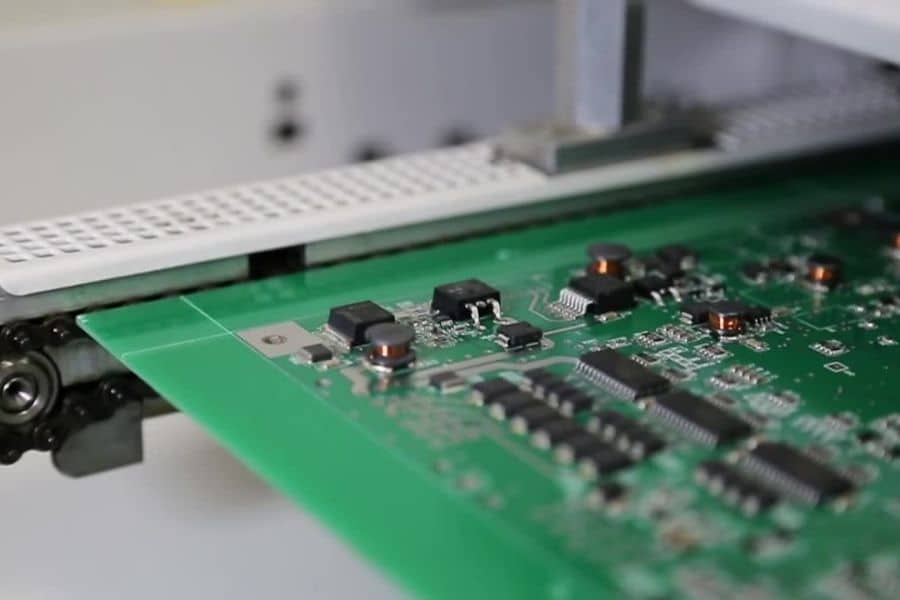

Our PCB Assembly Services for Server and Storage Solutions

In addition to PCB fabrication, we also offer comprehensive printed circuit board assembly services for server and data storage systems, enabling us to deliver fully assembled electronic solutions for this industry:

Assembly Technology

Our SMT lines, supported by advanced pick-and-place machines, are capable of placing components as small as 0201 chips (0.6mm x 0.3mm) with extreme precision. For high-pin count connectors, we offer specialized thru-hole assembly services as well. We also handle complex mixed-technology assembly involving both SMT and thru-hole components.

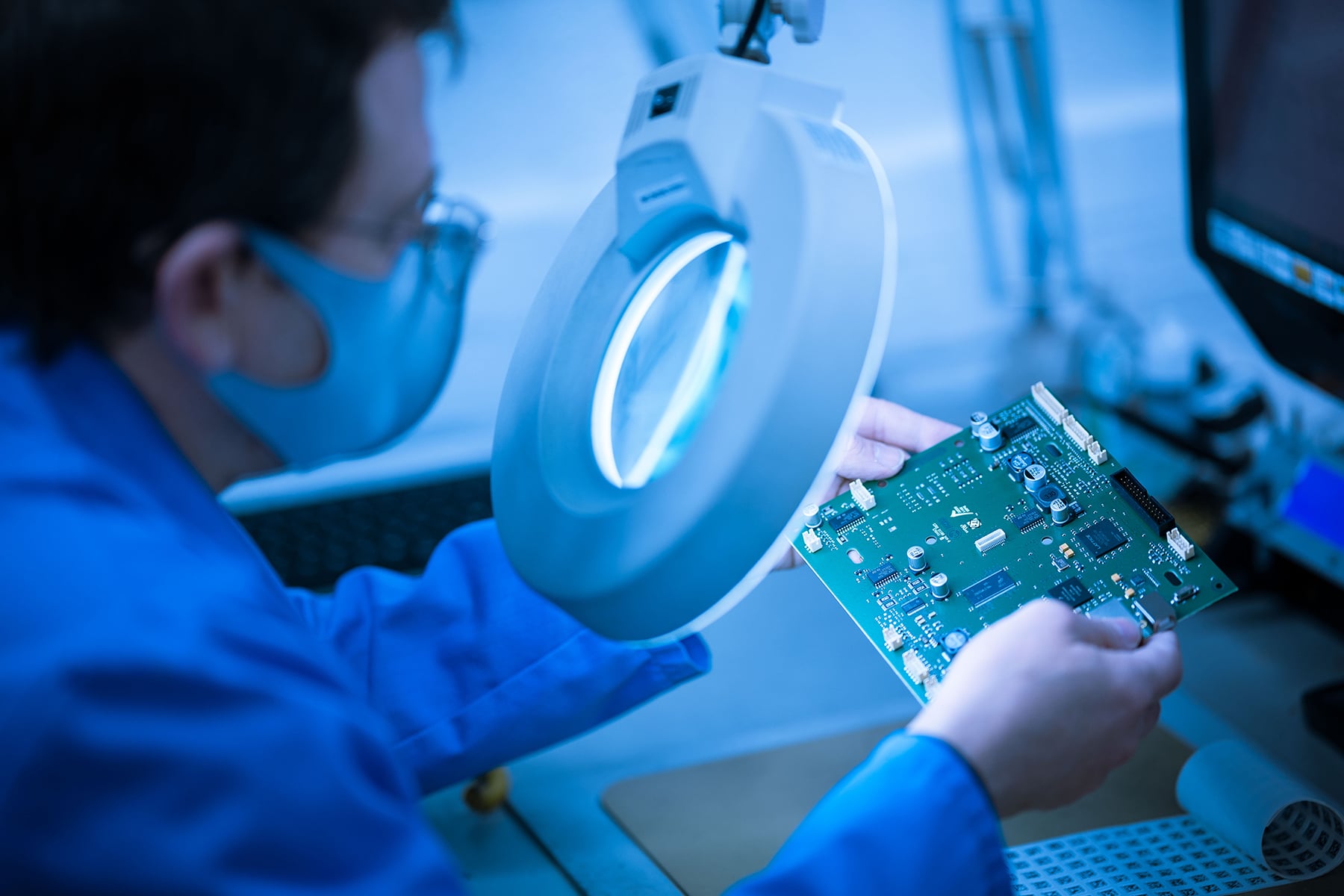

Testing and Inspection

Post assembly, the PCBs undergo rigorous testing and inspection including flying-probe, boundary scan, Automatic X-Ray Inspection (AXI) for assessing solder joint quality. We also perform functional testing of assembled boards by simulating temperature, voltage and data traffic profiles resembling real-world operating environments faced by servers and storage equipment.

By engaging us for board assembly services, OEMs catering to data centers can accelerate their product development cycles and speed up time-to-market.

Why Choose JHYPCB as Your Server/Storage PCB Partner

JHYPCB, with its strong focus and rich experience in manufacturing PCBs for high-speed, high-density data processing systems, is an ideal partner for server and data storage OEMs looking for a reliable PCB solutions provider. Here are some of the key reasons to choose us:

- Technical Expertise

With an experience of over 15 years specializing in advanced PCBs for networking and communications infrastructure including data centers, we possess the technical design, fabrication and assembly expertise needed to develop specialized PCB solutions tailored for servers and storage systems. - Quality Assurance

By following rigorous quality control practices backed by ISO 9001 certification and maintaining high production yields for PCBs meeting stringent requirements, we assure customers of receiving highly reliable boards that perform consistently. - Supply Chain Management

Through streamlined logistics, diversified sourcing from certified suppliers and maintaining optimal inventory levels, we fulfill PCB manufacturing and procurement needs of server/storage OEMs reliably while meeting demanding shipment schedules. - Customer Support

We provide comprehensive engineering support including design reviews, prototyping, maintaining custom product specifications so that customers can collaborate effectively with us during product development as well as sustainment cycles.

By partnering with us, server and data storage companies can stay focused on their core solution development while leveraging our capabilities across PCB design, fabrication, assembly and supply chain execution for meeting the electronic manufacturing demands efficiently.

JHYPCB - Leading High-Quality, Quick-Turn PCB Manufacturing

At JHYPCB, we are a premier PCB manufacturer providing one-stop PCB fabrication and assembly services to meet the diverse needs across multiple industries. With years of experience and cutting-edge capabilities, we deliver high-quality, quick-turn PCB solutions tailored to each application’s unique requirements.

Our Core Expertise:

- High-reliability PCBs for demanding applications

- Wide range of PCB technologies: HDI, rigid-flex, RF/microwave, thermal boards, and more

- Advanced manufacturing processes: high-density interconnect, buried/blind vias and more

- Fast prototype to production cycle times

- Strong engineering support from quote to delivery

Whether you need prototypes for new product development or high-volume PCB production, JHYPCB is your trusted partner. Explore our PCB capabilities for your industry below.