Fast Prototype PCB Assembly Service

Low Volume Fast Prototype PCB Fabrication and Assembly Services China Manufacturer

Home » PCB Assembly » Fast Prototype PCB Assembly Service

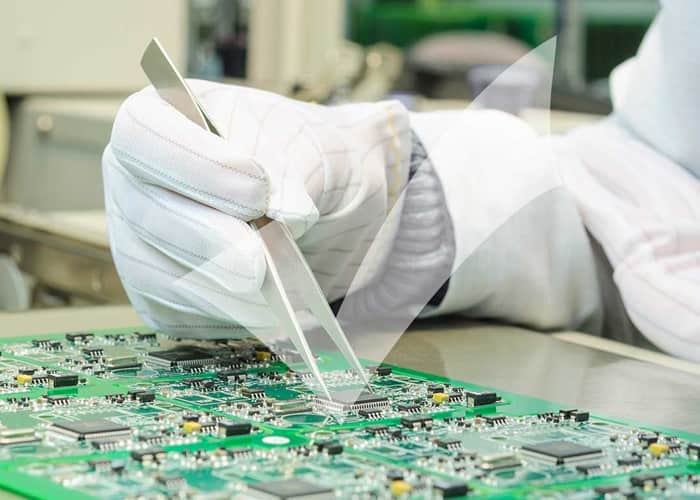

Looking for high-quality and reliable Prototype PCB Assembly Service? Look no further than our company. With years of experience and expertise in the field, we offer comprehensive solutions for all of your PCB assembly needs. From fast-turn prototypes to large production runs, our state-of-the-art equipment and skilled technicians can handle any project with ease. So why wait? Contact us today and see how we can help bring your ideas to life.

We offer trusted PCB prototype assembly services to go along with our high-quality PCB fabrication and component sourcing services. This includes quick turnaround, affordable prototype PCB assembly, and perform comprehensive testing to ensure they meet your precise performance requirements. We can provide a full turnkey and partial turnkey PCB prototype assembly featuring a one-stop shop approach that saves you time, money, and hassles.

Table of Contents

What is Prototype PCB Assembly?

A PCB assembly is the final product that has components installed on the PCB. Often, we are not sure of the results of the new designs and amendments; therefore, it’s better to order a prototype to evaluate the design and check for errors or any further amendments. A prototype PCB assembly is a testing assembly that is ordered before large batch production. It is used for testing purposes, and after satisfaction, mass production is carried out.

It is important to order a PCB prototype assembly to save money and time. If there is any problem with the prototype, it can be rectified without any hassle. In contrast, if there is any problem with mass production, your money and time will be wasted.

Usually, PCB prototype assembly is in low volume. You can even order one piece; it is commonly less than 30 pieces.

At JHYPCB, we are committed to providing you with fast and convenient prototype PCB assembly services to ensure that the PCB design can be quickly and effectively verified, thereby promoting mass production and project delivery. You can order as many PCBA as you need; there is no minimum order requirement. You only need to provide PCB Gerber, BOM (Bill of Materials), and special process requirements. Moreover, you can enjoy the following high-quality PCBA electronic manufacturing services:

- Fastest 3 days rapid prototype manufacturing service (including PCB fabrication, purchasing of materials, SMT and dual in-line package, and testing)

- The cost is at least 20% lower than the market price.

- Free DFM (Design for Manufacturability) check

- Electrostatic bag+bubble or bag+carton safe packaging

Our Prototype PCB Assembly is a specialized service. JHYPCB has strong technical strength and rich experience accumulation. We provide you with single-sided PCB, double-sided circuit boards, and multilayer printed circuit board assembly services. Our team can provide customers with the following packaged components:0402, 0603, 0805, 1206, 1210, 1812, BGA, CSP, PLCC, LGA, QFN, QFP, TQFP, QFN, PLCC, SOT, SOIC, etc.

JHYPCB ‘s Service Advantages

Our PCB assembly service offers several advantages that set us apart from the competition. We use state-of-the-art equipment and techniques to produce high-quality PCBs that meet industry standards. Our fast turnaround time ensures that you get your products on time, whether it’s a fast-turn prototype or a large production run. With transparent and accurate quoting, you can be assured of a fair price without any hidden fees.

We offer comprehensive solutions for all types of PCB assemblies, including single-sided, double-sided, and multilayer boards, as well as rigid and flexible circuit boards. Our experienced team of technicians ensures that every project undergoes rigorous quality control and testing, so you can be confident that you’re getting the best PCB assembly services.

- High-Quality Manufacturing: We use state-of-the-art equipment and techniques to produce high-quality PCB assembly products. We follow IPC standards to ensure every project meets industry standards.

- Fast Turnaround: We offer fast-turn prototypes, so you can get your PCBs in a short amount of time. We also ensure timely delivery when processing large orders.

- Competitive Pricing: Our prices are highly competitive, with no hidden fees. We provide transparent and accurate quotes to ensure your satisfaction.

- Comprehensive Solutions: Whether you need single-sided, double-sided, or multilayer PCB assembly, as well as rigid or flex circuit boards, we offer comprehensive solutions. We also provide a range of related services to support your PCB assembly needs.

- Experienced Team: We have an experienced team with deep knowledge and skills in PCB assembly. They will ensure every project is carefully inspected and quality-controlled, providing you with the best PCB assembly services.

Our service advantages make us stand out by providing high-quality PCB assembly, fast turnaround and competitive pricing. Whether you need single-sided, double-sided or multilayer PCB assembly, we offer the best solutions. Work with our team and trust us with your projects, allowing you to focus on other important business goals.

Special Capabilities in Flex and Rigid PCBs

We have extensive experience in producing both flex and rigid printed circuit boards, giving us the ability to provide comprehensive solutions for all of your PCB assembly needs.

Flex PCBs

Our technicians are skilled in handling flexible printed circuit boards (Flex PCBs), which are thin, lightweight, and highly adaptable. Flex PCBs can be bent, twisted, and folded into various shapes, allowing them to fit into tight spaces and unique designs. Our expertise in flex PCBs enables us to offer customized solutions for even the most complex projects.

Rigid PCBs

In addition to flex PCBs, we also specialize in rigid printed circuit boards (Rigid PCBs). These boards are thicker and more durable than flex PCBs, making them ideal for applications that require high reliability and stability. Our advanced equipment and manufacturing processes ensure that our rigid PCBs meet the highest standards of quality and consistency.

By leveraging our knowledge and expertise in both flex and rigid PCBs, we can provide you with a wide range of PCB assembly options tailored to your specific requirements. Whether you need single-sided, double-sided or multilayer PCB assembly, we have the capabilities to meet your needs.

Benefits of PCB Prototype Assembly

The reason for ordering a PCB prototype, it’s because is that you want to quickly assess how well your PCB design is going to work.

Specifically, the benefits of prototype PCB assembly include the following:

- Proof of concept

- Gain a better perspective

- Detect Flaws Early

- Test Components Individually

- Reduced Overall Costs

- Develop familiarity

- Authentic Representation of Standard PCB Performance

- Learn More

Why Choose us for prototype PCB assembly?

Prototype PCB assembly is integral to the electronic manufacturing process. It helps determine how harrowing or easy the production of high-volume PCB assembly will be. you must choose a PCB assembly service manufacturer who can deliver your boards on time and within the specified deadline.

- Prototype PCB Assembly Engineering Services: DFM, DFT

- Full Feature PCB Assembly Services: NPI, SMT, THT, Mixed Technology

- PCB Assembly Testing: Flying Probe Testing, Functional Testing, In-Circuit Testing(ICT), Burn-in Testing, Conformal Coating

- Fastest Turnaround Times

- Competitive Pricing and Quick Quote

- Reliability

Turnkey Prototype PCB Assembly Service

Turnkey prototype PCB assembly is one of our main businesses. With our expertise in electronic manufacturing services, extensive experience, and complete supply chain resources, we can smoothly complete all the work for you from prototype PCB manufacturing, and component sourcing to the circuit board assembly.

We accept full turnkey, and partial turnkey (consigned or kitted) parts assembly projects and are not subject to MOQ. You can choose any of our assembly services; of course, we recommend turnkey assembly because:

1. Save time

Purchasing components takes a lot of time and effort, and entrusting the task of component sourcing to us can save you a lot of trouble, and you can spend more time and energy focusing on your design.

2. Cost savings

Our component sourcing team will deal with as many component distributors as possible and complete component sourcing in the best and most cost-effective manner.

3. Specialization

Our dedicated electronic engineering team can recommend replacement parts when the required part in the BOM is no longer available and the original manufacturer has no production plan.

Prototype PCB Assembly Process

Step 1. PCB Design and Manufacturing

Prior to PCB assembly, PCB design and manufacturing is required. Once the design is completed and a prototype or sample is obtained, it can move on to the next stage.

Step 2. Component Procurement

Before starting PCB assembly, component procurement is necessary. We will choose appropriate components according to the specifications and requirements of the product to ensure high-quality finished products.

Step 3. Preparation and SMT Placement

Preparation work includes applying solder paste onto the substrate, placing the printed circuit board (PCB), and utilizing automated equipment to place and secure surface-mounted technology (SMT) components onto the PCB. These steps are typically performed by robots to ensure precision and speed.

Step 4. Through-Hole Components

If through-hole components are required, they must be manually installed. This is usually done by technicians.

Step 5. Soldering and Cleaning

Once all components are installed onto the PCB, soldering can take place. Afterwards, the PCB is sent for cleaning to remove any residues and ensure a smooth and clean finish.

Step 6. Quality Control and Testing

After cleaning, the PCB goes through quality control and testing. Various tools and equipment are used to inspect the circuit board connections and electrical characteristics to ensure they meet requirements.

Step 7. Packaging and Delivery

The final step is to package the finished product and label and categorize it according to customer requirements. The product is then safely delivered to the customer.

The above is a basic PCB assembly process, and each step is crucial. Our technicians and equipment can ensure each step is executed with extreme precision and efficiency, producing high-quality PCB assembly products.

Click here to learn more about PCB assembly process step Guide.

How to order a prototype PCB assembly?

1. Orders and Quotes

- Online Inquiry Form

We provide an online inquiry form to make it easy for customers to get a quote. Simply upload your BOM (Bill of Materials) and Gerber files, specify the options you need, and submit the form. Our sales team will get in touch with you as soon as possible with a transparent and accurate quote.

- Accurate Quotes

Our quotation process is fully transparent and there are no hidden fees or charges. We provide detailed quotes that include all costs associated with your project so that you can be assured of a fair price.

- Payment and Shipping Options

We offer flexible payment methods and shipping options to meet your needs. Our logistics team ensures that your product is delivered on time and in good condition.

- Timely Response

We understand that you have deadlines to meet, which is why we pride ourselves on providing timely responses to inquiries. Our sales team is dedicated to answering any questions you may have and helping you throughout the entire process.

With our online inquiry form, accurate quotes, flexible payment and shipping options, and timely response, we ensure a smooth and hassle-free experience for our customers. Contact us today for a quote and experience the convenience of our services.

2. Files Required for Quote and Ordering.

It is essential to provide the required files and documents for fast prototype PCB assembly. The buyer must give everything to ensure on-time delivery. You need to provide the following things while taking the PCB prototype assembly service.

a)Gerber files

Gerber files are essential, whether you need PCB or PCBA. It provides the information of your PCB design.

b)Pick and Place File

The components are placed in specific places. There is a designated place for each component; therefore, it’s necessary to place them in the right place. Pick and place file contains the information of components and their placement. The components are placed according to the XY coordinates and rotation mentioned in the file. The file guides the machines to place the right component at the right place.

c)Bill of Materials

The Bill of Materials includes the complete information regarding components used on the PCBA. It usually has Manufacturer Part Number, Manufacturer’s Name, Designators, Quantity, Description, and Value. There can be other details as well. It is essential for the procurement of components.

d)Special Technical Process Requirements (If any)

You need to provide special requirements for the PCBA. If you want anything to be emphasized, mention it while placing the order.

e)Assembly Drawing

The assembly drawing is a blueprint of the PCB board that tells the manufacturer about the design of the board. It contains various information, including board outline, part shapes, mechanical parts, drill locations, additional views, manufacturing labels, assembly notes, parts list, and a few other things. This file is not essential, but it is better to provide it to the manufacturer. The designer only knows how he has made the design, but an assembly drawing guides the manufacturer in assembling the PCB.

Prototype PCB Assembly Cost

Prototype PCB assembly at a competitive price

The cost of a PCB assembly depends on various factors and services. It includes the charges of different services. Some of the costs that are included in the total cost of a PCBA prototype are,

- PCB fabrication cost

- Stencil cost

- Component procurement cost

- Assembling cost

- Welding cost

- Testing cost

- Packaging cost

You don’t need to worry about the factors, services, and cost; provide us the required details, and we will provide you a reasonable cost. At JHYPCB, the cost of the PCB Assembly is 20% lower than other Chinese prototype PCB assembly service providers.

Quick Turn Prototype PCB Assembly Service

We understand it is important to provide fast PCB prototype assembly service for the quick evaluation of the design and fewer delays in mass production. The time for the delivery of PCB assembly depends on various factors, such as component procurement, PCB fabrication, placement of components, testing, packaging, shipping, etc.

Time Details of Low Volume Prototype PCB Assembly

Components procurement and PCB fabrication are generally carried out simultaneously. PCB production takes 3-10 days, and component procurement takes 2-15 days. The arrival time of components is relatively uncertain. SMT and DIP take 3-5 days in total, the PCBA test generally takes 1-3 days, and finished product assembly takes 2-5 days.

The PCBA processing process is relatively complicated and involves many processes. Generally, for small and medium-sized orders, the PCBA assembly processing cycle takes 25 days.

Turnkey PCB assembly service is what we are good at, even for prototype assembly. Our customers can benefit from JHYPCB PCB prototyping, parts sourcing, and PCB assembly services. You will get all PCB services under a single roof at JHYPCB. Our ISO, UL, and RoHS-certified quality management systems ensure high-quality products. We are always ready to process low volume prototype PCB assembly and low-medium PCB and PCBA services. For more information, feel free to contact us.

FAQs about Prototype PCB Assembly

PCB assembly refers to the process of attaching electronic components to a printed circuit board (PCB).

Prototype PCB assembly is the process of assembling a small quantity of PCBs for testing and validation purposes before moving on to full production.

We offer assembly services for single-sided, double-sided, and multilayer PCBs in both rigid and flex configurations.

Our turnaround time for prototype PCB assembly is typically 5-10 business days, depending on the complexity of the project.

We accept Gerber files, BOM (Bill of Materials) files, and other common file formats used in PCB design and manufacturing.

We follow IPC standards and have a rigorous quality control process that includes visual inspection, electrical testing, and functional testing to ensure high-quality end products.

We accept various payment methods, including credit cards, wire transfers, and PayPal.

Yes, we offer expedited shipping options to meet your project deadlines.

Our minimum order requirement for prototype PCB assembly is 5 pieces.

Our experienced team of technicians can provide technical support throughout the entire PCB assembly process, from design to manufacturing to testing.

Related Posts

- Complete Introduction To Flexible PCB Assembly Process

- Quick Turn PCB Manufacturer In China

- How To Search for a Reliable PCB Manufacturer

- The Main PCB Assembly process Steps

- Why Choose Chinese PCB Manufacturer

- How to Choose the Right PCB Manufacturer and Supplier

- What are the aspects of PCB Design For Manufacturing (DFM) and Design For Assembly (DFA)?

- Design For Manufacturability And Assemblability Of Printed Circuit Board

- IPC Standards: A Guide to Standards for PCB Manufacturing and Assembly

- What is the difference between wave soldering and reflow soldering?

- How to Use PCB Stencil-Step by Step Guideline

- Fast Prototype PCB Services for US Customers

- Key Differences Between Prototype and Production PCBs Explained

- How to Make Low Cost PCB Prototypes

- Fast, Affordable PCB Prototyping for UK Innovators

- Fast Prototype PCB Manufacturing Services in Canada by JHYPCB