As a company specialized in PCB prototype, PCB manufacturing, and PCB assembly services, JHYPCB understands the importance of choosing the right PCB prototyping service provider. In today’s fast-paced world, time-to-market is critical for businesses to succeed. That’s why PCB prototyping has become an essential part of the product development process.

What are PCB Prototyping Services?

PCB prototyping services involve producing a small batch of printed circuit boards to test and evaluate before going into full production. It allows designers and engineers to check the design, functionality, and performance of the PCB before committing to mass production. PCB prototypes are usually made using the same materials, technology, and processes as the final product.

Why are PCB Prototyping Services Important?

PCB prototyping services are crucial for businesses to succeed in today’s fast-paced world. They reduce the risk of costly errors and defects, minimize development time and costs, improve product quality and reliability, and ensure customer satisfaction by meeting their expectations. By producing a small batch of PCBs to test and evaluate before going into full production, designers and engineers can check the design, functionality, and performance of the PCB before committing to mass production. PCB prototypes are made using the same materials, technology, and processes as the final product, and they allow necessary modifications to be made before committing to mass production, eliminating the need for costly reworks and redesigns that may delay the product’s launch.

Benefits of Choosing PCB Prototyping Services

Cost-effective

One of the primary benefits of using PCB prototyping services is cost-effectiveness. Producing a large quantity of PCBs can be expensive, and any errors or defects found after mass production can be costly to fix. With PCB prototyping, you can test your design with a small batch of PCBs before committing to mass production, reducing the risk of costly mistakes.

Faster Turnaround Time

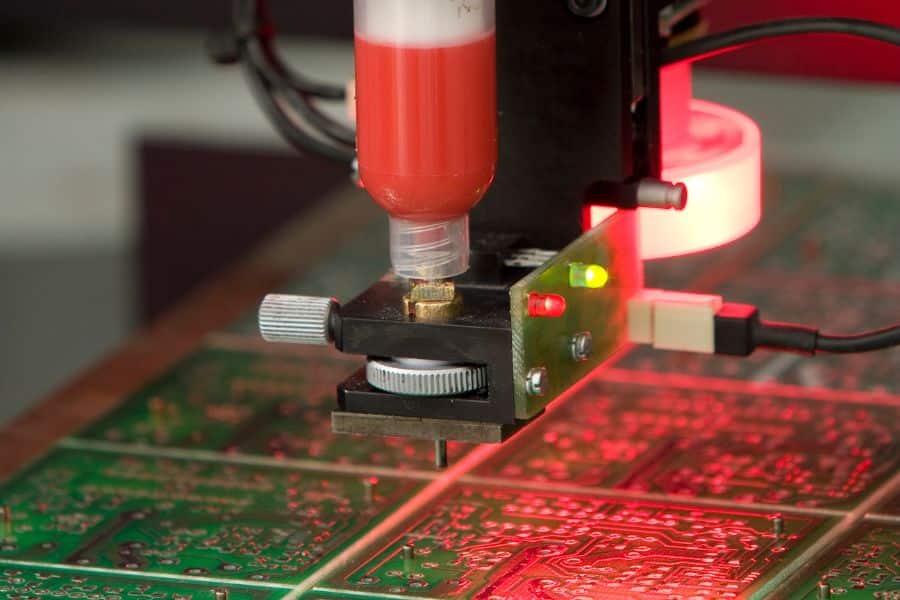

Another benefit of choosing PCB prototyping services is faster turnaround time. PCB prototypes can be produced much quicker than mass-produced PCBs. This is because prototype manufacturers typically have smaller machines that can produce small batches of PCBs quickly. Additionally, PCB prototyping services usually offer expedited shipping options, allowing you to receive your PCBs sooner.

High-quality PCBs

Choosing a reputable PCB prototyping service provider ensures high-quality PCBs. Prototyping manufacturers use the same materials and technology as mass production, ensuring that the prototype’s quality matches that of the final product. Furthermore, PCB prototyping services often perform thorough quality control checks to ensure that each prototype meets industry standards.

Ability to Test and Make Modifications

Perhaps the most significant benefit of PCB prototyping services is the ability to test and make modifications. Before committing to mass production, you can test your design and functionality, identify flaws and make necessary modifications, ensuring that the final product’s performance meets customer expectations. This eliminates the need for costly reworks and redesigns that may delay the product’s launch.

Types of PCB Prototyping Services

There are different types of PCB prototyping services available, depending on the project’s complexity and requirements. Here are some of the most common types:

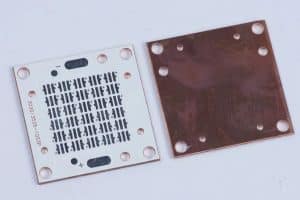

1. Single-sided PCB Prototyping

Single-sided PCBs have a conductive layer on only one side of the PCB substrate. They are commonly used in simple electronic devices that do not require complex circuitry. Single-sided PCB prototyping is the simplest and most cost-effective option for projects that do not require high-density designs.

2. Double-sided PCB Prototyping

Double-sided PCBs have two conductive layers on either side of the substrate. They offer more flexibility in design and can accommodate more complex circuits than single-sided PCBs. Double-sided PCB prototyping is suitable for projects that require medium to high-density designs.

3. Multilayer PCB Prototyping

Multilayer PCBs have three or more conductive layers separated by insulating materials. They offer the highest density and complexity and are used in advanced electronic devices such as smartphones, computers, and medical equipment. Multilayer PCB prototyping requires more advanced technology and is more expensive than single-sided or double-sided PCB prototyping.

Choosing the appropriate type of PCB prototyping service depends on the project’s complexity and requirements. It is essential to consult with a reputable PCB prototyping service provider to determine the best option for your project.

Factors to Consider When Choosing a PCB Prototyping Service

Choosing the right PCB prototyping service provider is crucial for the success of your project. Here are some factors to consider when selecting a PCB prototyping service:

1. Experience and Reputation

Choose a PCB prototyping service provider with years of experience in the industry and a good reputation. Check their track record by reading reviews, testimonials, and case studies from previous customers. This will give you an idea of their expertise and quality of work.

2. Quality Assurance and Certifications

Ensure that the PCB prototyping service provider has quality control processes and certifications in place. Look for certifications such as ISO 9001:2015, RoHS, and UL to ensure that they meet industry standards for quality and safety.

3. Turnaround Time and Delivery Options

Consider the turnaround time and delivery options offered by the PCB prototyping service provider. Choose a provider that offers a fast turnaround time without compromising the quality of work. Additionally, ensure that they offer flexible delivery options that suit your project’s needs.

4. Customer Service and Technical Support

Choose a PCB prototyping service provider with excellent customer service and technical support. They should be responsive to any inquiries or issues that you may have during the prototyping process. Ensure that they have a dedicated team of experts who can provide technical support and assistance.

Conclusion

PCB prototyping services offer several benefits that make them an essential part of the product development process. By providing cost-effective, high-quality PCBs, faster turnaround times, and the ability to test and make modifications, PCB prototyping reduces the risk of costly errors and defects, shortens development time and costs, improves product quality and reliability, and ensures customer satisfaction.

When choosing a PCB prototyping service provider, consider their experience and reputation, quality assurance and certifications, turnaround time and delivery options, and customer service and technical support to ensure that they meet your project’s requirements.