A completed Guide of Double-sided Flexible PCB

This article will comprehensively introduce the double-sided flexible PCB definition and the stack up, advantages, materials, applications of 2 layers flexible PCB, and the difference between a single-sided flexible PCB, double-sided flexible PCB, and a multilayer flexible PCB.

Home » PCB Manufacturing » Flexible PCB » Double-sided Flex PCB

What is Double Sided Flexible PCB?

A flexible PCB is a kind of printed circuit board, also called a flexible printed circuit, or FPC for short. FPC is made of adhesive material or non-adhesive material. The copper used in the FPC production process is divided into electrolytic copper and rolled copper, and non-stick rolled copper is more flexible and foldable.

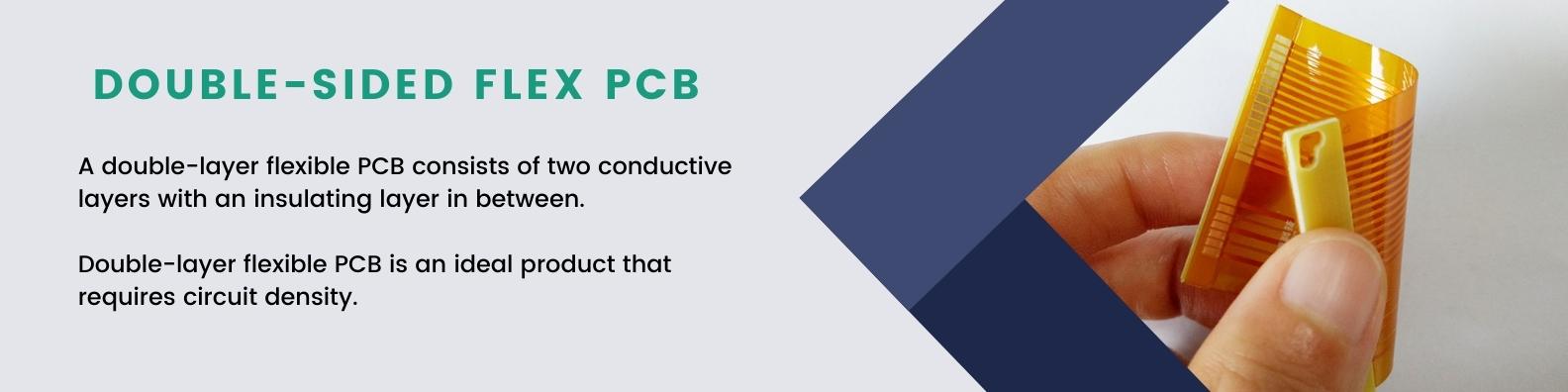

A double-layer flexible PCB consists of two conductive layers with an insulating layer in between. A double-layer flexible PCB is an ideal product that requires circuit density.

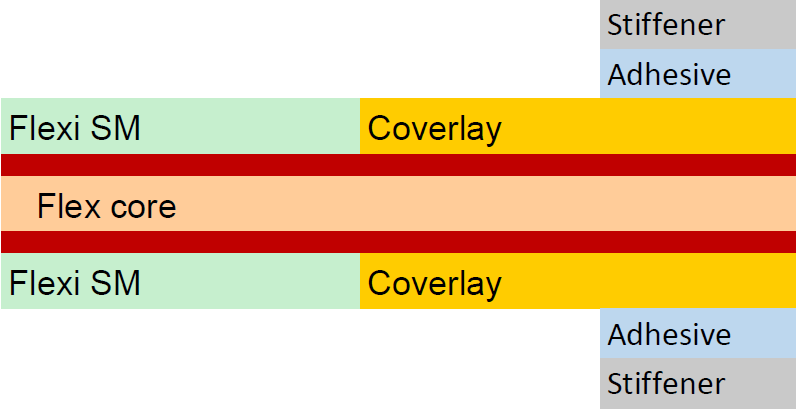

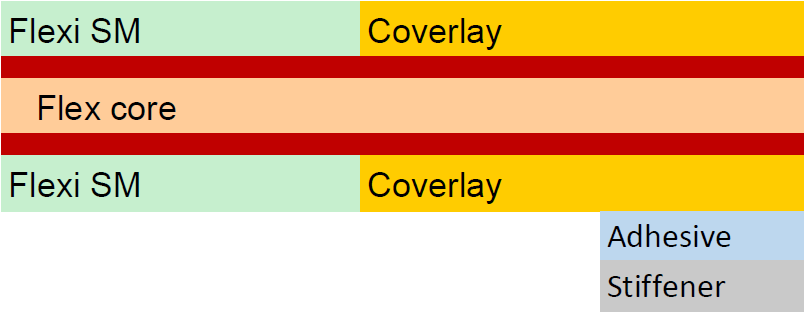

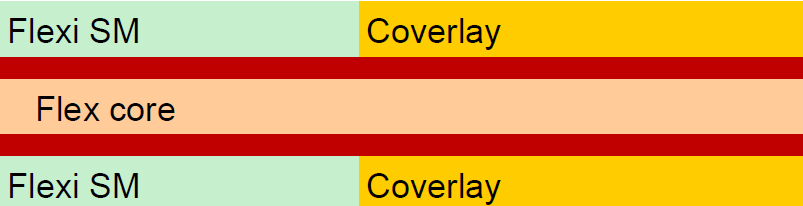

Double sided Flex PCB Stack up

Special possibilities

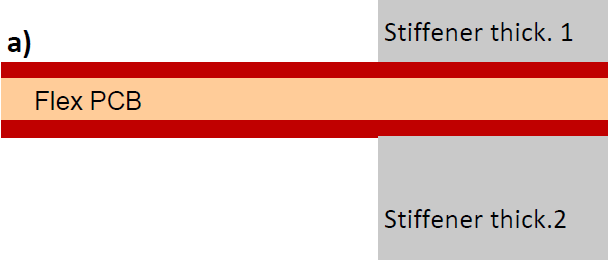

a)Different stiffener thicknes from each side are alowed

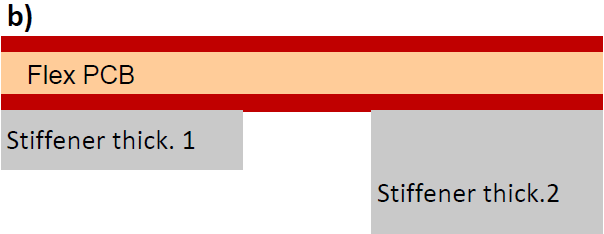

b)Also more sitiffener thickness from one side is alowed

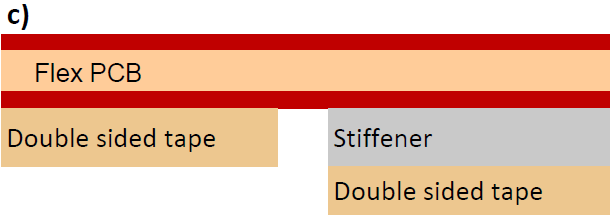

c)Double sided tape on flex or stiffener for sticking PCB to final product

Double Sided Flex PCB Material

There are many different choices of materials for double-sided flexible PCB manufacturing, such as PI, PET, PEN, LCP, etc. According to different application requirements, we can assist you in researching which options are more suitable for you. We also provide copper in different thicknesses to meet all your expectations and needs.

You can also choose polyimide, FR-4, steel sheet, aluminum sheet, etc., for Stiffener for double-sided flexible PCB.

Ralted Reading

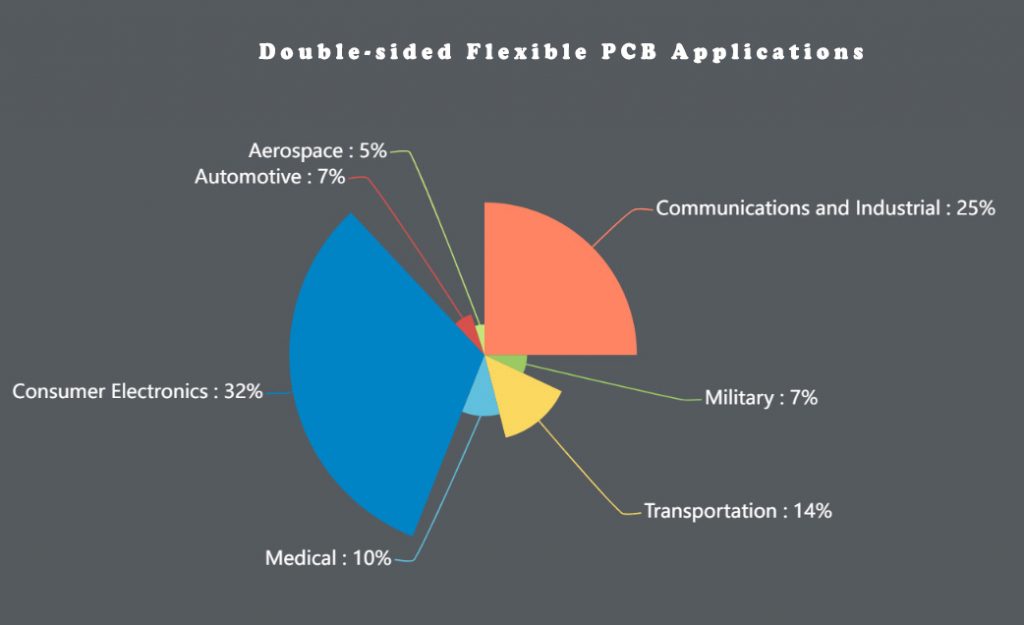

What are the applications of double-sided flex PCB?

Double-sided flexible PCB has been widely used due to its excellent performance, such as

- Communications

- Consumer Electronics

- Automotive

- Medical

- Industrial

- Aerospace

- Military

- Transportation etc.

The right figure is the application proportion of flexible PCB

Single-sided Flex PCB vs. double-sided Flex PCB vs. Multilayer Flex PCB.

- Single-sided Flex PCB or Single-layer flex PCB, install the original on one side of the board, and there is a conductor pattern on the other. A single-layer flexible PCB has only one layer of conductive material. Single-layer flexible PCB has the advantages of lower cost, more easy design, production, mass production, and delivery time.

- Double-sided flexible PCB has more layers than single-layer flexible PCB but fewer than multi-layer flexible PCB; double-layer flexible PCB has a layer of conductive metal on both sides, which increases the wiring density per unit area and is more suitable for routing.

The circuits and components on both sides of the double-sided flexible PCB can be electrically connected through through-hole mounting and surface mounting.

- Three or more double-sided flexible PCBs laminate into the multilayer flexible PCB. Each substrate layer in a multilayer PCB has conductive metal on both sides. These substrates are bonded with a unique adhesive, but an insulating material separates each substrate.

The electrical connection between each layer of the multilayer flexible PCB is achieved through holes, blind holes, or buried holes.

The advantages of multilayer flexible PCB are:

- More suitable for complex projects;

- Have higher quality and reliability;

- The density of multilayer flexible PCB circuits is increased, with higher operating capacity and operating speed, and overall product performance is improved;

- Improved durability. The more layers of the circuit board, the thicker its thickness, so it is more durable than single-sided flexible PCB or double-sided flexible PCB;

- Smaller size and lighter weight: Multilayer flexible PCB realizes a more compact circuit design, which can further compress the size and volume of the circuit board, thereby reducing weight.

How to choose single-sided, double-sided, multilayer flexible PCB?

When you have a headache choosing single-sided, double-sided, or multilayer flexible PCB for your project, you may wish to think from the following five perspectives:

- What level of functionality is needed? If it is more complicated, you need a multilayer flexible PCB;

- Circuit board size: We know that single-sided flexible PCB can only increase its size to achieve more wiring, while multilayer flexible PCB can achieve high-density installation in a smaller space;

- Durability. If you need to improve the durability of the product, choose a multilayer flexible PCB;

- Budget. If only from a budget point of view, single-layer flexible PCB is a good choice;

- Delivery time. Compared with rigid PCBs, flexible PCBs are more challenging to produce. The production difficulty coefficient of multilayer flexible PCBs is greater than that of double-sided flexible PCBs and single-sided flexible PCBs. The increase in the production difficulty coefficient means the extension of the delivery cycle.

Flexible PCB Manufacturing Capabilities

JHYPCB offers quick-turn flexible PCB prototype manufacturing services; we can turn your flexible PCB fabrication order in as quickly as 24 hours.

Whether you are looking for a single-sided flexible PCB, double-sided flex circuit, or complex multilayer flex PCB manufacturer and partner, we will all be your right choice.

There are also many options for the surface treatment process of double-sided flexible PCB:

- Immersion Gold

- Immersion Tin

- Immersion silver

- ENEPIG

- OSP

…

According to your needs, we can provide different types of insulation protection for your double-sided flexible PCB:

- Insulation film (Coverlay)

- Light imaging coverlay

- Photographic solder mask

- Silkscreen solder mask

Related Reading

- Knowledge of Flexible Printed Circuit Board Processing Technology

- The terms you have to know related to the manufacture of Flexible PCB

- Knowledge of Plating on Flexible Circuit Board Surface

- Complete Introduction To Flexible PCB Assembly Process

- Double-Sided PCB Manufacturing Process

- What Are Flexible PCB Stiffeners?

- 16 Factors Affecting The Cost And Price of Flexible PCB

- The Manufacturing Process Of Double-sided Flexible PCB Coverlay

- How To Select The Right Flexible PCB Manufacturer For Your Product: A 6-Step Guide

- Flexible PCB Manufacturing: A Guide To Fabrication And Assembly