Rigid PCB Circuit Board Fabrication Services

Rigid PCB , The Largest Number of PCB Manufactured

Home » PCB Manufacturing » Rigid PCB

Rigid PCB Definition

What is a Rigid PCB Circuit Board?

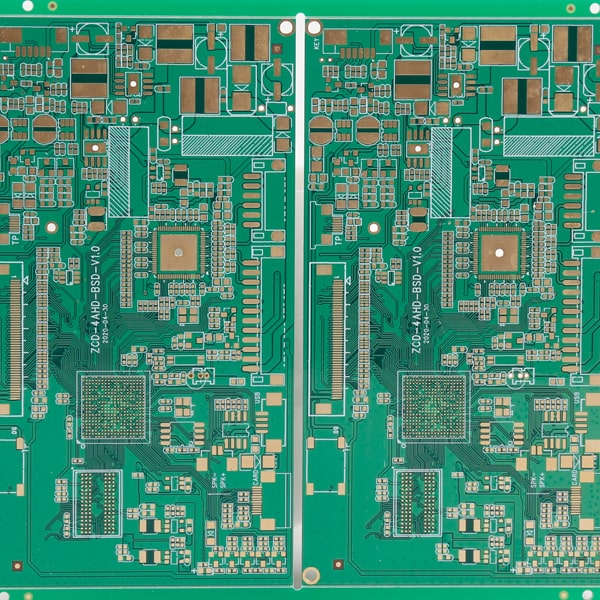

Rigid PCB is a kind of Printed Circuit Board and is the largest number of PCB manufactured. It is made of solid substrate material, which can effectively prevent the distortion of the circuit board. Perhaps the most common rigid PCB is the computer motherboard. The motherboard is a multi-layer PCB designed to distribute power from the power supply while allowing communication between all components of the computer, such as CPU, GPU, and RAM.

Rigid PCB can be used in any position where the PCB itself needs to be set to a shape and maintained during the remaining life of the equipment. Rigid PCBs can be anything from simple single-layer PCBs to eight or ten-layer multi-layer PCBs.

Rigid PCB and Flexible PCB are totally different. One is flexible and the other is rigid. Therefore, their application scenarios are different. In addition, there are Rigid-Flex PCB. There are similarities between them. However, all rigid PCBs have single-layer, double-layer, or multi-layer structure, so they have common application scope. This is the case.

Rigid PCB Examples

Characteristics of Rigid PCB

01

Rigid PCB is a kind of conventional PCB, which can not be like Flexi PCB because rigid PCB can not be twisted or folded into any shape because it has FR4 reinforcement, which is very useful for increasing stiffness.

02

Rigid PCB comprises copper trances and paths, which are incorporated on a single board to connect the different components on the board. The base material of the board is made of a rigid substrate which gives rigidity and strength to the board.

03

The computer motherboard is the best example of a rigid PCB with a rigid substrate material.

04

Once rigid PCBs are manufactured, they cannot be modified or folded into any other shape.

05

Rigid PCB is cheaper than flexible PCB. They are traditional PCBs and are widely used in many electronic products.

06

Flexible PCB and rigid PCB have their limitations and advantages in terms of ease of use and availability. Both of them are used to connect multiple electronic components on circuit boards.

How Are Rigid PCB Boards Manufactured?

What are PCBs made of?

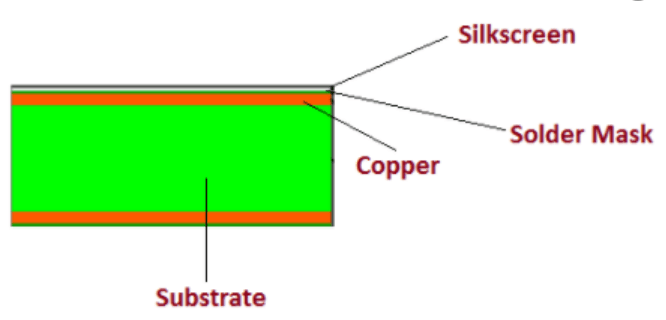

Rigid PCB comprises different layers that are joined together using adhesive and heat, providing a solid shape to board material. Following layers are used to develop a rigid PCB.

Rigid PCB stack up and materials for manufacturing

Substrate Layer

The substrate layer, also referred base material, is made of fiberglass.

The FR4 is mainly used as a substrate material, the most common fiberglass that provides rigidity and stiffness to the board.

Phenolics and epoxies are also used as a base material, but they are not as good as FR4. However, they are less expensive and feature a unique lousy smell.

The decomposition temperature of phenolics is too low, resulting in delamination of the layer if solder is placed for a long time.

Advanced Learning

Typical Structure of Rigid PCB

Multilayer Rigid PCB Stackup

Copper Layer

On the top of the substrate layer, a copper foil is laminated on the board with the help of the added amount of heat and adhesive.

In everyday use, both sides of the board are laminated with copper; however, some cheap electronics come with only one layer of copper material on the board.

Different boards come with different thicknesses, which are described in ounces per square foot.

Solder Mask Layer

Solder Mask Layer houses above the copper layer.

This layer is added on the board to add insulation on the copper layer to avoid any damage if any conduction material is touched with the copper layer.

Silkscreen Layer

The silkscreen layer is located above the solder mask layer.

It is used to add characters or symbols on the board to understand the board better.

White color is mainly used for silkscreen. However, other colors are also available, including grey, red, black, and yellow.

The Differences Between Rigid PCB And Flexible PCB

Most of the electronics made use of traditional rigid PCB. However, technology has been evolved, and many products abandoned rigid PCBs because of their inability to get folded or twisted. This has erupted the idea of flexible PCB, and soon it became the prerequisite for most of the professionals in the market.

The manufacturing process of rigid and flexible PCBs is identical, with some exceptions in their flexibility, softness, and cost.

Some extra measures are required for processing Flex PCB when it comes to material handling. Also, proper specifications are needed to avoid any cracked solder joints when the board is bent.

Flexible PCBs are most costly than rigid PCBs. However, we are referring to here individual cost of the flexible PCB, and it may happen the overall cost of the project using rigid PCB is higher than the cost of the flexible PCB. Still, the individual price of flexible PCB will be higher.

Many cheap electronics use rigid PCBs, including audio keyboards, desktop devices, solid-state drives, toys, and many electronic gadgets. However, flex circuits are observed in ultra-high-performance devices because they don`t involve connectors thinner than rigid boards and can be used in smartphones, cameras, tablets, and GPS control systems.

Both rigid and flexible boards can be incorporated together to construct a unified product with both strength and flexibility.

Some flex PCBs follow the same design as rigid circuit design, but they are not identical to rigid circuit boards.

Flexible PCBs provide flexible and bending solutions, and they also require less space and are mostly Single-Sided PCBs.

When to Use Rigid and When to Use Flexible

- Rigid PCBs typically cost less than flex circuits. I say “typically” because when considering the total cost of ownership, there are some applications that, when using flexible PCBs, may be less expensive compared to using rigid PCBs. To get a true and accurate understanding of the total cost of ownership, you first need to appreciate that flex circuits may eliminate the need for components such as connectors, wire harnesses, and other circuit boards. By removing these components from a design, material cost, labor and assembly cost, and scrap cost are all reduced.

- Many electronic devices (laptop and desktop computers, audio keyboards, solid-state drives (SSDs), flat-screen TVs and monitors, children’s toys, and various electronic gadgets) employ rigid PCBs instead of flexible PCBs. However, flex circuits may be found in ultra-compact and/or high-performance devices, including GPS units, tablets, smartphones, cameras, and wearables.

- Greater sophistication is not the only reason to use flex circuits; low-tech applications, such as LED lights, may utilize flex circuit technology in some cases because it makes installation much easier.

What are the rigid PCBs used for?

Rigid PCB Applications

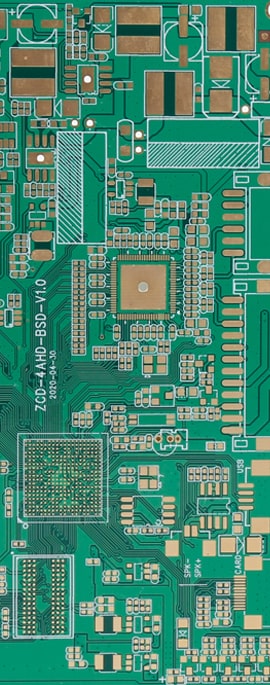

computer motherboard

A computer motherboard is a perfect example of rigid PCB, which is a Multilayer Rigid PCB, used to distribute electricity from the power supply and creates a conducting path between CPU, GPU, and RAM.

Electronic products

Some low-cost products use rigid PCBs like toys, electronics gadgets, desktop devices, and solid-state devices.

Others

You should also have a look at Double-Sided PCBs; these are also Rigid PCBs.

Different Types of Rigid PCB Provided by JHYPCB

Single-Sided PCB: These rigid printed circuit boards feature metal traces on a single side of the dielectric. Single-sided rigid PCBs are ideal for rapid production due to their manufacturability, as well as simple design.

Double-Sided PCB: As the name suggests, these printed circuit boards have a layer of dielectric sandwiched between two metal layers. The double-sided rigid printed circuit boards have become an industry staple. Their applications vary from low to high-temperature, fine line surface mounting, solder coatings, and high copper builds.

Multilayer PCB: Multilayer rigid PCBs feature more than two conductive metal layers, clearly separated by equal dielectric layers. These circuit boards allow our PCB designers to create a vast range of interconnects, as well as applications.

Advanced Learning:

JHYPCB is committed to providing the highest quality rigid Printed Circuit Boards at competitive prices. As the name suggests, these PCBs use an inflexible, solid, and rigid substrate material such as fiberglass, which prohibits these boards from bending. We can provide high-quality and performance-oriented rigid printed circuit boards in diverse specifications.

Learn more about JHYPCB by exploring the manufacturing capability of the Rigid Printed Circuit Board. We can do more than you can imagine.

FAQ

Most frequent questions and answers

Flexible printed circuit boards, also called Flexible PCBs or Flex PCBs, derive their name for their ability to enable the circuitry to be designed to fit the electronic device or product, as opposed to building the device to conform to the circuit board.

The substrate most commonly used in printed circuit boards is a glass fiber reinforced (fiberglass) epoxy resin with a copper foil bonded on to one or both sides. PCBs made from paper reinforced phenolic resin with a bonded copper foil are less expensive and are often used in household electrical devices.

Copper is an excellent electric and thermal conductor, thus improving heat transfer along and across the PCB, which reduces the damaging stress caused by uneven heating of the PCB. The stress otherwise may result in micro-fracturing of the PCB, and thus device failure.

Typically, the most common causes of PCB failures can be attributed to: Component Design Failure: Incorrect placement of components, power failure, and overheating due to lack of space on the PCB, are just a few examples of things that can go wrong at the design and manufacturing stage.

We are the factory, we have our PCB manufacturing & Assembly factory.

We can offer a one-stop service from PCB manufacturing to PCB assembling, testing, housing, and other value-added services.

Quantity, Gerber file and Technic requirements(material, surface finish treatment, copper thickness, board thickness,…) are necessary.

For more information, pleast Click PCB and PCBA Manufacturing File.

Gerber file: CAM350, RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

Our MOQ is 1 PCS.

The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the shipping cost.

We respect customer’s copyright and will never manufacture PCB for someone else with your files unless we receive written. Permission from you, nor we’ll share these files with any other 3rd parties.