How to Buy Prototype PCB Boards?

High Quality, Competitive Price, Better Service are the first things you should consider.

Home » Prototype PCB » How to Buy Prototype PCB Boards?

High Quality Competitive Price Better Service Quick Turn Low-cost

JHYPCB is a professional super-fast PCB factory, focusing on PCB prototype and small-batch PCB manufacturing services. JHYPCB makes electronic manufacturing more efficient and easier.

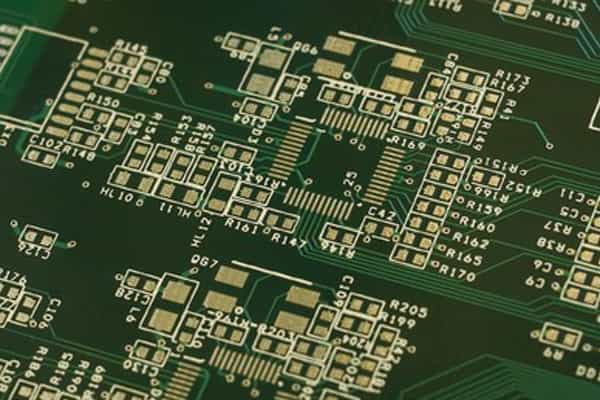

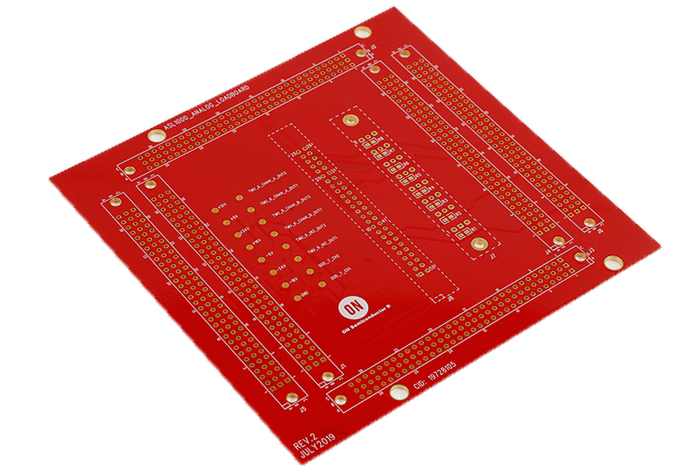

PCB prototypes are an essential part of printed circuit board design and production process. They are the initial versions of a PCB design that allows the engineers and designers to test and verify the functionality of the circuit before going into mass production.

A PCB prototype serves as a physical sample of the final product and helps in evaluating the feasibility of the design. It is also used for identifying any errors or issues early on in the development stage and making necessary modifications.

Learn More:

PCB Prototype Parameters

When buying a PCB prototype, it is essential to consider various parameters that determine the final product’s performance and quality. Here are some of the critical parameters that you need to look out for:

- Board Thickness: The board thickness is an essential parameter that determines the physical strength and rigidity of the PCB. It is typically measured in millimeters (mm) and ranges from 0.4mm to 3.2mm.

- Copper Thickness: Copper thickness is another critical parameter that influences the PCB’s conductivity and electrical properties. It is usually measured in ounces per square foot (oz/ft²) or microns (μm).

- Number of Layers: The number of layers in a PCB determines the complexity of the circuit design. It can range from single-layered to multi-layered boards with more than four layers.

- Hole Size: The hole size determines the diameter of the holes drilled into the PCB for component insertion and connection. It is measured in millimeters (mm) or inches (in).

- Line Width: Line width refers to the width of the copper trace on the PCB. It determines the amount of current that can pass through the trace and is typically measured in mils or millimeters.

- Surface Finish: Surface finish is the coating applied to copper traces on the PCB to protect them from oxidation and other environmental factors. It also helps with soldering components onto the board. Common surface finishes include HASL, ENIG, and OSP.

Choosing the Right PCB Prototype Supplier

Choosing the right PCB prototype supplier is crucial for ensuring the quality and timely delivery of your PCB prototypes. Here are some factors to consider while selecting a PCB prototype supplier:

- Comparison of PCB Prototype Suppliers: Compare various PCB prototype suppliers based on their experience, reputation, customer reviews, pricing, turnaround time, and quality standards. Look for suppliers who specialize in the type of PCB prototype you require.

- Recommendations for PCB Prototype Suppliers: Ask for recommendations from other engineers or designers who have used PCB prototype services before. They can recommend reliable and trustworthy suppliers they have worked with.

- Customer Service: Choose a supplier that provides excellent customer service, including prompt communication, technical support, and after-sales service. A good supplier should be responsive to your queries and provide timely updates on the status of your order.

After selecting the right PCB prototype supplier, the next step is to place an order for your PCB prototypes.

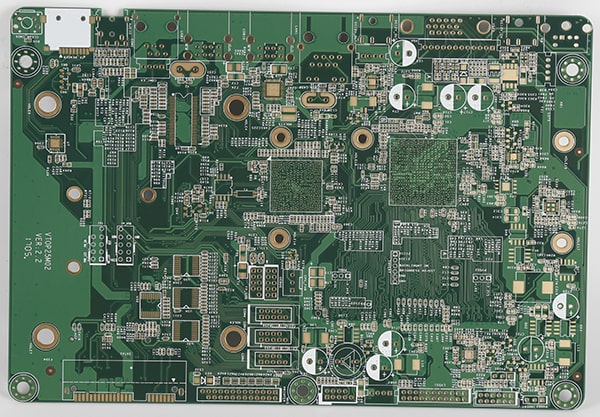

High Quality

We have been committed to high-quality printed circuit board production services and have won praise from customers worldwide. With advanced production equipment and an experienced team of engineers, JHYPCB ensures the excellent quality of PCB prototypes. Besides, all printed circuit boards pass strict tests before being delivered to each customer (we provide various test methods such as the flying probe tests). Therefore, JHYPCB is your best choice for purchasing PCB prototype boards.

Competitive Price

Among all the factors of ordering PCB prototype boards manufacturing services, the price of buying prototype PCB boards should be ranked first. As we all know, the prototype usually refers to small batch trial production, so there is no need to spend too much on it. Based on this, PCBELEC.COM provides you with cheap PCB prototype production. Also, the low cost will never mean low quality in JHYPCB. 100% quality assurance is the most powerful proof of our manufacturing capabilities, making customers worldwide have absolute trust in us.

Better Service

In addition to low cost and high quality, service levels should also be considered. I guess you may feel frustrated when you encounter difficulties. We fully understand this and provide you with quality service 24 hours a day. Our customer service staff and sales staff are not only professional but also enthusiastic, ready to help you at any time.

15 steps for PCB prototype Manufacturing

Before PCB prototype production, it is necessary to determine the substrate material, such as FR-4, CEM-1, 94V-0, aluminum, or copper.

- Step 1. Choose the proper PCB prototype manufacturer

Provide detailed PCB specifications and other information to the PCB prototype manufacturer, and place an order after the quotation is confirmed.

Advanced learning

- Step 2. Cut Laminate

The PCB prototype manufacturer cuts the copper-clad laminate into a suitable size according to the Gerber file provided by the customer.

- Step 3. Drilling

Drill holes on the copper clad board that meets the requirements. The buried blind hole in the PCB board mainly refers to the role of electrical connection.

- Step 4. Immersion copper

Copper sinking is depositing a thin layer of copper on the insulating holes by chemical methods.

- Step 5. Image transfer

Transfer the image on the production film to the board.

- Step 6. Pattern plating

They are electroplating a copper layer with the required thickness and a gold-nickel or tin layer with the necessary thickness on the exposed copper skin or the hole wall of the circuit pattern.

- Step 7. Remove the film

Use NaOH solution to remove the anti-electroplating coating film to expose the non-circuit copper layer.

- Step 8. Etching

Use chemical reagent copper to remove non-circuit parts.

- Step 9. Solder Mask

There are many colors of solder masks, and green is the most common one. The function of the solder mask is to protect the circuit and prevent tin on the circuit when welding parts.

- Step 10. Silkscreen Legend

Print some characters on the circuit board for easy identification.

- Step 11. Surface Finish

The surface treatment process includes OSP|HASL|HASL Lead-Free (HASL LF)|Immersion Silver|Immersion Tin|Plated Gold|Immersion Gold(ENIG)|ENEPIG|Golden Finger+HASL|ENIG+OSP|ENIG+Golden Finger|OSP+Golden Finger, etc.

- Step 12. Gold-plated fingers

The gold finger is generally used as a connector, and a layer of nickel or gold that meets the thickness requirements is plated on the gold finger to make it more rigid and wear-resistant.

- Step 13. Routing

Through die stamping or CNC gong machine gong the shape required by the customer.

- Step 14: Testing

The flying probe tester is used for testing to detect defects that affect functionality, such as open circuits and short circuits that are not easy to find visually.

- Step 15. Pack & Shipping

After the test is completed, the PCB board can be shipped to customers after vacuum and anti-static packaging.

Click here to learn more about the PCB fabrication process and flowchart.

What Consider before ordering PCB prototypes?

Before choosing a PCB prototype manufacturer, you must consider various factors, such as the manufacturer’s process capabilities. Here are three things to remember when looking for a PCB prototyping manufacturer.

1. Budget

You should design the PCB according to your budget and choose premium or common materials.

2. Manufacturing capacity

The process capabilities of each PCB prototyping manufacturer are different. Complex designs can only be produced by powerful PCB factories.

3. Delivery time

Delivery time is another important consideration when ordering PCB prototypes. Fast turnaround prototype PCB manufacturing can be submitted for delivery, but it also means you need to pay more. Also, you can’t afford any longer than expected delivery times.

Placing an Order for PCB Prototypes

Once you have chosen the right PCB prototype supplier, the next step is to place an order for your prototypes. Here are the steps involved in ordering PCB prototypes:

- Sending Design Files: Send your design files to the supplier in the format they specify. Most suppliers accept Gerber files or Excellon drill files.

- Waiting for Quotation: The supplier will then review your design files and provide a quotation based on the parameters you require, such as board thickness, copper thickness, number of layers, hole size, line width, surface finish, and quantity.

- Confirming the Order: Upon receiving the quotation, review it carefully and make any necessary changes or clarifications. Once you are satisfied with the quote, confirm the order by making payment and providing any additional details or specifications required.

After confirming the order, the supplier will manufacture the PCB prototypes and deliver them to your doorstep.

Receiving and Inspecting PCB Prototypes

Upon receiving your PCB prototypes, it is crucial to inspect them carefully to ensure they meet your specifications and quality standards. Here are some steps to follow when receiving and inspecting your PCB prototypes:

- Receiving PCB Prototypes: Inspect the package upon delivery for any damages or signs of mishandling during transport. If there are any damages, take pictures immediately and contact the supplier for a resolution.

- Checking Specifications: Check the specifications of the PCB prototypes against what you ordered, including board thickness, copper thickness, number of layers, hole size, line width, and surface finish. Ensure that they match your requirements.

- Performing Electrical Tests: Perform electrical tests on the PCB prototypes using a multimeter or oscilloscope to verify their functionality and performance. Check for shorts, opens, and other electrical issues.

- Evaluating Visual Quality: Evaluate the visual quality of the PCB prototypes, including the cleanliness of the board, solder mask alignment, silkscreen clarity, and overall appearance.

If you discover any issues with the PCB prototypes during inspection, contact the supplier immediately to resolve the issue. Most suppliers have return policies in place for defective or non-conforming products.

Conclusion

In conclusion, PCB prototypes are an essential part of the printed circuit board design and production process. They allow engineers and designers to test and verify the functionality of the circuit before going into mass production. When buying PCB prototypes, it is crucial to consider various parameters such as board thickness, copper thickness, number of layers, hole size, line width, and surface finish.

Choosing the right PCB prototype supplier is also critical for ensuring the quality and timely delivery of your prototypes. Look for suppliers with a good reputation, experience, and excellent customer service.

At JHYPCB, we provide reliable and high-quality PCB prototype services to meet your design specifications and requirements. We specialize in different types of PCB prototypes, including single-layer, double-layer, and multi-layered boards. Our experienced engineers ensure that your designs are manufactured correctly, and our customer service team provides prompt communication to keep you informed throughout the manufacturing process.

Thank you for considering JHYPCB for your PCB prototype needs.

Recommended PCB Fabrication Services

How to place a PCB order to us?

To sum up, here are the standards for buying prototype PCB board now: price, quality as well as service. Fortunately, PCBELEC.COM is able to satisfy all these demands, all you have to do is checking by yourself.

You only need to contact our online customer service staff or send the PCB Gerber file directly to sales@pcbjhy.com to enjoy the above services.

FAQ

Most frequent questions and answers

PCB prototype manufacturing needs to provide PCB or Gerber files, board making instructions: PCB layer number, board thickness, surface treatment, silkscreen legend color, IPC standard, panelization requirements, material, pad process, solder mask color, whether there is impedance requirement, etc. . The Gerber file formats acceptable to our company are Gerber RX-274X, .brd, .pcb, .pcbdoc, etc.

There are many things to pay attention to when ordering PCB prototype manufacturing, and the price is one of the focuses of buyers’ attention. Factors affecting the cost of PCB prototype manufacturing include:

1) Delivery Cycle

2) Quantity

3) Number of PCB Layers

4) Manufacturing Process

5) PCB Material

6) Engineering Cost

7) Location of the PCB Supplier

8) Transportation Cost

For more detailed instructions, please refer to here.

Advanced Learning:

We all know the importance of PCB prototyping before mass production because PCB prototyping can provide us with the following benefits:

- Check the possible errors in the PCB design process;

- Functional test;

- Save time and cost;

- Manufacturability inspection;

- Can help us improve our design;

- Ensure that the final product is error-free;

- Ensure successful mass production

You can click here and read the following article for more information: