Table of Contents

What is PCB Prototype?

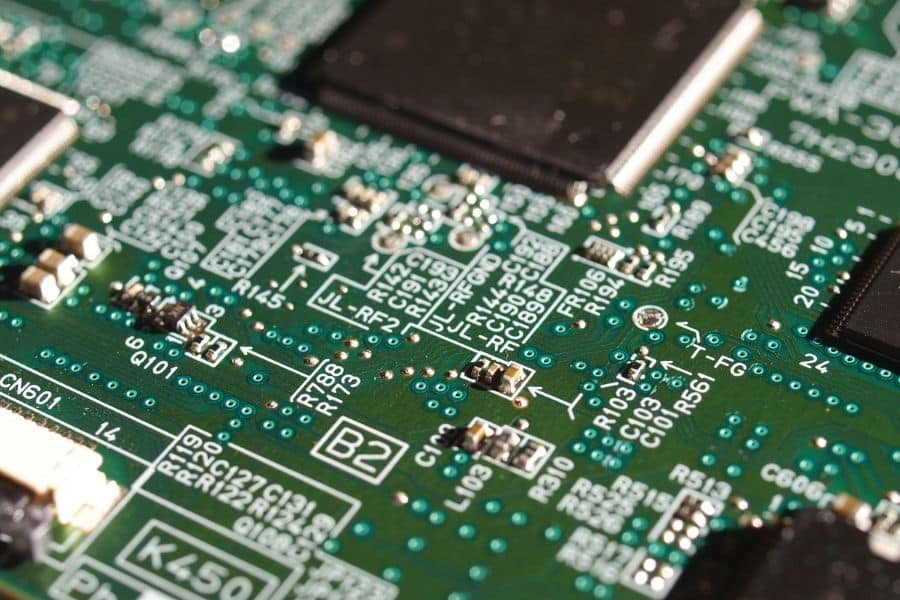

A printed circuit board prototype refers to the initial version of a printed circuit board design that is fabricated for concept verification and testing. As one of the most crucial steps in electronics product development, building a prototype PCB provides the first physical form of the circuit schematics to examine functionality, analyze signal integrity, and evaluate manufacturability before high-volume production. This process is also known as prototype PCB assembly.

In essence, PCB prototype assembly enables developers and engineers to convert electronic designs into tangible boards with components soldered on them. It bridges the gap between theoretical schematics and mass manufacturing, providing key insights and optimization opportunities early in the cycle. Both the fabrication and assembly processes are critical for prototype construction. While PCB fabrication focuses on turning CAD designs into physical boards, prototype PCB assembly is the process of soldering electronic components onto those boards based on bill of materials (BOM) requirements to build functioning prototypes.

As proof of design concept and part of product development cycle, prototype PCB assembly offers electronics companies and innovators the chance to de-risk technological and manufacturing uncertainties at relatively low cost and lead time. It is an indispensable step to validate functionality, safety and performance metrics before ramping up production with bulk orders. Hence, choosing a qualified prototype assembly partner bears significant impact on ultimate product success.

Why Use Prototype PCB Assembly?

There are several key reasons why investing in professional prototype PCB assembly services is worthwhile for most electronics hardware companies and developers today:

- Verify design functionality and concepts The number one goal of building prototype boards is examining the real-world functionality and performance of electronic designs. By putting schematics into testable boards, prototype assembly enables validation of design correctness and detection of potential flaws that may compromise functionality. This verification process mitigates risks prior to large-scale manufacturing.

- Accelerate product development and time-to-market Through early verification and problem discovery, quality PCB prototype assembly helps compress development cycles significantly. Rather than finding issues after production investment, prototyping offers an efficient and low-cost approach to optimizing and finalizing designs, saving overall engineering time by over 60% according to research.

- Facilitate demonstration, marketing and funding An assembled PCB prototype lets innovators demonstrate product viability and technology capacity to secure marketing leads, early adopters and investor funding ahead of production. For hardware startups, an impressive prototype builds business case for securing the financing to proceed further.

- Refine designs for manufacturability By reflecting real-world manufacturing processes more closely, prototype assembly finds design for manufacturability (DFM) issues as well design flaws to optimize. This lessens surprises down the line, and leads to more efficient transition from prototyping to mass production.

In essence, investing in professional PCB prototype assembly services creates remarkable value. It transforms designs from ideas to functioning boards efficiently, enabling concept validation, performance verification, design refinements, demonstration exhibits, and business case shaping before large-scale manufacturing commitments.

Types of Prototype PCB Assembly

There are several key categories and techniques for assembling electronic components onto PCB prototypes which cater to different production needs:

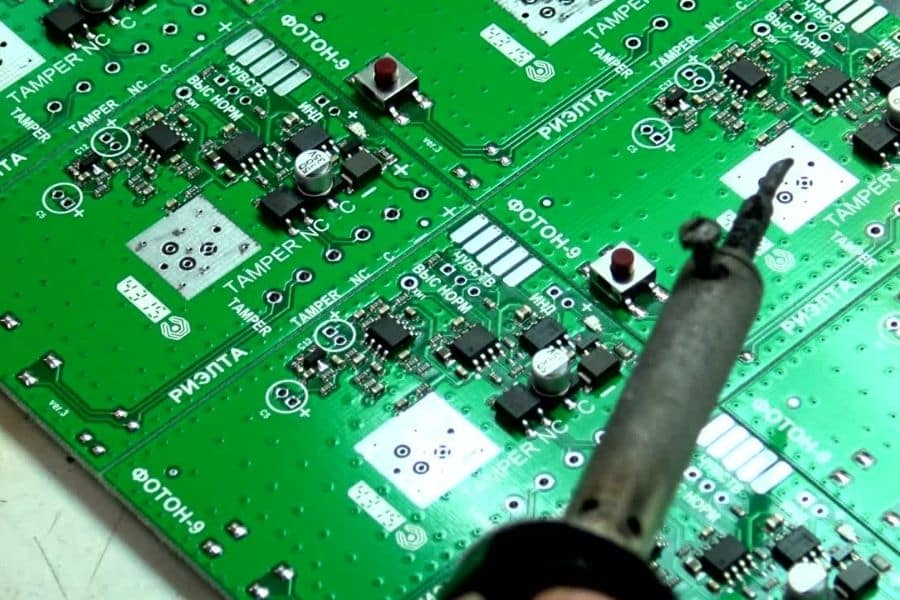

- Manual Assembly vs Automated SMT Assembly

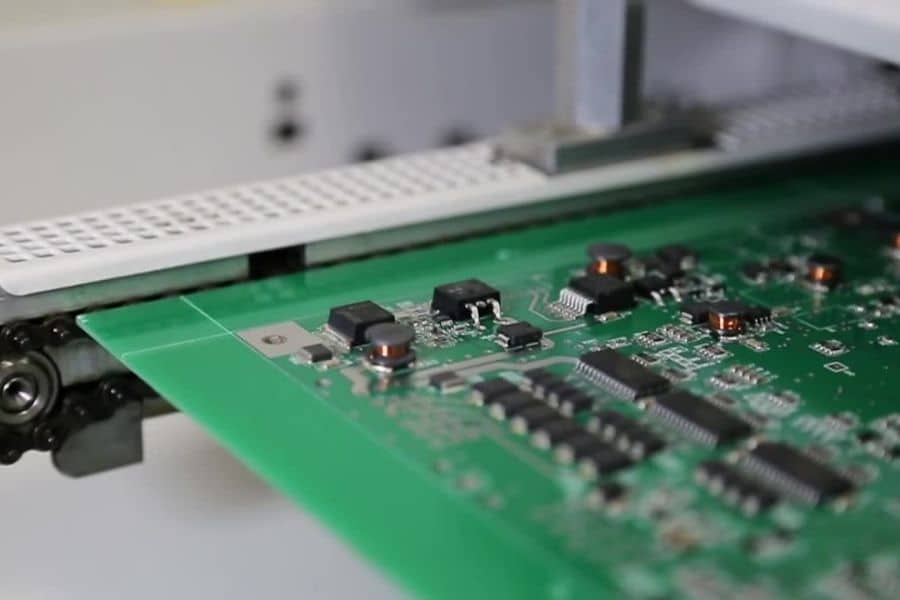

The simplest prototype PCB assembly uses manual soldering of components by technicians, suitable for very low volume or limited quantity orders. However automated surface mount technology assembly offers higher efficiency, consistency and manufacturability for complex board productions. - Through-Hole vs SMT Assembly

While through-hole components have connector pins for passing through holes in boards, SMT or surface-mount components get directly soldered onto surface pads. Both through-hole assembly (THA) and SMT assembly have respective applications. Advanced tech allows mixing THA parts on primarily SMT boards. - Single-sided vs Double-sided Assembly

How components are placed and soldered on a PCB depends much on the design – from plain single-sided prototype PCB assembly to more complex double-sided assembly which solders parts on both sides of boards and enables higher component density overall. - Hybrid Assembly Techniques

With state-of-the-art manufacturing capabilities, leading prototype assembly services allow component mixtures on boards, say combining 0201 size tiny chips along with larger SMT parts and some through-hole passives on double-side boards for optimized productions. Such hybrid assembly provides the needed flexibility.

In summary, professional prototype PCB assembly partners offer a spectrum of verified assembly processes catering from simple manual builds to advanced automated mixed productions in both low to medium quantities, providing the right solution for customers’ prototyping needs prior to mass manufacturing orders.

Prototype PCB Assembly Process Steps

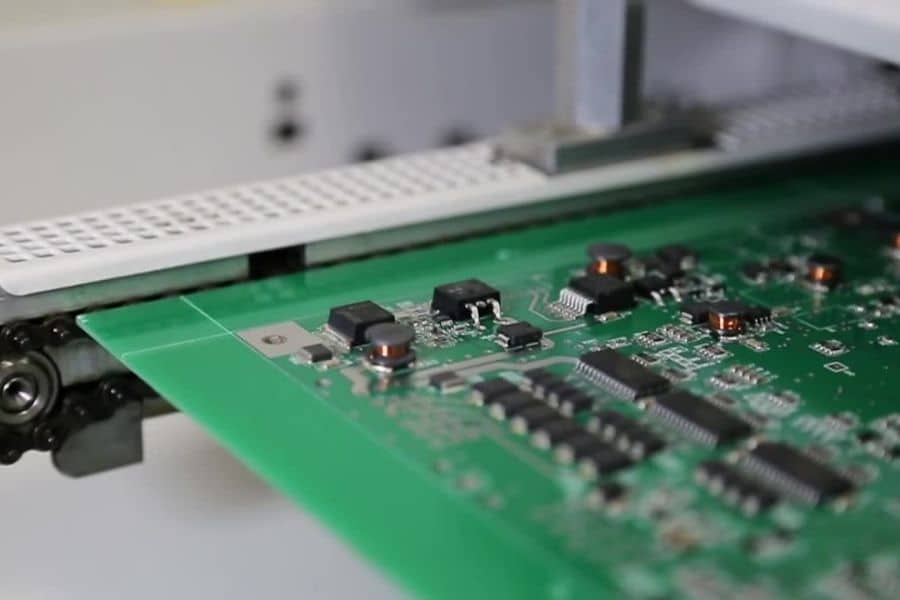

The professional process of assembling prototype PCBs, whether utilizing automated SMT lines or manual assembly, generally follows standardized assembly stages to actualize CAD designs into functioning boards:

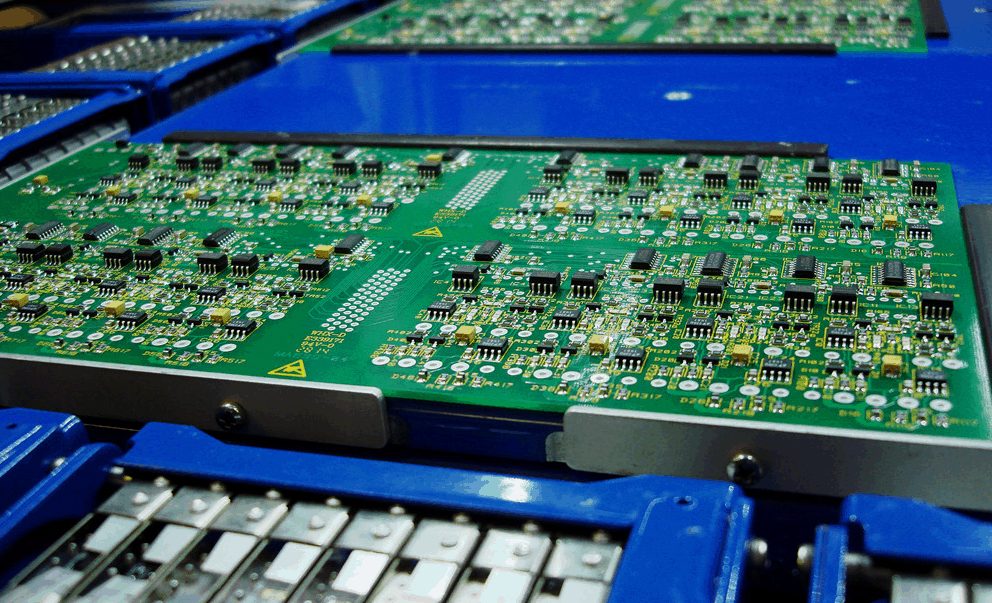

- SMT Pick-and-Place Stage

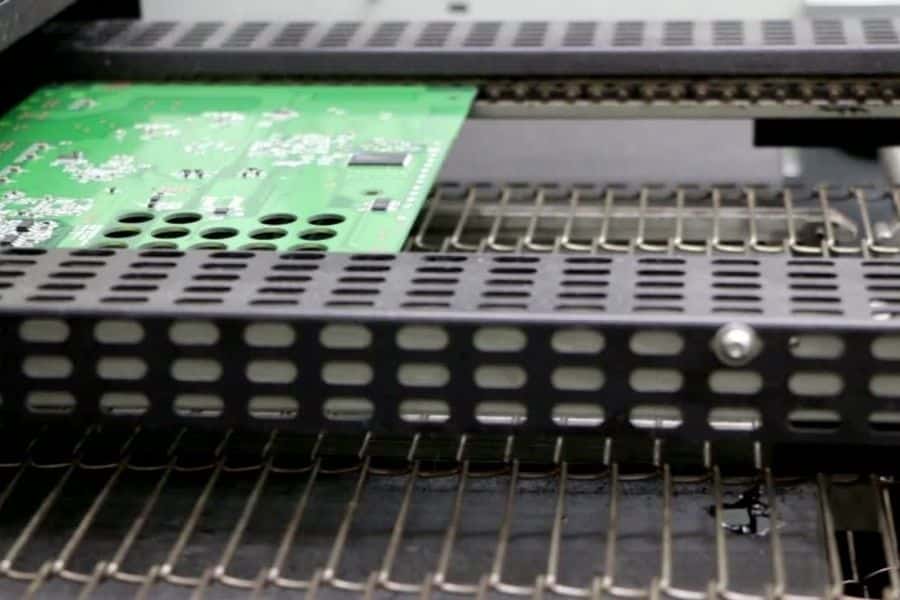

The core process uses advanced pick-and-place machines to selectively populate components onto circuit boards based on optimized programming and feeders setup. High precision and traceability is ensured during this mass component placement stage. - SMT Reflow Soldering

After accurate component positioning, the boards pass through industrial reflow ovens for simultaneous precision soldering of SMT parts under carefully optimized thermal profiling to permanently attach parts to board surfaces. - Cleaning/Washing

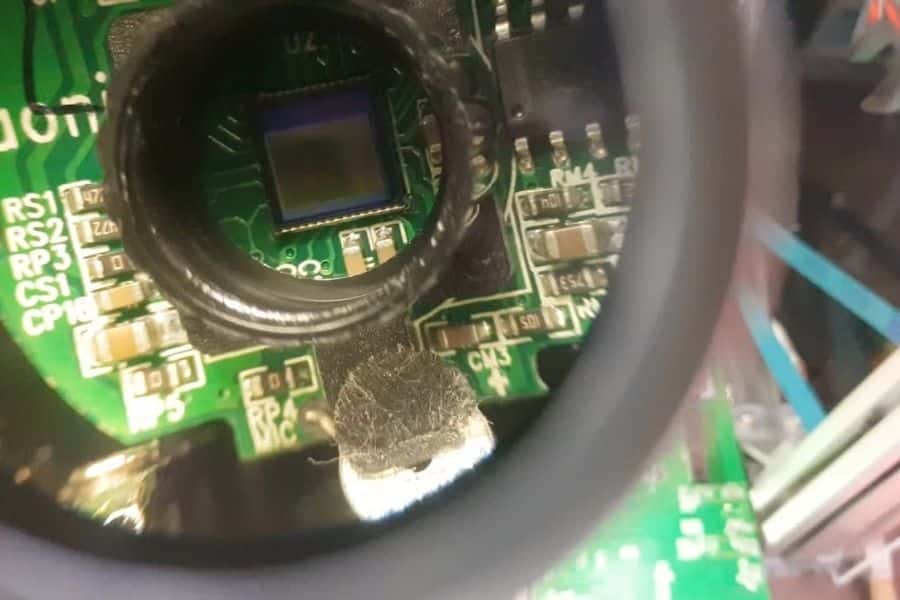

Once boards are reworked for any fixes, the assembly process proceeds to using cleaning solutions to thoroughly wash flux residues off board surfaces after soldering, ensuring ionic cleanliness. - AOI and Functional Testing

Quality checks follow assembly stages – automated optical inspection checks component placement while rigorous functional testing examines board performance metrics to specification compliance using fixture testing among other methods before programming final firmware builds onto boards. - Final Programming/Flashing

These downloads optimized software/firmware builds to boards through interfaces, completing the prototype PCB assembly for design validation before shipping to customers.

In summary, by following robust assembly protocols and quality management systems, professional PCB assembly partners deliver exceptionally functioning, reliable and clean prototype boards on short lead times.

Factors Affecting Lead Time & Cost

The lead time to obtain assembled PCB prototypes as well as the associated cost depend on a mix of factors related to design specifications and assembly requirements:

- Order Quantity and Batch Size

The production volume ordered has significant impact – lower order quantities generally mean higher NRE costs from the assembler, while having 3-5 boards per batch streamlines assembly processes and reduces costs somewhat. - Degree of Assembly Complexity

The intricacy of component placements, density of parts along with challenges of achieving reliable solder joints for chosen parts also adds to assembly effort and costs. Slopes of advanced SMT parts on double-sided boards increases complexity for instance. - Test Requirements Scope

The extent of functional tests and quality assurance checks involved after assembly also affects labor efforts and thereby overall cost. In-circuit tests, environmental stress screening along with conformance validation require additional investments. - Component Sourcing Lead Times

Hard-to-source parts locally means longer procurement lead times, pushing out overall assembly timelines significantly. The sooner clients finalize their bill of materials with readily available parts, the quicker assembly progresses. - Production Responsiveness

During prototyping, design changes occur as testing provides feedbacks. Hence choosing assemblers with quick-turnaround manual assembly capabilities allows accommodating revisions swiftly.

Overall, PCB prototype assembly cost varies in the range of $100 to $5000 based on above criteria while lead times can span 5 days to 4 weeks depending on order specifics and assembler capacities.

Finding A Good Prototype Assembly Partner

Given the significant impacts of PCB prototype assembly quality on product development cycles, how to select the right assembly partner becomes extremely important. Here are key criteria companies should consider:

- Assembly Quality and Technical Capabilities

The foremost selection criteria is assessing partners’ technical capabilities across assembly techniques, production grade equipment, process controls and workmanship thresholds to meet quality and reliability requirements reliably. - On-Time Delivery Track Record

Analyzing past delivery timeliness for orders via metrics such as on-time delivery rates offers insights into partners’ production bandwidths, responsiveness and capacities to meet lead time commitments despite inevitable prototype complexities. - Competitive and Transparent Pricing

Partners should offer clear assembly quotes benchmarked competitively against other prototype assemblers in alignment with capabilities, while outlining what service aspects influence costs to avoid hidden charges later. Reasonable pricing indicates good cost control abilities. - Customer Service and Responsiveness

From assembly-ready design reviews to post-production support, partners’ consultation quality and uptime directly impacts collaboration effectiveness during prototyping rush jobs. Quick issue resolution indicates strong service competence.

In essence, aligning with PCB assembly partners with strong technical expertise, on-time delivery records, pricing clarity and responsive support ensures high-quality yet cost-effective prototyping critical for new product introduction success.

Summary - Importance of Prototype PCB Assembly

In summary, prototype PCB assembly provides indispensable functional verification and concept validation capabilities for electronics product development teams through transforming design files into functioning boards with components soldered on accurately and reliably.

The assembly build quality directly impacts downstream processes from design optimizations to securing financing for productions. Hence quality considerations, balanced costs, responsive turnarounds and technical alignment are vital for companies to reap the most business value from the PCB assembly prototyping process while de-risking technology uncertainties early.

Along with fabrication partners, competent prototype assembly services like JHYPCB reshape notions into testable boards rapidly to meet fast-paced market dynamics, offering firms and innovators the competitive edges vital for commercial success. JHYPCB specializes in professional turnkey PCB prototype assembly catering from concept verification builds to pilot productions, and has supported thousands of customers globally with exceptional quality deliveries and responsive support. Finding the right assembly partner makes all the difference in setting out innovation trajectories impactfully.