High TG PCB - High Temerature Circuit Board for PCB applications that requires high temperature.

JHYPCB is specialized manufacturers from China, High-Temperature Circuit Board, High TG PCB supplier, and factory, provides high-quality products of High TG Circuit Board manufacturing service, we have the perfect after-sales service and technical support.Look forward to your cooperation!

Home » PCB Manufacturing » High TG PCB

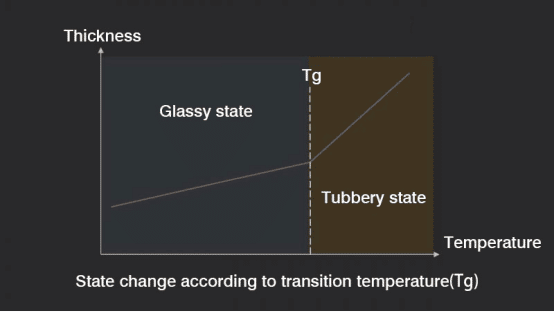

With the development of electronic technology, there is a tremendous demand for boards with high Tg. And Tg is one of the most important properties of any epoxy and is the temperature region where the base material (polymer or glass) changes from a solid, rigid, and glassy state to a rubbery state. Every printed circuit board has a different Tg value based on its substrate. And standard PCB will start to change its state if the operating temperature of the PCB exceeds its Tg value. High Tg PCB has better stability at high temperatures because the substrate provides better heat resistance and mechanical and chemical stability for the board.

Lifting The Mystery of High TG PCB Circuit Board

Glass Transition Temperature

What is TG?

TG stands for Glass Transitions Temperature. It is an important physical characteristic of polymers that must be considered while selecting a material. It tells where and in which conditions the material can be used.

Glass Transition Temperature is the temperature after which the polymer is no longer a rigid material. The material changes its state as the operating temperature exceeds TG. It transitions from a glassy state to a rubbery or soft state, which is why the temperature is termed as Glass Transition Temperature (TG). The material becomes soft and can bend easily. The value of TG depends on the chemical structure of the material. So, the value changes from material to material.

When we heat any material, the energy of the particles (atoms or molecules) rises. The particles vibrate faster. At glass transition temperature, the vibration is at maximum. If the vibration increases above this level, the particles will abandon the vibration movement. They will have more energy, so the attraction between the particles will be reduced. Thus, due to low attraction, they will be able to glide over one another. It indicates the change of state, and in polymers, the material changes its glassy state to a rubbery state.

In simple words, the TG defines the limit of temperature for the user. If the user wants to keep the material in a rigid state, the operating temperature must not exceed TG. Typically, the operating temperature must be 25°C lower than the TG to ensure the expected state of the material.

We need to understand the value of TG of any material if we want to use it. It helps us to determine the limits at which the material can work as expected. TG is also helpful when we aim to modify the physical properties of a material, such as its shape.

High Temperature PCB

What is High TG PCB?

Usually, the printed circuit board is made of material with Tg≥170℃, which we call High Tg PCB.

PCBs are also made from different polymer bases, including FR-4 and Polyimide. Thus, these materials also have a TG value that must be considered before using them for the PCB. Keep in mind that TG is only related to polymer PCBs; there is nothing to worry about the temperature in the case of metal core PCBs.

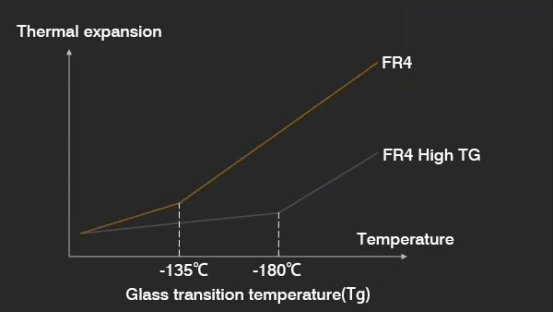

PCB bases have a typical TG value. For instance, the typical TG of FR-4 is 130°C. We mean that the value is above the standard TG value by high TG. FR-4 boards are also available in higher TGs, known as High TG PCBs. Generally, PCBs having a TG of more than 170°C are known as High TG PCBs. However, it also depends on the base material/substrate type.

| How to differentiate high Tg materials? | ||

| Materials | TG | MOT |

| FR-4 common Tg | 130℃ | 110℃ |

| FR-4 Medium Tg | 150℃ | 130℃ |

| FR-4 High Tg | 170℃ | 150℃ |

| PI Ultra-high Tg | 260℃ | 240℃ |

| Tg value of common PCB materials | |

| Tg is defined as “glass transition temperature,” and there is no Tg value in ceramic substrates, polytetrafluoroethylene substrates, polyimide (PI) substrates that do not contain any glass fibers. However, for these three substrates, it is generally considered that the Tg value is greater than 200°C. In this case, Tg only represents its high-temperature resistance. | |

| Materials | TG |

| CEM-1 | 110-130℃ |

| FR-4 | 120-180℃ |

| PTFE | 200-260℃ |

| Ceramic | 200-300℃ |

| PI | 200-350℃ |

High TG PCBs have the capability to withstand higher temperature stress. They can work in extreme conditions. If the operating temperature is high, it is necessary to use a High TG PCB to ensure optimum and reliable performance.

Why is High TG PCB Used?

PCBs are used in different environments. The conditions can be normal or extreme, but we cannot use a PCB in every condition. For instance, if the TG value of a PCB is 150°C, then we can use it in any environment having an operating temperature below 125°C.

If the temperature of the environment, where the PCB is in operation, increases above the TG value, the PCB will start to change its state. It will become a rubbery material, which will affect the performance of the PCB. It could bend and change its shape. The electrical performance of the PCB is badly affected. In extreme cases, it can stop working. Thus, it is necessary to ensure that the operating temperature is 25°C lower than the TG.

The 25°C difference ensures no change in the state of the polymer. It is because the polymer experience changes when the temperature is near TG, and in this case, the performance and lifespan of the PCB are badly affected. Therefore, it is a must to have this difference in temperature.

Some applications have a high operating temperature. They require a high TG PCB for optimum performance. Standard and normal PCBs cannot work in such areas. Therefore, High TG PCBs enjoy high demand and importance in the industry. Moreover, some projects require high TG PCBs to get certification and compliance.

High TG materials are widely used for making multilayer PCBs. The component density in multilayer PCBs is more than a simple PCB. The surface is thickly populated, which is why the heat generation is more than a single-layer PCB. Therefore, it is necessary to use a high TG material to deal with excessive heat and higher operating temperatures. Another way is to reduce the heat generation of the PCB board, but this is neither cost-effective nor easy. You will need to change the components and design, and sometimes it is not possible. Thus, the only cost-effective and feasible solution is using a High TG PCB.

Advantages of High TG PCB

There are various advantages for High TG PCBs, which is why it is preferred for many applications and in various industries.

The first benefit of High TG PCBs is that they have a high-temperature resistance. They can bear high-temperature stress; therefore, they can perform well in extreme conditions. The performance of the PCB remains perfect even in high-temperature conditions. The PCB never changes its shape due to temperature and remains intact.

High TG PCBs have excellent mechanical strength. They are durable and can bear pressure stress. They are quite hard and strong, and the strength increases as the number of layers increases.

High TG PCBs are more reliable than normal PCBs. We know they can perform well in high temperatures, so they can deal with any extreme conditions. There is no effect on the electrical performance of the PCB due to temperature. Thus, they are reliable. On the other hand, standard PCBs start to bend and lose their shape. This badly affects the reliability.

Components dissipate heat, which is why we cannot have high power density in normal PCBs. As high TG PCBs can bear high-temperature stress, they can deal with heat dissipation. More components are placed on them, and there is no need to worry about excessive heat dissipation.

High TG PCBs also last for a long time as they can bear high temperature and pressure stress. They do not deteriorate with time, so you don’t need to replace or repair them. They can increase the life of your product.

This is the most important benefit of High TG PCBs. They have a very low thermal expansion.

Thermal expansion in PCB is not desired as it will destroy the electrical performance. The most vulnerable impact of expansion is on vias. The vias, especially plated through hole (PTH) vias, are affected due to expansion in the Z dimension. When the PCB expands on the Z-axis, the coating of the copper layer inside the vias is disturbed, and in the worst case, there is no connection left between the layers. The copper pads are deformed due to expansion, and the PCB loses its electrical performance.

Moreover, the PCBs that have SMDs are also affected by the expansion in the X and Y axes. The components are placed on the surface, and due to expansion, the copper pads are disturbed.

High TG PCBs have a low coefficient of thermal expansion (CTE), especially the CTE for the Z-axis. It does not expand much that could create issues in the electrical performance of the PCB. Therefore, these PCBs have an extra advantage over other PCBs.

High Temperature Circuit Board Material

High TG PCB Materials

The high-temperature resistant PCB can help PCB assembly smoothly

At JHYPCB, we offer Complete PCB Assembly solutions for all types of High-Quality PCB Fabrication and High-Quality PCB Assembly requirements. Among the most common special requirements for PCB Fabrication is the need for high-temperature tolerance to withstand demanding operating conditions and/or environments.

We often encounter questions from our clients about the temperature requirements for the PCB Assembly Process itself, and whether or not a specific material selection will be required for Lead-Free PCB Assembly. Since our facilities are all fully RoHS Compliant, all of our default materials are suited to the higher Reflow Soldering temperatures of lead-free processes. You never have to worry about selecting a more robust heat profile for the production process itself, but in some cases, the finished boards must operate at high-temperature levels for prolonged periods. In this case, we provide a selection of PCB Materials that can meet your specific needs.

Fr-4, code for grades of fire-resistant materials

Temperature profiles for PCB material are generally expressed through the Tg (Glass Transition Temperature) of the material. This metric notes the temperature at which the stiff, glass-like polymer softens and is subject to warping or other physical defects. If you do not specify a minimum Tg level for your boards in your PCB Design Files, we will generally use our default Tg 140 FR4 material, which is sufficient to withstand the reflow soldering process and the majority of standard operating conditions.

We also offer higher Tg materials for your convenience, such as Tg 170 FR4 material, and IT180A with a characteristic Tg 180. We still provide all of our Standard PCB Options with high-Tg boards, so you will not have to worry about changing your design as a result of this material selection.

What Is FR-4 PCB?

FR-4 is a grade designation for flame-retardant fiberglass reinforced epoxy material. Thus, FR-4 PCB offers a much greater level of resistance to heat than a standard PCB. FR-4 circuit boards are divided into four classifications that are determined by the number of copper trace layers found in the material:

• Single-sided PCB / Single-layer PCB

• Double-sided PCB / Double-layer PCB

• Four or more than ten layers PCB / Multilayer PCB

High Tg FR-4 Material Product Data Sheet Download

Applications for High-Temp PCBs

High TG PCBs are widely used. They are suitable for any application that has a high operating temperature. These PCBs can work well and offer reliable performance in extreme conditions.

High TG PCBs are used in almost every industry, but some areas and sectors demand more.

High TG PCBs are mostly used in automobiles. The reason behind this is the excessive temperature due to the engine, and normal/standard PCBs cannot survive in this environment; they will bend and deteriorate with time. Therefore, high TG PCBs are used to withstand such a temperature and offer the best performance.

Industrial electronics also require high TG PCBs as they ensure the prolonged lifespan of the electronics devices. Usually, there can be extreme temperatures in the operating area, so high TG PCBs are the optimal solution.

Power supplies and inverters have many heat dissipating components. There are power transistors and other components that emit heat and become extremely hot. In such a case, high TG PCBs are used, and components are tied with heat sinks to dissipate the heat away from the board.

Power supplies and inverters are quite common nowadays because of the increasing demand for renewable energy. Consequently, the demand for High TG has also increased.

Multilayer PCBs have a high component density. Due to different layers, the surface of the PCB has more space, and it can accommodate more components. But due to high component density, the board has to deal with magnificent heat, which is why High TG materials are used to create multilayer PCBs.

Engine controllers are in a high-temperature stress environment. Standard PCBs cannot bear the heat and environment of engines. Therefore, it is necessary to use High TG PCBs for the application.

Summary of High Tg

The Tg point or melting point is the critical temperature when the substrate melts from a solid state to an elastic fluid.

The higher the Tg point, the higher the temperature requirements of the substrate during pressing, and the pressed substrate will be more rigid and brittle, which will affect the quality of the mechanical drilling (if any) in the subsequent process and the electrical properties.

The Tg point is the maximum temperature (°C) at which the substrate remains rigid. That is to say, ordinary PCB substrate materials soften, deform, and melt at high temperatures and show a sharp decline in mechanical and electrical properties.

China High Tg PCB Manufacturer

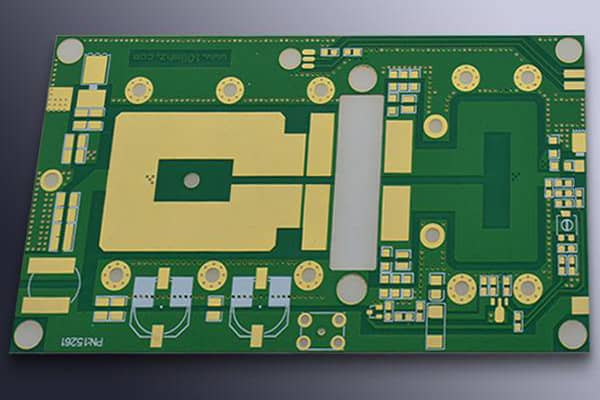

High TG PCB Manufacturer and manufacturing capability

JHYPCB can manufacture High-Tg Circuit Boards with a Tg value of up to 180°C.

Meanwhile, we can also provide customers with metal-based PCBs with excellent heat dissipation performance, such as aluminum PCB, LED PCB Circuit Board, Metal Core PCB, Copper-based PCB, etc.

We use the below High Tg materials usually; if you need a Data Sheet, please contact us directly.

| Material | TG | Td | CTE-z | Td260 | Td288 |

|---|---|---|---|---|---|

| (DSC, °C) | (Wt, °C) | (ppm/°C) | (min) | (min) | |

| S1141 (FR4) | 175 | 300 | 55 | 8 | / |

| S1000-2M (FR4) | 180 | 345 | 45 | 60 | 20 |

| IT180A | 180 | 345 | 45 | 60 | 20 |

| Rogers 4350B | 280 | 390 | 50 | / | / |

Order High TG PCBs and PCBAs from JHYPCB

JHYPCB is a leading PCB and PCBA manufacturer and solution provider based in China. We can deal with small to large volume orders of any type of PCB or PCBA. Our large facility is equipped with the latest technology that can manufacture any PCB and PCBA in the shortest time. Our experts can deal with complex designs and can help buyers deal with design and manufacturing issues.

We can provide superior High TG PCBs without any restriction of minimum order. We can deal with quick prototypes and turnkey PCBAs. We have a strict quality management system that is according to international standards and certified by RoHS, UL, and ISO. You can order any type of PCB with confidence, and we will provide high-performing PCBs in the shortest time. For more information, quotes, and queries, feel free to contact sales@pcbjhy.com.

FAQs

High Tg PCB means that the TG value of the PCB material is more significant than 170°C. The higher the TG value, the better the heat resistance, chemical resistance, and stability of the PCB.

In the hot state, especially in the case of heat after absorbing moisture, there are differences in the mechanical strength, dimensional stability, adhesiveness, water absorption, thermal decomposition, and thermal expansion of the material. High Tg FR-4 is Better than ordinary FR-4 substrate material.

Low TG sheets cannot be mixed with high TG sheets because the Tg values of materials are different. The higher the Tg value, the better the temperature resistance of the substrate, especially in the lead-free process. As the glass transition temperature of high Tg and low Tg substrates are different, if the two are mixed and stacked, it may cause the board to burst or be too thin.

High FR4-Tg will have better mechanical and chemical resistance to heat and moisture than standard FR4. The higher the Tg value, the better the temperature resistance of the material, so high Tg is more and more popular.

High Tg materials have the following properties:

- Resistance to high temperatures

- Long delamination durability (aging of materials to consider for safety reasons)

- Low thermal expansion (Lower Z-axis CTE)

- Excellent PTH reliability

- Good mechanical properties

- High-temperature durability

- High thermal shock resistance

- Excellent thermal stress resistance

If your PCB board can not bear a thermal load more significant than 25 degrees centigrade below the Tg, you will need a high Tg PCB for your applications. Moreover, it also ensures safety with high Tg PCB if your product operates in the 130 degrees centigrade range or higher. The main reason for high Tg PCB is the movement to RoHS PCB. So, more PCB industries are moving toward high Tg materials as the lead-free solder to flow needs higher temperatures.

If you’re looking to guard your PCBs against the high temperatures of your appliances’ process, then high Tg PCBs are necessary.

Hence, there are three important ways to dissipate heat produced by electronics with High Tg PCBs.

- Conduction

In the process of conduction, heat will cool down when it’s placed next to its source. This is done by using a sink for the heat that has been produced- similar to electricity flowing through an electric system. - Radiation

With a powerful enough radiation, the electromagnetic waves will create an exit path to leave. - Convection

The process of convection is a great example. It’s the movement of heat to water or air, enabling it to flow out from an area. For instance, you can see this in action when using pumps and fans that push hot air over surfaces while also drawing away some of its heat with the device.

Related PCB Manufacturing Services

Related Posts

- What factors determine the price of PCB?

- Find Out Now, What Should You Do For Fast PCB Classification?

- The Cheapest PCB Prototype Manufacturer-Your Best Choice

- How to store PCB boards?

- 10 Types of PCB Surface Finishes: All You Need to Know

- Plated Through Hole, Blind Via, and Buried Via in PCB Fabrication

- IPC Standards: A Guide to Standards for PCB Manufacturing and Assembly

- What are the aspects of PCB Design For Manufacturing (DFM) and Design For Assembly (DFA)?