Table of Contents

In today’s fast-paced world of product development, time is money. The ability to rapidly prototype and manufacture PCBs can mean the difference between being first-to-market or falling behind the competition. That’s why understanding rapid PCB prototyping and production timelines is crucial for accelerating product launch cycles.

For hardware companies, getting functional prototypes quickly is essential for proof of concept, design validation, and early user testing. Rapid PCB prototyping services offer turnaround times as short as 24 hours or even same-day, allowing you to iterate through multiple design revisions swiftly. This agile approach enables you to identify and resolve issues early, saving valuable time and resources down the line.

On the manufacturing end, fast PCB production with short lead times is key to meeting market demands and capitalize on time-sensitive opportunities. Accelerated PCB assembly services provide the flexibility to rapidly scale up production volumes or fulfill urgent circuit board needs, preventing costly delays from disadvantaging your product.

Whether you’re a hardware startup, product designer, or an established manufacturer, understanding the capabilities of rapid PCB prototyping and production can give you a significant competitive edge. In this article, we’ll dive deep into express PCB solutions, exploring turnaround times, processes, and real-world examples of how leveraging these services leads to agile product development cycles.

Rapid PCB Prototyping Turnaround Times

When it comes to iterating through hardware designs quickly, rapid PCB prototyping services are invaluable. These express solutions provide a range of accelerated options to suit your urgent prototyping needs, from same-day PCB prototypes to 24-hour or weekend turnarounds.

The key benefit of quick-turn PCB prototypes is verifying your design functionality and making adjustments on the fly. This proof of concept is critical early in the development cycle, allowing you to validate your circuit board before committing to volume manufacturing. Rapid prototyping also enables efficient design iterations – you can quickly implement changes based on test findings and have an updated prototype in hand within days.

But how fast can you really get prototypes? Turnaround times depend on the complexity of your PCB, including layer count, board size, and any special requirements like micro-vias or controlled impedance. For example, a simple 2-layer prototype could be produced the same day, while an 8-layer board with buried vias may take 3-5 days using express services.

Many rapid PCB prototyping experts provide clear build time estimates based on these factors. You can easily plan your schedule knowing whether you’ll receive prototypes for testing later the same day, over the weekend, or early the next week. This transparency allows you to set accurate expectations with your team and stakeholders.

The convenience of quick prototyping is incredibly valuable when working through proof of concept for new product designs. You can rapidly pivot using real-world testing data rather than theoretical analysis alone. Accelerated PCB prototyping services are a vital part of the agile hardware development cycle for startups striving to be first-to-market or established brands looking to outpace competitors.

Factors Affecting Turnaround Times

While JHYPCB is able to produce quality prototypes faster than competitors, there are a few factors that can potentially affect quoted turnaround times:

- Existing Order Volume – JHYPCB strives to ensure above-average service, but sometimes high volumes of existing orders can delay a new request slightly. If this occurs, we’re happy to discuss solutions to ensure your satisfaction.

- Order Quantity – The size of your prototype order can also impact lead times. However, our in-house manufacturing capabilities allow us to provide adjusted scale and predictions for larger enterprise-level requirements.

- Design Complexity – More complex PCB designs with advanced technologies may require additional prototyping time. Builds relying heavily on automation could see quicker turnarounds.

- Unforeseen Events – While our optimized production model safeguards against disruptions, rare outside circumstances beyond our control could potentially cause delays. Superior communication ensures customers stay informed.

Potential Delay Factors

- Disruptions to raw material supply chains

- High-volume enterprise orders

- Special requirements for by-hand prototype builds

- Particularly busy seasonal order volumes

By being aware of these factors, you can plan your prototyping timelines accordingly. And you can rely on JHYPCB’s rapid capabilities and transparent communication to minimize any impacts.

Fast PCB Production Lead Times

Once your prototype has been thoroughly validated, the next step is volume manufacturing of the final PCB design. Here again, speed is paramount to ensuring a successful product launch and quickly fulfilling customer orders. Accelerated PCB production services with rapid lead times allow you to compress your manufacturing timeline significantly.

Traditional PCB production cycles can take weeks or even months from order placement to delivery. However, streamlined quick-turn PCB manufacturing solutions cut those lead times dramatically – many providers offer 5-10 working days production capabilities or even faster for simpler designs and smaller volumes.

The key advantage of these accelerated PCB assembly services lies in their flexibility and responsiveness. Need to ramp up volumes unexpectedly to meet a surge in demand? Quick-turn PCB manufacturing has you covered with fast scaling. Landed a last-minute contract with tight deadlines? Express production runs to ensure you can deliver those urgent circuit board orders on time.

While standard lead times may depend heavily on board complexity, quick-turn capabilities are more consistent across different PCB types. Simple 2-layer boards could be produced in 5 days, while more complex 8-layer boards may only add another 2-3 days using optimized processes.

This speed and flexibility are invaluable when responding to evolving market conditions and time-sensitive opportunities. Companies who leverage quick-turn PCB production can seize windows of demand swiftly before their competitors – capitalizing on those first-mover advantages.

By combining rapid prototyping and fast production solutions, hardware companies can dramatically accelerate their product development and launch cycles from concept to delivery. This agile methodology provides a critical edge in today’s landscape of disruption and innovation.

Comparing Rapid PCB Prototyping vs Standard PCB Production

While rapid PCB prototyping and accelerated production services share the common goal of reducing development timelines, there are some key differences to understand between these two processes.

Rapid PCB Prototyping

By definition, PCB prototyping involves creating an initial physical model to prove out the design before full-scale manufacturing. Rapid PCB prototyping services, with expedited turnaround times like 24 hours or same-day, focus on quickly producing these functional prototypes for design verification and testing.

The prototyping process tends to be streamlined for speed – optimizing fabrication steps like imagesetup, plating, and etching. However, volume production considerations like panel utilization may be secondary. The primary purpose is simply to get prototypes in hand as fast as possible for proof of concept.

Quick-turn PCB prototypes also tend to cost more per unit than PCB volume production runs due to the accelerated cycle time. But this expense is negligible compared to the value of rapidly iterating through design revisions before committing to manufacturing.

Standard PCB Production

In contrast, the standard PCB production process emphasizes cost optimization, throughput, and overall efficiency for higher volumes. While quick-turn PCB production exists, traditional 2-4 weeks lead times are more common.

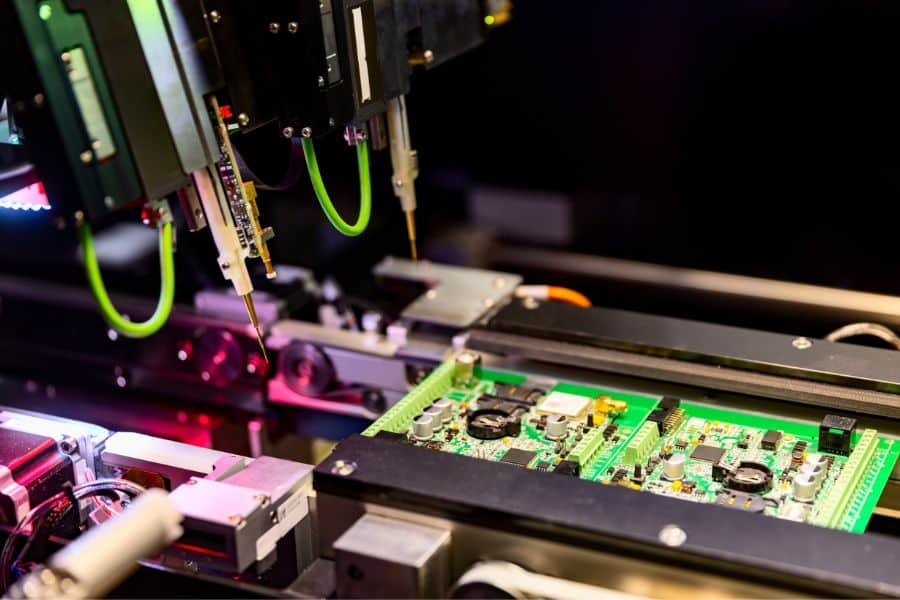

For the assembly process, standard production lines are calibrated for quality, repeatable output. Product cyles like solder paste printing, component placement, and reflow are finely tuned. These high-volume lines are less flexible for fast pivots.

Additionally, standard production employs techniques like panelization to maximize material usage and lower cost per unit. But this panel optimization adds setup time versus rapid PCB prototyping’s single-unit focus.

So in essence, rapid PCB prototyping prioritizes speed for design iteration, while full production optimizes more for throughput and cost efficiency at scale. Both have essential roles in the hardware development cycle – rapid PCB prototyping is ideal for the design phase, while PCB production services enable final delivery to customers once the product design is frozen.

Combining both these capabilities under one roof at a PCB manufacturing partner provides a seamless experience for transitioning from concept through each stage of the product development lifecycle. This integrated approach accelerates your overall time-to-market by eliminating hand-offs and streamlining communication.

PCB Expedited Service at JHYPCB

For those projects demanding an even shorter schedule, especially when excess time was spent on the design or engineering stages, JHYPCB offers an expedited PCB service with lead times starting from just 48 hours (rush fees apply). This rapid PCB option ensures you can meet urgent deadlines without sacrificing the high-quality standards of our regular PCB production.

Using our PCB Expedited Service is an ideal solution when ordering printed circuit boards with tight timelines. Since JHYPCB has both fabrication and assembly capabilities in-house, we can streamline the process for exceptionally fast turnarounds on your boards.

Do you require an urgent PCB order? Simply send your Gerber files, desired quantities, and target lead time to our sales team using this form. We’ll provide an expedited pricing quote promptly.

Whether utilizing our standard lead times or taking advantage of the expedited 48-hour option, you can count on JHYPCB to deliver reliable, high-quality PCB production rapidly to keep your projects on schedule.

Conclusion

In the race to market, leveraging rapid PCB prototyping and fast production is key to staying ahead of the competition. Agile design iterations enabled by 24-hour PCB prototyping services allow you to validate concepts quickly. And with accelerated manufacturing lead times as low as 5 days, you can rapidly fulfill large orders or adapt to changing demands.

At JHYPCB, we provide a full suite of quick-turn PCB solutions to compress your development cycles. Our rapid PCB prototyping services, including low-cost options, ensure you can iterate through revisions swiftly. Then our fast PCB mass production capabilities get your final designs into customers’ hands rapidly.

From concept to high-volume delivery, our integrated approach streamlines your hardware launches without delays. Gain a competitive edge with JHYPCB’s agile PCB prototyping and production services. Contact us today to accelerate your time-to-market.

Related Posts

- PCB Prototype Cost: An In-Depth Look at What Determines the Price

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- Evaluating and Selecting Quick-Turn PCB Assembly Manufacturers in China

- What Is Prototype PCB Assembly?

- How to Make Low Cost PCB Prototypes

- Key Differences Between Prototype and Production PCBs Explained

- Why Should You Consider PCB Prototyping for Your Next Project?

- The Ultimate Guide to PCB Prototype Manufacturing: Everything You Need to Know

- The Importance of Choosing a Reliable PCB Prototype Manufacturer

- How to Get a Quote and Order PCB Assembly?

- Exploring the Benefits and Challenges of China PCB Prototype Manufacturing

- Why Do You Need a PCB Prototype?