PCB prototypes are an essential part of the manufacturing process for electronic devices. In this article, we will provide you with a comprehensive guide to PCB prototype manufacturing, including the basics of production, factors to consider in choosing a manufacturer, and an introduction to JHYPCB’s PCB prototype service.

What is a PCB Prototype?

A printed circuit board prototype is a sample version of a final product that is used to test and validate the design before mass production. PCB prototypes are critical because they allow engineers to identify any design flaws or issues that may arise during production.

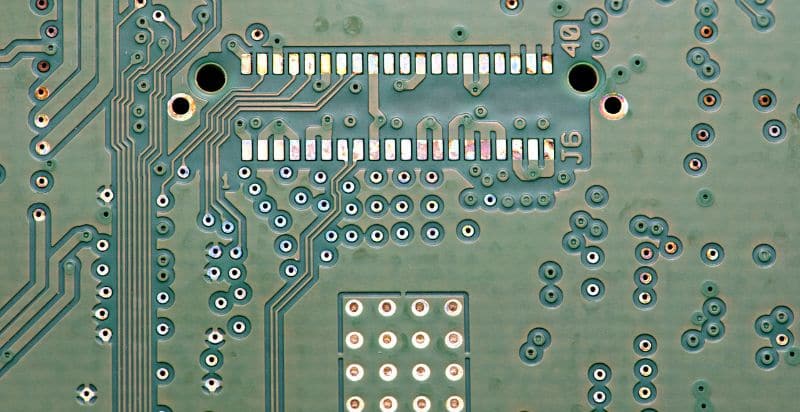

A PCB prototype consists of layers of copper foil laminated onto a substrate material. The layers are etched with a specific design to create conductive pathways that connect the various components on the board. These components can include resistors, capacitors, diodes, and integrated circuits, among others.

There are several types of PCB prototypes, including single-sided, double-sided, and multi-layered PCB boards. Single-sided PCBs have components and conductive pathways on only one side of the board, while double-sided PCBs have them on both sides. Multi-layered PCBs consist of multiple layers of conductive pathways and components separated by insulating layers.

PCB prototypes are commonly used for testing functionality, verifying design parameters, and troubleshooting errors. By using a prototype, engineers can identify any potential issues with the design early in the process, which can help save time and money in the long run. Moreover, it helps to ensure that the final product meets the desired specifications and quality standards.

PCB Prototype Manufacturing Process

The PCB prototype manufacturing process is a complex series of steps that involves several different stages. The following are the primary steps involved in the PCB prototype manufacturing process:

Design: The first step is to create a design for the PCB prototype. This process involves using computer-aided design (CAD) software to create a blueprint of the board’s layout, including the placement of components and the routing of conductive pathways.

Printing: Once the design is complete, the next step is to print a copy of the design onto a special type of paper or film called a photomask. This photomask will be used in the etching process to transfer the design onto the board.

Drilling: After the printing process, the board is drilled with holes where the components will be inserted. These holes are typically very small and require precision drilling equipment to ensure accuracy.

Plating: Next, the board is plated to create a layer of copper over the entire surface of the board. This process helps to make the conductive pathways more robust and durable.

Etching: After the plating process, the board is etched to remove any excess copper, leaving only the desired conductive pathways behind. This process involves exposing the board to an acidic solution that selectively removes the unwanted copper.

Soldering: Once the conductive pathways have been created, the next step is to solder the components onto the board. This process involves heating the metal connections on both the components and the board to fuse them together.

Testing: Finally, the finished PCB prototype undergoes rigorous testing to ensure that it meets the desired specifications. Various tests, such as functional testing, voltage testing, and temperature testing, are performed to ensure that the board works correctly.

PCB prototype assembly is an additional step that may be included in the process, depending on the needs of the project. PCB prototype assembly involves the complete assembly of the board, including soldering the components and testing the finished product. This step is typically used when a more comprehensive testing process is needed before mass production.

Factors to Consider in Choosing a PCB Prototype Manufacturer

When choosing a PCB prototype manufacturer, it is essential to consider several key factors to ensure that you get the best quality product and service. Here are some important factors to keep in mind:

Quality: The quality of the PCB prototype is crucial to its overall performance and durability. Look for a manufacturer that has strict quality control measures in place and uses high-quality materials to create their products.

Experience and Expertise: Choose a PCB prototype manufacturer with many years of experience and expertise in the industry. A manufacturer with a proven track record of delivering exceptional results can ensure that your needs are met and your expectations are exceeded.

Turnaround Time: The turnaround time for producing PCB prototypes is an important consideration, particularly if you have tight deadlines to meet. Look for a manufacturer that can deliver within the timeframe needed for your project.

Cost-Effectiveness: It is essential to find a balance between cost and quality when selecting a PCB prototype manufacturer. Choose a manufacturer that offers competitive pricing without compromising on quality.

Customization: Depending on your project’s requirements, you may need customized solutions or support from your manufacturer. Look for a manufacturer that can provide customized solutions to meet your specific needs.

Communication: Effective communication is essential to ensure that your needs are understood and met by the manufacturer. Look for a manufacturer that has a responsive and helpful customer service team that can answer your questions and provide support throughout the process.

Common mistakes to avoid when choosing a PCB prototype manufacturer include:

- Choosing a low-cost option without considering quality

- Failing to communicate effectively with the manufacturer about your needs and requirements

- Not verifying the manufacturer’s experience and expertise before making a decision

- Overlooking the importance of turnaround time and delivery schedules

- Choosing a manufacturer without understanding their quality control processes and materials used.

In summary, when choosing a PCB prototype manufacturer, it is essential to consider factors such as quality, experience, turnaround time, cost-effectiveness, customization options, and effective communication. Avoid common mistakes by thoroughly researching potential manufacturers and their processes before making a decision. With careful consideration, you can choose a manufacturer that meets your specific needs and delivers high-quality results.

JHYPCB's PCB Prototype Service

JHYPCB is a leading PCB prototype manufacturer based in China that provides customers with high-quality PCB prototypes at an affordable price. Here is an overview of JHYPCB’s PCB prototype service, including capabilities and features.

PCB Prototype Types: JHYPCB offers single-sided, double-sided, and multi-layered PCB prototypes, giving customers flexibility to choose the right type for their project.

Surface Finishes: JHYPCB provides a range of surface finishes, including HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), and more. This variety allows customers to select the best surface finish that meets their requirements.

Solder Masks: JHYPCB offers several solder mask colors, including green, black, red, white, blue, and yellow. Customers can choose the color that best suits their needs.

Fast Turnaround Times: JHYPCB understands the importance of delivering projects on time. That’s why they offer fast turnaround times, starting from as little as 24 hours.

High-Quality Standards: JHYPCB has strict quality control systems in place to ensure that all PCB prototypes meet the highest quality standards. They use advanced testing equipment and procedures to verify that every product meets the desired specifications.

Affordable Pricing: JHYPCB offers competitive pricing that is affordable for both small and large scale projects. They believe in providing customers with cost-effective solutions without compromising on quality.

Customer Support: JHYPCB has a team of experienced customer support agents that are available to assist customers throughout the entirety of their project. They provide quick response times and helpful advice to ensure that customers have the best experience possible.

Conclusion

In conclusion, PCB prototypes are an essential part of the manufacturing process for electronic devices. To ensure that your PCB prototypes meet your specific needs and requirements, it is important to choose a reliable and experienced manufacturer. At JHYPCB, we are committed to providing our customers with high-quality PCB prototypes that exceed their expectations. Contact us today to learn more about our PCB prototype service.