Classification of PCB materials and How to Choose the Correct PCB Substrate

In order to mitigate the risk of project failure due to PCB material, you need to select the PCB material carefully. You need to discuss yours requirements with the PCB manufacturer or fabricator. You should understand the characteristics of different PCB materials and how to choose PCB substrates.

How to Choose PCB Material?

Today, you will find PCB in almost all kinds of electronic devices. From satellites to wristwatches, we use PCBs. It reduces the size of the device and makes it compact because a large circuit can be embedded on a small PCB. All small and delicate components can be placed on it easily. It also provides a mechanical supporting base to the components besides providing electrical conductivity. The use of PCB is common nowadays, and the performance of your project depends on the PCB material you use. Therefore, if the PCB is perfect, then your project will work perfectly. A cheap PCB cannot provide the desired results with accuracy.

In order to mitigate the risk of project failure due to PCB material, you need to select the PCB material carefully. You need to discuss yours requirements with the PCB manufacturer or fabricator. You should understand the characteristics of different PCB materials and how to choose PCB substrates.

1.What is PCB Material?

A PCB circuit board is simply a physical board that provides conductive paths to the components and connects them electrically. It is a necessary circuit board for equipment and appliances. It is also a necessary carrier for the functions of the software. Different devices have different PCB materials, different circuit boards, and different components. PCB is made from a special material, which is the most important thing in PCB manufacturing. There are different insulating materials used to make the layer of PCB. This layer serves as the base on which the electrical/electronic components are placed. To make an excellent PCB, you need to choose the right PCB material. Therefore, PCB material plays an important role in determining its quality.

2. The Classification of PCB Materials

General PCB Board materials can be divided into two categories: rigid substrate materials and flexible substrate materials.

a) Rigid Printed Circuit Board (Rigid PCB or RPCB)

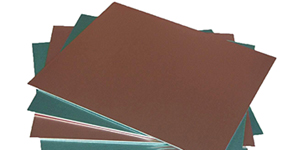

The general rigid substrate material for rigid PCB is copper-clad laminate(CCL), which is made of reinforcing material. There are a few steps involved in the preparation of the laminate. It is first dried and then cut into the required size and shape. The pieces are laminated into blanks. At this stage, the PCB is a pure insulator. There are no conducting paths on it. A copper foil is then placed on its top and pressed using high temperature and high-pressure forming. Pure copper is used because it has high conductivity, and good weldability, and its commonly used thickness is 35-50 / ma. The thickness of the commonly used copper-clad laminate is 1.0mm, 1.5mm, and 2.0mm.

b) Common Flexible PCB materials

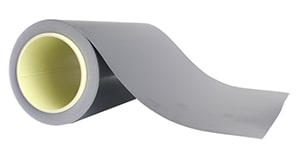

You cannot install flat PCBs everywhere because not all devices are flat. There are irregular shapes and designs. Therefore, flexible PCBs are required. During the past few years, flexible PCBs had a very high demand because of their application. They can be folded and bent easily, so you can install them on a variety of devices. They can be bent, but they carry the current in the whole PCB without any hassle. Their bending feature does not affect the conductivity. They are excellent and widely used nowadays.

Common flexible PCB materials(FLEXIBLE COPPER CLAD LAMINATE: FCCL) include polyester film, polyimide film, and fluorinated ethylene propylene film.

2.1 Types of Materials Uesd for PCB Manufacturing

There are three major types of materials used for the fabrication of PCBs:

- FR-4

This is the most commonly used material in PCBs. It is a glass-reinforced epoxy laminate sheet. The epoxy used is flame-retardant and water-resistant. It provides excellent strength-to-weight ratios. The tensile strength offered by this material is very high.

Related Posts:

- PTFE (Teflon)

PTFE is a kind of plastic material that does not provide any resistance. Thus it is used for high-speed, high-frequency applications. PTFE is exceptionally flexible, making it invaluable in applications with tight tolerances. It is also extremely lightweight, allowing it to be used across various industries. It is also flame-resistant, exhibits high physical strength, provides temperature stability, and is versatile in application.

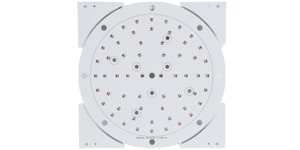

- Metal

The traditional materials of copper, aluminum, iron, etc., are still used in PCBs. These materials allow the use of Surface Mount Technology (SMT) for the integration of components. They also provide mechanical durability. Thus, the product life of metal base PCBs is much longer.

Typical PCB products using metal are: copper clad PCB, aluminum PCB, led PCB, metal core PCB.

The different materials used for the PCB design and fabrication, all offer a variety of advantages and disadvantages. The content is chosen according to the application, and the result needed environmental factors, and any other constraints the PCB will face. You should select the material of the PCB depending on the results that are expected.

3. Principles of Selecting PCB Substrate

Typically, people choose certain types of PCB substrates for their projects using basic principles. If you know the purpose of the PCB and where it will be used, then you can pick the right substrate easily.

The common principles are,

1) If your project is a general electronic product that has normal ambient temperature and frequency, then FR-4 is suitable for the purpose. It will be a cost-effective choice.

2) If the use of PCB is in a high-temperature range, it will require a high-temperature resistance. Such as High-Tg PCB. Learn more about: Unveil the mystery of high TG PCB circuit boards Materials

3) Some circuits have high-frequency components; therefore, they require a special PCB. You can use the PTFE glass fiber in this case.

4) In some circuits, there are some electronic components that dissipate a lot of heat. The heat can easily bend common PCBs, so you need to use metal substrates.

4. Factors to Consider When Selecting PCB Materials

To select the right PCB material, you need to see a few factors. If you know about the factors that you need to look at, then you can easily get the best PCB material for your project, and the PCB will provide the required results. You can also talk to the PCB manufacturer or fabricator about these factors. Let’s look at the factors that are essential to consider while selecting a PCB material.

a) Glass Transition Temperature

The substrate should have a high glass transition temperature (Tg). A high Tg can deal with heat dissipation and ambient temperature. You must select those materials that have a higher Tg than the circuit temperature. Otherwise, the substrate will melt down or bend during the operation.

b) Coefficient of Thermal Expansion

The PCB material should have a low coefficient of thermal expansion. If the coefficient is high, then it will expand more per unit increase in temperature. This will affect the length, width, and thickness of the PCB board. The PCB will change its shape easily and may cause damage to the board and components. Make sure to select the material that has a low coefficient of thermal expansion.

c) Heat Resistance

High heat resistance is required. Generally, PCB must have a heat resistance of 250 ℃ / the 50S. If you need more heat resistance, then you can discuss it with your PCB manufacturer.

d) Flatness

There should be excellent flatness. The warpage should be less than 0.0075mm / mm.

e) Dielectric Constant and Losses

The PCB material should have an excellent dielectric constant. It will provide excellent insulation and offer the desired results. Moreover, the dielectric losses should be low to save energy.

f) Degree of Bending

The PCB should not bend easily. If it bends on the ambient temperature of the device where it is installed, then it will wear quickly. It will not last for a long time. Therefore, the PCB should have a low degree of bending so that it cannot bend on the circuit operating temperature. Its heat resistance should be high, depending on the place where it will be used. Some substrates, like FR-4 have a low degree of bending, which is suitable. The degree of bending matters a lot when the PCB is larger than 3.2 × 1.6mm. Due to the large size, it is affected more due to bending. So, you need to be more careful in the case of large PCBs. Moreover, the appearance is required to be smooth and flat without warpage, cracks, scratches, and rust.

g) Cost factor

The cost of PCB is an essential factor. An expensive PCB might not be feasible for the project, while a cheap PCB will not provide the required results. The cost of PCB depends on its features. The more the elements, the higher the cost will be; when the PCB has features like filling and buried vias, its price increases. Moreover, the price also increases when we require less width spacing because it is more delicate. Due to these features, you need special machinery and processes that increase the cost of the PCB. You must see the price and get the required features only. Otherwise, the cost of the PCB will increase, which will increase the cost of your project.

Learn more about: What factors determine the price of PCB?

5. The Metal Heat Dissipation Substrate

There are so-called metal heat dissipation substrates. Generally, the two types are the aluminum substrate and copper substrate. As a professional PCB manufacturer, we recommend that you use a cost-effective aluminum substrate. The price of copper substrates and aluminum substrates are much different. Although copper substrates are better than aluminum in terms of thermal conductivity, their cost and weight are much higher than aluminum, so it is best to use aluminum substrates.

On the other hand, many PCB manufacturers currently use temperature control methods for high-power lamps. That is to say, add a temperature control switch in the place where the aluminum substrate may generate the highest temperature, and set its temperature value (for example, about 65 degrees). When the temperature is higher than this value, the current will drop immediately. Although the lights are dimmer, the average person may not pay attention to them, so this method is still feasible.

6. Common PCB Material Brands

Common PCB Material Brands

- Arlon

- Bergquist

- Chin-Shi

- Denka

- Dupont

- EMC

- Grace

- Isola

- ITEQ

- Kingboard

- Laird

- Matsushita

Common PCB Material Brands

- Metclad

- Nanya

- Nelco

- Neltec

- Panasonic

- Rogers

- Shengyi

- Taconic

- ThinFlex

- Tuc

- Polyflon

- Ventec

Common PCB Materials

- CEM

- CEM-1

- CEM-2

- CEM-3

- Duroid

- FR-1

- FR-2

- FR-3

- FR-4

- FR-5

- Kapton

Common PCB Materials

- Polyester

- Polyethylene

- Polyflon

- Polyimide

- PTFE

- Pyralux

- Teflon

- XPC

- Rogers 3000 series

- Rogers 4000 series

And many more!

Top 5 well-known PCB material manufacturers

Isola is a world-renowned PCB material supplier dedicated to the production and development of copper clad laminates (CCL)and dielectric prepregs for the manufacture of advanced multilayer printed circuit boards.

To learn more about Isola’s PCB Laminate and Prepreg Materials, please click here.

Rogers is the world’s leading manufacturer and supplier of advanced printed circuit board laminates, adhesive layers, and prepregs. Rogers’ RO3000 series and RT/duroid laminates are mainly used in high-frequency and high-speed circuit boards.

The laminate produced by Rogers has excellent dielectric constant control capabilities. This special material is a reliable choice for 5G wireless communications, automotive radar sensors, aerospace, satellite, and other applications.

To learn more about Rogers’ various series of laminates, please click here.

Panasonic, a world-renowned Japanese electrical appliance manufacturing and industrial solution provider. Its main products include the production of electronic materials for printed circuit boards, especially Multi-layer circuit board materials for ICT infrastructure equipment “MEGTRON” series,Multi-layer Circuit Board Materials for wireless/RF communication equipment,Multi-layer Circuit Board Materials for Automotive Components “HIPER” series,Circuit Board Materials for LED lightings “ECOOL” series,and Flexible Circuit Board Materials for Mobile Products “FELIOS” series,etc.

Click here for more information.

Dupont company provides materials that support all aspects of PCB manufacturing for many types of PCBs: single- or double-sided PCB boards and flexible, rigid-flex, or rigid configurations. PCB materials includes films, laminates, photoresists, and metallization.

Click here for more information.

Arlon is an American manufacturer of electronic materials for printed circuit boards, Thermoset polyimide resin was the preferred high temperature laminate system known for its thermal stability, good chemical resistance, excellent mechanical properties and very good heat resistance.

Arlon Products includes Polyimide Products, Low Flow Products, Epoxy Products, Controlled Thermal Expansion/SMT, etc.

Click here to learn more Arlon Products & Typical Properties

High-quality products must require high-quality raw materials. We are committed to establishing long-term partnerships with the brand-name and good quality of raw materials suppliers to achieve mutual benefit and joint development.

7. Is FR-4 a Kind of Circuit Board Material?

The FR-4 we often choose is not the name of any material. In fact, it is a code name for a flammable material grade. This grade shows that the material can extinguish the fire on its own. It is not the name of a material, but a material grade. You will find these FR-4 grade materials in many circuit boards. They are widely used.

FR-4 has high-temperature resistance, insulation, flame retardancy, and other functional characteristics. So, when we choose PCB materials, we must understand what characteristics we need to achieve.

8. The Most Important Point to Choose PCB Substrate: Quality First

There is no doubt that everyone likes to enjoy the best service at the lowest price, but the quality is more important. Thus, you must find a PCB substrate that has a high-quality and reasonable cost. Whether your PCB circuit board is used in household appliances, consumer electronics, or industrial equipment, quality is critical. Whether it is a cheap or expensive circuit board, it is necessary to ensure that the product has excellent performance during its service life.

9. What kind of PCB material can we provide in JHY PCB?

JHY PCB has a perfect PCB material supply chain in Shenzhen, China. Our company has also been constantly building and improving the supplier management system. PCB material procurement has been very strict, and quality control measures are adopted to ensure that the quality of our customized PCB products remains the best. As a company that provides one-stop PCB manufacturing and PCB assembly services to customers around the world, JHY PCB can handle the most popular and most widely used laminate materials and substrate materials, including FR-4, Rogers, etc. If your PCB requires special plates, you can also tell us. To learn more about our services, feel free to contact us. We can also provide you an instant quotation.

PCB Materials FAQs

PCB Manufacturing requires a lot of raw materials, including Copper Clad Laminate, Insulated Metal Substrate, Pre-Preg, Copper Foil, Solder Mask Ink, Silkscreen Ink, and some Chemicals. For flexible PCB manufacturing, the raw materials include Polyimide and Polyester Flexible Copper Clad Laminate, Coverlay, Adhesive, EMI film, and sometimes steel sheet or Fr-4 for stiffeners.

The proportion of raw material cost in PCB operation cost is high, about 60-70%. Therefore, raw material significantly impacts the PCB industry as a whole. Copper-clad laminate plays an important role, accounting for the most significant proportion of the cost, close to 40%, followed by semi-cured sheet, gold salt, copper foil, and copper ball. In CCL, copper foil accounts for 30% of the cost of a CCL thick plate and 50% of a thin plate; glass fiber cloth accounts for 40% of the cost of a CCL thick plate and 25% of that of a thin plate, and epoxy resin accounts for about 15%.

FR-4 is a printed circuit board base material made from a flame-retardant epoxy resin and glass fabric composite. FR stands for flame retardant and meets the requirements of UL94V-0.

FR4 is rightly the most used material in PCB construction. PCB Boards made from FR4 are robust, water resistant, and provide good insulation between copper layers that minimizes interference and supports good signal integrity.

The standard thickness of PCBs is 1.57 mm. Some manufacturers will accommodate other specific thicknesses of 0.78 mm or 2.36mm. When we say “thick” or “thin” FR-4, we generally compare it to the standard thickness of 1.57 mm.

Standard FR4 has a Tg of 130° C (266° F) and a maximum operating temperature of 110° C (230° F). Thin inner laminates for multi-layer PCB boards are also made of this material. Like FR4 but thermally more consistent. FR5 has a Tg of 160° C (320° F) and a maximum operating temperature of 140° C (284° F).

FR means “Flame Retardant,” and 4 means fiberglass epoxy. This term describes the most popular material to manufacture circuit boards.

1. According to mechanical rigidity, it can be divided into rigid PCB, flexible PCB and rigid-flexible PCB.

2. According to the number of PCB layers, it can be divided into: single-sided PCB, double-sided PCB and multi-layer PCB.

Of course, there are other types of printed circuit boards, such as high frequency PCB, high Tg PCB, etc.

Each type of PCB contains different layers that contribute to its functionality. However, no matter which type of PCB you choose, each board contains the same essential foundation. This means that all PCBs contain the following 4 layers:

- Substrate layer

- Copper layer

- Solder mask layer

- Silkscreen layer