Custom PCB & PCB Manufacturing Services In China

Home » PCB Manufacturing

Rapid PCB Manufacturing services

Top PCB Manufacturer in China

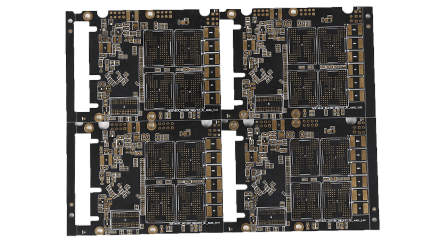

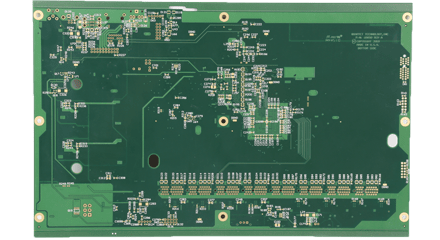

We are the leading PCB manufacturing service supplier in China. We aim to fulfill the demands of our customer base for PCB fabrication services, including from Prototype PCB to all types of small-medium volume PCB and high-volume PCB production. We have over ten years of experience providing printed circuit board manufacturing and fabrication services. We provide you with products at an affordable price, including testing services.

PCB Fabrication Services

What We Do

PCBs are one of the significant parts of electronics. PCB is a board that physically supports wires, socketed, and surface-mounted devices in most electronics. Made from laminate material such as composite epoxy or fiberglass, quality PCB allows signal and power transfer between physical devices.

For many years, we have demonstrated our capacity for high-quality PCB manufacturing services, from prototype to low-volume and high-volume needs.

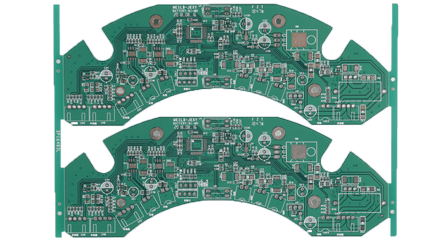

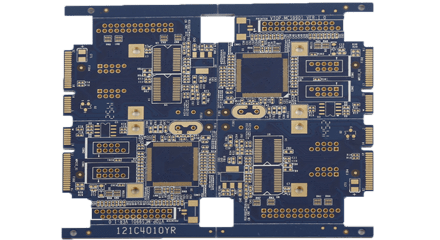

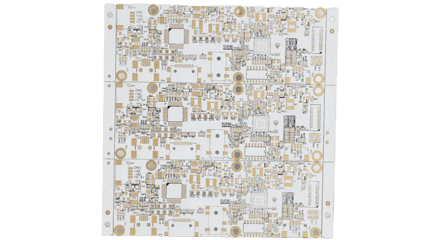

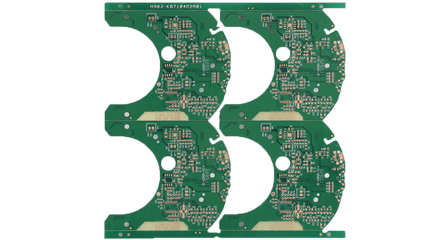

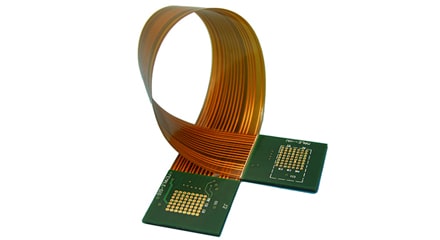

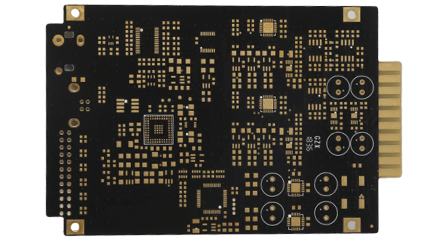

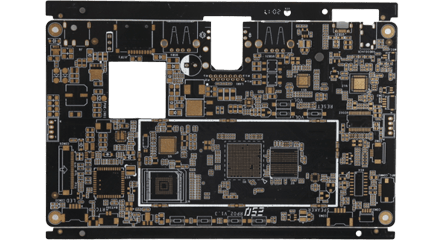

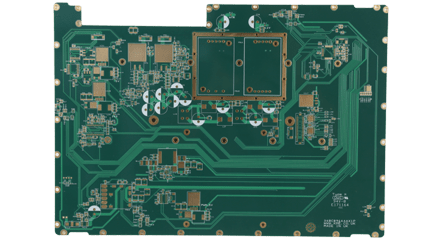

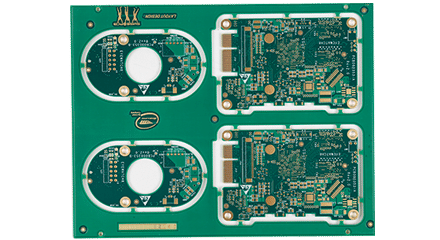

The primary factor that makes JHYPCB the preferred PCB manufacturer is the wide range of our products and services and the flexibility of our solutions. We can manufacture any PCB, from Rigid PCB to Flexible PCB and Rigid-flex PCB, from Single-sided PCB to multilayer PCB, from standard FR4 of PCB materials to high-tg and high frequency, and others.

We also pride ourselves on having experts in each stage of PCB development. JHYPCB is a start-to-finish, turnkey, full-feature PCB manufacturing and assembly service provider. We can assist you with designing, manufacturing, and assembly of your printed circuit board to the end product’s testing, packaging, and shipping. When you trust us with your PCB manufacturing and assembly, you will save yourself the hassle of managing various suppliers.

Why Choose us?

Reliable PCB Manufacturer in China

JHYPCB is a leading and top PCB manufacturer and supplier in China; we experts PCB manufactureing and fabrication,help you with the following:

- PCB production & manufacturing services

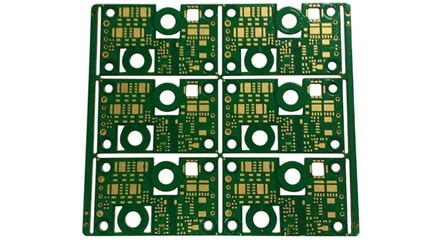

- Quick turn PCB prototypes

- Low-volume PCB manufacturing

- Large-scale PCB manufacturing

- Free DFM check by our experts and professionals

- Over 99% customer satisfaction

- 24/7 customer service to get in touch.

- Fast 3-day turnaround service as standard

- A friendly, efficient, and highly professional team

Total Quality Control

We have implemented a strict internal quality management system to provide our customers with the highest quality PCB manufacturing services.

Save Cost

Cost saving is our promise to our customers. We are experts in the field of PCB manufacturing, and we know how to save manufacturing costs for our customers.

Quick Turnaround Time

JHYPCB offers quick turnaround times that significantly impact your go-to-market plans. Our customer-centric culture and responsiveness also ensure you get quick quotes and support.

Security and Safety

We will sign a non-disclosure agreement (NDA) with you based on industry standards and guidelines to ensure the security and safety of your PCB manufacturing and assembly process.

PCB Capabilities

PCB Manufacturing Capabilities

What is impossible for others we handle every day.

We understand that different industries require special manufacturing PCBs. Meet any type of printed circuit board manufacturing requirement with our capabilities:

- Rigid, Flexible and Rigid-flex PCB

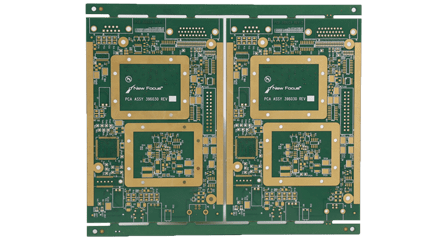

- Single-layer, Double-sided and up to 64 layers Multilayer PCB

- Controlled Impedance

- HDI PCBs up to 32 layers with laser drilling

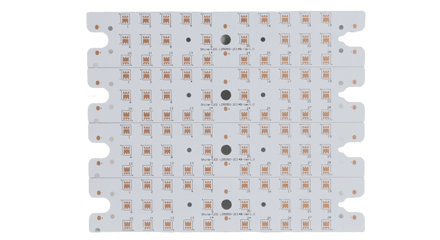

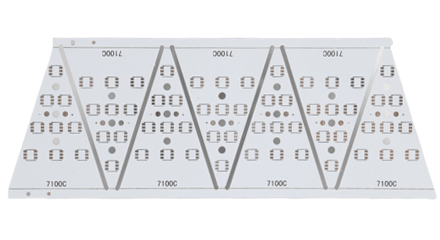

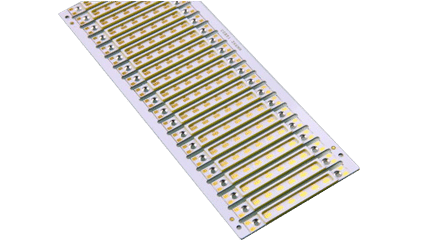

- IMS PCB – Aluminum PCB up to 4 layers, Metal core PCB, Copper core PCB

- Heavy Copper or Thick copper PCB

- Line Width/Space to 3mil/3mil

- Blind & Buried vias

- X-ray Inspection and flying probe testing

- Board Thickness: 0.1~8.0mm

- Max Board Size: 533.4 * 762 mm

- Via-in-pad, Filled vias

- Lead-Free PCB (RoHS Compliant)

- RoHS & WEEE Compliant PCB Manufacturer

How To Make a Printed Circuit Board?

PCB Manufacturing Process

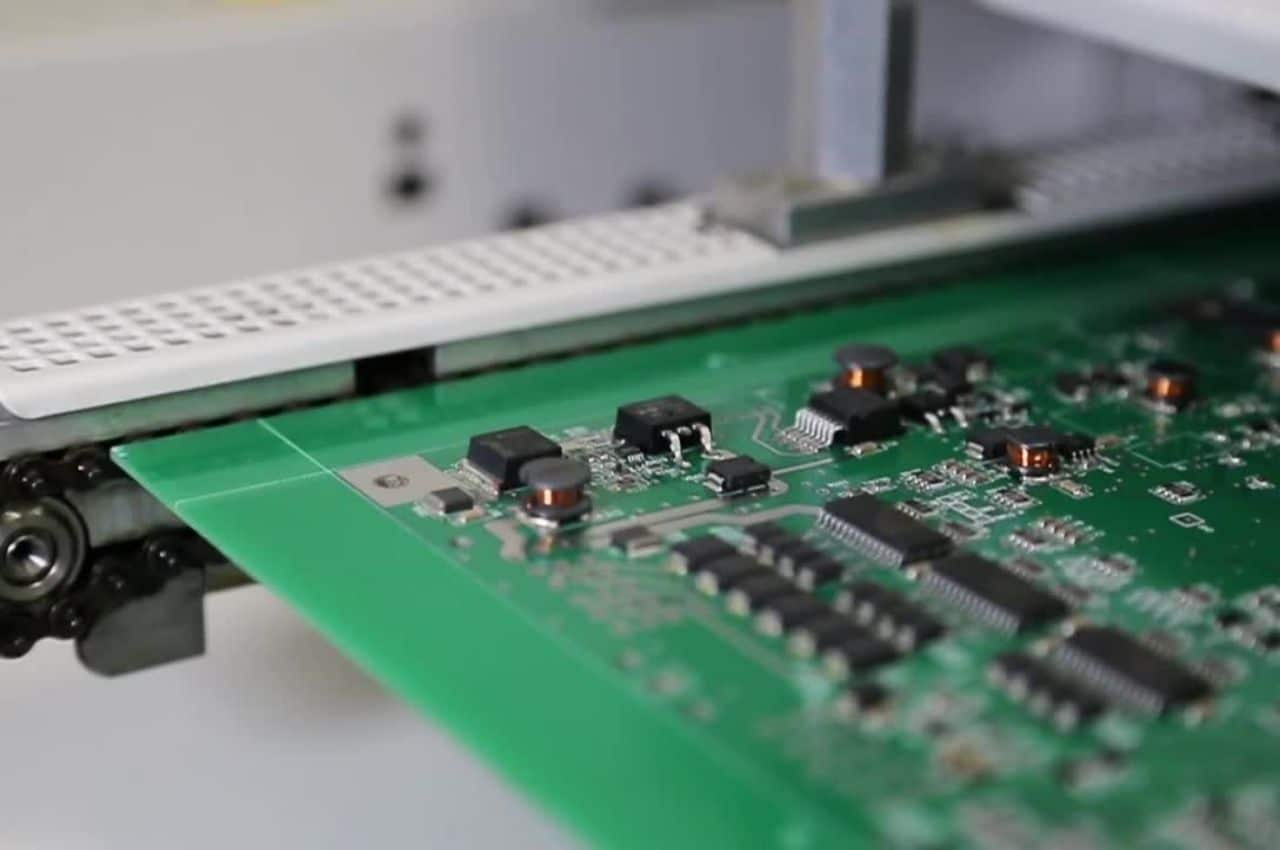

Used in desktop and laptop computers, PCBs are the substructure for many internal computer components such as network interface cards, controller cards, expansion cards, and video cards. Besides computers, high-quality PCB is used in other electronic devices such as cell phones, tablets, digital cameras, radios, and TVs. Therefore, understanding the fabrication process of custom PCBs is essential. Following are the steps involved in the quality PCB fabrication process.

PCB Manufacturing Flow

Photoworks→Cam-Bearbeitung→CNC drilling→Through-hole plating→Brushing→Resist lamination→Resist exposure→Resist development→ECC→Resist stripping→Etching→Tin stripping→Application of soldermask→Silkscreen→Tempering→Surface finish→Routing→Electrical test

Click here to learn more about PCB manufacturing process.

PCB Materials

- FR4

- FR4 High Tg 130-180

- Rogers

- Polymide

- Aluminum

- Nelco

- Halogen Free

- Shengyi

- Isola

- Arlon

- Dupont

- Nanya

Surface Finishes

- OSP

- HASL (Leaded)

- HASL Lead-Free

- Immersion Gold (ENIG)

- Immersion Silver

- Immersion Tin

- EPIG

- ENEPIG

- Gold Flash

Mask

- LPI – Matte

- LPI – Gloss

- Dry Film

- SRS Series

- Variety of Colors

Testing

- Netlist Testing

- Continuty Testing

- Flying Probe Testing

- IST- Interconnect Stress Testing

Related Reading

- 10 Types of PCB Surface Finishes: All You Need to Know

- Standard PCB Thickness—All You Need To Know

- Guide to Multilayer PCB Layer Stackup and thickness

- What is PCB solder mask?

- Key Process Flow of Rigid-Fled PCB Production

- Introduction to Aluminum PCB Manufacturing Process

- Knowledge Of Flexible PCB Manufacturing Process Steps

PCB FABRICATION FAQs

PCB manufacturing is the process of manufacturing or transforming the design into a structure based on the specifications provided in the circuit board design package.

Yes, we will provide a complete quotation with an estimated delivery time for PCB manufacturing services.

Yes, we can stock the PCB boards. You can click here to learn more about storing PCBs.

Yes, we provide high precision and high reliability multi-layer PCB manufacturing services.

Mostly we provide green color. Also, we provide black, purple, red, and blue colors as per the customer’s requirement.

Gerber files with RS-274-X format is necessary and widely used in PCB fabrication, which can be opened by the CAM350 and Genesis2000 software tool.

Gerber files include all information about PCB, such as the circuit in each layer, silkscreen layer, Copper layer, Solder mask layer, and Outline layer.NC drill …, It would be better if you could also provide manufacturing Drawing and Readme files to show your requirements.

In addition, to deliver to you faster, you also need to provide parameters such as quantity, PCB material, panel file, surface finish process, solder mask color, etc.

For more information on PCB fabrication and assembly, you can click here.

Helpful Resources