Table of Contents

Introduction to Custom PCB Assembly

When it comes to bringing an electronic product idea to life, the journey from concept to reality can be daunting, especially for small businesses, hobbyists, and academic researchers. Traditional mass manufacturing processes are often ill-suited for low-volume or specialized needs, leaving a gap in the market for a more tailored solution. This is where custom PCB assembly services shine, offering a perfect blend of flexibility, expertise, and cost-effectiveness.

Custom PCB assembly refers to the process of manufacturing and assembling printed circuit boards according to specific customer requirements. Whether you need a small batch of prototypes, unique component integration, or specialized testing procedures, a trusted custom PCB assembly partner can make your vision a reality.

The beauty of customized PCB assembly lies in its versatility. From startups and entrepreneurs to DIY enthusiasts and academic institutions, this service caters to diverse clients with varying needs. By understanding the unique challenges faced by low-volume and specialty projects, custom PCB assembly providers offer tailored solutions that streamline the entire process, from design to final assembly.

This comprehensive guide explores the world of custom PCB assembly, its numerous benefits, and why it’s the ideal choice for those seeking specialized or low-volume electronic manufacturing services. Get ready to unlock new possibilities and bring your innovative ideas to fruition with the power of customized PCB assembly solutions.

Ideal for Low-Volume and Prototype PCB Assembly Runs

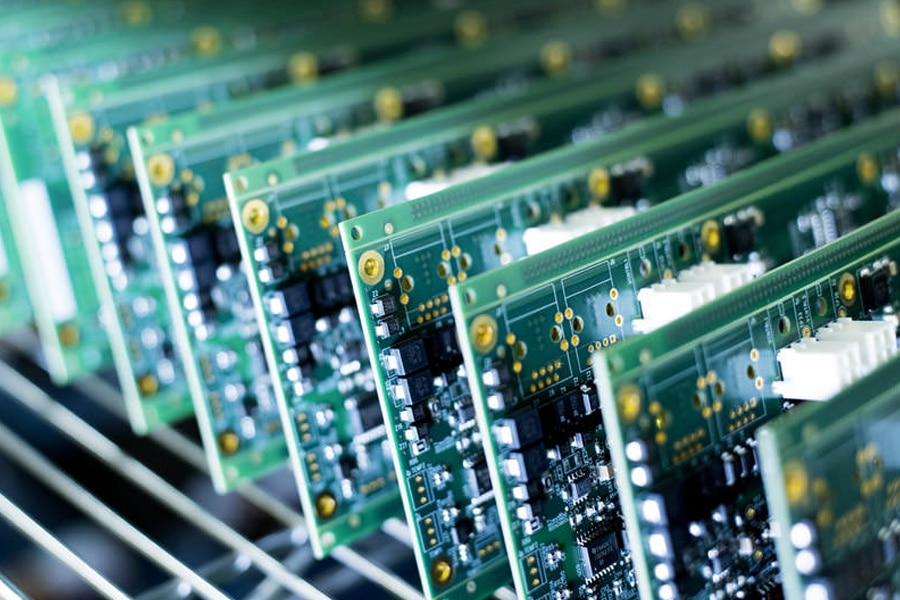

One of the primary advantages of custom PCB assembly services is their ability to cater to low-volume and prototype runs efficiently. Traditional mass production lines are optimized for large-scale manufacturing, making them inefficient and cost-prohibitive for small batches or one-off prototypes. This is where custom PCB assembly providers shine, offering a dedicated and specialized approach tailored to your specific needs.

Small Batch PCB Assembly:

For businesses launching new products, startups seeking funding, or hobbyists pursuing passion projects, the need for small-batch PCB assembly is paramount. Custom PCB assembly partners understand the unique challenges associated with low-volume runs, such as minimizing setup costs, ensuring flexibility, and maintaining consistent quality control. With their expertise, they can streamline the manufacturing process, enabling you to produce the exact quantity you require without the overhead associated with mass production.

Quick Turnaround for Prototype PCB assembly:

In the fast-paced world of product development, time is of the essence. Custom PCB assembly services excel in delivering quick turnaround times for prototypes, allowing you to iterate, test, and refine your designs rapidly. Whether you’re a hardware startup seeking investor funding or an established company exploring new product lines, the ability to create functional prototypes quickly can be a game-changer. By leveraging cutting-edge equipment and optimized workflows, custom PCB assembly partners can manufacture and assemble your prototypes in a matter of days or weeks, instead of months.

Cost-Effective for Low Quantities:

Producing small batches or prototypes through traditional mass manufacturing channels can be prohibitively expensive due to high setup costs and minimum order quantities. Custom PCB assembly services eliminate these barriers by tailoring their processes to your specific needs. With no minimum order requirements and optimized material usage, you can produce the exact quantity you need without wasting resources or incurring unnecessary expenses. This cost-effectiveness makes custom PCB assembly an attractive option for businesses of all sizes, enabling them to validate their designs, conduct market testing, or simply explore new ideas without breaking the bank.

Whether you’re a seasoned professional or a budding inventor, custom PCB assembly services offer the flexibility, speed, and cost-efficiency necessary to bring your low-volume or prototype projects to life, setting the stage for future success.

Specialized Requirements? No Problem!

While low-volume and prototype PCB assembly runs are a significant part of custom PCB assembly, these services truly shine when it comes to handling specialized requirements. Whether you need to integrate non-standard components, adhere to unique testing protocols, or incorporate specialized manufacturing processes, a trusted custom PCB assembly partner can easily navigate these challenges.

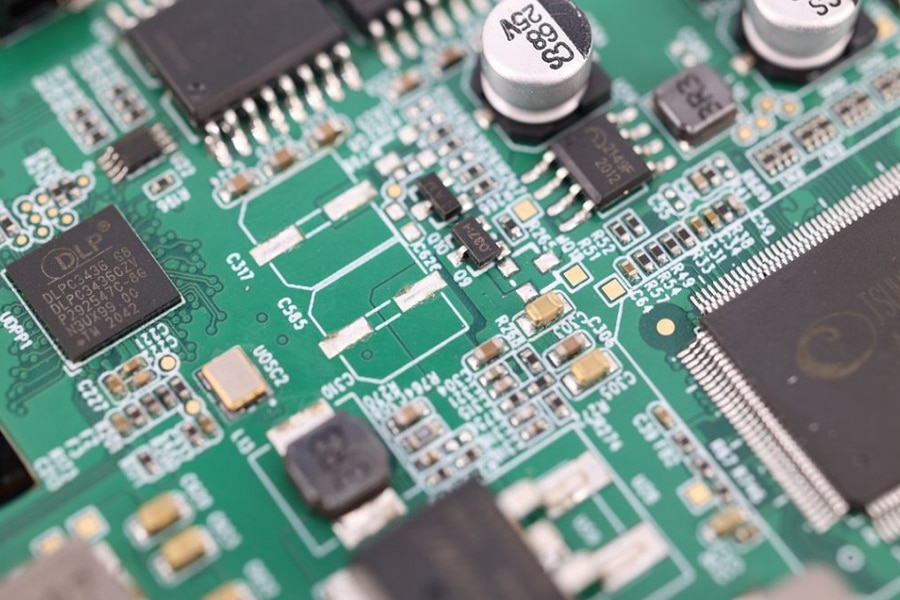

Non-standard Components and Materials

In the world of electronics, innovation often means pushing boundaries and exploring new frontiers. If your design incorporates unique or hard-to-find components, custom PCB assembly services can accommodate your needs. From specialized sensors and actuators to cutting-edge microprocessors, these providers have the expertise and resources to source and integrate even the most obscure components seamlessly into your PCB assembly.

Additionally, some applications may require the use of specialized materials, such as high-temperature substrates, flexible circuits, or shielding materials. Custom PCB assembly partners can work with these materials, ensuring proper handling, processing, and integration into your final product.

Unique Testing Requirements

Certain industries, such as aerospace, automotive, or medical electronics, often have stringent testing and validation requirements. Custom PCB assembly services are well-versed in meeting these demanding standards, offering specialized testing capabilities tailored to your specific needs. From environmental stress testing to EMC testing, these providers can ensure your final product meets all relevant regulatory and industry-specific certifications.

Specialized Manufacturing Processes

Some projects may require specialized manufacturing processes beyond traditional surface mount technology and through-hole technology assembly. Custom PCB assembly services can accommodate techniques like chip-on-board (CoB), flip-chip assembly, or even advanced processes like 3D printing for intricate enclosures or housings. By leveraging their expertise and cutting-edge equipment, these providers can execute even the most complex manufacturing processes with precision and quality.

With a custom PCB assembly partner by your side, you can rest assured that your specialized requirements will be met with the highest level of expertise and attention to detail. Whether you’re pushing the boundaries of technology or navigating unique industry demands, these services empower you to bring your most ambitious projects to life without compromise.

One-Stop Service: From Design to Final Assembly

One of the key advantages of partnering with a custom PCB assembly service is their ability to provide a true one-stop solution, streamlining the entire process from initial design to final assembled product. This comprehensive approach simplifies your workflow and ensures seamless integration and quality control throughout the entire product development cycle.

Turnkey PCB Assembly Solutions

With a turnkey PCB assembly service, you can hand off your project requirements to a dedicated team of experts who will guide you through every step of the process. From reviewing your initial design specifications and providing valuable feedback to sourcing components, fabricating PCBs, and performing final assembly and testing, a reputable custom PCB assembly partner will handle it all under one roof. This integrated approach minimizes the risk of miscommunication, delays, or quality issues that can arise when working with multiple vendors.

In-house PCB Design and Fabrication

Many custom PCB assembly services offer in-house design and fabrication capabilities, allowing for a truly seamless transition from concept to reality. Their experienced design engineers can work closely with you to optimize your PCB layouts, ensuring efficient routing, signal integrity, and adherence to industry standards. Once the design is finalized, their state-of-the-art fabrication facilities can produce high-quality PCBs tailored to your specifications, using advanced techniques such as HDI or rigid-flex technology when required.

Full Testing and Quality Control

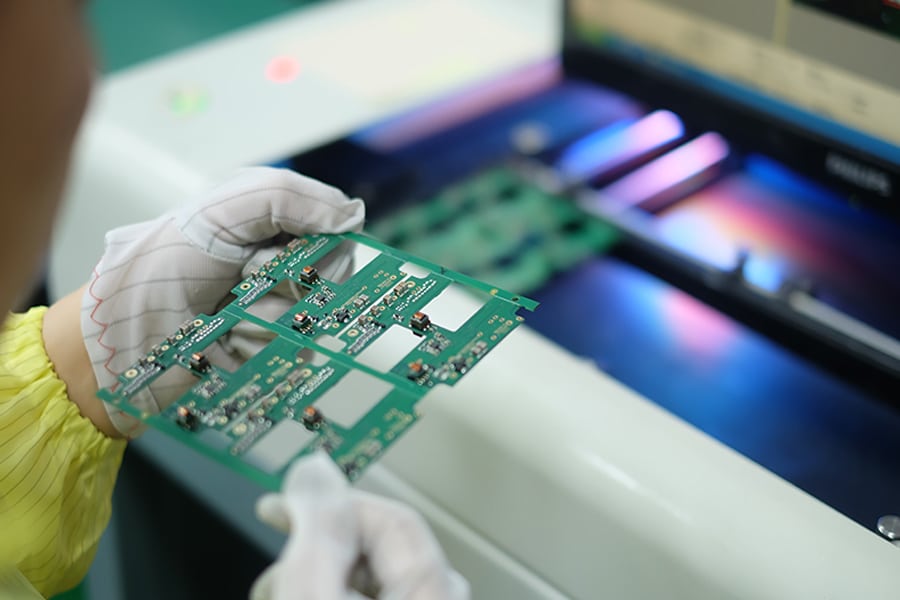

Quality is paramount when it comes to electronic products, and custom PCB assembly services understand this better than anyone. With comprehensive testing and quality control procedures in place, these providers ensure that your assembled PCBs meet the highest performance and reliability standards. From AOI and in-circuit testing to functional testing and environmental stress screening, every aspect of your product is meticulously evaluated before final delivery.

By leveraging the one-stop capabilities of a custom PCB assembly service, you can streamline your product development process, minimize potential risks, and benefit from a seamless integration of design, fabrication, assembly, and testing. This end-to-end approach not only saves time and resources but also ensures consistent quality and reliable performance, giving you the peace of mind to focus on bringing your innovative ideas to market.

Perfect for Hobbyists, Startups, and Academia

Custom PCB assembly services are not just for established businesses; they also provide invaluable support for hobbyists, startups, and academic institutions pursuing innovative projects. These specialized services cater to the unique needs of these diverse groups, fostering creativity, facilitating product development, and advancing research and educational initiatives.

DIY Electronics Projects:

Custom PCB assembly opens up a world of possibilities for hobbyists and makers. Whether you’re building a smart home automation system, developing a new robotics project, or exploring the realm of wearable technology, access to professional-grade PCB assembly services can take your DIY electronics projects to the next level. With the ability to produce high-quality, customized PCBs, even complex designs can be brought to life with precision and reliability.

Early-Stage Product Development:

Startups and entrepreneurs often face significant challenges when it comes to transforming their innovative ideas into tangible products. Custom PCB assembly services provide the perfect solution for early-stage product development, enabling startups to create functional prototypes, conduct user testing, and iterate rapidly without the substantial upfront investment required for mass production. By leveraging these specialized services, startups can validate their concepts, attract investors, and refine their products before committing to larger-scale manufacturing.

Research and Educational Purposes:

Academia and research institutions are at the forefront of technological innovation, constantly pushing the boundaries of what’s possible. Custom PCB assembly services play a crucial role in supporting these endeavors by providing tailored solutions for research projects, experimental setups, and educational initiatives. From building specialized instrumentation for scientific experiments to creating learning platforms for engineering students, these services enable researchers and educators to bring their unique designs to life with precision and flexibility.

By catering to the diverse needs of hobbyists, startups, and academic institutions, custom PCB assembly services foster an ecosystem of innovation, exploration, and knowledge-sharing. Whether you’re a passionate maker, an aspiring entrepreneur, or a researcher pushing the boundaries of technology, these specialized services empower you to turn your ideas into reality, driving progress and inspiring future generations.

Why Choose a Custom PCB Assembly Partner?

With so many options available in the market, choosing the right custom PCB assembly partner can make all the difference in the success of your project. A reputable and experienced provider offers a range of advantages that go beyond mere manufacturing capabilities, ensuring your project is handled with the utmost care, expertise, and attention to detail.

Expertise and Experience:

One of the most significant benefits of partnering with a custom PCB assembly service is their deep-rooted expertise and extensive experience in the field. These providers have assembled countless projects, each with its unique requirements and complexities. This wealth of knowledge translates into a comprehensive understanding of the latest technologies, manufacturing processes, and industry best practices. From navigating complex design challenges to implementing stringent quality control measures, their expertise ensures your project is in capable hands.

Flexibility and Customization:

No two projects are alike, and a reliable custom PCB assembly partner understands this fundamental truth. They offer unparalleled flexibility, tailoring their services to meet your specific needs and requirements. Whether you need to integrate non-standard components, adhere to unique testing protocols, or incorporate specialized manufacturing processes, a dedicated partner will work closely with you to deliver a customized solution that aligns with your vision.

High Quality and Reliability:

Quality and reliability are paramount in the world of electronics, and a trusted custom PCB assembly service prioritizes these factors above all else. From stringent component sourcing and inspection processes to rigorous testing and quality control measures, these providers leave no stone unturned to ensure your assembled PCBs meet the highest performance and durability standards. By leveraging their advanced facilities, cutting-edge equipment, and meticulous attention to detail, they deliver products you can rely on, minimizing the risk of failures and ensuring long-lasting operation.

Choosing a reputable custom PCB assembly partner gives you access to a wealth of expertise, flexibility, and an unwavering commitment to quality and reliability. This partnership streamlines your project and provides peace of mind, allowing you to focus on your core competencies while entrusting the manufacturing and assembly process to seasoned professionals.

Get Started with Your Custom PCB Assembly Today!

In the ever-evolving world of electronics, staying ahead of the curve is crucial. Whether you’re a small business seeking to launch a new product, a hobbyist exploring the boundaries of innovation, or an academic institution conducting cutting-edge research, our custom PCB assembly services provide the perfect solution to bring your ideas to life.

Design and Manufacturing Capabilities:

Our team of experienced engineers and designers are equipped with the latest tools and technologies to translate your concepts into functional reality. From PCB layout and design optimization to advanced manufacturing processes like HDI, rigid-flex, and 3D printing, we have the capabilities to handle even the most complex projects with precision and efficiency.

Quick Quote and Fast Turnaround:

Time is of the essence, and we understand the importance of rapid prototyping and time-to-market. Our streamlined processes and dedicated production lines ensure quick turnaround times, allowing you to iterate, test, and refine your designs rapidly. Simply provide us with your requirements, and we’ll provide you with a detailed quote, enabling you to make informed decisions and stay on track with your project timelines.

Quality-Focused and Customer-Oriented:

An unwavering commitment to quality and customer satisfaction is at the core of our custom PCB assembly services. Our state-of-the-art facilities, stringent quality control measures, and adherence to industry standards ensure that every assembled PCB meets the highest levels of performance and reliability. Moreover, our customer-centric approach means that we work closely with you, understanding your unique needs and providing personalized support throughout the entire process.

Take the first step towards realizing your vision today by partnering with our custom PCB assembly experts. Whether you require small batches, prototypes, or specialized manufacturing services, we have the expertise, flexibility, and dedication to transform your ideas into tangible products of the highest quality.

Contact us now to discuss your project requirements, and let’s embark on a journey of innovation together!

Related Posts

- What is the Bill of Materials(BOM) and how to create one?

- The Main PCB Assembly Process Steps

- The Production Process and Specifications of PCB SMT stencil

- How long can PCBA finished products be stored?

- How to Store PCB and PCBA?

- Reflow Soldering VS. Wave Soldering: What’s the difference?

- What is the difference between SMT and SMD?

- Solder Paste and Solder Paste Printing in SMT PCB Assembly

- SMT PCB Assembly Manufacturing Process Introduces

- The Two Typical SMT Reflow Soldering Temperature Curve Modes

- What is the defference between PCB and PCBA?

- 30 Common SMT PCB Assembly Defects

- Electronic PCB Assembly Process and Flow Chart

- The Advantages and Disadvantages of Surface Mount Technology (SMT)

- How to Get a Quote and Order PCB Assembly?

- Shenzhen – The Global Hub for High-Quality PCB Assembly Manufacturing

- What Is Prototype PCB Assembly?