Table of Contents

What is a PCB Manufacturer? Understanding Their Role and Responsibilities

As an essential part of the electronics manufacturing supply chain, a PCB manufacturer plays a crucial role in producing the backbone of various electronic devices. But what exactly is a PCB manufacturer, and what are their primary responsibilities? Let’s delve into this topic.

A PCB manufacturer is a company specializing in fabricating printed circuit boards, the foundational components that interconnect and support electronic components in virtually all electronic products. These specialized manufacturers have the expertise, equipment, and processes to transform PCB designs into physical boards that facilitate the integration and functionality of electronic circuits.

The Role of PCB Manufacturers in the Electronics Industry PCB manufacturers are an indispensable link in the electronics production chain. Their intricate work ensures that PCBs meet the stringent requirements for quality, reliability, and performance demanded by various industries, including consumer electronics, telecommunications, aerospace, automotive, and medical devices.

Key Responsibilities of a PCB Manufacturer

- PCB Design and Engineering Support

While PCB manufacturers may not always handle the initial design phase, they often collaborate closely with electronics design teams to ensure the manufacturability and feasibility of PCB layouts. Their expertise in PCB fabrication processes allows them to provide valuable insights and recommendations for optimizing designs. - PCB Fabrication and Production

The core responsibility of a PCB manufacturer is to fabricate printed circuit boards according to client specifications and designs. This process involves multiple stages, including imaging, etching, drilling, plating, and final finishing. Manufacturers must adhere to strict quality control measures to ensure the boards meet industry standards and customer requirements. - PCB Testing and Inspection

Quality assurance is paramount in the PCB manufacturing process. Manufacturers conduct rigorous testing and inspection procedures to verify the fabricated PCBs’ functionality, electrical integrity, and physical characteristics. This step is crucial for identifying and addressing any potential defects or issues before the boards are integrated into final products. - Supply Chain Management and Logistics

Efficient supply chain management is another key responsibility of PCB manufacturers. They must coordinate the procurement of raw materials, manage inventory levels, and ensure timely delivery of finished PCBs to their customers, often adhering to strict production schedules and lead times.

By understanding the role and responsibilities of a PCB manufacturer, businesses and individuals can better appreciate the vital contribution these specialized companies make to the electronics industry. Choosing a reputable and capable PCB manufacturer is essential for ensuring electronic product quality, reliability, and successful integration.

The Intricate Process of PCB Manufacturing: A Closer Look

A PCB, a marvel of engineering and precision manufacturing, is at the heart of every electronic device. To understand the capabilities of a PCB manufacturer, it’s essential to delve into the intricate process they follow to transform PCB designs into functional reality.

- PCB Design

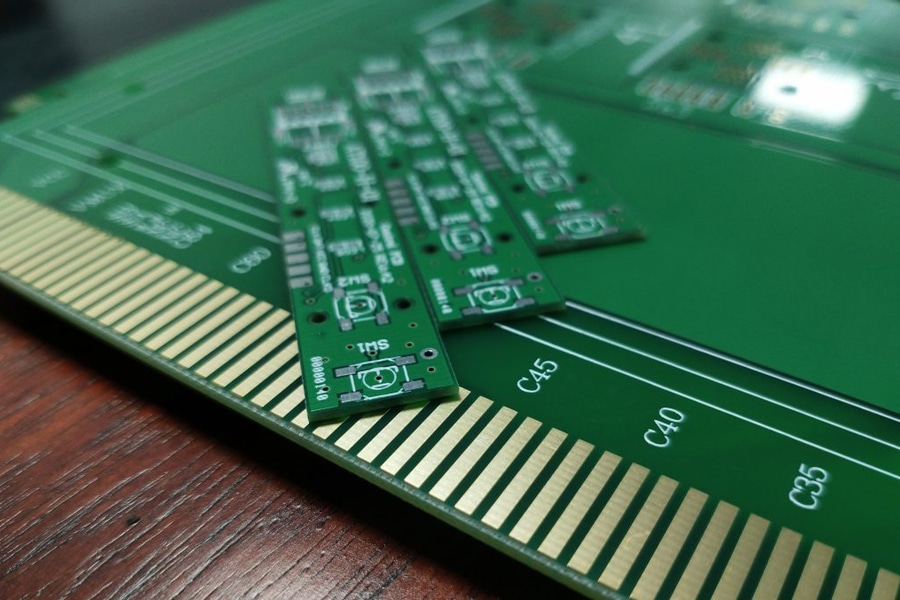

The PCB manufacturing process begins with the design phase, where electronic engineers create detailed schematics and layouts using specialized CAD software. These designs not only specify the placement of components but also define the intricate network of copper traces that will interconnect them. - PCB Fabrication

Once the design is finalized, the PCB fabrication process commences. This multi-step procedure involves several critical stages:

a. Imaging: The PCB design is transferred onto a photosensitive layer applied to a copper-clad laminate using advanced imaging techniques, such as direct imaging or photolithography.

b. Etching: The exposed areas of the copper layer are selectively removed through chemical etching, leaving behind the desired circuit patterns.

c. Drilling: Precise holes are drilled into the board to accommodate component leads and create vias (conductive pathways between layers) for multilayer PCBs.

d. Plating: Copper or other conductive materials are electroplated onto the drilled holes and circuit patterns to enhance conductivity and facilitate component mounting.

e. Solder Masking: A protective solder mask layer is applied to the PCB, leaving only the necessary areas exposed for component soldering. - PCB Testing and Inspection

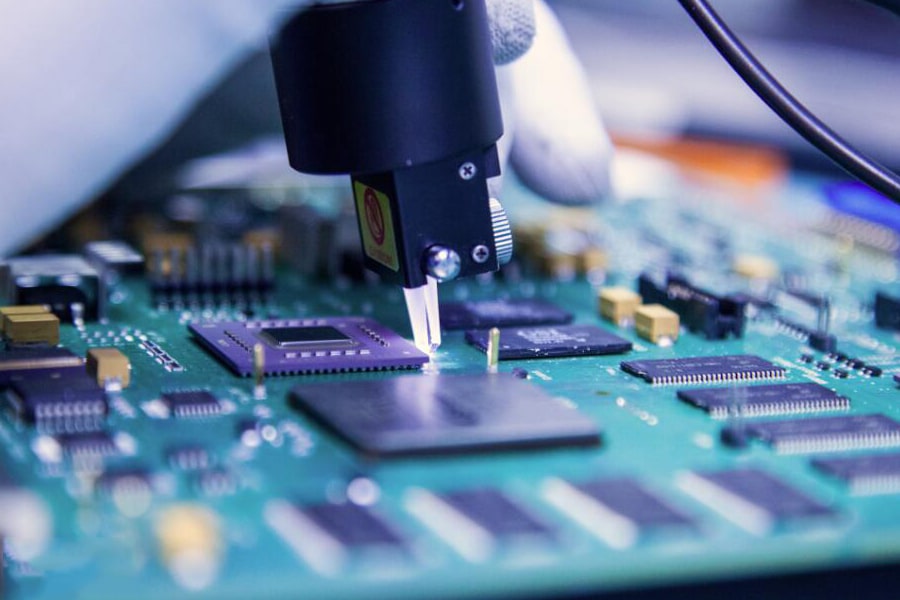

Quality assurance is a paramount concern for PCB manufacturers. After fabrication, the boards undergo rigorous testing and inspection processes to ensure compliance with design specifications and industry standards. Electrical testing, visual inspection, and advanced techniques like AOI are employed to identify and rectify any defects or anomalies. - PCB Assembly (Optional)

While some PCB manufacturers focus solely on bare board fabrication, others offer additional assembly services. This involves mounting and soldering electronic components onto the PCB, either through manual or automated processes, resulting in a fully assembled and functional circuit board.

Throughout this intricate process, PCB manufacturers must maintain strict quality control measures, adhere to industry regulations, and implement best practices to ensure the highest levels of precision, reliability, and performance in the final product.

By understanding the PCB manufacturing process, businesses can better appreciate the complexity and attention to detail required by PCB manufacturers to deliver high-quality boards that form the backbone of modern electronics.

Learn more about the PCB fabrication process:

- Navigating the PCB Manufacturing Process Part 1: Unveiling MI, Cutting, and Drilling

- Navigating The PCB Manufacturing Process Part 2: Copper Plating, Routing

- Navigating The PCB Manufacturing Process Part 3: Pattern And AOI

- Navigating The PCB Manufacturing Process Part 4: Solder Mask, Silkscreen, Surface Finish

- Navigating The PCB Manufacturing Process Part 5: Testing, V-cut, QC, And Shipping

Cutting-Edge Technologies Powering PCB Manufacturing

The PCB manufacturing industry is a constantly evolving landscape, driven by advancements in technology and the ever-increasing demand for smaller, more complex, and higher-performing electronic devices. To meet these demands, PCB manufacturers continuously invest in and adopt cutting-edge technologies that enable them to push the boundaries of what’s possible.

- PCB Fabrication Technologies

Direct Imaging: Direct imaging technology has revolutionized the PCB imaging process by using highly focused laser beams or UV light sources to directly transfer the circuit patterns onto the photosensitive layer, eliminating the need for photomasks and improving accuracy.

Advanced Etching Processes: Manufacturers employ various advanced etching techniques, such as plasma etching and laser etching, to achieve finer circuit features and better dimensional control, enabling the production of HDI PCBs. - PCB Material Innovations

a. High-Performance Laminates: The development of high-performance laminates, such as low-loss materials, thermal-resistant materials, and flexible circuit materials, has enabled the production of PCBs for specialized applications, including high-frequency communications, automotive electronics, and wearable devices.

b. Conductive Materials: Advances in conductive materials, like copper foils and conductive pastes, have improved signal integrity, power delivery, and thermal management capabilities of PCBs, allowing for higher-speed data transfer and better heat dissipation. - PCB Testing and Inspection Technologies

a. AOI: AOI systems use advanced imaging technologies and algorithms to automatically inspect PCBs for defects, such as shorts, opens, misalignments, and component placement errors, ensuring a high level of quality control.

b. Electrical Testing: Manufacturers employ various electrical testing methods, including flying probe testers, in-circuit testers, and boundary scan testing, to verify the functionality and electrical integrity of PCBs, identifying and isolating potential issues before final assembly. - Precision Manufacturing Techniques

a. Laser Depaneling: Laser depaneling technology enables precise separation of individual PCBs from larger panels, reducing stress and potential damage compared to traditional mechanical routing methods.

b. Automated Assembly Lines: Highly automated assembly lines, equipped with advanced pick-and-place machines and reflow soldering systems, allow for efficient and accurate component mounting and soldering, ensuring consistent quality and high throughput.

By embracing and mastering these cutting-edge technologies, PCB manufacturers can deliver innovative solutions that meet the ever-evolving demands of the electronics industry. From miniaturization and increased complexity to improved performance and reliability, these advanced technologies are shaping the future of PCB manufacturing and enabling the development of next-generation electronic devices.

The Comprehensive Service Offerings of a PCB Manufacturer

As the backbone of electronic devices, PCBs are essential components that require precision manufacturing and specialized expertise. PCB manufacturers offer a wide range of services to cater to the diverse needs of their clients, from large-scale production runs to custom prototyping solutions.

- Standard PCB Production

One of the core services PCB manufacturers provide is the production of standard PCBs in various sizes, layer counts, and materials. These boards are commonly used in consumer electronics, industrial control systems, and telecommunication equipment. Manufacturers employ advanced fabrication techniques and stringent quality control measures to ensure consistent performance and reliability. - High-End PCB Manufacturing

As technology advances, the demand for high-performance PCBs has grown significantly. PCB manufacturers offer specialized services for producing HDI PCBs, rigid-flex PCBs, and other advanced PCB board types. These boards are essential for applications that require high-speed data transfer, compact form factors, and exceptional thermal management, such as in the aerospace, defense, and medical industries. - Small Batch and Prototype PCB Services

In addition to large-scale PCB production, many PCB manufacturers provide small batch and PCB prototyping services to cater to the needs of product development teams, hobbyists, and businesses with low-volume requirements. These services allow clients to quickly and cost-effectively produce small quantities of PCBs for testing, evaluation, and early-stage product development.

PCB Prototyping: PCB Prototyping services enable clients to quickly iterate and refine their PCB designs before committing to full-scale production. Manufacturers use specialized equipment and techniques to produce high-quality PCB prototypes, often with quick turnaround times.

Low-Volume PCB Production: For projects with limited production runs or small batch requirements, PCB manufacturers offer low-volume PCB production services, ensuring the same level of quality and precision as larger-scale operations. - Product Development and Technical Support

Many PCB manufacturers offer comprehensive product development and technical support beyond fabrication services. Their teams of experienced engineers collaborate with clients to optimize PCB designs, provide manufacturing feasibility analysis, and suggest improvements to enhance performance, reliability, and manufacturability.

By offering a comprehensive range of services, PCB manufacturers position themselves as trusted partners for businesses across various industries, from startups and hobbyists to established electronics companies. Their expertise, advanced capabilities, and commitment to quality enable them to deliver reliable and high-performing PCBs that form the foundation of innovative electronic products.

Choosing the Right PCB Manufacturer: Key Considerations

In the ever-evolving electronics industry, partnering with a reliable and capable PCB manufacturer is crucial for ensuring the success of your electronic products. With a multitude of options available, selecting the right PCB manufacturing partner requires careful evaluation of several key factors.

- Technical Expertise and Capabilities

Their technical expertise and manufacturing capabilities should be a top priority when assessing potential PCB manufacturers. Look for manufacturers with a proven track record in producing high-quality PCBs for your specific application or industry. Evaluate their experience in handling various board complexities, layer counts, materials, and specialized requirements such as HDI or rigid-flex designs. - Quality Assurance and Certifications

Quality is paramount in the PCB manufacturing process, as defects or subpar workmanship can significantly impact the performance and reliability of your electronic products. Reputable PCB manufacturers should have robust quality assurance systems in place, including stringent inspection procedures, electrical testing, and adherence to industry standards and certifications (e.g., ISO 9001, IPC-A-600, UL, and RoHS). - Production Capacity and Lead Times

Consider the PCB manufacturer’s production capacity and lead times to ensure they can meet your volume requirements and delivery schedules. Reliable manufacturers should have the ability to scale up production and offer reasonable lead times, minimizing potential supply chain disruptions or delays in your product development or manufacturing cycles. - Customer Service and Technical Support

Effective communication and technical support are essential when working with a PCB manufacturer. Evaluate their responsiveness, communication channels, and the availability of dedicated support teams to address your queries, design clarifications, or any issues that may arise during the manufacturing process. - Pricing and Cost-Effectiveness

While cost should not be the sole determining factor, it is essential to consider the overall value proposition offered by the PCB manufacturer. Compare pricing structures, minimum order quantities, and any additional services or fees. Look for manufacturers that strike a balance between competitive pricing and high-quality standards, ensuring cost-effectiveness without compromising on quality or reliability. - Reputation and Customer Testimonials

Research the PCB manufacturer’s reputation within the industry by reading customer testimonials, reviews, and case studies. A reputable manufacturer with a strong track record of satisfied clients can provide valuable insights into their capabilities, service quality, and overall customer experience.

By carefully evaluating these key factors, you can increase your chances of finding a PCB manufacturer that aligns with your specific requirements, enabling you to bring high-quality, reliable, and competitive electronic products to market.

Frequently Asked Questions

A PCB manufacturer is a company that specializes in fabricating printed circuit boards – the foundation that interconnects and supports electronic components in virtually all electronic devices.

PCB stands for “Printed Circuit Board.” It refers to the boards made of insulating material with conductive pathways etched onto their surfaces to connect different components.

PCB manufacturers serve a wide range of industries, including consumer electronics, telecommunications, aerospace, automotive, medical devices, and many more. Any industry that involves electronic products or components will likely require PCB manufacturing services.

In manufacturing, PCBs are essential components that provide the physical base and electrical connections for mounting and integrating various electronic components such as chips, capacitors, and resistors to create functional electronic products.

Lead times can vary depending on factors such as order volume, complexity, and the manufacturer’s production capacity. However, for standard PCB orders, lead times typically range from a few days to a couple of weeks. Rush or prototype services may be available for quicker turnaround times.

Yes, many PCB manufacturers offer additional assembly services, including component mounting, soldering, and full system assembly. This can be a convenient one-stop solution for clients seeking turnkey PCB assembly solutions.

Common PCB materials include fiberglass reinforced epoxy laminate (FR4), polyimide, ceramic, and various metal finishes (e.g., copper, tin, gold). The choice of material depends on factors such as electrical performance, thermal management, and application requirements.

Reputable PCB manufacturers follow strict quality control processes, including electrical testing, visual inspection, and compliance with industry standards (e.g., IPC, UL). Additionally, requesting certifications, reviewing customer testimonials, and establishing clear acceptance criteria can help ensure quality.

PCBs are manufactured by specialized companies known as PCB fabricators or PCB manufacturers. These companies have the expertise, equipment, and processes required to produce high-quality PCBs according to client specifications.

PCB manufacturing is the process of fabricating printed circuit boards through a series of steps, including design, imaging, etching, drilling, plating, and final assembly. It involves transforming PCB designs into physical boards ready for component integration.

Conclusion

Understanding the intricate world of PCB manufacturing is crucial for businesses and individuals seeking reliable electronic solutions. This comprehensive guide has explored the roles and responsibilities of PCB manufacturers, delving into their manufacturing processes, cutting-edge technologies, and diverse service offerings. By recognizing the key factors to consider when selecting a PCB manufacturing partner, you can ensure the quality, reliability, and timely delivery of your electronic products. Whether you’re an electronics engineer, product developer, or an enthusiast, this knowledge empowers you to navigate the PCB manufacturing landscape with confidence, enabling you to bring innovative ideas to life.

Related Posts

- Custom PCB Assembly Services for Low-Volume & Specialty Needs

- Custom PCB Fabrication in China – Prototyping & Mass Production

- Expedited PCB Services – Quick Turnaround for Your Urgent Needs

- Rapid PCB Prototyping and Production – The Keys to Accelerating Your Product Launch

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- Choosing the Right PCB Assembly Manufacturer for Your Needs

- How to Select the Right Flexible PCB Manufacturer for Your Product: A 6-Step Guide

- The Importance of Choosing a Reliable PCB Prototype Manufacturer

- How to Select the Right Low-volume PCB Assembly Manufacturer

- The Cheapest PCB Prototype Manufacturer-Your Best Choice

- Choosing the Right Metal Core PCB Manufacturer is Critical to Your Success