Rigid-Flex PCB -Manufacturing, Prototype, and Application

Rigid-flex PCB Prototype Manufacturer | Rigid-flex PCB Stackup | Rigid-flex PCB Design Guide | Rigid-flex PCB Manufacturing Process

Home » PCB Manufacturing » Rigid-Flex PCB

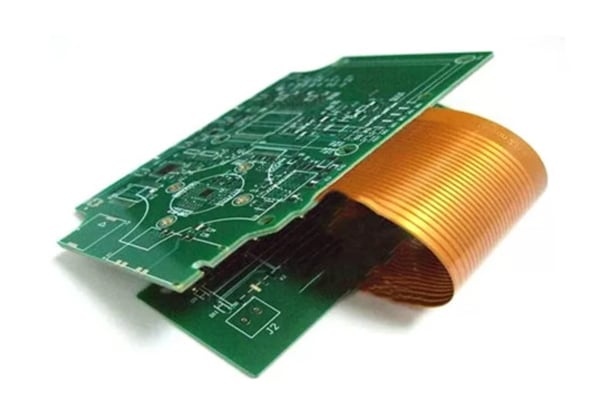

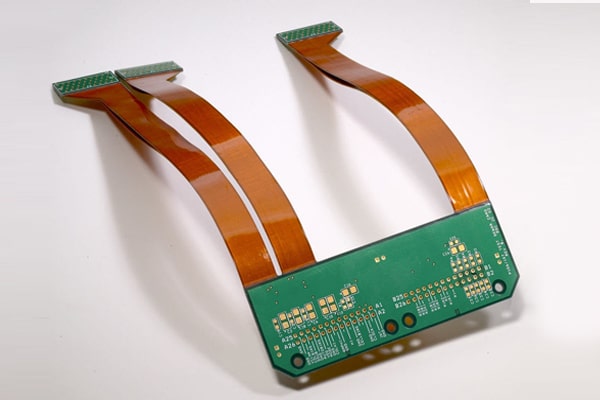

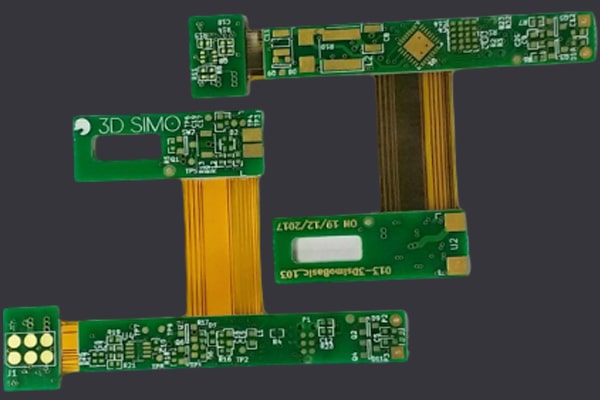

Rigid-Flex PCB, Combine the Best of Both Rigid PCB and Flexible Circuit Board into One Unit. Rigid-Flex designs are more challenging than a typical rigid printed circuit board environment, as these circuit boards are designed in a 3D space and offer greater spatial efficiency.

Rigid-Flex PCB Manufacturer - JHYPCB

PCBs have gone through many advancements and changes, and we still see new advancements. The technology is improving day by day to overcome the problems and offer more reliable and accurate performance. A few decades ago, rigid PCBs were common, and they were being used in almost every application. But there were still many complications of rigid PCBs. The main problem with rigid PCBs is that they cannot bend, which is the reason you need a specific shape and space for the PCB. They can break easily and do not have the capability to adjust in different spaces. Thus, they cannot be used in every device, especially compact ones. Fortunately, many of such problems have been solved by Rigid-Flex PCBs.

Rigid-Flex PCBs are not very new, as they were first used in a spacecraft; however, they become common when they were being used in common electronic products, especially mobile phones and laptops. Nowadays, Rigid-Flex PCBs are not only common, but they are the need. Many compact devices and appliances require Rigid-Flex PCBs.

There is no doubt Rigid-Flex PCBs have various advantages that rigid and flexible PCBs do not have. It actually offers the benefits of both types. At JHYPCB, we have automated and latest technology that can create flawless Rigid-Flex PCBs with perfection. Our expert teams carry out small-large volumes of Rigid-Flex PCBs and offer all services from PCB fabrication to assembling.

Contents of Table

Rigid-flex PCB Definition

What is Rigid-Flex PCB?

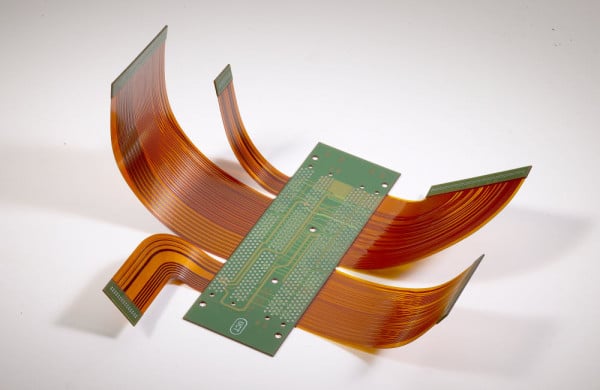

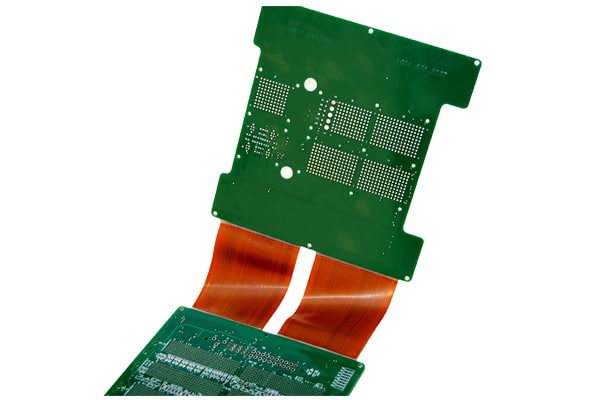

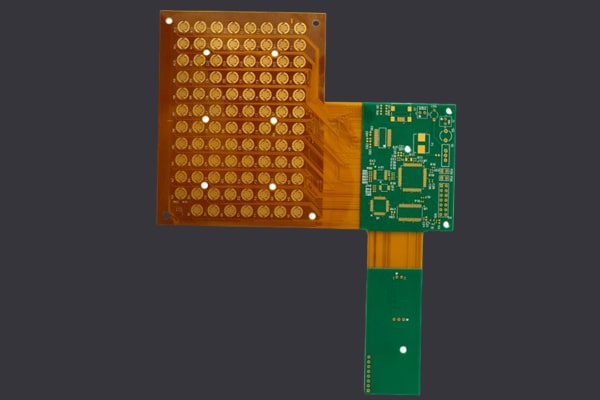

In simple words, a Rigid-Flex PCB is a combination of two types of PCBs: Rigid PCB and Flexible PCB. A rigid PCB is hard and has an unbending base. Sometimes, we need such a PCB, but sometimes, we need PCBs to bend. On the other hand, flexible PCBs can adjust in any shape, so they can easily work in smaller spaces and bend without compromising performance. However, in most cases, we need the combination for both rigid and flexible PCBs, and this combination is found in Rigid-Flex PCBs.

Rigid-Flex PCBs have the benefits of both worlds, and not only that, but they are also cost-effective and more reliable as compared to Rigid PCBs. These PCBs have a higher component density, fewer parts requirements, long life, and exceptional quality control.

Because of its flexible and rigid nature, the PCB can be used in any type of device and modern era electrical appliances. These are compact and lightweight, which ultimately reduces the size and weight of the final product.

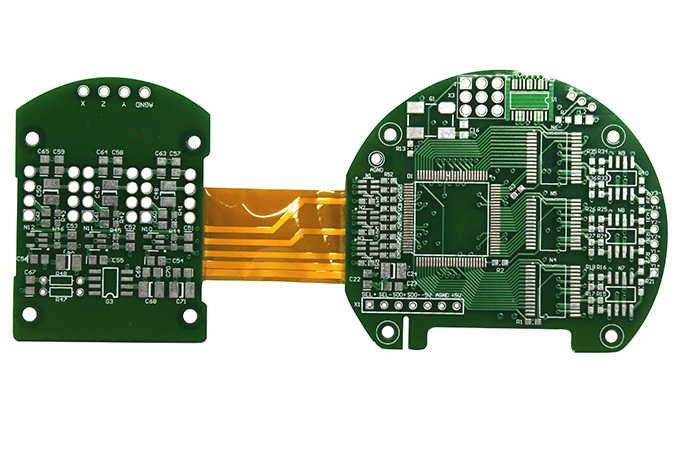

There are two parts in a rigid-flex PCB. The flexible parts are usually made of Polyimide (PI), while the rigid parts are made of FR4. There can be multiple layers of the rigid PCB board and the flexible circuit board. Commonly, there are 4, 6, and 8 layers of Rigid-Flex PCB. However, at JHYPCB, we can make up to 12 layers.

A 4 layer Rigid-Flex PCB means that there will be four conductive layers, which are usually two for the rigid and two for flexible layers. A 6 layer Rigid-Flex PCB means it would have six conductive layers. The conductive layers are distributed among the rigid and flex parts as required. It could be two layers of rigid part and four layers of flexible part, vice versa, or any other combination. The flexible boards are glued on the rigid board to complete the whole circuitry.

If we consider the designing of Rigid-Flex PCB, then you will find it a bit difficult. No doubt, the PCB is quite flexible, but the designer needs to consider the whole 3D space where it will fit easily.

Advanced Learning

- Basic Knowledge of PCB Pad Design

- 10 Tips To Improve PCB Design For Manufacturability

- Five factors that FPC PCB designers should know about impedance control

- What are the aspects of PCB Design For Manufacturing (DFM) and Design For Assembly (DFA)?

- PCB Design Software Free Download

- Rigid PCB vs Flex PCB: What Is The Difference?

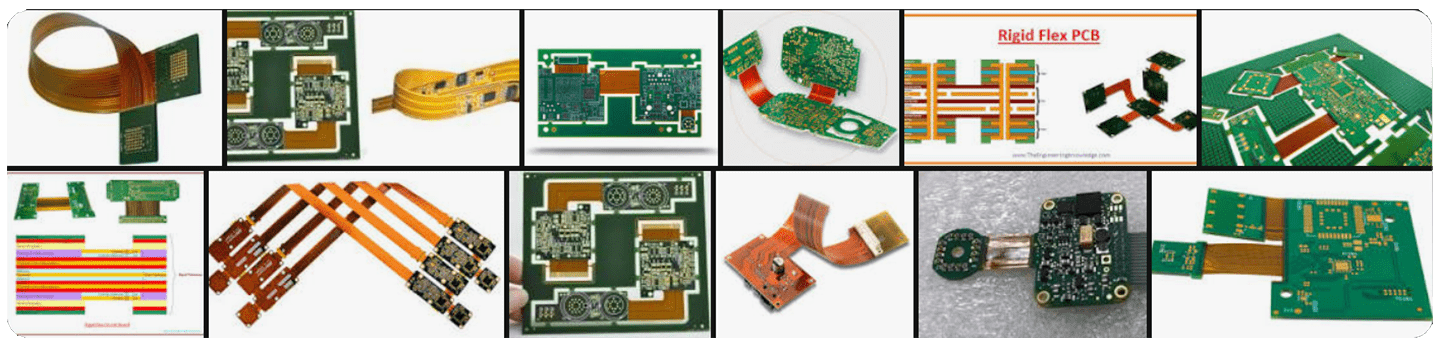

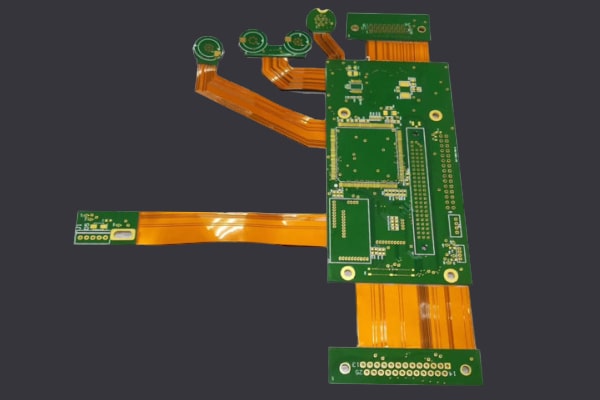

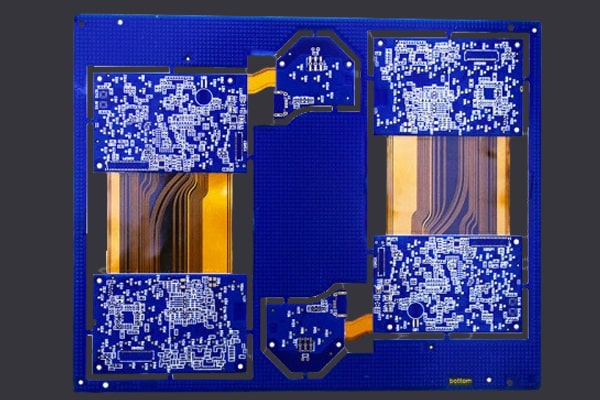

What Kinds of Rigid-Flex PCBs Can We Fabrication?

Rigid-Flex PCB Fabrication Service

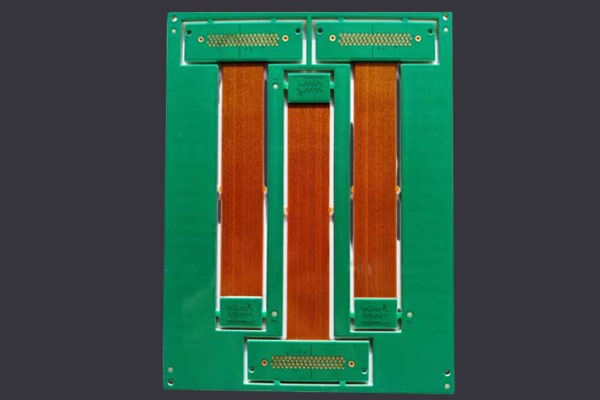

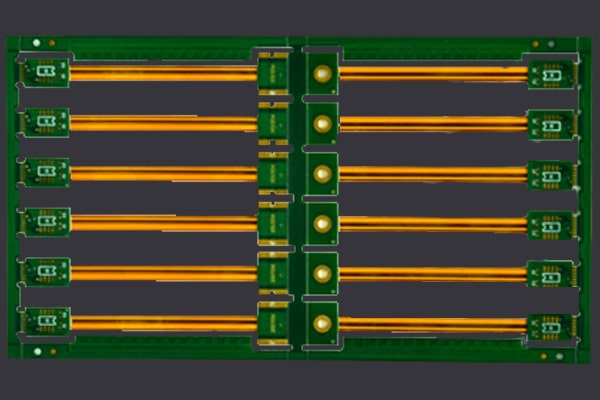

With our experience in PCB manufacturing and assembly industry, JHY can provide high-quality, high-reliability rigid-flex PCB, flex rigid PCB, single-layer rigid-flex PCB, double-sided rigid-flex PCB, multilayer rigid-flex PCB, quick turn rigid-flex PCB, HDI rigid-flex PCB, 4 layer rigid-flex PCB, customized rigid-flex PCB fabrication service, and rigid-flex PCB assembly service.

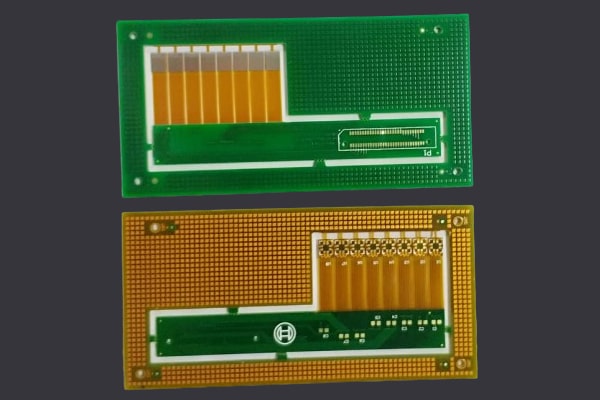

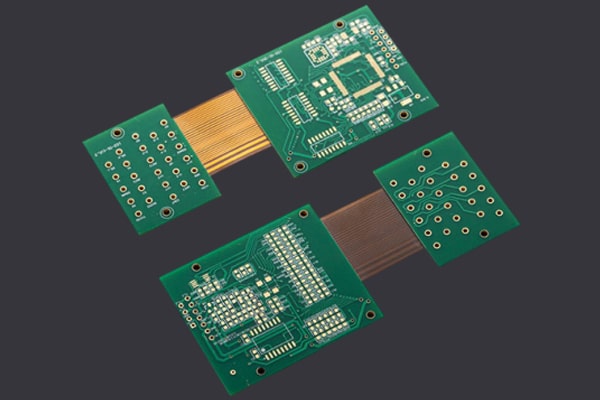

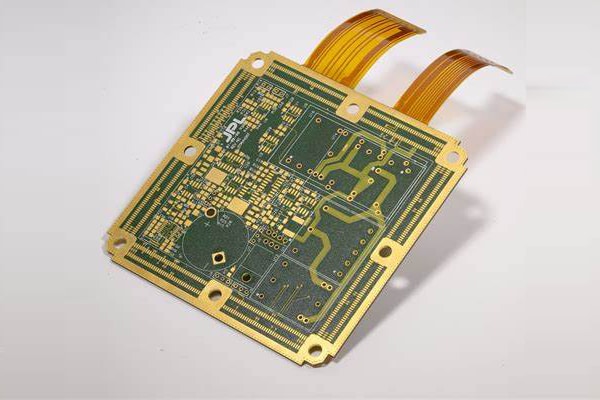

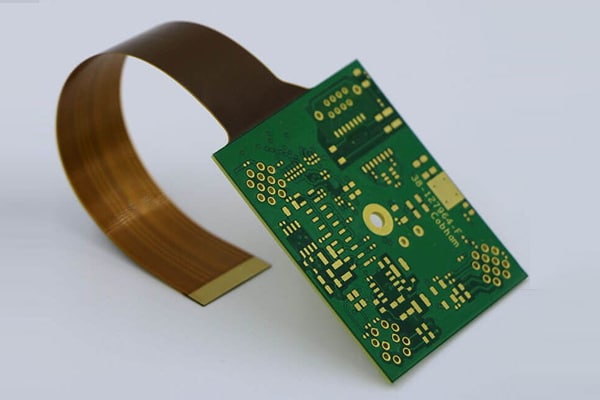

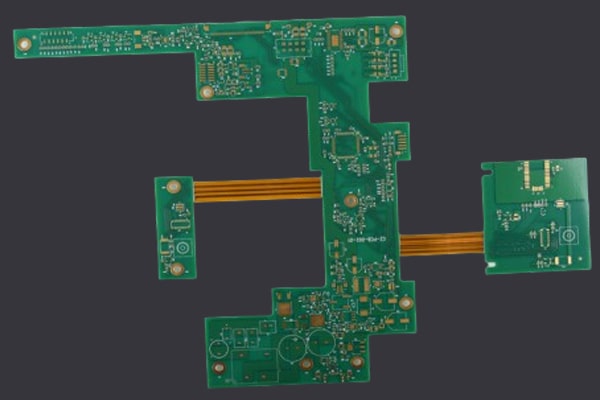

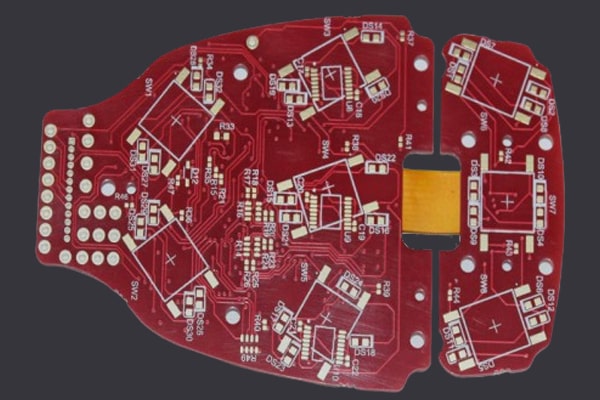

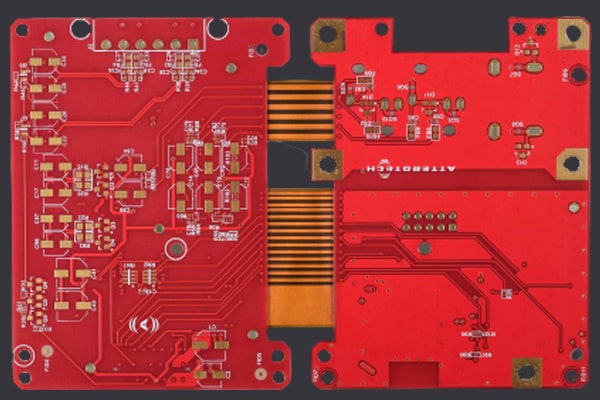

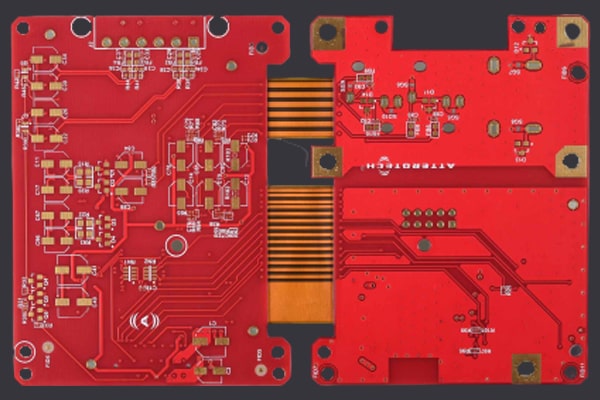

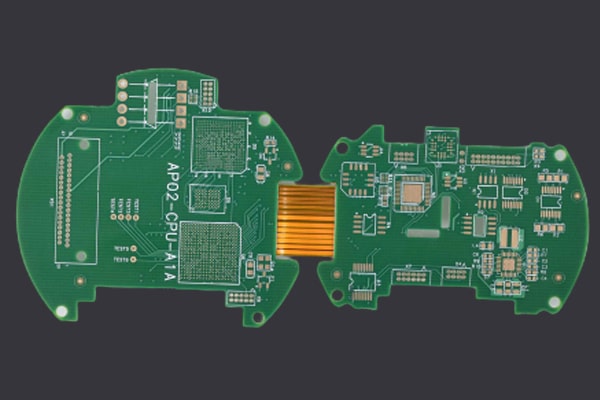

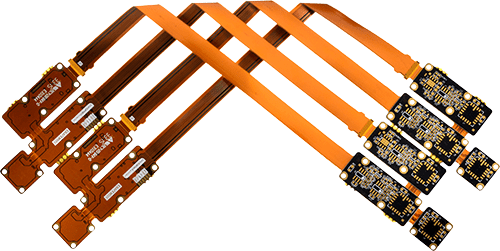

As a professional rigid-flex PCB manufacturer in China, the following are some of the flex rigid PCBs we manufacture:

Rigid-Flex PCB Design

Early in the rigid flex PCB manufacturing process, it is essential to work through the PCB design requirements to ensure reliability. Some of the design guidelines followed by our experienced engineer include:

- Define the rigid to flex transition areas.

- Making the right choice of material based on bespoke requirements.

- Having additional layers in the Gerber files relating to artwork layers that define the cover layer and bond ply sections.

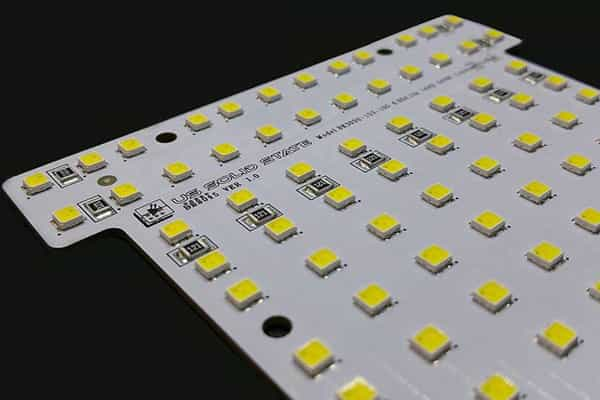

Single Layer Rigid-Flex PCB

A single-layer rigid-flexible PCB has only one conductive copper layer between two insulating polyimide layers.

Double-sided Rigid-Flex PCB

A double-sided rigid-flex PCB has two conductive copper layers. The signal transmission between double-side rigid-flex PCB layers is done through plated through holes.

Multilayer Rigid-Flex PCB

The multilayer rigid-flex PCB is a more complex rigid-flex PCB stackup that can achieve more functions. The electrical connection between layers of a multilayer rigid-flex PCB can be achieved using plated-through holes, buried holes, or blind holes.

4 Layer Rigid-Flex PCB

4 layer PCB is the most common type of multilayer PCB, and it is also a kind of multilayer PCB produced by JHY. Depending on the needs of the application, a 4 layer rigid-flex PCB is a suitable choice.

A typical 4 layer rigid-flex PCB stack up is 4 layer rigid PCB + 2 layer flexible PCB.

HDI Rigid-Flex PCB

HDI (High-density interconnects) rigid-flex PCBs are among the most flexible and Most Popular PCBs. HDI rigid-flex PCBs combine flexible PCBs’ flexibility with FR-4 PCBs’ stiffness.

JHY has many years of experience in HDI rigid-flex PCB manufacturing, which can meet your individual needs.

Quick Turn Rigid-Flex PCB

Fast turnaround time is one of our service advantages. Quick turn rigid-flex PCB is our most commendable service, from single-layer rigid-flex circuits and double-sided rigid-flex circuits to multilayer rigid-flex boards with blind or buried vias.

Rgid-Flex PCB Assembly Service

JHY has extensive experience assembling flexible and rigid-flex PCBs. We offer a one-stop solution — including fabrication, components sourcing, assembly, and testing — we can work out any issues and possible problems before assembly. This not only minimizes any possible project delays, but it also saves our customers time and money.

Why choose rigid-flex PCB?

What are the benefits and advantages of the rigid-flex PCB board?

- Space Saving: The first important benefit of Rigid-Flex PCB is space-saving. Because of the combination of rigid and flex parts, the PCB can take any type of space and bend itself according to it. It can save a lot of space as the PCB can be created according to the available space in the device. In the case of rigid PCBs, rigid-Flex PCB manufacturers have to consider the size of the PCB before designing the product. But in the case of Rigid-Flex PCB, there is a bit of leniency as these PCBs can be made according to space and dimensions available.

As these PCBs can save space and adapt to any area, these are quite popular. They are used in mobile phones and other electronic devices that require such PCBs.

- Shock and Vibration Resistance: Another problem with rigid PCBs is that they cannot bear shocks and vibrations. The PCB could break, and the connection could be affected because of shock. In contrast, Rigid-Flex PCBs are quite flexible. They can easily absorb shocks as the flexible parts allow the PCBs to absorb them. Thus, in applications where there are more shocks and vibrations, Rigid-Flex PCBs are excellent.

These PCBs are also used in folding mobile phones as the flexible part can bend easily without affecting the performance of the device.

- Lightweight and Cost-effective: In Rigid-Flex PCBs, there is no need for connectors and cable assemblies. Therefore, there is more space available on the board, and there are fewer things required. Because of fewer parts, the PCB is not only compact, but it is also lightweight. Moreover, due to fewer components, the cost is reduced.

Even if there is a need for multiple circuits, Rigid-Flex PCBs will be much cheaper as there is no need for connectors and other assemblies that connect these circuit boards; the flexible PCB is more than enough to connect all the rigid boards.

- Simple and Fast Assembly Process: The PCB assembly process is simple and fast as there is only one assembly line required to create the whole Rigid-Flex PCB, and later, its assembling is also easy due to fewer components. In contrast, rigid PCBs require multiple production runs and assembly, which makes the whole process more time-consuming and complicated.

- High Reliability: The connectors and cable assemblies are not as reliable as Rigid-Flex PCBs. The connectors create problems later. The Rigid-Flex PCBs have fewer joints and connections as compared to its rigid alternative. There are no extra wires that can create a problem in extreme conditions. Thus, there are fewer possibilities of a poor connection. The flexible PCBs connect the rigid boards in a reliable way and ensure better performance in every condition.

- Easy Testing: Every PCB has to go through a testing process, and the same is the case with Rigid-Flex PCBs. However, Rigid-Flex PCBs go through an easier and simple testing procedure. It is because there are no connectors and cables, and they do have fewer joints to check. There are fewer possibilities of errors.

Learning more about PCB and PCBA testing methods

China Rigid-Flex PCB Manufacturer

Rigid-Flex PCB Manufacturing Process

How to make a rigid-flex PCB board?

The production or manufacturing process of Rigid-Flex PCBs is quite similar to rigid PCBs, except for a few things. Before starting the manufacturing process, our experts check all the files provided by the buyer. We offer free DFM PCB design checking to ensure there is no problem with the design. Our experts ensure the quality standards. This checking can eliminate the delays and ensure the delivery at the right time.

1) Material Selection

At first, the material is selected for the rigid and flexible parts. We have already discussed that Polyimide (PI) is commonly used for the flexible part, and FR-4 is used for the rigid part. However, everything depends on the buyer. Once the buyer informs what material will be used, everything is procured according to that. After the selection of material, the process of PCB fabrication starts.

After the selection of the board, it is thoroughly cleaned by going through various processes. It is cut into the required sizes, and the final product is ready to be used.

2) Drilling

The drilling of the board is sometimes carried out at the start, while some manufacturers do it after the etching of the board when it has the complete circuitry.

However, at this stage, the board is empty, so drilling would be quite easy. Moreover, it will be easier to clean the dirt and other pollution after the drilling as there is no circuitry on the board. The drilling is carried out according to the requirement. It is an automated process that completes the drilling according to the Gerber file. After drilling, the board is cleaned through various chemical processes, according to the type of material used. The common methods are the sulphuric acid method, chromic acid method, and plasma method.

After that, the boards can have plated through holes (PTH) after going through a chemical process. There are various baths of chemicals. The electroplating process is done with care because Polyimide is a delicate material, which might swell in the presence of strong alkalis.

Learn more about what is via the hole in PCB?

3) Copper Plating

The PCB requires a certain thickness of copper plating, which acts as the conductive layer. The copper is plated as required by the buyer.

4) Circuit Pattern

Until this stage, the board only has holes; there is no circuitry on it. Now, it is time to generate the circuit pattern. Typically, the board is exposed to UV light. Before exposing the board to the UV light, a photo-resistive film is applied to the board. The film has the required circuit, and when the board is exposed to UV light, a pattern is created on the board. The board is now ready for etching.

5) Etching

The board has the pattern of the circuit. When it goes through the etching process, the copper from the unwanted area is removed, leaving behind the copper on the desired circuit only. A powerful alkaline solution is used carefully with Rigid-Flex PCBs as they are very delicate. The circuit board is dipped into the etching solution, or the solution is sprayed over the board. Usually, in the case of polyimide, an acidic copper chloride etching solution is preferred instead of an alkaline etching solution to prevent swelling.

6) Inspection

The board is almost ready, so it is inspected through various techniques. It goes through AOI (Automated Optical Inspection). In this inspection, there are various cameras at different angles to take the images of the PCB. It detects various errors at the surface of the PCB. It finds out open circuits, solder bridges, solder shorts, and excess or insufficient solder. The test uses statistical values and parameters to compare the board with the ideal one.

7) Solder Mask, Silk Screen, and Surface Finish

These are the three steps that are taken one by one. The solder mask is applied as required. It prevents the shortage and creation of solder bridges. We have various colors of solder masks available, including Green, White, Blue, Black, Red, and Yellow. We also offer peelable solder masks to our customers.

Silkscreen is the labeling of components and symbols on the board through various inks. It helps to understand the placement of components. It can be in any color you want, including white, black, and yellow.

The copper circuit on the board requires protection as it can undergo oxidation. Therefore, a surface finish is applied to protect the circuit. We offer various types of surface finishes according to the requirements of the buyer, such as OSP, HASL, HASL (Lead-free), Immersion Tin, Immersion Silver, ENIG, and Flash Gold.

8) Testing

Testing is the final step before cleaning the PCB and packaging. It requires detailed testing of the performance of the PCBs. There are different types of tests carried out on the PCB to find errors. Typically, the flying probe test is the most common one because it checks various solder pads and nodes to find the shorts and opens. Other types of tests include In-circuit Testing (ICT), AOI, Burn Testing, and X-Ray inspection.

Advanced Learning

Rigid-Flex PCB Fabrication Capability

| PCB Layers | 1-12 Layers |

| Materials | Polyimide, FR4 |

| Board Size | 610X640mm |

| Board Thickness | 0.20 mm – 5.50 mm |

| Copper Thickness | 1/3-30 OZ |

| Min Tracing/Spacing | 2.5mil/2.5mil |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Surface Finish | OSP, HASL, Flash Gold, ENIG, Immersion Tin/Silver |

| Stiffener | PI, FR4, Steel, Aluminum |

Learn more our rigid-flex PCB manufacturing capability

Advanced Features of Rigid-Flex PCB

As the Rigid-flex circuit market continues to expand, there have been many advances in technology, including:

- Pressure Sensitive Adhesives (PSAs)– PSAs with a release liner are used in applications where a portion(s) of the circuit needs to be secured to a specific location within the final product.

- Shielding – Shielding is applied when an application requires limits in electromagnetic and/or electrostatic interference.

- Controlled Impedance – With today’s higher speed requirements, controlled impedance traces are designed to minimize electrical reflections and ensure an error-free transition between the track and interconnections.

- Panelization – Multiple circuits are partially die cut with break out tabs to allow them to remain in the panel for component assembly during the “pick & place” and wave soldering processes.

- Air Gap – At JHYPCB, we are proud to be a leading designer of this air gap technology allowing your designs more flexibility.

Rigid-Flex PCB Material

What is the best material for rigid-flex PCB fabrication?

For the fabrication of Rigid-Flex PCBs, there are various materials required. There are different materials for different purposes. The person ordering the Rigid-Flex PCBs must understand different materials used for the purpose.

1) Conductor

A PCB is made for the reliable conduction of signals between the components. Thus, the main purpose is conduction; therefore, the conductor used in the PCB plays a very important role. There are many conductors of electricity, but for PCBs, the most preferred one is copper. Rolled Annealed Copper and Electro Deposited Copper are used. Silver, aluminum, gold, and iron can also be used, but copper is preferred.

Copper has excellent conductivity, long-life, and optimum reliability. There are issues of corrosion; however, they can be easily dealt with using an excellent surface finish. There is no need to use costly material like gold if there is no exceptional case. The cost of copper is also reasonable, and it offers everything that you are looking for.

If we use Aluminum, the PCB will be of less cost, but it won’t offer the desired performance as copper.

The thickness of copper depends on the buyer. There are different thicknesses for the inner and outer layers. At JHYPCB, we are capable of offering the thickness of the copper layer in the range of 1/3-28OZ and 1/7-28OZ for inner and outer layers, respectively.

2) Base/Insulator

The base/insulator of the rigid and flexible PCBs are different. The flexible part is commonly made of Polyimide (PI) or, sometimes, PET. These are also available from different companies, such as Dupont and Shengyi. For the rigid part, there are many materials; however, FR-4 is commonly used. There can be PTFE (Teflon) or metal. Rigid PCBs can also be made on metallic bases, such as Aluminum and Iron.

3) Surface Finish

Surface Finish is quite important to protect the conductor. It ensures long life and prevents corrosion and blistering. There are different types of surface finishes that are used for different purposes. We offer all kinds of surface finish. The most common surface finishes for Rigid-Flex PCBs are,

- OSP

- HASL

- HASL (Lead-free)

- Immersion Tin

- Immersion Silver

- ENIG

- Flash Gold

You can order any type of surface finish according to your requirements.

4) Adhesives

Adhesives are also available in a wide range, and they are used according to the customer’s needs. The common adhesives used in Rigid-Flex PCBs are,

- Epoxy

- Pre-preg

- Acrylic

- Pressure Sensitive Adhesive (PSA)

Rigid-Flex PCB Prototype Manufacturing Service

The Necessity of Rigid-Flex Prototype

A prototype is necessary before going to mass manufacturing. It eliminates the current errors and allows you to improve the design. There can be dozens of errors in the first stage; therefore, obtaining a PCB prototype service is more than necessary. Otherwise, you might lose your precious time and money. Moreover, if there are errors in the batch production, it will increase the cost and take more time to rectify those errors.

At JHYPCB, we offer Rigid-Flex PCB prototypes. We can also offer assembly prototypes so that you can check everything at your end. You can order even one prototype to save time and money. Once you are sure your prototype is working perfectly well and there are no errors, you can order the mass manufacturing of the PCBs.

Our experts help you in eliminating the errors. We first go through the DFM check to eliminate the errors. Most importantly, our experts understand the industry standards; therefore, they can easily find the problems and help you arrive at the right decision.

Advanced learning

Rigid-Flex PCB Applications

What are the applications of the rigid-flex PCB?

The applications of Rigid-Flex PCB are stretched far and wide. It is used for many purposes, and you might be using dozens of things that could contain Rigid-Flex PCBs.

- Communication: One of the major uses of Rigid-Flex PCBs is communications. From satellites to mobile, these are used prominently. In the communication industry, reliability is quite important, and Rigid-Flex PCB is perfect for it. It can easily handle the complicated structures of mobile phones and other communication devices. These are used in satellites, wireless communications systems, signal processing, servers, and media transmission.

- Automobiles: The automobile industry has adopted the Rigid-Flex PCBs because of their excellent shock absorbing capability and space-saving. These PCBs offer a longer life as compared to normal rigid PCBs, and they offer better reliability even in extreme conditions. The PCBs are commonly used in control modules, LCD displays, entertainment systems, control systems, etc.

- Medical Equipment: Medical equipment also requires Rigid-Flex PCBs because of extreme reliability requirements, flexible design, and space-saving. The PCBs are used in various machines, including ultrasound machines, X-Ray machines, MRI machines, and wireless controllers. These can be found in small and delicate media devices, such as pacemakers and cochlear implants. Rigid-Flex PCBs have the capability to adjust in any type of space and offer better performance.

- Aerospace: Aerospace equipment and technologies require lightweight, long-lasting, reliable, and flexible PCBs. The only type of PCB that can provide all these features is the Rigid-Flex PCB. Moreover, the PCBs for these could use gold as a conducting material instead of copper. The devices include radar, GPS, sensor & detectors, and weather monitoring systems.

- Consumer Electronics: There is a wide range of consumer electronics that require Rigid-Flex PCBs. Your TV, remote, lighting system, kitchen appliances, cameras, alternate energy systems, and dozens of other things have such PCBs. If you have a look inside your home, you can easily find more than a dozen electronic devices that contain Rigid-Flex PCBs.

Rigid-Flex PCB Design Guide

How to design rigid-flex PCB?

The trend of PCB design is to develop towards lightness, thinness, and smallness. In addition to high-density circuit board design, there is also an essential and complicated field such as the three-dimensional connection and assembly of rigid and flexible boards.

PCB design is the first step in the development of all electronic products. Designing any PCB is a three-dimensional design process, especially when designing a rigid-flex PCB board because the physical characteristics of the rigid-flex PCB board require it to have the rigidity of a rigid PCB and the flexibility of a flexible circuit board.

The choice of PCB design software is also very important, and Altium is a good choice. Want to learn more about how to Design a Rigid-Flex circuit in Altium Designer? Please click here. You can also click here to download and read the rigid-flex PCB design guidebook by Altium’s Ben Jordan.

Learn more about Rigid-Flex PCB Stackup

Helpful Resources

Flex-Rigid Circuit Board FAQs

Most frequent questions and answers about rigid-flex PCB

Yes, this is exactly the advantage of Rigid-Flex PCB.

There are a lot of manufacturers that can manufacture rigid-flex PCBs. JHYPCB is a professional rigid-flex PCB manufacturer in China. We can produce 2-8 layers of rigid-flex PCB with both reasonable price and high quality.

PCBs can be divided into many types according to different classification standards. For example, physical hardness can be divided into rigid PCB, flexible PCB, and rigid-flex PCB; according to the number of layers, it can be divided into single-sided PCB, double-layer PCB, and multilayer PCB. To learn more about PCB classification, please click here.

Yes, quick turn PCB prototype and mass production with high quality is our benefits.

Yes, we are known for providing quick turn PCB prototyping and assembly services with no MOQ requirements.

Yes, our rich Rigid-Flex PCB manufacturing experience and state-of-the-art manufacturing technology can provide cost-effective Rigid-Flex board manufacturing services without compromising quality.

The rigid-flex PCB gives you the best of both worlds. A rigid-flex PCB combines flexible circuits’ flexibility with a rigid PCB’s durability. A flexible PCB has only flexible materials, usually polyimide or polyester-based. They can be single-layer, double-layer, or multilayer boards. A rigid-flexible PCB has both flexible and rigid materials, with flexible layers sandwiched between rigid layers with conductors and plated through holes connecting them to the other layers.

Flexible PCBs alone may not stand up to the wear of specific challenging applications, but standard rigid PCBs tend to be heavy and take up a lot of space. Combining rigid PCB boards with flexible PCBs reduces weight and space, giving you a streamlined product you can use in various industrial situations.

China Rigid-Flex PCB Supplier

Fulfill your Requirements with our Rigid-Flex PCB Manufacturing Service

JHYPCB is providing a complete range of PCB services for more than 10 years. Our large facility is based in China. We have an advanced and latest PCB fabrication, testing, and assembling system. You can order all types of PCBs, assemblies, stencils, and everything, including the Rigid-Flex PCB assembly.

Our experts and quality team will ensure error-free and high-performing PCBs at a low cost. Our strict quality management system is ISO, UL, and RoHS certified. We can handle small-large volume PCBs without any restriction on the minimum order. You can also order one Rigid-Flex PCB. We also make Rigid-Flex PCB prototypes and quick-turn assemblies. We have all solutions available under one roof.

For more information and details, feel free to contact us any time. Our 24/7 support team and experts will help you out.