PCBs - The Backbone of Modern Electronics

In our rapidly evolving digital world, printed circuit boards form the very backbone of virtually every electronic device we use daily. From smartphones and computers to home appliances and industrial equipment, these intricate boards are integral to their functionality.

As PCB manufacturers, we at JHYPCB understand the criticality of choosing the right PCB material for your application’s unique requirements. Two materials that often come into consideration are aluminum and FR4 (flame resistant 4) – each with its own distinct advantages and tradeoffs.

Aluminum PCBs have emerged as a popular choice, particularly for applications demanding superior thermal management and mechanical robustness. Their metal core dissipates heat far more efficiently compared to traditional FR4 laminates. This thermal advantage makes aluminum PCBs ideal for LED lighting, power electronics, and other high heat-generating applications.

On the other hand, FR4 PCBs have been the industry workhorse for decades. Their proven manufacturing processes, multi-layer capabilities, and cost-effectiveness continue to make them a versatile solution for consumer electronics, telecommunications, and countless other applications where thermal management is less critical.

As PCB design complexity increases and performance demands intensify, understanding the strengths and limitations of aluminum vs FR4 PCBs becomes paramount. This comprehensive guide aims to equip you with the knowledge to make an informed decision tailored to your unique project needs.

Diving Deep: Aluminum PCBs vs FR4 PCBs

While both aluminum and FR4 PCBs serve as substrates for mounting electronic components, their material properties and construction differ significantly. Let’s explore the critical distinctions between these two PCB types:

- Thermal Management

One of aluminum’s standout advantages is its exceptional thermal conductivity – around 600 times greater than FR4. This inherent property allows aluminum PCBs to rapidly dissipate heat, making them ideal for applications generating substantial thermal loads like LED lighting, motor controllers, and power converters. FR4’s poor heat dissipation can limit its use in such high temperature environments. - Coefficient of Thermal Expansion (CTE)

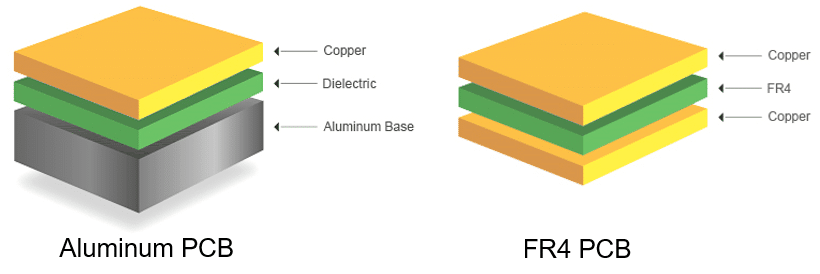

CTE mismatches between PCB layers can lead to failures like delamination, cracks, or broken conductor traces when subjected to thermal cycling. FR4’s high CTE of 12-24 ppm/°C, especially through the thickness, poses reliability risks as it differs greatly from copper’s 17 ppm/°C CTE. Aluminum’s CTE of around 24 ppm/°C more closely matches copper, reducing thermal stress issues. - Layer Construction

FR4 PCBs offer design flexibility with single, double, or multi-layered options. In contrast, aluminum PCBs employ a tri-layer construction – an aluminum core sandwiched between a copper foil layer and a dielectric layer. While limiting vertical integration, this rugged aluminum composite excels in high temperature applications. - Mechanical Strength and Rigidity

Thanks to their metal core, aluminum PCBs exhibit superior mechanical strength and rigidity over FR4 counterparts. This robustness allows larger PCB dimensions and higher component density, suiting applications like telecoms, industrial controls, and automotive electronics. - Board Thickness

While FR4 PCBs can achieve greater thicknesses by adding layers, aluminum PCBs are inherently restricted by their tri-layer configuration, typically ranging from 0.8mm to 4mm thick. The aluminum core itself contributes significantly to overall board thickness. - Dielectric Properties

FR4’s ceramic reinforced polymer construction gives it excellent dielectric properties with a low dissipation factor around 0.02 at 1MHz. Aluminum PCBs employ specialized dielectric layers like polyimide or aluminum oxide depending on frequency requirements.

Aluminum PCBs - Exploring the Pros and Cons

While aluminum PCBs offer compelling benefits over FR4 in certain applications, it’s essential to understand their strengths and limitations to make an informed decision. Let’s dive into the key pros and cons:

Advantages of Aluminum PCBs

- Thermal Management Powerhouse

Unparalleled thermal conductivity makes aluminum PCBs the go-to choice for dissipating high heat loads. The metal substrate efficiently transfers heat, preventing hot spots and increasing product reliability. - Mechanically Robust

The aluminum core provides exceptional strength and rigidity. This allows larger PCBs with increased component density without sacrificing structural integrity – ideal for harsh environments. - Reliable Thermal Matching

With a CTE close to copper, aluminum PCBs experience minimal thermal stress during temperature cycling, reducing risks like trace cracking, delamination, and solder joint failures. - Extended Operating Temperatures

The inherent heat dissipation capabilities enable aluminum PCBs to operate reliably at extreme temperatures up to 200°C, suiting high heat flux applications like downhole drilling electronics.

Disadvantages of Aluminum PCBs

- Higher Cost

Aluminum PCBs demand specialized manufacturing processes and materials, making them more expensive than conventional FR4 counterparts, especially for prototyping and low volumes. - Limited Thickness Options

The tri-layer aluminum composite construction restricts maximum thicknesses typically between 0.8mm to 4mm, limiting high-density vertical integration. - Galvanic Corrosion Susceptibility

Direct contact between aluminum and copper risks galvanic corrosion. Dielectric coatings and design strategies to isolate metals are essential. - Specialized PCB Design Rules

Aluminum’s higher CTE requires tailored PCB design rules like wider conductors and anti-pad sizes to accommodate thermal expansion and prevent short circuits.

FR4 PCBs - Tried and Tested Workhorses

For decades, FR4 glass-reinforced epoxy laminate has been the trusted workhorse material for the majority of PCB applications. Its wide adoption is backed by a compelling set of advantages along with some inherent limitations. Let’s explore them in detail:

Advantages of FR4 PCBs

- Cost-Effectiveness

FR4’s mature and established manufacturing processes, along with readily available raw materials, make it one of the most cost-effective PCB solutions – particularly for high-volume production runs. - Design Flexibility

With support for single, double and multi-layered configurations, FR4 PCBs offer tremendous design flexibility to meet diverse routing densities and vertical integration needs. - Wide Thickness Range

Unbounded by restrictive construction methods, FR4 PCBs can be manufactured across a wide range of thicknesses from ultra-thin (0.2mm) to very thick (>5mm) by adding layers. - Excellent High-Frequency Performance

The inherent low loss and stable dielectric properties of FR4 allow it to reliably handle high-frequency signals up to the gigahertz range for applications like RF/wireless communications.

Disadvantages of FR4 PCBs

- Poor Thermal Dissipation

The relatively low thermal conductivity of FR4 (0.3 W/m.K) poses challenges for high-power applications, risking component performance degradation or failures due to overheating. - Coefficient of Thermal Expansion Mismatch

FR4’s substantially higher CTE compared to copper conductors increases risks like trace cracking, barrel fatigue and delamination under thermal cycling, compromising long-term reliability. - Moisture Absorption

While advances have been made, FR4’s hygroscopic nature can lead to moisture absorption and consequent electrical property shifts if not properly protected. - Maximum Temperature Limitations

The glass transition temperature of standard FR4 (around 130-180°C) limits its suitability for very high temperature applications common in automotive, aerospace and industrial domains.

Navigating the Application Landscape

With a clear understanding of the pros and cons of aluminum PCBs and FR4 PCBs, it becomes easier to determine which material best aligns with the unique requirements of your application. Let’s explore some prominent use cases for each:

Where Aluminum PCBs Shine

- LED Lighting Systems

The high heat fluxes generated by high-power LED arrays necessitate superior thermal management – a key strength of aluminum PCBs. Their efficient heat dissipation prevents premature lumen degradation and color shifts. - Power Electronics

Switch-mode power supplies, inverters, and converters generate substantial heat loads. Aluminum PCBs’ ability to handle high temperatures reliably makes them ideal for power semiconductor applications. - Automotive & Aerospace Electronics

With an operating temperature range of -55°C to 200°C, aluminum PCBs enable reliable performance in the extreme environments of automotive underhood, aerospace avionics, and downhole drilling electronics. - Industrial Automation & Controls

The mechanical robustness of aluminum PCBs suits industrial applications prone to vibrations, shocks, and high g-forces like CNC machines, robotics, and industrial motor drives. - Telecom Infrastructure

Handling high component densities with effective thermal management, aluminum PCBs find use in outdoor telecom cabinets, 5G network equipment, and high-frequency microwave systems.

When FR4 PCBs are the Right Fit

- Consumer Electronics

With their cost-effectiveness, FR4 PCBs dominate lower-power consumer devices like smartphones, laptops, TVs and home appliances where thermal challenges are minimal. - Computing Hardware

FR4’s excellent high-speed signal integrity facilitates its use in motherboards, graphics cards, memory modules and other high-performance computing hardware. - Internet of Things (IoT) Devices

The compact, low-power nature and ubiquity of IoT devices like sensors and wearables makes cost-effective FR4 PCBs the ideal substrate choice. - RF/Wireless Communications

FR4’s stable electrical properties up to multi-gigahertz frequencies enable its use in RF signal chains for cellular base stations, WiFi/Bluetooth modules and IoT radios. - Low to Mid-Range Industrial Controls

For industrial applications with modest power levels and temperatures within FR4’s capabilities, its combination of performance and affordability offers compelling value.

Making the Right PCB Material Choice

With a thorough understanding of how aluminum and FR4 PCBs compare across thermal, mechanical, electrical and cost parameters, along with their typical application fit, the next step is to carefully evaluate your specific product requirements. Several critical factors should guide your PCB material selection:

- Operating Temperature Range

This is often the primary deciding criteria. If your application involves high temperatures exceeding 125-150°C, aluminum PCBs become an necessity to ensure reliable long-term operation. FR4’s glass transition limits its maximum temperature range. - Power Dissipation Needs

Products generating high heat fluxes mandate the superior thermal dissipation of aluminum PCBs to prevent hot spots, thermal issues and failures. Estimate your power levels and heat dissipation needs. - Mechanical Loads & Vibrations

For harsh-environment applications subjected to mechanical shocks, vibrations or high G-forces, the exceptional rigidity and strength of aluminum PCBs offer a rugged solution over FR4. - Operating Frequency Range

While aluminum PCBs support RF/microwave frequencies, their performance can degrade at higher frequencies. FR4’s stable electrical properties make it ideal for multi-gigahertz applications. - Form Factor Constraints

Aluminum’s tri-layer construction limits maximum thicknesses, so high-density integration requiring thicker boards may necessitate an FR4 solution despite its thermal tradeoffs. - Cost Considerations

For lower volume, prototyping or cost-sensitive applications where thermal issues are manageable, FR4’s cost-effectiveness may outweigh aluminum PCBs’ performance benefits. - Environmental Factors

Sustained humidity or moisture exposure can degrade FR4’s electrical properties. For harsh environments, aluminum PCBs provide better resistance.

Peering into the Future: Emerging Trends and Prospects

As electronics continue rapidly evolving with increasing performance demands, thermal challenges, and new application frontiers, both aluminum and FR4 PCBs are witnessing continuous advancements and competing alternatives. Let’s explore the key trends shaping the future landscape:

- Aluminum PCBs: Rising Adoption Across Diverse Sectors

With their exceptional thermal capabilities, aluminum PCBs are seeing a surge in adoption across power electronics, automotive electronics, LED lighting, 5G infrastructure and more. Increasing electrification and power density are key drivers. Ongoing research focuses on developing lower-cost aluminum PCB manufacturing processes to drive higher volumes. - Emerging Alternatives: Metal-Core and Ceramic PCBs

While offering thermal performance similar to aluminum PCBs, metal-core PCBs using copper or copper-invar-copper cores can provide higher operating frequencies and reliability. However, their costs are even higher than aluminum. Ceramic PCBs like aluminum nitride (AlN) and beryllium oxide (BeO) push thermal capabilities further but with extremely high prices. - Advanced Thermal Interface Materials

Innovative thermal interface materials like thermally conductive adhesives, gap fillers and phase-change materials are enhancing heat transfer between components and metal-core PCBs. This improves thermal performance while providing electrical isolation and mechanical stability. - Higher Frequency and Speed Challenges

As digital signals extend into millimeter-wave frequencies for 5G/6G and beyond, the electrical performance limitations of conventional PCB laminates like FR4 become pronounced. This is driving adoption of radio-frequency PCB materials optimized for low loss and stable dielectric properties at high frequencies. - FR4 PCB Innovations and Enhanced Variants

While basic FR4 remains cost-effective, enhanced FR4 variants with improved thermal conductivity, lower loss tangents and higher glass transition temperatures are emerging. These extend FR4’s capabilities while preserving its manufacturing economies of scale. - Environmental Sustainability Push

With increasing environmental consciousness, pressure is mounting for developing more eco-friendly and recyclable PCB laminates. Alternative reinforcement fibers and bio-sourced resins aim to reduce ecological footprints over conventional glass-epoxy FR4.

In Conclusion

The choice between aluminum PCBs and FR4 PCBs significantly impacts product performance, reliability, and costs. By thoroughly understanding their distinct thermal, mechanical, electrical, and manufacturing characteristics, you can optimally align the PCB material to your application’s unique demands.

Aluminum PCBs excel in thermally-challenging scenarios like LED lighting, power electronics, automotive underhood, and telecom infrastructure where effective heat dissipation is paramount. Their superior mechanical robustness also suits harsh industrial environments. However, their higher costs and inherent thickness limitations must be considered.

FR4 PCBs remain the industry workhorse, offering proven cost-effectiveness along with excellent high-frequency capabilities. They continue dominating consumer electronics, computing hardware, RF/wireless communications and industrial controls where thermal constraints are manageable.

As emerging trends like 5G/6G, electrification and power densification intensify thermal management needs, innovative PCB materials like metal-cores and ceramics are gaining traction despite higher prices. Sustainability is also a growing priority driving eco-friendly PCB developments.

At JHYPCB, we stay ahead of the curve, offering comprehensive PCB prototyping and manufacturing services. Our portfolio spans multi-layer FR4 PCBs, aluminum PCBs, metal-core PCBs, ceramic PCBs – enabling you to select the optimal material solution for your application.

Leverage our expertise to navigate this complex landscape and bring your cutting-edge product designs to life with supreme quality, reliability, and a keen focus on your success.

Related Posts

- Choosing the Right Metal Core PCB Manufacturer is Critical to Your Success

- Single-layer PCB vs. Double-sided PCB: How to Choose?

- Unveil the mystery of high TG PCB circuit boards Materials

- Why is FR4 Used to Make High Tg PCBs?

- Introduction to Aluminum PCB Manufacturing Process

- What Is Rogers Material PCB?

- Choosing the Right PCB Material for Your Prototype: A Comprehensive Guide