Everything You Need to Know about Multilayer Flexible PCB

JHYPCB is a leading flexible PCB manufacturer in China.

Home » PCB Manufacturing » Flexible PCB » Multilayer Flexible PCB

JHYPCB can provide you with one-stop single-sided flexible PCB, double-sided flexible PCB, and multilayer flexible PCB manufacturing and assembly services.

- We have more than 10 years of flexible PCB manufacturing experience;

- We can provide you with 1-16 layer flexible circuit board manufacturing service;

- All the flexible circuit boards we produce meet the IPC level 2 or 3 standards;

- We can provide fast turn multilayer flexible PCB prototype manufacturing services;

- We have advanced multilayer flexible PCB production equipment;

- The thickness of the multilayer FPC is 0.04-2.5mm, and the copper thickness is 1/3oz-2oz, 6oz;

- We provide the most cost-effective services to meet your project budget;

- We provide 7*24 hours of sales, technical, and after-sales service support.

What is A Multilayer Flexible PCB?

Multilayer flexible PCB is a printed circuit board with multiple circuitry layers. Multilayer flexible PCB uses PI or PET as the substrate. Like rigid multilayer PCBs, multilayer laminate technology makes multilayer FPC. The simplest multilayer flexible PCB is a three-layer flexible PCB formed by covering two copper shielding layers on both sides of a single-sided flexible PCB. This three-layer flexible PCB is equivalent to a coaxial wire or shielded to a wire in electrical performance. The most commonly used multilayer flexible PCB structure is a four-layer structure, which uses metalized holes to realize interlayer interconnection. The middle two layers are generally the power layer and the ground layer.

The advantage of multilayer flexible PCB is that the base film is light and has excellent electrical properties, such as low dielectric constant. The multilayer flexible PCB made of polyimide film as the base material is about 1/3 lighter than the rigid epoxy glass cloth multilayer PCB.

Recommended Reading

- Find Out Now, What Should You Do For Fast PCB Classification?

- What is a Multilayer PCB and What are the Advantages?

- Quality Control of Engineering Data for Multilayer PCB

- Single-Sided Vs. Double-Sided PCB

- Development and Applications of FPC Flexible PCB

- Rigid PCB vs Flex PCB: What Is The Difference?

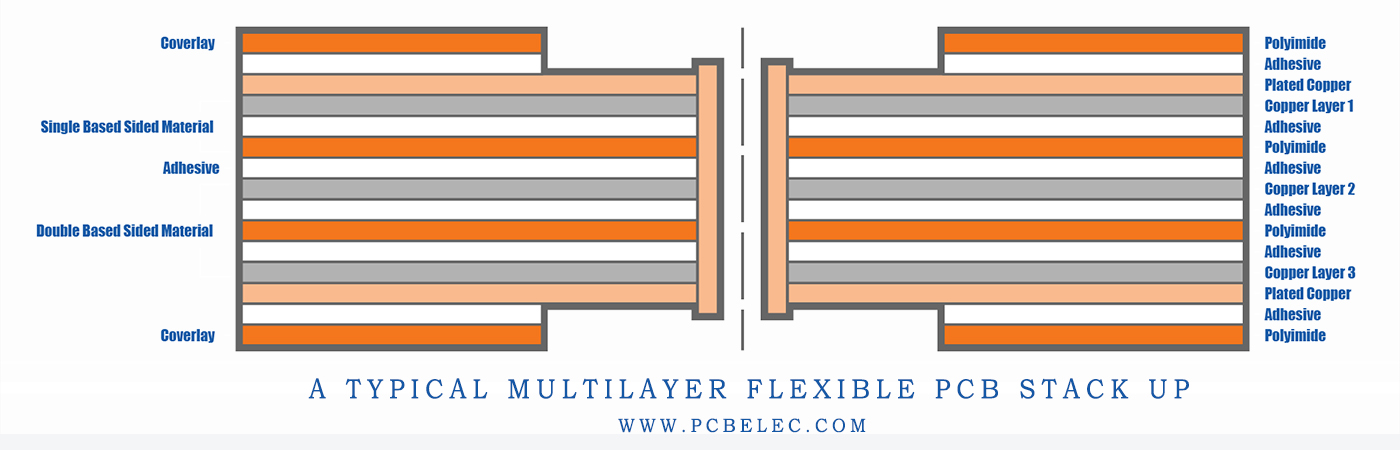

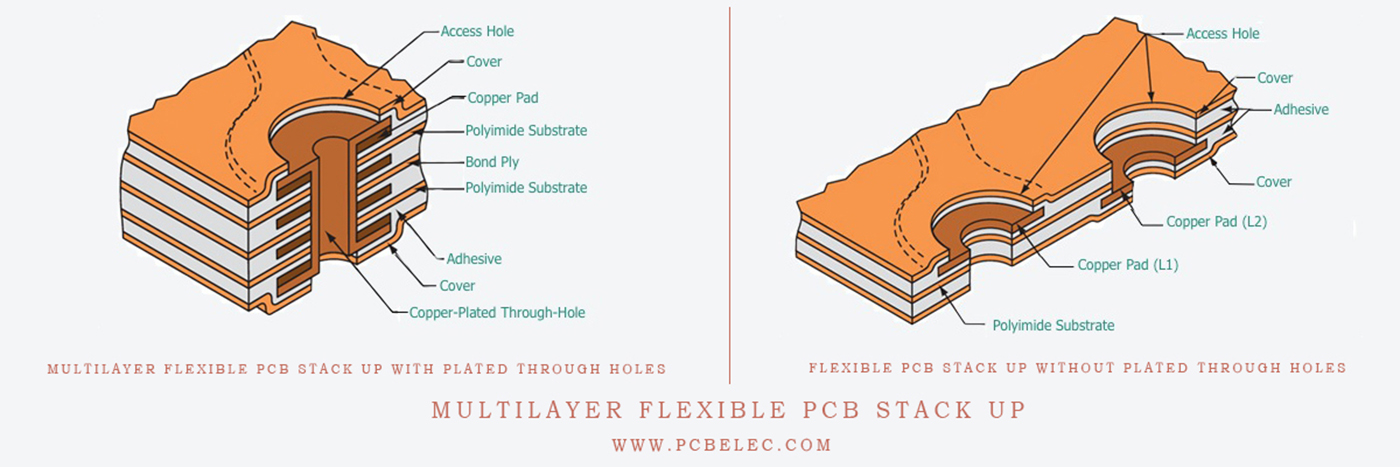

What is the stack up or structure of a multilayer flexible PCB?

The multilayer flexible PCB is composed of “multiple single-sided copper-clad laminates (CCL) + adhesive + coverlay (CVL)” pressed together, and the wires of each layer are connected through the PTH hole. Due to many layers, multilayer flex PCB flexibility is worse than single-sided flexible PCB and double-sided flexible PCB.

What are the materials used to manufacture multilayer flexible PCBs?

The primary raw materials for making multilayer flexible PCB are base material, cover film, reinforcing material, and other auxiliary materials.

- Substrate

Substrates for multi-layer flexible PCBs are divided into glue-free and glue-free substrates.

Adhesive substrate: The adhesive base material is mainly composed of copper foil, adhesive, and PI. Adhesive substrates can be divided into single-sided adhesive substrates and double-sided adhesive substrates.

Adhesive-free substrate: Adhesive-free substrate is the substrate without an adhesive layer. Adhesive-free substrates are thinner, have better dimensional stability, higher heat resistance, higher bending resistance, better chemical resistance, etc., so it has been widely used now.

- Cover Film

The cover film comprises three parts: release paper, adhesive, and PI; the only remaining parts on the flexible circuit board are adhesive and PI. The release paper will be peeled off during the production process.

- Reinforcing materials

The reinforcing material is material unique to the flexible PCB. Reinforcing material is used in a specific part of the flexible circuit board to enhance the supporting strength of that part of the flexible circuit, thereby making up for the “flexible” characteristic of FPC.

Currently commonly used reinforcement materials are FR4, steel sheet, PI and aluminum sheet, etc.

- Other auxiliary materials

Other auxiliary materials used for multi-layer flexible PCBs include adhesives (pure glue, mainly used for soft and hard bonding boards and bonding FR-4 or steel sheet reinforcement materials to play a bonding role), electromagnetic protective film, pure Copper foil (mainly used in the production of hollow flexible PCB).

Recommended Reading

Multi-layer flexible PCB laminate materials and brand options

Below we list the multi-layer flexible materials and brands to choose from

Brand | Laminate Materials | Brand | Laminate Materials |

| Isola | FR406 | Isola | FR408 HR |

| Isola | P95/96 | Isola | 370HR |

| Iteq | IT180 | Panasonic | R1766 |

| Panasonic | R1755 | Panasonic | Megtron |

| Nelco | N4000-13 | Nelco | N4000-29 |

| Nelco | BT N5000 | Nelco | N7000-2 |

Multilayer flexible PCB production process

As a flexible PCB manufacturer with rich experience, JHYPCB can provide you with 1-16 layer flexible PCB manufacturing services.

Related Reading

- Flexible PCB Fabrication Capability

- Knowledge of Flexible Printed Circuit Board Processing Technology

- Knowledge of Plating on Flexible Circuit Board Surface

- Complete Introduction To Flexible PCB Assembly Process

- Double-Sided PCB Manufacturing Process

- Introduction to aluminum PCB manufacturing process

- Key Process Flow of Rigid-Fled PCB Production

Multilayer flexible PCB surface finishes options

Since copper is easily oxidized in the air, the purpose of PCB surface finish is to prevent the oxidation of copper and ensure good solderability and electrical properties on the surface of the PCB pad.

PCB surface finish options are HASL (Vertical or Horizontal), Lead-Free HASL, OSP, Electrolytic Soft Gold, Electrolytic Hard Gold, Selective Gold, Immersion Gold, Immersion silver, Immersion thin, etc. For the surface treatment process of multilayer flexible PCB, we recommend Electrolytic Soft Gold, Electrolytic Hard Gold, or Selective Gold.

What are the advantages of multilayer flexible PCB?

Multilayer flexible PCBs offer several benefits that make them an ever-increasingly popular choice for engineers. Here, we will take a closer look at some of these best benefits.

- Higher performance and reliability

Multilayer flexible PCBs offer higher performance and reliability than traditional rigid PCBs. Multilayer flexible PCBs are often the preferred choice for high-end applications that require extreme performance and reliability.

The increased flexibility of multilayer flexible PCBs allows them to withstand better stress and vibration, which can often cause damage to traditional rigid PCBs. Additionally, multiple layers allow for more efficient routing of signals and power, resulting in improved performance and reliability.

- Reduced weight and size

Multilayer flexible PCBs are also significantly lighter and smaller than traditional rigid PCBs, which can be helpful in applications where the size and weight of the PCB significantly impact performance or efficiency, i.e., drones or aircraft.

The multilayer construction of a flexible PCB also allows for more efficient use of space, which can be crucial in smaller applications or those with limited room.

- Increased signal frequency and bandwidth

Multilayer flexible PCBs also offer increased signal frequency and bandwidth, important in high-speed applications or high data volume.

Higher frequency signals can be routed on multilayer flexible PCBs more effectively than traditional rigid PCBs due to multiple layers and advanced materials, such as high-speed signal routing systems.

- Improved power efficiency

Another benefit that multilayer flexible PCBs offer is improved power efficiency.

Because multilayer flexible PCBs are more efficient at routing power, they can help improve power efficiency, which can be important for applications requiring long battery life.

- Improved environmental compliance

The multilayer design of a flexible PCB can also help to improve environmental compliance.

By using multiple layers, a multilayer flexible PCB can route signals and power more effectively, which can help to reduce the amount of radiation and electromagnetic interference emitted from the PCB.

What are the disadvantages of multilayer flexible PCB?

- High cost

Since the multilayer flexible PCB is designed and manufactured for special applications, the cost of circuit design and wiring from the beginning is relatively high. Therefore, except for special applications, high-multilayer flexible PCBs are rarely used.

- The size of the finished product is restricted

The production of multi-layer PCB is limited by the size of its production equipment, and it cannot be made very long or very wide.

- Low yield rate

Due to the difficulty of manufacturing multi-layer flexible PCBs, the scrap rate of finished products is also high, which virtually increases the price of flexible PCBs.

- Improper assembly can easily cause circuit damage

Improper operation of the assembly personnel can easily cause damage to the flexible circuit, and its soldering and rework require professional operations.

What are the applications of multilayer flexible PCB?

Multilayer flexible PCBs have many applications. Some of the most common include:

- Consumer electronic devices

Smartphones, e-readers, tablet PCs, and GPS units are a few of the many consumer electronics products that often use multilayer flexible PCBs. Multilayer flexible circuits are also found in high-end printers, desktop computers, laptops, and digital cameras.

- Industrial equipment

Multilayer flexible PCBs are used extensively in industrial equipment. This includes medical devices, power generation equipment, factory automation hardware, and traffic control equipment.

- Automotive components

From HVsAC to infotainment systems, flexible multilayer circuits are found in many automotive components.

- Military/Aerospace products

The military and aerospace industries often rely on flexible multilayer circuits. They can be found in various products, from communication equipment to wearable electronics and avionics systems.

- Other applications

Multilayer flexible circuits are also used to construct industrial machinery, robotics, buoys, and renewable energy products.

Since multilayer flexible PCBs can be used in a wide range of products, many manufacturers have begun to offer multilayer flexible PCB assemblies. This saves you time and money because the boards are assembled when they arrive at your facility.