SMD LED PCB Board Assembly, LED Light Circuit Board Assembly Service

Full Turnkey LED PCB Board Manufacturing and Assembly Services in China

Home » PCB Assembly » LED PCB Assembly

LED PCB assembly has transformed the world of lighting. Nowadays, you will find LED PCBs wherever lighting is required. It is preferred as compared to other lighting technologies. The technology is evolving day by day with the increasing demand for LED Light Circuit Board Assembly.

The LED industry has had a significant impact on the demand after introducing a better-LED circuit board Assembly. Now, the LED PCB assemblies are more durable, long-lasting, and high-performing. LED lighting is preferred over traditional fluorescent lamps and incandescent lamps.

At first, LED lighting was not that popular because of the higher heat dissipation requirement. Due to high temperatures, the PCB could not last for a long time, and the LEDs were also affected due to high temperatures. But due to metal core PCBs, heat dissipation is not a problem anymore. Metalcore PCBs, such as Aluminum and Copper, can efficiently dissipate heat and reduce the temperature of the board. They can dissipate heat without heat sinks. Typically, you will find Aluminum PCBs for LED because of their low cost and excellent performance.

Learn more about Aluminum PCB Vs. Fr4 PCB, How to Choose? and The difference between aluminum substrate and FR-4 sheet

LED Circuit Board Assembly Service

Turnkey LED PCB Board Assembly

LED Strip Lighting PCB Assembly

LED Aluminum Base PCB Assembly

Metal Core PCB

SMD LED PCB Assembly Machine

What is an LED?

LED stands for Light Emitting Diode. A diode is a semiconductor device, but it emits light when current passes through it. Due to its light-emitting feature, it is known as LED. This special device emits light in the visible range so that it can be used for lighting. It can illuminate any place.

Nowadays, LEDs are used in almost every industry and sector. They are used for lighting and indications purposes. The LED industry is at its peak because of its complete applications.

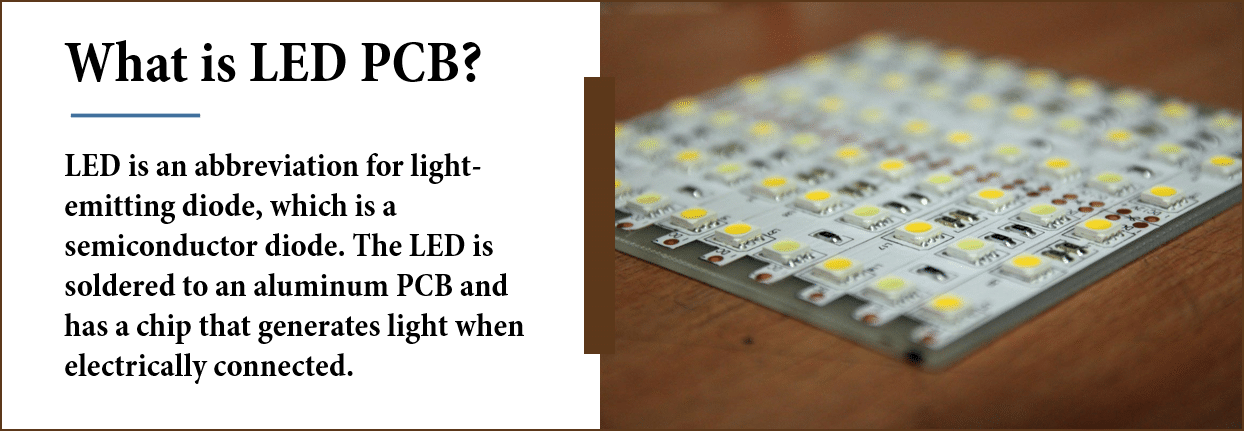

What is LED PCB?

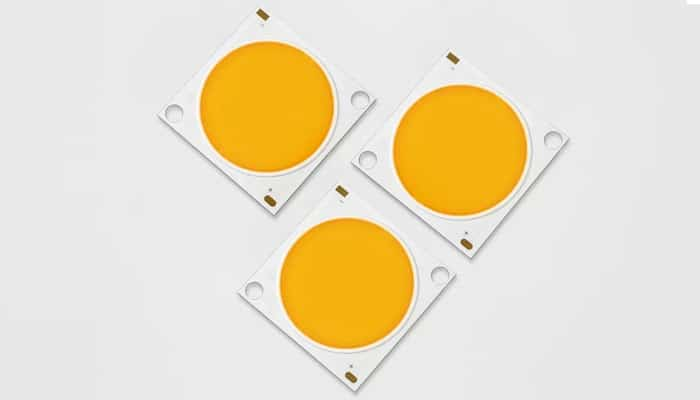

What is an LED PCB? LED PCB is a type of printed circuit board used in the production of specific LED lighting fixtures. High-power LEDs generate a lot of heat during operation, and aluminum is a high thermal conductivity material with excellent thermal conductivity. Therefore, LED PCBs often use aluminum as their substrate material. LED PCB is a kind of printed circuit board on which the circuit is printed on the aluminum plane with good thermal conductivity, and then the electronic components are soldered on it.

The main factors affecting the quality of LED PCB are the aluminum model, hardness, surface treatment, thickness, etc., and suitable specifications should also be selected according to the heat generation of the product.

What is LED PCB Assembly?

A PCB with all the components installed is known as PCB Assembly. If the assembly is for LED lighting, then it is referred to as an LED PCB assembly. In an LED PCB Assembly, there are several LEDs as required and some other components. The assembly is usually made of aluminum to dissipate heat at a faster rate. It is durable and rigid. It can bear wear and tear and work for a long time. There can be any shape of assembly as required by the buyer. Commonly, you will find LED PCB strips, and circular and rectangular boards.

An LED PCB assembly service means the fabrication of a PCB and the installation of components on it. It is a long process that includes every step. A turnkey PCB assembly service is a service in which everything is the responsibility of the contract manufacturer. From the procurement of components to the LED PCB assembly testing, everything is the manufacturer’s responsibility.

At JHYPCB, we provide full turnkey PCB assembly services. We can also provide quick-turn prototypes PCB assembly service.

Why Choose us

LED PCB Assembly Manufacturer

Your Leading LED PCB Assembly Supplier in China

As a leading LED PCB fabrication and assembly manufacturer with experienced in China, JHYPCB assures the fastest turnaround times on all LED PCBs manufacturing and assembly.

Turnkey Service

- LED circuit board manufacturing

- LED components sourcing

- Free DFA and DFT check

- 100% original LED chip

- 100% Testing - Flying probe, function testing

- Quality control system - X-ray, AOI, FAI

- LED PCB assembly service

Capabilities

- Prototype assembly service

- Mass production

- No MOQ

- Competitive price

- 24 hours fast LED PCB assembly expedite services

- LED PCB assembly up to 1.8 meter long

Why LEDs and LED PCB Assemblies?

LED has almost eliminated the use of other lighting technologies, and there are many reasons behind it.

LEDs are very compact, and they take a little space. They can be used in a small space where it is difficult to place an incandescent bulb. LEDs can be easily integrated into complex PCBAs because of their small size.

LED PCB assemblies are very compact, and any kind of design can be easily achieved by placing multiple LEDs as desired. There is design flexibility in LED PCB assemblies.

LEDs are long-lasting as compared to fluorescent and incandescent light. They work approximately 25 times longer than other technologies. Therefore, LED is preferred because you don’t need to replace it frequently. Consequently, it saves money. The LED PCB assembly is the reason that makes it long-lasting because it dissipates the heat effectively.

LED lights are more efficient because they do not need to heat up to produce light. They produce light when current passes through them. This is the reason there is a minimum loss of energy in terms of heat. Only 5% of the energy is wasted, and the rest is converted to light. Thus, LEDs consume less energy and can give the same level of light. You can save up to 90% of the energy as compared to other lighting technologies. In short, your energy bill will be greatly reduced if you shift to LED technology.

LED is the most environmentally friendly option that does not harm the environment in any way. Other technologies have mercury and other toxic substances that are dangerous. There is no toxic substance in the manufacturing of the LED PCB Assembly. So, it is safe for the environment.

LEDs can easily work on low voltages. They are better for indoor lighting. They are under less voltage stress. They are much safer, even in the case of any problems.

LED PCB Assemblies can work in every environment, whether it is cold or hot. The assembly is made for versatile applications and can even bear extreme ambient temperatures.

LED Circuit Board Assembly Process

LED PCB Assembly is very similar to other PCB assemblies in the manufacturing process. It involves various steps.

First, the customer places an order after discussing the requirements of the PCB assembly. He provides all the required files and documents, such as Gerber files and BOM. After that, Design for Manufacturability (DFM) is carried out. It is necessary to make the process feasible. At JHYPCB, our experts check the files provided by the buyer and check for any problems. We make sure everything is perfect before starting the process.

Components are placed on the board, so it is necessary to fabricate the PCB in the first step. For the LED PCB Assembly, the PCB is made of Aluminum. Aluminum is an excellent material to offer durability and heat dissipation. In an Aluminum PCB, there are three layers. The first layer of the PCB is the copper layer for electrical connections. The second layer is of a dielectric material, which is responsible for transferring the heat produced by LEDs. The last layer is the Aluminum base layer.

The PCB is fabricated according to the requirements of the buyer.

The components required on the PCB are ordered from different vendors. This step takes time and can take 3-5 days, depending on the components required. The components are ordered according to the BOM list. SMD LEDs, resistors, and other required components are bought.

Solder paste is applied to connect the components with the board. At first, the paste is applied to the bare PCB using a stencil. The stencil helps in applying the paste to the places where it is required. The paste is applied with a wiper. The wiper applies the paste and removes the excess paste. The application of solder paste is for placing and soldering the SMDs.

As the paste on the PCB is applied, it is time to place the components. Components placement is an automated process that is done with a machine. The instructions are given to the machine using a file. The file contains the XY coordinates of the PCB and rotation. It is also known as Pick and Place file. The machine places the components according to the instructions. At this step, the components are only placed at the desired place; they are not soldered.

The PCB is passed through a reflow oven in the next step. Due to heat in the oven, the applied solder melts and forms a connection of the components with the board. After melting, the board is hot, so it is cooled before coming out of the oven.

Reflow soldering is for SMDs. If there are through-hole components, then they are soldered manually. If the PCB is one-sided, then wave soldering can also be helpful and quick. In wave soldering, molten solder is applied at the bottom of the PCB.

Advanced Learning

What is the difference between wave soldering and reflow soldering?

There can be many problems with the PCB after soldering. There can be any short circuit, missing joint, or any other problem that needs to be addressed. Inspection is an important step to ensure the performance of the LED PCB assembly. It is done manually in the first step. After that, the AOI (Automatic Optical Inspection) can detect faults. There are various cameras at different angles to take pictures of the PCB assembly. AOI is a quick process that thoroughly analyses and detects the problems.

X-ray inspection is an advanced inspection method, which is better than AOI. It has the capability to observe connections under the components. The rays are passed through the PCB assembly and create an image after reflection. The images are then analyzed using image processing methods.

Even if everything is up to mark in the final inspection, the results provided by the PCB are not guaranteed. To ensure the proper operation and expected results, the LED PCB assembly goes through a final test. It is tested through various methods, for example, flying probe test, functionality test, and reliability test.

Why are SMD LEDs preferred in LED PCB Assembly?

SMD components are very compact, and they can be easily placed on the board and soldered through reflow soldering. The process is simple and takes less time. SMD LEDs are much smaller than through-hole LEDs. They offer flexibility in designing the LED PCB assembly.

Although SMD LEDs are compact, they provide considerable lumen output, which is the reason they are preferred. Moreover, they consume less energy. These LEDs have three colors (Red, Green, and Blue), so any color can be achieved by the combination.

In SMD LEDs, there are small connectors on both ends of the device. These connectors can be used to join the component to the board.

Advanced Learning: What is the difference between SMT and SMD?

5050 LED PCB Assembly

5050 LED is a type of SMD LEDs. The size of these LEDs is 50mm x 50mm, which is the reason for their name. It can provide around 1000 lumens per meter. These LEDs contain three to four chips in a single package to offer different colors. If there are three chips, then the SMD can provide three colors: Red, Green, and Blue. Four chips are for Red, Green, Blue, and White. The LEDs have RGB color characteristics to obtain any color through combination.

Due to different colors, these LEDs are preferred for colorful lighting. These are used to make colorful stripes that can be used for decoration and lighting. 5050 LED PCB assembly remains in demand.

LED PCB Assembly Guide

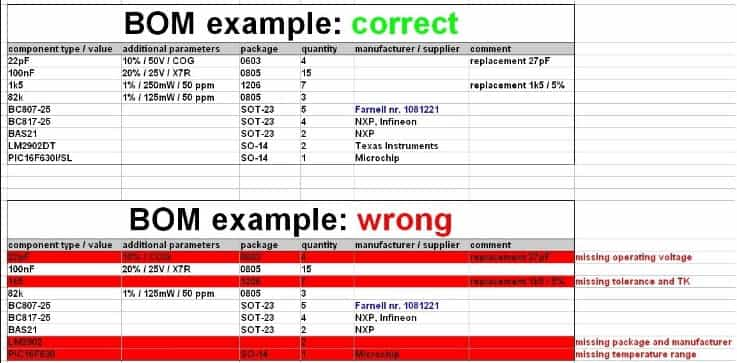

1. BOM For LED PCB Assembly

What is the BOM? BOM is the abbreviation of the bill of material, and it is one of the most critical data used in the entire electronic assembly process.

The BOM is generated by PCB design software, and it contains a list of all materials needed for PCB assembly.

The perfect BOM table records the basic information about electronic components in detail so that PCB assembly service providers can collect all the elements that meet the requirements.

BOM is very important, and no errors are allowed because any slight error may cause considerable losses.

What information should be included in the BOM?

Before creating a BOM, we need to know what it contains.

- Manufacturer Part Number

- Manufacturer’s Name

- Value

- Description

- Quantity (Essential)

- Reference Designator (Essential)

Correct BOM vs. Wrong BOM

Things to note when creating a BOM

1. Choose existing or readily available materials as much as possible. When the scheduled initial electronic components are out of stock, it is necessary to find replacements as soon as possible.

2. The quality of electronic components is crucial, which directly determines the durability of LED PCB Assembly.

Here is a detailed introduction about what BOM is and how to create a qualified BOM.

2. LED PCB Assembly Technology

There are three leading LED PCB mounting technologies as follows:

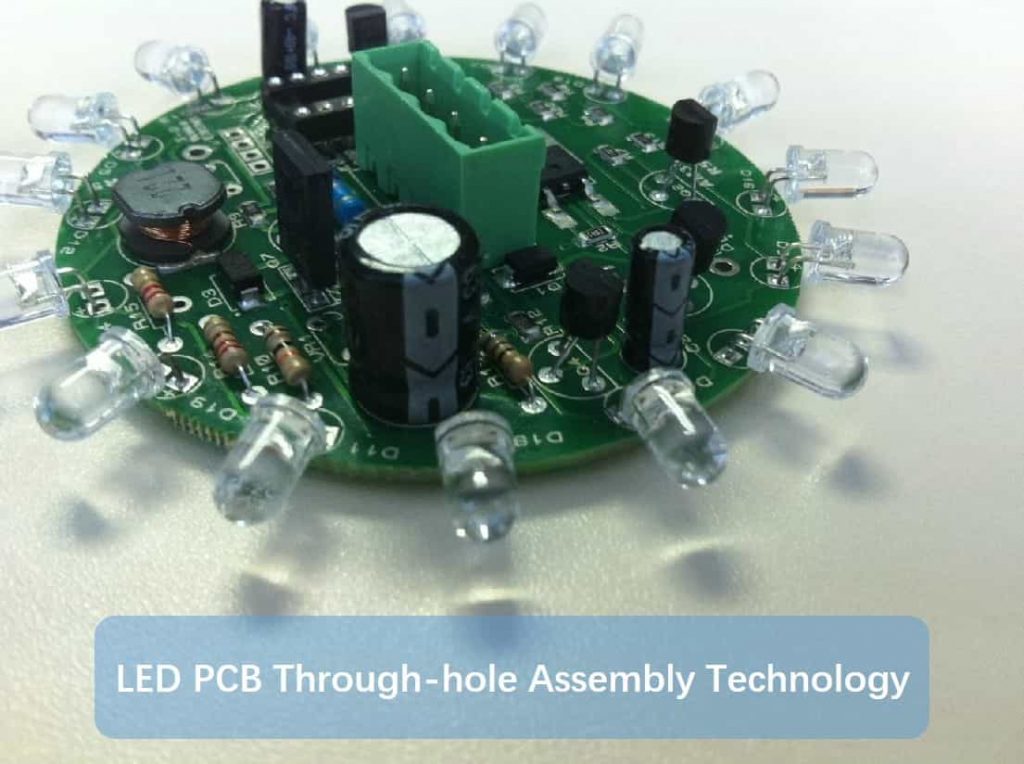

- Through-hole LED PCB assembly technology

Through-hole PCB assembly technology originated in the 1940s and was widely used in the electronic assembly industry. It was the mainstream of early electronic assembly technology. With the advancement of technology, through-hole PCB assembly technology is gradually replaced by surface mount technology. However, through-hole assembly technology also has its own unique advantages that cannot be replaced, such as:

Through-hole assembly technology makes it easier to assemble PCB prototypes;

Through-hole assembly technology welds stronger and can withstand more significant impact, so it has higher durability;

- LED PCB surface mounting technology

Surface mount technology is currently the most popular assembly technology in the electronics assembly industry. Surface mount technology originated in the 1960s and gradually replaced through-hole assembly technology in the 1980s.

Surface mount technology is applied to smaller surface mount devices such as different types of capacitors and resistors.

LED PCB Assembly primarily uses surface mount technology.

Because surface mount technology has some advantages as follows:

Use surface mount to assemble small size equipment in time;

Achieved automated assembly and improved production efficiency;

Surface mounting provides the possibility of double-sided PCB mounting;

Cost-effective, reducing the cost of the product;

Surface mount technology can be assembled faster than through-hole assembly technology

SMT Manufacturer and Factory

- COB (Chip-On-Board)

3. Two methods of LED PCB assembly

There are two methods for LED PCB assembly to choose from, which are manual plug-in or soldering and automated assembly.

- LED PCB manual assembly

The manual assembly process of LED PCB is that the technicians of the PCB assembly factory assemble by the manual plug-in method. Another way is to weld the electronic components to the LED PCB by manual welding to complete the LED PCB assembly work.

The shortcomings of manual assembly of LED PCB are low production efficiency, which slows down the production speed and requires the functional skills of the operators.

- LED PCB automated assembly

Automated assembly generally uses high-speed placement machines of Samsung and other brands, which are typically used for surface mount technology. Many LED components can be quickly picked up and placed on the circuit board by a sophisticated high-speed placement machine.

The production efficiency of automated assembly is often several times that of manual assembly.

LED PCB Assembly Videos

LED Strip Light SMT Process in Factory

This video will let you understand the SMT process of led strips.

SMT process: Electronic manufacturing using surface mount technology means the assembly of electronic components using automated machines that place the components on the surface of the circuit board.

LED PCB Assembly Process Steps: LED PCB manufacturing-SMT process-reflow soldering-soldering-glue covering-tape sticking and packaging-LED light bar.

SMT PCB Assembly Process | Surface Mount Technology Process

SMT means surface mount technology. SMT PCB assembly technology is a technology for soldering SMD electronic components to the surface of a printed circuit board. The SMT technology is different from the through-hole PCB assembly process, and SMT assembly is becoming more and more popular.

The core technology of SMT assembly is to solder SMD electronic components to the PCB through reflow soldering or selective soldering.

Soldering SMD LED Diodes by hands

SMT solutions for LED PCB assembly -pick and place machine.

FAQ

Most frequent questions and answers

1. Compared with traditional light sources, the main advantages of LEDs are long service life and higher efficiency because, under the same brightness, the energy consumption of LEDs is 3-5 times less than that of halogen lamps or incandescent lamps.

2. The LED will generate a lot of heat during continuous operation. Due to the unique materials and design of the LED circuit board, the heat can be well dissipated.

For more information about the advantages of LED PCB, please click here.

According to different applications, LED PCBs also present different shapes. Common ones are: square LED PCB, long strip LED PCB, super long LED PCB, round LED PCB, five-pointed star LED PCB and hexagonal star LED PCB, Irregular shape LED PCB, etc.

LED circuit boards can be seen in many applications, such as car lights, panel lights, street lights, etc. LED PCBs are widely used, mainly based on:

- Reduce weight and volume;

- Reduce energy consumption, which is conducive to environmental protection;

- Better dimensional stability;

- Good heat dissipation performance;

- The perfect combination of high power and low energy consumption;

- Reduce costs and Flexible design

Thermal management refers to the transfer of a large amount of heat generated by the LED during operation from electrical components to less critical areas, such as heat sinks (usually aluminum sheets), metal cores or copper layers, etc., to achieve correct and timely The function of adjusting the temperature of the components.

To obtain a good component yield, we recommend that thermal management be consistent with the selected application type.

LED SMD uses SMT surface mount technology to mount SMD and other LED chips on the LED circuit board.

The advantage of SMD LED is that its assembly method is straightforward: applying SMT technology, use solder paste to solder the components directly on the surface of the LED PCB without drilling.

Using SMD can reduce the size of the LED circuit board and correspondingly reduce the volume of electronic equipment.

SMD LED can be applied to most of the LED lighting equipment on the market.

With the continuous development of LED lighting technology, people’s interest in manufacturing ultra-bright LED light sources constantly increases.

This ultra-bright LED lighting equipment has replaced traditional incandescent lamps. They can be seen in many areas of our life and work: outdoor lighting flashlights, miner’s lamps, street lights, automotive lighting, emergency lighting, billboards, LED panels, LED indicator lights, traffic lights, etc.

The LED module is a product composed of LEDs (light-emitting diodes) arranged according to a certain rule and then packaged with some waterproof treatments.

LED modules can be divided into LED light-emitting modules and LED backlight modules. The LED backlight module mainly provides a uniform and high-brightness light source for the LCD panel.

LED light-emitting modules are widely used in LED products, and there are also significant differences in structure and electronics. The simple thing is to use a circuit board and housing equipped with LEDs to become an LED module. Adding control, constant current source, and related heat dissipation treatment improves LED life and luminous intensity.

As long as the LED module is used to display the display effect of advertising fonts and logos at night, it uses text or logos as the medium and is installed on the roof or wall of the building. It can display the logo during the day and use LED as a light source at night. It shows another effect, coupled with LED lighting application control system, dynamic video control of text or logo, in some places with an intense entertainment atmosphere, LED light source modules have become the most important choice for companies to show their self-image.

LED module classification can be divided into:

1. According to the occasion of use, it can be divided into indoor, semi-outdoor, and outdoor modules.

2. According to the color, it can be divided into the single-color module, two-color module, and complete color module

3. According to the pitch, it can be divided into indoor P2.5, P3, p4, p5, P6, p7, p8, etc.; outdoor p10, p12, p16, p20 P25, etc.

4. According to the power of LED lamp beads: low power (under 0.3W), medium power (0.3-0.5W), high power (1W and above)

5. Divided from the distributor: in-line LED display module, indoor dot matrix LED display module, surface mount LED display module.

Please combine the following files into a single ZIP or RAR file and send it to sales@pcbjhy.com for a quick and free quotation.

- Gerber Files

- Bill of materials

- Clear pictures of sample (If have)

- Quantity and delivery required

- Test method for PCBA

- Assembly drawing

Get the Best LED PCB Assembly Services

JHYPCB proudly offers the best LED PCB Assembly services. We are one of the well-known LED PCB assembly manufacturers in China. Our quality management system is according to international standards and is certified by ISO, RoHS, and UL. We ensure high quality and quick turn LED PCB assembly services. We have a wide range of pre-designed LED PCB assemblies, and you can also order custom assemblies according to your needs. Moreover, we are good at turnkey PCB services. We will take care of everything from the first step to the last. For more information and details, feel free to contact us.

Related Posts

- PCB Assembly Capability

- The Main PCB Assembly process Steps

- Top PCB Board Manufacturer And Supplier In China

- Why Choose Chinese PCB Manufacturer

- Design For Manufacturability And Assemblability Of Printed Circuit Board

- PCB Stencil fabrication Capability

- Testing & Inspection Methods For PCB And PCBA

- Introduction to aluminum PCB manufacturing process

- How to Store PCB and PCBA?

- How long can PCBA finished products be stored?

- How to Use PCB Stencil-Step by Step Guideline

- 30 Common SMT PCB Assembly Defects

- LED PCB for Grow Lighting Fabrication Service

- Choosing the Right PCB Assembly Manufacturer for Your Needs

- Leveraging Turnkey PCB Assembly Manufacturing Services

- Evaluating and Selecting Quick-Turn PCB Assembly Manufacturers in China

- Shenzhen – The Global Hub for High-Quality PCB Assembly Manufacturing