Table of Contents

When choosing a PCB manufacturer in Europe, several key factors demand close attention to ensure a reliable partnership. Location, PCB manufacturing expertise, quality certifications, turnaround times, and customer service are all crucial considerations.

Proximity to a local or regional PCB supplier offers advantages like reduced lead times, shipping costs, and smoother communication. However, this must be balanced against their PCB production capabilities to meet your project’s specific requirements for PCB types, layer counts, and design complexities.

Quality is paramount, so look for PCB manufacturers holding ISO and industry certifications like IPC and UL. These demonstrate their commitment to rigorous standards and continuous improvement processes.

In today’s fast-paced climate, reliable turnaround times and on-time delivery performance are vital for meeting project deadlines. Efficient PCB prototyping, production scheduling, and logistics solutions are essential.

Finally, responsive customer service, clear communication, and a collaborative approach are hallmarks of a trustworthy European PCB partner for handling complex projects smoothly.

Evaluating these key factors thoroughly will increase your chances of finding the most suitable, reliable PCB manufacturer in Europe for your needs.

Evaluating European PCB Manufacturers' Locations

Geographic location plays a pivotal role when choosing a PCB manufacturer in Europe. Proximity to your business or target market can offer significant advantages in terms of shorter lead times, reduced shipping costs, and streamlined communication.

Working with a local or regional PCB supplier often translates into faster turnaround times for prototype and production orders. With a PCB manufacturer located nearby, your circuit boards can be shipped and delivered more quickly, minimizing potential delays and keeping your projects on schedule.

Additionally, closer geographic proximity typically means lower shipping and logistics costs. By sourcing from a PCB maker within Europe, you can avoid the extra expenses and complexities associated with international shipping from distant locations, ultimately saving your business valuable resources.

Effective communication is another key benefit of partnering with a European PCB manufacturer in your region. Speaking the same language, sharing similar time zones, and being familiar with local customs and business practices can facilitate smoother collaboration and problem-solving throughout the design and production process.

While location is an important consideration, it’s also crucial to understand Europe’s major PCB manufacturing hubs. Countries like Germany, Italy, France, and the UK have well-established PCB industries with reputable suppliers offering a wide range of capabilities and services.

By researching and evaluating the strengths of different regional PCB manufacturing clusters, you can identify potential partners that not only offer geographic convenience but also possess the specific expertise and resources required for your unique project needs.

Remember, while location is a significant factor, it should be weighed alongside other critical criteria such as manufacturing capabilities, quality standards, and customer service to ensure a truly reliable and successful partnership with your chosen European PCB manufacturer.

European PCB Companies' Manufacturing Capabilities

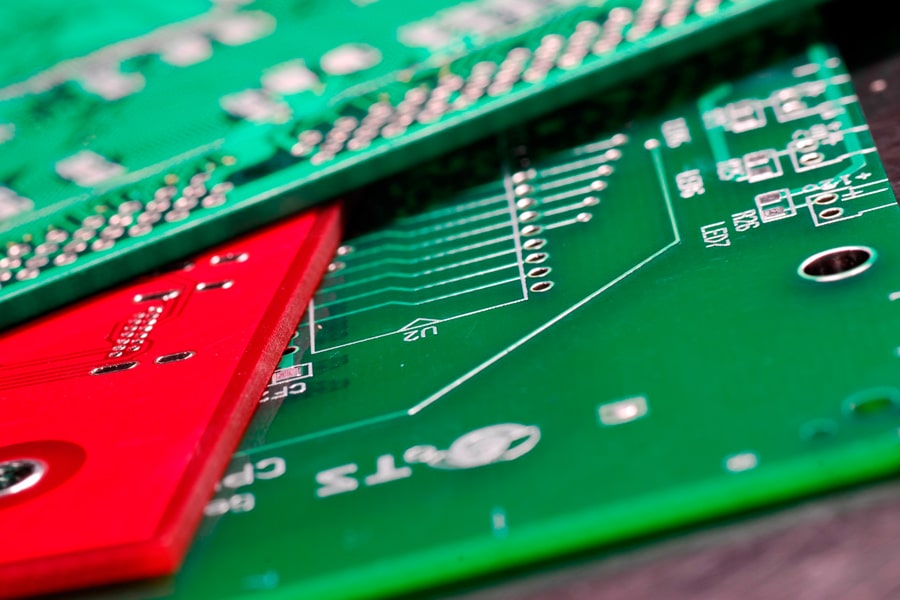

When selecting a PCB manufacturer in Europe, it’s essential to thoroughly assess their manufacturing capabilities to ensure they can meet your project’s specific requirements. The PCB industry is highly diverse, with various board types, layer counts, materials, and production processes.

One of the primary considerations is the type of PCBs a manufacturer can produce. Some companies specialize in rigid PCBs, while others focus on flexible or rigid-flex boards. Depending on your application, you may require a supplier with expertise in a particular PCB type or the ability to handle multiple types.

Layer count and board complexity are also crucial factors to evaluate. Many modern electronic devices and systems demand high-layer-count PCBs with intricate designs and tight tolerances. Ensure that your chosen European PCB manufacturer has the equipment and skills to handle the required layer counts and design complexities reliably.

Additionally, certain industries or applications may necessitate the use of specialty PCB materials or finishes. For instance, military and aerospace projects often require specific materials designed to withstand extreme temperatures or harsh environments. If your project demands unique material or finish requirements, verify that the PCB maker can accommodate these needs.

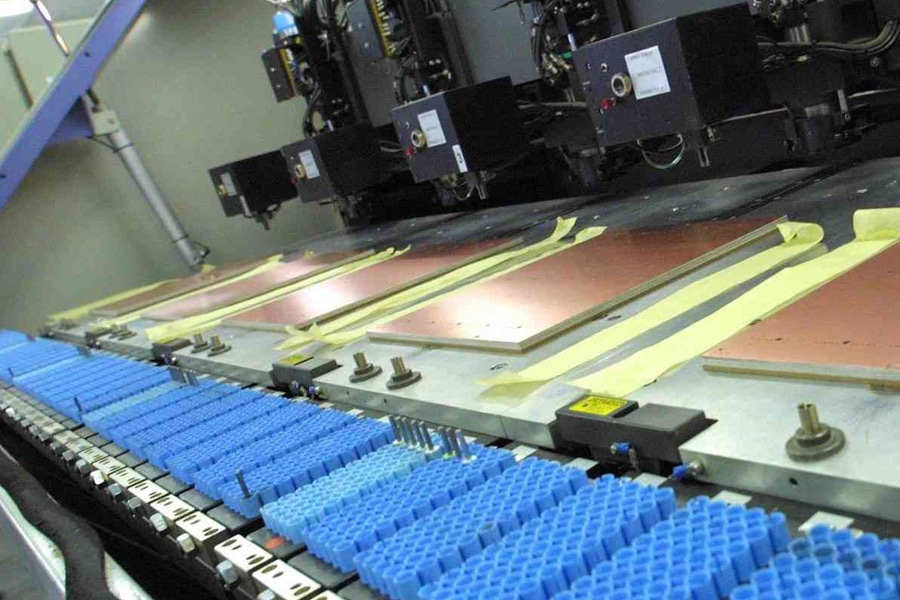

PCB prototyping and low-volume production capabilities are equally important, especially for startups, product developers, or businesses with rapidly evolving designs. A reliable European PCB manufacturer should offer efficient prototyping services and the flexibility to handle small production batches cost-effectively.

By carefully evaluating a potential supplier’s manufacturing capabilities across these key areas, you can ensure they have the necessary resources and expertise to deliver high-quality PCBs that meet your project’s exact specifications, timelines, and quality standards.

Remember, open communication with prospective PCB manufacturers is crucial. Don’t hesitate to ask detailed questions about their capabilities, processes, and experience with projects similar to yours. This dialogue will help you make an informed decision and foster a collaborative partnership from the outset.

Importance of Quality Certifications for PCB Makers

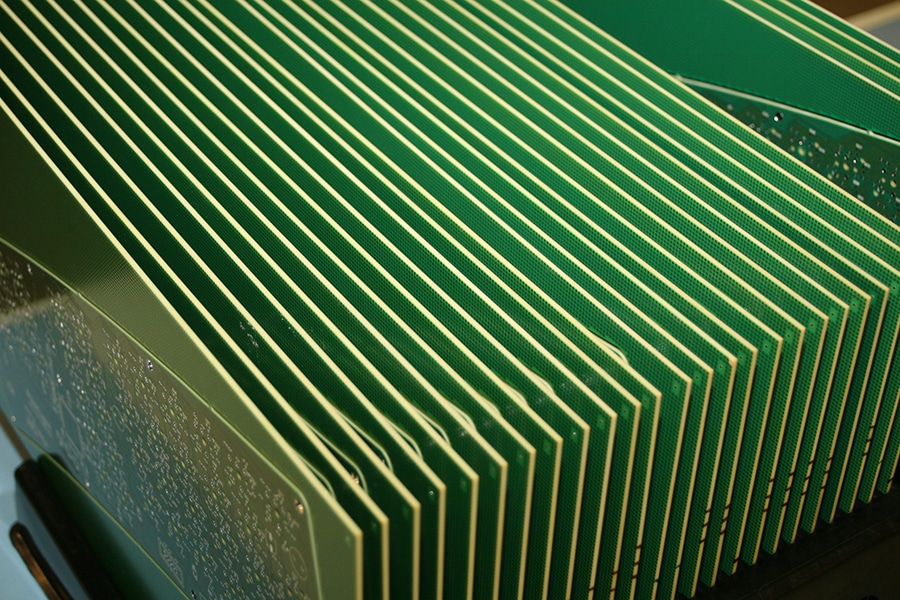

In the world of PCB manufacturing, quality is paramount. Choosing a supplier with robust quality management systems and industry-recognized certifications is crucial to ensuring consistent, reliable, and compliant PCB production.

One of the most widely respected quality certifications is the ISO 9001 standard for quality management systems. PCB manufacturers that have achieved ISO 9001 certification have demonstrated their ability to implement and maintain effective processes for quality assurance, continuous improvement, and customer satisfaction.

In addition to ISO 9001, many leading PCB companies in Europe also hold certifications specific to the electronics and PCB industries. The IPC (Association Connecting Electronics Industries) is a globally recognized organization that sets rigorous standards for PCB design, materials, and manufacturing processes. IPC certifications, such as IPC-A-600 and IPC-6012, signify that a manufacturer adheres to industry best practices and stringent quality control measures.

Another essential certification for PCB makers is UL (Underwriters Laboratories) approval. UL is a globally respected safety certification company that evaluates and certifies products for safety and compliance with applicable standards and regulations. PCB manufacturers with UL certification have demonstrated their ability to produce boards that meet rigorous safety requirements, which is particularly critical for industries like aerospace, automotive, and medical devices.

Beyond specific certifications, it’s also important to consider a PCB manufacturer’s commitment to continuous improvement and investment in advanced quality control systems and equipment. Leaders in the industry frequently adopt cutting-edge technologies, such as automated optical inspection and x-ray inspection, to ensure the highest levels of quality and reliability.

By prioritizing PCB manufacturers with relevant quality certifications and a strong focus on quality assurance, you can have greater confidence in the integrity and performance of the PCBs you receive, minimizing the risks of defects, rework, and potential product failures.

Why Turnaround Time Matters for European PCB Suppliers

In today’s fast-paced and highly competitive market, time is of the essence. When it comes to PCB manufacturing, a PCB supplier’s ability to deliver orders promptly can significantly impact project timelines, product development cycles, and overall business success.

For many companies, quick PCB prototyping services are a critical requirement. The ability to rapidly produce prototype PCBs allows for efficient design iterations, testing, and validation before moving to full-scale production. A European PCB manufacturer that offers reliable quick-turn PCB prototyping can help you bring products to market faster and stay ahead of the competition.

Efficient production schedules are equally important once a design is finalized and ready for manufacturing. Reliable European PCB suppliers should have streamlined processes and sufficient capacity to handle orders within agreed-upon lead times, ensuring that your production schedules are not disrupted by delays or capacity constraints.

In addition to quick PCB prototyping and efficient production, the logistics and shipping capabilities of a PCB manufacturer can also impact turnaround times. Strategically located suppliers with robust shipping and logistics solutions can minimize transportation delays, ensuring that your PCBs are delivered on time, every time.

Furthermore, some industries or applications may have exceptionally tight deadlines or time-critical projects. In such cases, having a European PCB partner that offers expedited services and prioritizes urgent orders can be invaluable, helping you avoid costly delays and potential penalties.

By prioritizing turnaround time as a key factor in your selection process, you can ensure that your chosen European PCB manufacturer has the ability to meet your deadlines consistently. This not only helps you maintain efficient production schedules but also contributes to customer satisfaction and a competitive edge in your respective market.

Top Customer Service from European PCB Manufacturers

While PCB manufacturing capabilities and quality certifications are undoubtedly crucial, exceptional customer service can make a significant difference in your overall experience with a European PCB supplier. A truly reliable PCB partner should offer responsive support, clear communication, and a collaborative approach to problem-solving.

Responsive support is essential, especially when dealing with complex projects or tight deadlines. Look for a PCB manufacturer that provides dedicated account managers or customer service representatives who are readily available to address your inquiries, concerns, or any issues that may arise throughout the production process.

Clear and transparent communication is another hallmark of top-notch customer service. A reliable European PCB partner should keep you informed every step of the way, providing regular updates on order status, production progress, and any potential delays or challenges. Open and honest communication fosters trust and helps mitigate potential misunderstandings or setbacks.

Moreover, a collaborative approach to problem-solving can be invaluable when working on intricate or challenging PCB designs. Rather than merely following instructions, a customer-centric PCB manufacturer should be willing to work closely with your design team, offering expertise and suggestions to optimize the design for manufacturability, cost-effectiveness, and performance.

Leading European PCB companies often go above and beyond by offering value-added services and support. This may include DFM feedback, component sourcing assistance, or even turnkey solutions that encompass PCB assembly and box-build services, streamlining your supply chain and reducing the need for multiple vendors.

By prioritizing customer service as a key selection criterion, you can establish a strong partnership with a European PCB manufacturer that truly understands your needs and is committed to your success. This collaborative approach can lead to smoother projects, fewer delays, and ultimately, a more positive and productive working relationship.

How to Find the Best European PCB Manufacturer

With a clear understanding of the key factors to consider, it’s time to embark on the journey of finding the right European PCB manufacturer for your needs. This process involves thorough research, requesting quotes and samples, and evaluating potential suppliers based on their capabilities, quality standards, and customer testimonials.

Begin by compiling a list of reputable PCB manufacturers in Europe that align with your geographic preferences and general requirements. Online directories, industry associations, and trade publications can be valuable resources for identifying potential candidates. Additionally, attending trade shows or industry events can provide opportunities to connect with PCB suppliers face-to-face and gather firsthand information.

Once you have a shortlist of prospective manufacturers, request detailed quotes that outline their pricing, lead times, and any additional services or capabilities relevant to your project. Don’t hesitate to ask specific questions about their manufacturing processes, quality control measures, and experience with projects similar to yours.

Requesting sample PCBs can also be highly insightful, allowing you to personally evaluate the quality, workmanship, and adherence to your specifications. This hands-on assessment can reveal valuable insights into a manufacturer’s capabilities that may not be apparent from marketing materials alone.

In addition to evaluating samples, thoroughly research each potential supplier’s customer reviews and testimonials. Look for feedback from clients in similar industries or with comparable project requirements to gain a better understanding of their strengths, weaknesses, and overall reputation for reliability and customer service.

Finally, consider arranging site visits or virtual tours of the PCB manufacturing facilities you are seriously considering. This can provide firsthand insights into their operations, equipment, and quality control processes, further solidifying your decision-making process.

By taking a comprehensive approach to researching, evaluating, and vetting potential European PCB manufacturers, you can increase your chances of finding a partner that truly meets your needs, exceeds your expectations, and contributes to the long-term success of your projects.

List of Major PCB Manufacturers in Europe

- AT&S (Austria)

- Headquarters: Leoben, Austria

- Manufacturing facilities in Austria, India, China

- Specializes in HDI, rigid, rigid-flex, and IC substrates

- Wurth Elektronik (Germany)

- Headquarters: Niedernhall, Germany

- Manufacturing sites across Europe and Asia

- Produces rigid, flex, rigid-flex and aluminum PCBs

- Somacis (Finland)

- Headquarters: Siuntio, Finland

- High-tech PCB manufacturing plant in Finland

- Specializes in HDI, rigid-flex, and thermal management PCBs

- Printca (Denmark)

- Headquarters: Karlslunde, Denmark

- One of the largest PCB manufacturers in Scandinavia

- Offers rigid, flex, rigid-flex and aluminum PCBs

- NCAB Group (Sweden)

- Headquarters: Bromma, Sweden

- Manufacturing partners across Europe and Asia

- Provides PCB production, assembly and box-build services

- Printed Circuits Ltd (UK)

- Headquarters: Essex, United Kingdom

- Manufacturing facilities in the UK and Malaysia

- Specializes in quick-turn PCB prototypes and low-volume runs

Why Consider a Chinese PCB Manufacturer like JHYPCB?

While choosing a local European PCB supplier offers proximity advantages, it’s also worth considering a reputable Chinese manufacturer like JHYPCB for your PCB needs. As a leading PCB provider with a global customer base, JHYPCB offers a compelling value proposition for European businesses:

- Cost-effectiveness: With highly efficient operations and economies of scale, Chinese PCB manufacturers can often provide more competitive pricing without compromising on quality.

- Advanced manufacturing capabilities: Top Chinese PCB companies invest heavily in state-of-the-art equipment and technology, enabling them to handle even the most complex PCB designs and requirements.

- Quick turnaround times: Despite being located overseas, JHYPCB and other leading Chinese suppliers prioritize fast production cycles and reliable logistics to ensure on-time delivery worldwide.

- Stringent quality control: Quality is a top priority, with strict adherence to international standards like ISO 9001, IPC, and UL, backed by robust quality management systems.

- Responsive customer service: JHYPCB assigns dedicated support teams to provide attentive service, clear communication, and collaborative problem-solving for customers globally.

By considering suppliers like JHYPCB alongside European PCB manufacturers, you can broaden your options, compare value propositions, and ultimately select the partner that best fits your project needs, budget, and timeline requirements.

Common Questions About PCB Manufacturers in Europe

The major PCB manufacturing countries in Europe include Germany, Italy, France, the United Kingdom, Spain, Poland, and the Netherlands.

Some of the leading PCB manufacturers based in the UK are Ventec, Electrolytic, Merlin Circuit Technology, Printed Circuits Limited, and Photronics.

Notable PCB companies in Finland include Aspocomp, Kadflex, and Somacis.

Opinions may vary, but companies like Ventec, Electrolytic, and Merlin Circuit Technology are often cited among the top PCB suppliers in the UK for their quality, capabilities, and customer service.

No, PCBs are not banned in Europe. However, there are strict regulations regarding the use of certain hazardous substances in PCBs and electronic products sold in the EU market (e.g., RoHS, REACH).

The majority of PCBs are manufactured in Asia, with China being the largest producer and exporter, followed by Taiwan, Japan, and South Korea.

Yes, while many PCBs are imported, the USA still has several notable PCB manufacturers, including TTM Technologies, Isola Group, Summit Interconnect, and Printed Circuits Inc.

Many PCB manufacturers in Europe offer turnkey PCB assembly services in addition to fabrication. Research companies that provide complete PCB design, fabrication, and assembly solutions.

Summary

Selecting a reliable PCB manufacturer in Europe requires a thorough evaluation of several key factors to ensure a successful partnership. Geographic proximity offers advantages like reduced lead times and shipping costs but must be balanced against manufacturing capabilities, quality standards, turnaround times, and customer service.

When assessing potential suppliers, prioritize those with proven expertise in your required PCB types, layer counts, and material specialties. Certifications like ISO 9001, IPC, and UL demonstrate commitment to stringent quality control processes.

Efficient PCB prototyping services and dependable production schedules are vital for meeting project timelines. Top manufacturers offer reliable quick-turn PCB solutions backed by robust logistics.

Paramount is a partner providing responsive support, clear communication, and a collaborative approach to addressing challenges. This ensures a smooth experience from design through delivery.

Research diligently, request samples, and scrutinize customer feedback to identify the best-fit European PCB manufacturer aligned with your needs. Conducting site visits can provide further valuable insights.

Ultimately, the right PCB partner will have the specialized capabilities, rigorous quality focus, and customer-centric approach to support your long-term success. Don’t overlook global suppliers like JHYPCB that combine advanced manufacturing with competitive pricing and attentive service.

By carefully evaluating locations, certifications, turnaround times, service standards, and value propositions, you’ll position yourself to forge a productive relationship with a European PCB manufacturer you can trust.

Related Posts

- Custom PCB Manufacturing in Germany – Fast Prototype & Assembly Services

- Worry-Free Custom PCB Manufacturing – JHYPCB, The Preferred Choice for American Customers

- Custom PCB Fabrication in China – Prototyping & Mass Production

- Expedited PCB Services – Quick Turnaround for Your Urgent Needs

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- Fast and Reliable PCB Prototyping with JHYPCB in Australia

- Applications of Different Types of PCBs in Major Industries

- Shenzhen – The Global Hub for High-Quality PCB Assembly Manufacturing

- Evaluating and Selecting Quick-Turn PCB Assembly Manufacturers in China

- Choosing the Right PCB Assembly Manufacturer for Your Needs

- Finding the Right China PCB Manufacturers:5 Vetting Tips

- Fast Prototype PCB Manufacturing Services in Canada by JHYPCB

- UK PCB Prototype Manufacturing: Fast, Affordable, and High-Quality

- Fast Prototype PCB Services for US Customers

- The Importance of Choosing a Reliable PCB Prototype Manufacturer

- Choosing the right PCB manufacturer and supplier. An ultimate quest that will payback in the future.

- The Cheapest PCB Prototype Manufacturer-Your Best Choice