Why Choose us

As a High-end Circuit Board Manufacturer, JHYPCB Has the Ability to Provide a Variety of Tricky PCBs Manufacturing.

Fast Delivery, Quality Assurance is Our Core, One-stop PCB Circuit Board Manufacturing and PCBA Assembly Services, To Save Time and Cost for Customers.

Home » PCB Manufacturer » Why US

Made in Shenzhen China

The Best PCB Factory and Supplier

We are the long-term designated partner of many large enterprises in China and even the world. The most reliable circuit board brand, circuit board manufacturers around you.

Shenzhen, one of the most dynamic cities in China, is a gathering place for PCB manufacturers and PCB material suppliers in China, with a complete supply chain and supporting facilities.

China, the world’s factory, can provide high-quality products to the whole world, and the low price is one of its advantages.

We are eager to win your PCB order and become your primary supplier of PCB for a long time. Since the company’s establishment, we have been adhering to providing customers with the most cost-effective, high-quality PCB products and providing industry-leading customer service.

One-stop Solution

One-step Service From PCB Fabrication to PCB Assembly

Focus

Concern Design Based on Product Life Cycle

24*7

24 Hours Engineering Support From Concept Design to Mass Production

PROFESSIONAL

Skilled and Experienced PCB Manufacturing Team

One-stop

Service of Material Sourcing, DFM Evaluation, Design Rules and Economical Solution etc.

Pre-sale Service

- Best Cost Solutions

- High Reliability

- Solutions

- Best DFM Solutions

Sale of Service

- Quick Turn

- Fast Response

After-sale Service

- Quality Tracing

- Fast Response

- Continuous Improvement

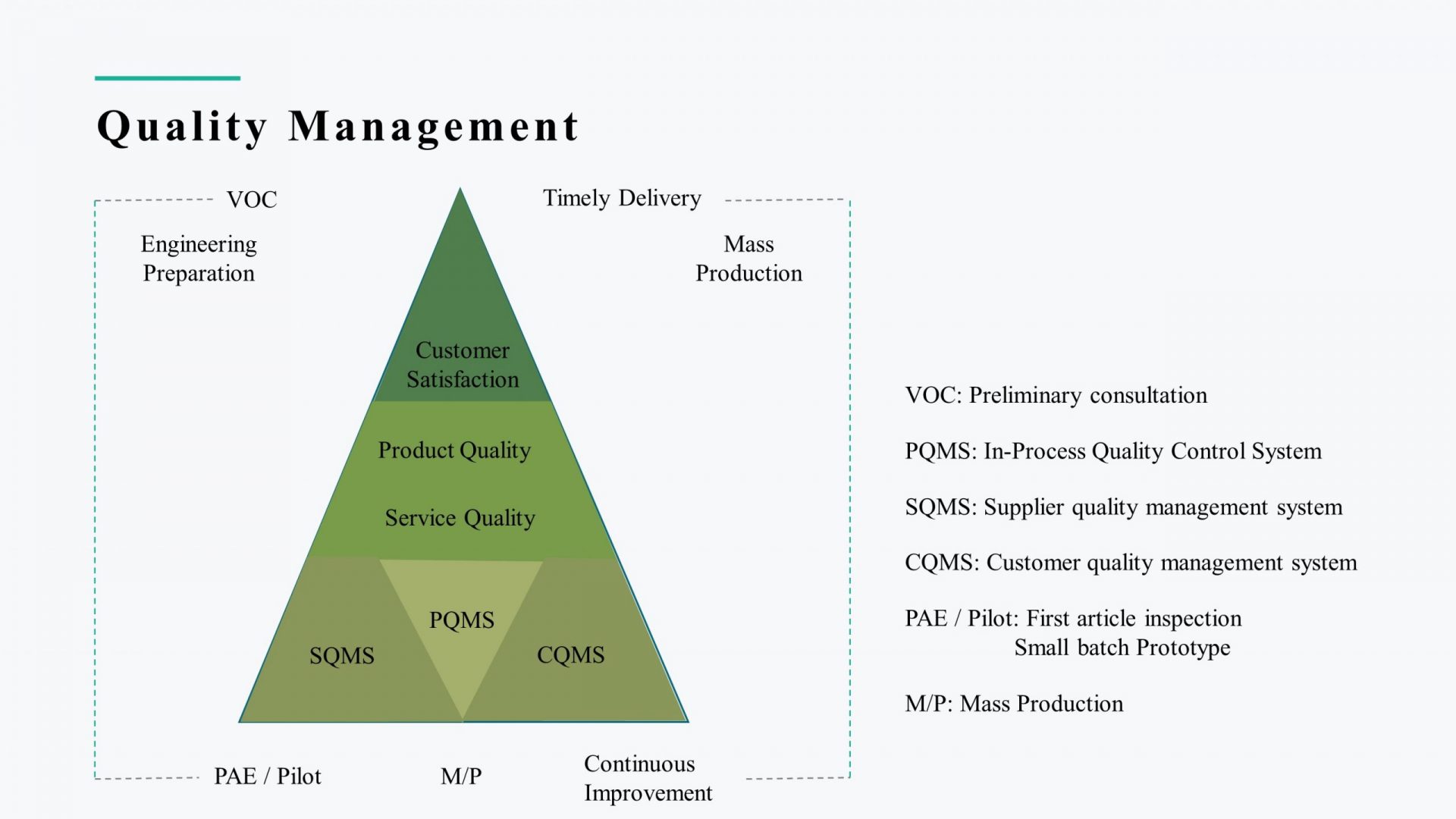

Quality Assurance And Management

Our company fully carries out ISO9001 quality system certification, the full implementation of ROHS certification standards.

Our company is approved by UL, TS16949, ISO-9001, and RoHS compliance.

Click here to learn more about our Quality Management Policy.

All boards are produced according to IPC-6012 standards and inspected according to IPC-A-600 in the latest version. More than 90 percent of them were exported to Europe, North America, South America.

Incoming Quality Control

We use international famous brand raw materials, establish incoming inspection specifications according to international standards and customer standards, continuously track and promote supplier quality improvement activities, and establish and maintain a good partnership with suppliers.

In-Process Quality Control

High-quality products are manufactured, not inspected. We have a standardized production process and detailed operation instructions for each method of the production line to ensure the correct implementation of the operating specifications and operation standards.

Final Quality Control

We strictly follow the international standards and customer standards to inspect and control the delivery quality, timely follow up the quality performance of the products after delivery, and take quick and effective improvement actions for the feedback of customer’s abnormal condition.

We believe in the quality of work, which means better products with lower costs and wastage.

In order to facilitate smooth production in our craft and minimize customer loss, we always produce the best quality products to our clients. We have incorporated the In-Process Quality Checking (IPQC) procedure in our production line. Any defective components or manufacturing errors are detected instantly and are eliminated. This is a responsibility that everyone participates to showcase our ultimate commitment to quality.

Introduced various management systems and international standards.

In supporting our staff members to systemically uphold our quality commitment, we have introduced various management systems and international standards as checkpoints and guidelines. Total Productive Management (TPM), Total Quality Management (TQM),5S+Safety (6S), ISO9000, ISO14000, TS16949, AQL, MIL, IPC, U/L, and RoHS are systems and standards that we have seamlessly incorporated into our manufacturing process.

Our quality commitment extends to reach our customers.

We are constantly interacting with our customers and providing assistance in time management before, during, and after production. Dedicated staff members are to handle customers’ feedback and complaints. Their one working day performance pledge ensures fast response to resolve any problem that our customer may encounter. Providing quality service in addition to on-time delivery is also included in our quest to total customer satisfaction.

IPC Standard

Standards and technical specifications

| IPC-A-600 | Acceptability of Printed Circuit Boards (default class 2) |

|---|---|

| IPC-A-600J | Acceptance of Printed Circuit Boards |

| IPC-6011 | Generic Performance Specification for Printed Circuit Boards |

| IPC-6012 | Qualification and Performance Specification for Rigid Printed Circuit Boards. (default class 2) |

| IPC-6018 | Qualification and Performance Specification for High Frequency (Microwave) Printed Ciruit Boards |

| IPC-TM-650 | Printed Circuit board Quality Test Standard |

| IPC-SM-840 | Quality and Performance Standards for Permanent Solder Masks |

| IPC-4101 | Specification for Base Materials Rigid / Multi-layer PCB |

| MIL-PFR-55110 | Military Performance and Specifications-Tucson |

8 Advantages

5G Mobile Communication. Taconic/Rogers/Arlon PCB. Heat sink PCB/AL PCB. Antenna PCB. PA PCB/Hybrid PCB. High Precision Multilayer / Impedance PCB. Half hole PCB/film cover PCB. Other special PCB. Normal FR-4 PCB.

Own PCB manufacturing and PCB assembly factory,We can provide the most cost-effective products.

1L:12 hours

2L:12 hours

4L:12 hours

6L:12 hours

Technical support engineers provide one-to-one service from product proofing to mass production to after-sales, realizing order online tracking and after-sales service.

Quotation System: Quote within 24 Hours

Service System: Respond within 30 Minutes

EQ System: Nearly 30 technical support teams responded quickly within 24 hours

Language services: Chinese, English, Korean, Japanese and Vietnamese

Excellent QA, production management system and technology team to assure quality.

JHYPCB has a strong technical team and advanced PCB manufacturing equipment, which can provide excellent technical support and after-sales service in an all-round to provide customers with efficient manufacturing and reliable products.

SQM regularly audits qualified raw material suppliers to promote continuous improvement and ensure quality.

CRM regularly collects customer needs and problems to better provide customers with quality solutions.

ERP can track the order status at any time through the production base ERP system.

Service Commitment

Excellent service, Quick response, Fully Support

Quotation response within one hour

Comprehensive marketing service with 24 hours

Professional technical support with 24 hours

24-hour production running

24-hour delivery service

Professional customized Service

On Time Delivery Rate

As we all know, product quality is very important; in addition, on-time delivery is also essential, especially for PCB prototype manufacturing, because whether the on-time delivery can directly affect the subsequent work.

Standard Lead Time

PCB circuit boards are customized products, so the delivery time varies according to the complexity and quantity of the circuit board. However, our standard PCB prototype delivery time is 7 days. In addition, we also provide 12 hours, 24 hours, 36 hours, 5 days, and 10 days turnaround time.

Quick Turn Lead Time

For single-layer and simple double-sided PCB prototype manufacturing, we can complete it in 12 hours. For the multi-layer PCB with more than two layers, the specific delivery time will be reflected in the quotation according to the Gerber documents you provided, the manufacturing difficulty, the number of PCB layers, and the quantity.

Of course, an urgent order will cost more than a standard order.

We are very proud of our strong team of engineers, rapid quotation response speed, continuous improvement of the production process, constantly updated and iterative production equipment, and skilled technical workers to achieve our on-time delivery rate of 99%.

It is our high-quality products and on-time delivery that have won our customers’ support and trust.

Competitive Cost for PCB Manufacturing

We offer high-quality customized PCB Boards with reasonable cost and the best service because we know the cost is significant to a product’s success. We have cost control for each process to provide reasonable PCB costs for our customers.

The reason why we can provide you with low-priced PCB manufacturing services is that we have a very complete supply chain management system and maintain a perfect and solid cooperative relationship with suppliers, and through mass procurement and mass production to reduce costs to a greater extent to customers so that you enjoy lower prices than the same industry, higher than the quality of the same industry.

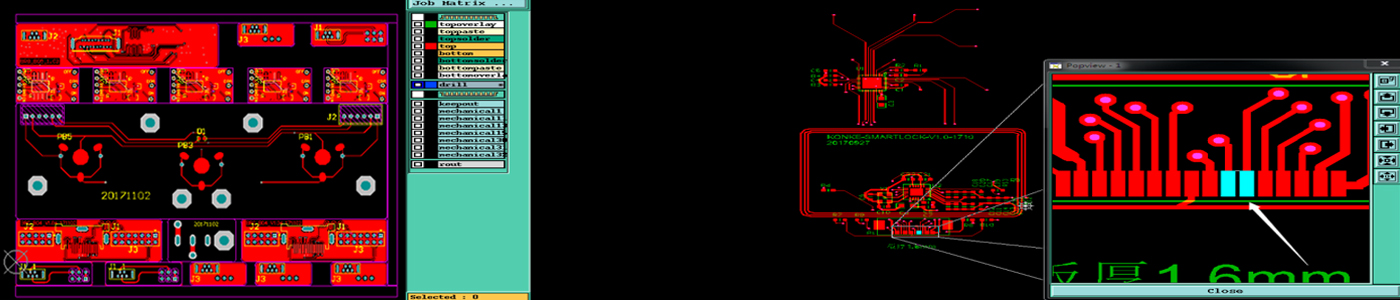

Free DFM PCB Design Checking

We have a professional engineering team to provide complete engineering support for customers. Free DFM helps to save cost and reduce potential problems during PCB (printed circuit board) manufacturing.

Ten professional PCB engineers with over 12 years of PCB experience, with rich experience in various industry standards and process quality requirements, provide customers with optimized design PCB solutions at the design-in stage.

Perfect PCB material supply chain management system

Quality PCB raw materials, from the source to ensure product quality.

Board materials we keep in stock:

- FR4 (Tg – 135C, 145C, 170C)

- Rogers Ultralam 2000

- Rogers RO4350

- Rogers RO4003

- Polyimide

- Teflon

- Black FR4

- Arlon AR350

- Getek Copper

- Clad Thermal

- Substrates

- Hybrid (Rogers and FR4)

- BT Epoxy

- Nelco 4013

Available PCB finishes:

- HASL – Leaded Solder Tin/Nickel

- LF HASL – Lead Free Solder

- Electroless Soft Gold

- Wire Bondable Soft Gold

- Nickel Flash Gold

- Electroless Nickel

- OSP

- Electrolytic Nickel /Hard Gold & Selective Gold

- Immersion Silver

- Immersion Tin

- Carbon Ink

- ENIG

- ENIG+Golden Finger

- OSP+Golden Finger

Excellent Suppliers

CCL: TUC, SYL, Isola, Rogers, Arlon,Nelco, Taconic, Hitachi, etc.

SM oil: Taiyo INK (Japan), KUANGSHUN(China), RONGDA(China), Coates Screen(UK), S.M Materials(Taiwan, China)

Chemical: Rohm&Haas (US), Atotech (Germany), Umicore (Germany)

Advanced Automatic Production Equipment

Advanced PCB manufacturing and PCB assembly Production Equipment, Skilled Technical Workers are the Guarantee of Product Quality.

We Guarantee to Provide Reliable Products Based on Advanced Manufacturing Testing Equipments, Well-known Raw Materials and Comprehensive Management Systems.

Learn More About Our Factory and Equipment.

Exquisite PCB Fabrication and PCBA Manufacture Capacity

The following is a list of some of our current manufacturing capacity, but not all. In addition, thanks to the fact that we are a private enterprise, in order to meet the needs of customers, we are constantly upgrading our own production equipment and production process.

Please trust us. We can provide a one-stop complete service from PCB prototyping to PCB assembly. Please feel free to contact us to find out if we can manufacture your PCB, give us a chance to work with you and give yourself a chance to find a more suitable PCB supplier.

Just send us your Gerber file, our professional sales staff will provide you with a fast and accurate PCB quote.

| Item | Manufacturing Capability |

|---|---|

| PCB Layers | 1~30 layer |

| Laminate | FR-4,S1141,S1000-2,IT180A,Isola-FR408HR,FR406,Isola 370 HR, Rogers, Taconic, Arlon, Halogen Free, etc. |

| Max Board Size | 533.4 * 762 mm |

| tBoard Thickness | 0.1~8.0mm |

| Board Thickness Tolerance | ±0.1mm / ±10% |

| Copper Thickness | Outer layer:1/3oz~10oz,Inner layer:1/2oz~6oz |

| Min Mechanical Drilling Hole Size | 6mil(0.15mm) |

| Min Laser Drilling Hole Size | 3mil(0.075mm) |

| Min Line Width/Line Space | 2/2mil(Outer layer:1/3oz,Inner layer:1/2oz) |