Home » Industries Served » PCBs for Medical Devices

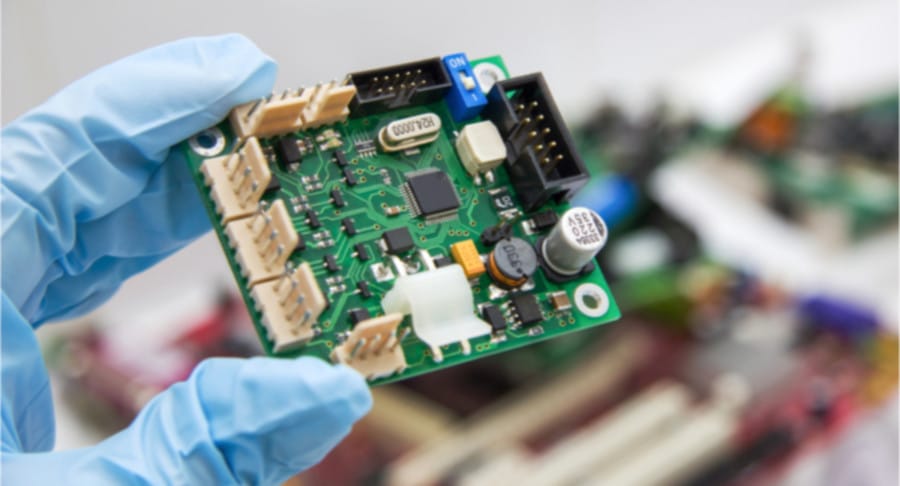

PCB Manufacturing for Medical Devices

As medical devices become more sophisticated and revolutionize patient care, the printed circuit boards powering these innovations play an indispensable role. However, manufacturing PCBs for the latest medical equipment also poses unique demands around miniaturization, reliability, and regulatory compliance.

At JHYPCB, we specialize in delivering premium quality PCB solutions designed specifically for medical device OEMs. For over 15 years, leading medtech companies have trusted us to actualize their electronic designs and elevate performance in mission-critical applications – from patient monitors to surgical robots.

This article provides an overview of our medical PCB manufacturing and assembly services. Discover how we address key industry challenges, provide specialized capabilities across the product lifecycle, and ensure adherence to the industry’s stringent quality standards – all while delivering exceptional value.

Challenges of Medical Device PCB Manufacturing

Manufacturing PCBs for the medical device industry poses unique challenges that PCB suppliers must address to ensure high performance, reliability, and compliance. Here are three main difficulties we take into consideration:

- Compliance with Standards

Medical devices must adhere to rigorous regulatory standards and requirements around materials, production processes, testing, and documentation. Our manufacturing facilities are certified to quality management standards like ISO 13485 to demonstrate our ability to meet compliance. We also maintain detailed production records with lot traceability. - Miniaturization

Many medical devices are becoming smaller, calling for PCBs with higher-density interconnects and smaller features. Our investments in advanced HDI technology and equipment allow us to produce high-quality boards meeting the tightest space constraints. - Reliability

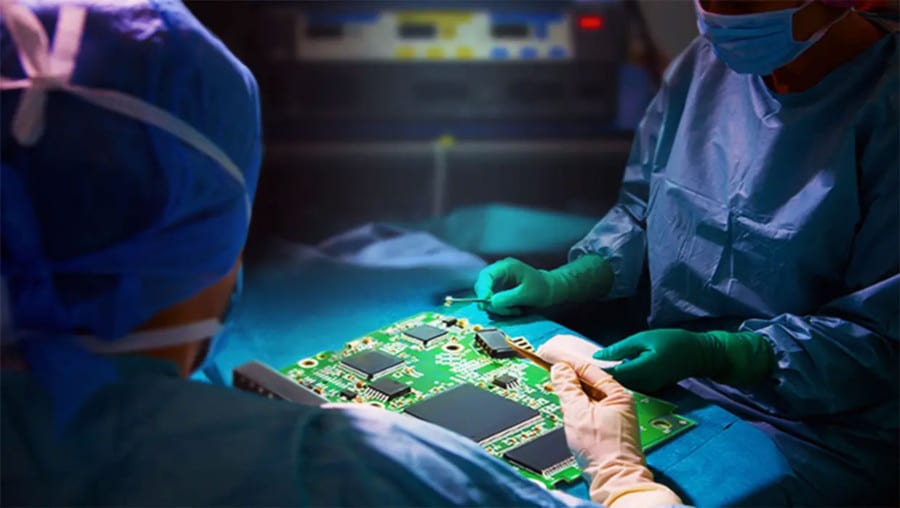

Failure is not an option for medical device PCBs where lives are on the line. We utilize high-reliability materials and components, as well as subject every board to extensive testing to ensure they can withstand shock, vibration, temperature extremes, and other environmental conditions.

Key Considerations For Medical Grade PCBs

Designing PCBs for medical applications requires careful consideration of requirements around materials, performance, and manufacturability. Here are some of the main options we provide to meet the unique needs of medical devices:

- Flexible PCBs

Flex circuits provide tight space savings and can withstand repeated bending cycles, making them well-suited for wearable monitors and imaging equipment. We utilize advanced flexible materials like polyimide to produce thin, durable, and reliable flex PCBs. - Ceramic PCBs

Ceramic boards offer exceptionally high heat tolerance and electrical insulation required in applications like surgical devices and analyzers. Our ceramic PCBs provide the robust thermal and mechanical performance needed in high-stress medical environments. - Rigid-Flex PCBs

By combining rigid and flexible materials in one design, rigid-flex PCBs offer versatility for complex layouts and motion applications. The rigid portions provide strength and stability while the flex areas allow for compact 3D configurations. From imaging machinery to patient monitors, our rigid-flex boards deliver reliability and space savings.

We have over a decade of experience manufacturing a wide range of medical PCBs to meet specialized requirements. Please let us know if you need any specific material, construction or design to best suit your medical device applications.

Medical Device Applications

We have built or collaborated on many different types of medical device applications. Some devices and areas of interest we have built or collaborated on include:

- Lab Analysis

- Diagnostic Imaging

- Blood Chemistry Monitors

- Patient Monitoring

- Implantable Devices

- Therapeutic Applications

- Surgical & Other Medical Robotics

- Disposables

- Microfluidics

- Molecular Diagnostics

- Neurostimulation

- Device Assisted Drug Delivery

- Wearables & Sensored Connected Devices

- Ultrasonic Technology

- Neurological Stimulus

- EMG Activity Systems

- Vesicle Pressure Measurement

- Infusion Fluid Controls

- Peristaltic Infusion Technology

- Flow Rate & Dispensing Systems

Current Trends Driving Medical PCB Innovation

The medical PCB sector continues advancing through several key technology trends to meet evolving demands. We stay at the forefront to best support customers.

- Miniaturization and HDI

Patients increasingly prefer small, non-invasive instruments generating demand for tinier, denser PCBs. Our investments in HDI fabrication methods and flexible PCB materials enable 3D form factors to save space without sacrificing performance. - IoT Integration

Linking devices through the cloud allows for smarter diagnostics and targeted treatment. Our manufacturing integrates sensor arrays and wireless connectivity onto PCBs, laying the groundwork for scalable, reliable IoT in healthcare. - 5G and Advanced Connectivity

Fast, reliable data fuels medical breakthroughs. By optimizing PCB signal integrity through careful layout and layer stackup design, we enable consistently clear 5G communication for bandwidth-intensive applications. - Sustainable Manufacturing

Healthcare aims to heal without harming. We continually improve our production efficiency to minimize ecological impact through responsible water and energy use while exploring recyclable and biodegradable materials.

Our Medical PCB Manufacturing Capabilities

We provide complete solutions for taking your medical device PCB from initial concept through volume production and product lifecycle management. Our capabilities include:

- Prototyping

We can quickly produce prototypes of new PCB designs to allow functional validation before investing in full production. Our rapid prototyping services help shorten time-to-market. - Engineering Support

From material selection advice tailored to medical applications to design-for-manufacturing recommendations to lower costs, our engineering experts support you through the development process. We also offer testing services to identify potential points of failure before release. - Manufacturing

Both our China-based facilities use cutting-edge equipment to produce complex, reliable PCBs in a range of production volumes, from low to high. And we put every board through rigorous testing protocols based on IPC standards before they leave our factory. - Lifecycle Management

We support clients over the entire lifecycle of their medical device product from production to aftermarket support. This includes managing revisions updates with minimal disruptions as well as failure analysis services to improve next generations.

Our focus is providing exceptional value, agility and transparency to medical device companies through PCB solutions customized for their needs. Contact us to learn more!

Why Choose Us For Your Medical PCBs

When choosing a manufacturing partner for medical-grade PCBs, quality, reliability and compliance are non-negotiable. Here are four key reasons to select us:

- Quality Assurance

Our rigorous quality management system complies with ISO 13485 standards specific to medical devices spanning supplier controls, manufacturing process controls and traceability. We inspect and test 100% of boards to ensure zero defects. - On-Time Delivery Guarantee

We understand delays are unacceptable for medical product launches. Our optimized workflow and strict production schedules enable us to guarantee on-time delivery of all orders, allowing you to meet critical market windows. - Cost Competitiveness

By leveraging our high-volume purchasing of materials, state-of-art automation, and optimized manufacturing processes, we offer exceptional value without ever compromising on quality for medical PCB production and assembly. - Complete Support

From collaborating with your engineers early in the design phase all the way through aftermarket revisions management, we act as an integrated partner to streamline your medical PCB production needs in a transparent manner.

Our ultimate priority is ensuring patient safety by delivering defect-free, high-performance PCB solutions for medical device manufacturers.

Contact Us for Medical PCB Solutions

We strive to be the foremost PCB manufacturing partner for medical device OEMs across the product development lifecycle. With certified quality systems, guaranteed on-time delivery, and end-to-end support, we help bring innovative medical products from conception to commercialization.

To learn more about our specialized medical PCB manufacturing and assembly services, simply contact us today to speak with an engineer or representative. We offer free evaluations of your current designs as well as recommendations to enhance performance, speed up timelines, and reduce costs without impeding quality or compliance factors.

Whether you require rapid prototyping services, complex multi-layer production runs or have unique material needs, we have the solutions. We also deliver full turnkey assembly, testing, and order fulfillment catered specifically to medical OEM requirements.

Bring your medical device vision to reality with our patient-centric PCB solutions. Reach out now to get started and elevate what’s possible in healthcare innovation.

JHYPCB - Leading High-Quality, Quick-Turn PCB Manufacturing

At JHYPCB, we are a premier PCB manufacturer providing one-stop PCB fabrication and assembly services to meet the diverse needs across multiple industries. With years of experience and cutting-edge capabilities, we deliver high-quality, quick-turn PCB solutions tailored to each application’s unique requirements.

Our Core Expertise:

- High-reliability PCBs for demanding applications

- Wide range of PCB technologies: HDI, rigid-flex, RF/microwave, thermal boards, and more

- Advanced manufacturing processes: high-density interconnect, buried/blind vias and more

- Fast prototype to production cycle times

- Strong engineering support from quote to delivery

Whether you need prototypes for new product development or high-volume PCB production, JHYPCB is your trusted partner. Explore our PCB capabilities for your industry below.