PCBs For New Energy Applications

The Top PCB Partner for Innovations in Energy and Renewable Technologies

Home » Industries Served » PCBs For New Energy Applications

Engineering the Future of Sustainable Energy

As global energy demand continues to rise, there has been a growing focus on developing renewable and sustainable energy solutions. Solar, wind, hydroelectric, geothermal, biomass, and hydrogen fuel cells are some of the major sources of renewable energy gaining momentum worldwide. At the heart of these innovative clean energy systems lies advanced power electronics and control equipment built on specifically engineered printed circuit boards.

As a leading PCB manufacturer with over 15 years of experience, we understand the specialized needs of new energy industries. Renewable energy PCBs have unique requirements to withstand high voltage, vibration, extreme temperatures, and demanding operating conditions within solar inverters, wind turbine converters, battery storage systems, electric vehicle (EV) powertrains, and fuel cell applications.

Our comprehensive PCB manufacturing and assembly services offer customized solutions engineered for reliability and high performance in new energy applications. With proven expertise in fabricating complex multi-layer PCBs for power electronics, strict quality assurance at every process stage, and responsive customer support, we aim to accelerate the transition towards sustainable energy with every PCB solution we create.

PCB Solutions for New Energy Applications

Types of PCBs Used

- High Voltage PCBs: Designed to operate efficiently at voltages exceeding 1,000V; proper layout separation and electrical isolation are key considerations.

- Thick Copper PCBs: Utilize thicker copper layers able to carry higher electrical loads with lower resistive losses and less heat generation.

- Aluminum PCBs: Aluminum backing helps conduct heat rapidly and prevents warping of boards at high temperatures.

- Metal Core PCBs: Built with a solid metal layer as base that serves as an efficient heat spreader for high power devices.

- High Frequency PCBs: Optimized for radio frequency and microwave signal integrity for telemetry and communication systems.

- Flexible PCBs: Withstand vibration, shock, and flexion stresses; suitable for dynamic movement and field installations.

PCB Specifications Required for New Energy Systems

- Withstand High Voltage: 1000V and higher AC/DC isolation and insulation resistance.

- Handle High Current Loads: 100A – 400A+; thick high ampacity copper traces.

- Survive Harsh Environments: Wide operating temperatures, humidity, mechanical shock loads.

- Ensure Signal Integrity: Controlled impedance, cross-talk and propagation delays.

- Facilitate Thermal Dissipation: Maximum heat spreading through materials and structural layers choice.

- Meet Industry Standards: Adherence to IPC specifications for electrical and assembly performance.

Our Manufacturing and Assembly Services

We offer specialized printed circuit board fabrication and assembly tailored for renewable energy applications. With decades of experience and advanced manufacturing capabilities, we provide full-service PCB solutions – from rapid prototyping services to volume production support.

- High layer count boards up to 32 layers+ to integrate advanced power electronics

- Blind and buried vias for interlayer connections without sacrificing board space

- Flex and rigid-flex boards for installations requiring dynamic movement

- Ultra-fine line to 6 mil width conductors and 4 mil isolation spacing

- ENIG surface finish that withstands oxidation for long-term performance

- Prototype to medium volume production in as fast as 24 hours

PCB Assembly Capabilities

- SMT assembly with extremely high placement precision of 01005 sized components

- Selective soldering and through-hole assembly

- Complex parts procurement and supply chain management

- Manual soldering capabilities for large busbars, pins, and connectors

- Quality inspection using 3D SPI, AOI and X-ray imaging

- Final product testing, burn-in, validation, and life cycle analysis

We are ready to partner in realizing robust PCB solutions tailored for solar, wind or energy storage systems that will perform reliably for decades in harsh real-world renewable energy project environments.

Application of PCB in new energy

PCBs are indispensable components across various facets of new energy technologies, allowing effective energy conversion, regulation, and administration. Their design and fabrication are customized to satisfy the distinct demands and difficulties of each use case, thereby enhancing the holistic effectiveness and robustness of new energy systems.

Across the domain of renewable energy, PCBs undertake a paramount role within an array of implementations. Below are certain illustrations of how PCBs constitute core elements within cutting-edge energy solutions:

Solar Power Systems

PCBs undertake an integral role within solar energy installations for modulating and regulating electrical current. They are deployed in solar inverters, which transform the direct current (DC) harnessed by solar arrays into usable alternating current (AC) for residential and commercial spaces. Solar inverter PCBs facilitate optimized power inversion, real-time system monitoring, along with safeguarded operation.

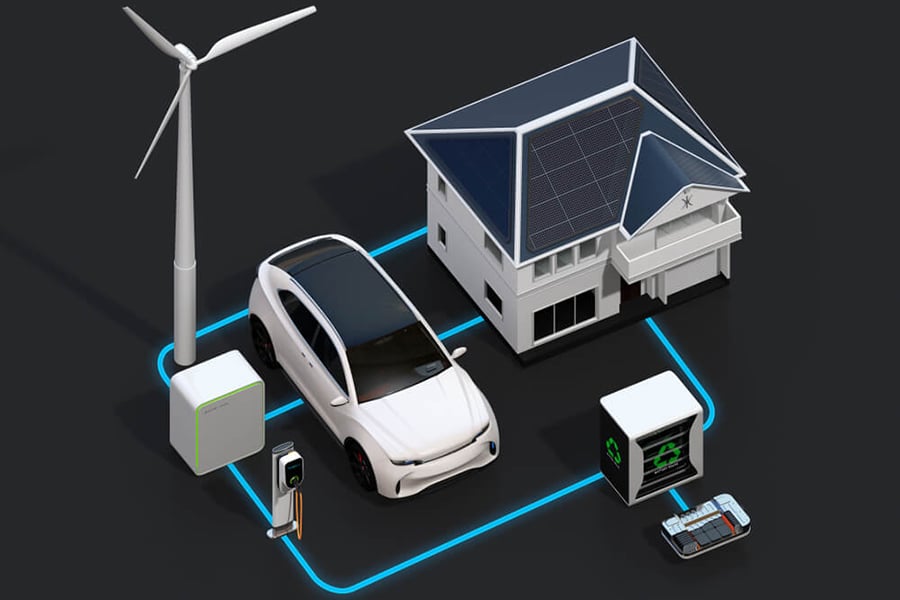

Energy Storage Systems

PCBs constitute indispensable components within energy storage solutions as batteries utilized in renewable energy use cases. They are embedded within battery management systems (BMS) for regulating charge and discharge cycles. This further balances cell voltages, besides safeguarding against overcharge or excessive drainage scenarios. By enabling streamlined and reliable operation of energy reservoirs, PCBs bolster overall effectiveness alongside longevity.

Hydropower Systems

PCBs are indispensable in hydroelectric installations for modulating and administering power generation from flowing water sources. They constitute integral components within control infrastructures across plants, spanning turbine regulation terminals, voltage modulation systems, alongside performance tracking equipment. Hydropower PCBs are pivotal to optimized and protected operations by calibrating turbine rotational velocity and yield and regulating water inflow while monitoring real-time analytics and safety parameters.

Electric Vehicle Charging Systems

PCBs are embedded across electric vehicle charging equipment, encompassing both charging terminals and regulation units. They govern power transmission, supervise charging advancement along with protective safeguards, in tandem enabling interconnectivity between portal and vehicle endpoints. Through streamlining communication protocols, regulating electricity flow, and upholding cross-platform compatibilities, EV charging system PCBs prove instrumental for user-friendly and reliable operations.

Wind Power Systems

PCBs fulfill multifaceted roles within wind turbines across an array of structural facets. They are commissioned within turbine regulation frameworks for calibrating blade pitch alignment, tracing wind velocity patterns alongside vector orientation, and modulating power output. Additionally, wind turbine PCBs also constitute key elements within multiple power electronics segments, encompassing converter equipment which transforms the variable frequency AC current harnessing into standardized grid electricity.

Power Electronics and Power Distribution

PCBs constitute indispensable components within new energy infrastructures, across power generation as well distribution links. They are commissioned within converters, inverters, rectifiers, and voltage command terminals to direct and optimize electrical flow. By facilitating seamless power transformation, curbing wastages, alongside furnishing consistent and stabilized supply, PCBs engender streamlined operations through new energy value chains.

Environmental Considerations

We understand the importance of responsible and sustainable manufacturing for renewable energy PCBs. By adopting green design and production methods, we minimize the environmental impact through:

Compliance to Health and Safety Standards

- RoHS, REACH and other directives to restrict hazardous substances

- Rigorous testing to ensure chemical safety for all component materials

Lead-Free and Halogen-Free Processes

- Employ lead-free soldering and SN100C alloy for assembly operations

- Use halogen-free laminates and dielectric prepreg materials

Reducing Our Environmental Footprint

- Optimization of chemistry usage, energy consumption and waste generation

- Water conservation, responsible wastewater treatment and reuse policies

- Workforce education on sustainability initiatives and carbon footprint reduction

We also conduct product life cycle assessments to select PCB solutions with maximal potential for reuse, refurbishment or recycling after end-of-life in renewable energy projects. With ISO 14001 certification and a steadfast commitment to ethical principles, we meet and exceed expectations for eco-friendly PCB development and manufacturing.

Why Choose Us As Your PCB Partner

Whether you are an R&D specialist or purchasing manager, choosing the right PCB partner is crucial in new energy technology projects. Here are five reasons why we stand out as a trusted PCB manufacturing and assembly solutions provider:

15+ Years Leading the Industry

With over two decades of experience as a pioneering PCB company, we have manufactured over millions of PCBs spanning across sectors. Our expertise and consistent innovation empowers the success of customers worldwide.

Uncompromising Quality Commitment

We have stringent quality control systems at every production stage combined with a sober and conscientious work ethic to deliver flawless PCB solutions. ISO 9001, ISO 13485 and IATF 16949 certifications validate our PCB quality commitment.

Responsive Communication

We make it a priority to actively listen and fully understand your current challenges and future goals to provide tailored solutions in the renewable energy context.

Competitive Cost-Effectiveness

By smartly leveraging our vast production economies of scale while practicing lean manufacturing, we offer PCB solutions at supreme value with excellent quality.

Exceptional Customer Service Our pre-sales engineers provide technical guidance and PCB design support while our customer service team offers prompt responses and rapid solutions before and after securing your business.

JHYPCB - Leading High-Quality, Quick-Turn PCB Manufacturing

At JHYPCB, we are a premier PCB manufacturer providing one-stop PCB fabrication and assembly services to meet the diverse needs across multiple industries. With years of experience and cutting-edge capabilities, we deliver high-quality, quick-turn PCB solutions tailored to each application’s unique requirements.

Our Core Expertise:

- High-reliability PCBs for demanding applications

- Wide range of PCB technologies: HDI, rigid-flex, RF/microwave, thermal boards, and more

- Advanced manufacturing processes: high-density interconnect, buried/blind vias and more

- Fast prototype to production cycle times

- Strong engineering support from quote to delivery

Whether you need prototypes for new product development or high-volume PCB production, JHYPCB is your trusted partner. Explore our PCB capabilities for your industry below.