PCBs for New Energy Vehicle

Home » Industries Served » New Energy Vehicle PCB

New Energy Vehicle PCB Opportunities

The new energy vehicle industry has entered a phase of massive growth worldwide. According to research firm IDTechEx, the electric car market is projected to reach $1.3 trillion by 2040. Major factors propelling this trend are government policies, technology improvements, and consumer demand for sustainable transportation.

In China, the largest electric car market, over 6 million new energy vehicles were sold in 2022. The China Association of Automobile Manufacturers predicts new energy vehicle sales will increase by 56% in 2023. Strict government mandates are accelerating adoption. By 2025, 20% of cars sold must be electric.

This exponential transition is catalyzing demand for specialized printed circuit boards. As new energy vehicles replace far more mechanical functions with electronic systems, they utilize considerably more PCBs than internal combustion engine vehicles. Critical applications include battery management, powertrain systems, charging, instrumentation and control electronics.

PCB manufacturers can capitalize on this trend by developing solutions tailored to address new energy vehicle requirements like high-power density, ruggedness, safety and EMI control. Companies that build capabilities ahead of the curve will secure significant competitive advantage as the electric mobility revolution continues gaining momentum globally.

Premium PCB Manufacturing and Assembly Services for New Energy Vehicles

Over the years, we have focused on delivering high-quality PCB manufacturing and assembly services for the new energy vehicle industry. Our flexible production lines can fabricate everything from single-sided boards to multilayer HDI PCBs, combined with professional SMT capabilities for mass electronics assembly.

We have accumulated extensive experience in application-specific PCBs for new energy vehicles. By continuously refining our design and production processes, we ensure products fully meet the rigorous quality, reliability and safety requirements of this demanding application space.

We also maintain partnerships with leading chip vendors and test houses, enabling early evaluation of emerging technologies and validation of our PCB performance parameters.

Backed by excellence in technology and a robust quality system, our new energy vehicle PCB products and services enjoy strong market recognition. We are confident to continue serving as a reliable high-quality PCB supplier for global electric vehicle manufacturers.

Common PCB Applications in New Energy Vehicles

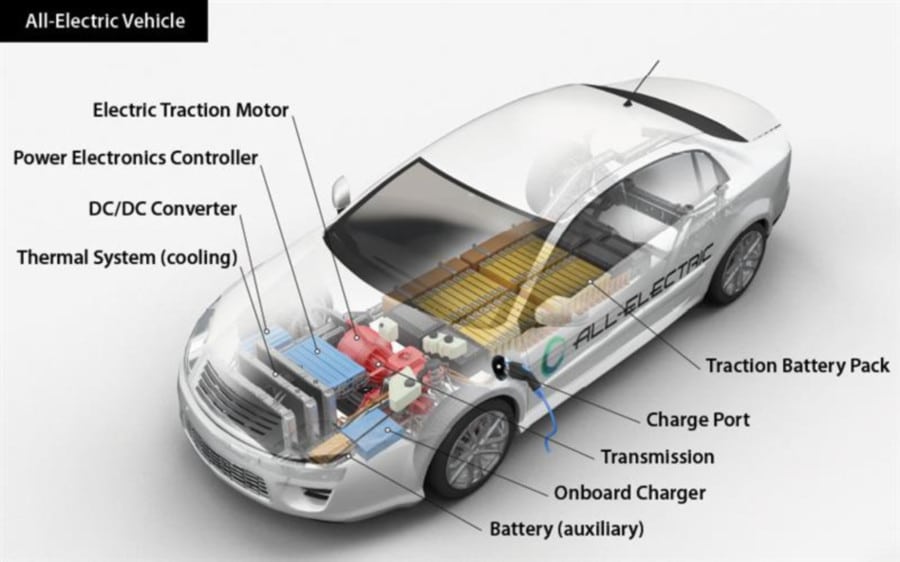

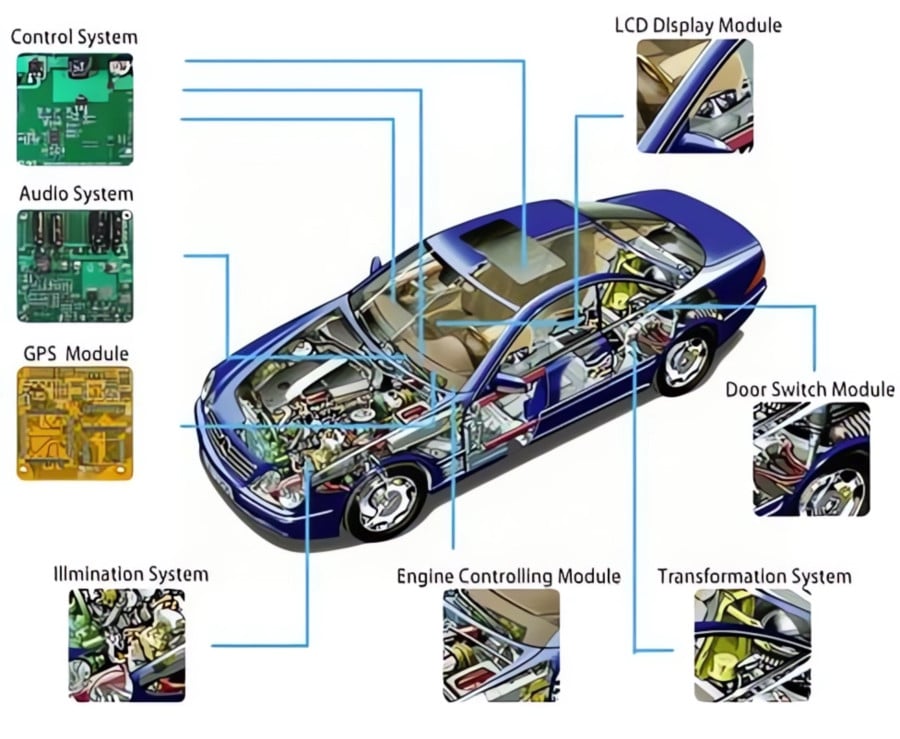

As new energy vehicles replace more mechanical functions with electronics, PCB demand rises significantly across many systems:

Battery Management Systems

Battery management is crucial in electric vehicles to monitor cell conditions and prevent thermal runaway. Multilayer PCBs are common to consolidate the complex monitoring and balancing circuitry needed. We optimize designs for thermal dissipation and electromagnetic shielding.

Inverter/Converter PCBs

Power inverters and converters play vital roles in electric vehicle powertrains for functions like DC-AC conversion to run AC motors. High power density design paired with robust thermal management is critical here. We implement special high frequency dielectrics and layout techniques tuned for these circuits.

Onboard Chargers

The onboard charging system converts grid AC power to charge the high voltage battery pack. Tight integration of switching devices combined with noise isolation is important in charger PCBs. Our extensive experience in power device PCBs ensures high stability charging.

Vehicle Control Units

VCUs orchestrate functions from torque control to charging management. With microprocessors operating at high clock frequencies plus many peripherals, noise control and timing design are paramount here. We optimize stack-ups and grounding for ultra reliable VCU control.

Common Printed Circuit Boards in New Energy Vehicles

As new energy vehicles handle high voltage and current, various PCB types are utilized to conduct and control electricity safely across functions:

Multi-layer PCBs

6-12+ layer boards employ complex internal circuitry to precisely transmit signals and power between electronic modules. More layers enable more robust connectivity.

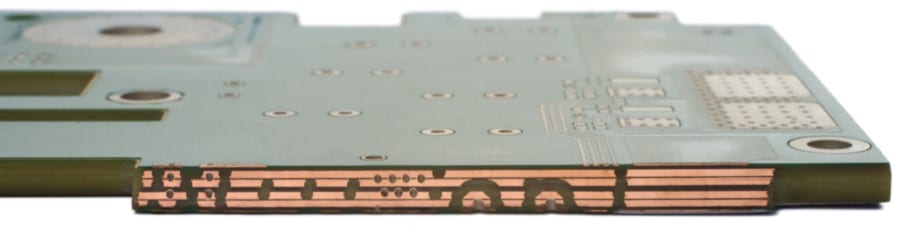

Thick Copper PCBs

Ultra-thick 2oz, 3oz and even 4oz copper reliably channels currents up to 400A+, applied for motor control and power conversion requiring stable high ampacity traces.

HDI PCBs

High-density interconnect technology with microscopic vias and dense circuitry allows integrating more functionality and components in confined control units, saving space and weight.

Large-area PCBs

Sprawling PCBs powering functions like body electronics and chassis controls enable more consolidated layouts and simplified connectivity.

Realize Electric Vehicle Innovations with Our Proven PCB Expertise

As new energy vehicles go mainstream, product success depends on reliable, high performance PCBs. With over 15 years focused on advancing automotive board technologies specifically for stringent vehicle requirements, we have the expertise and capabilities to help bring your visions to life.

Connect with our engineering team today to explore how our manufacturing services can enhance your next generation electric vehicle designs. We offer an agile approach, combining rigorous quality processes with tailored solutions, to help you gain a competitive edge.

JHYPCB - Leading High-Quality, Quick-Turn PCB Manufacturing

At JHYPCB, we are a premier PCB manufacturer providing one-stop PCB fabrication and assembly services to meet the diverse needs across multiple industries. With years of experience and cutting-edge capabilities, we deliver high-quality, quick-turn PCB solutions tailored to each application’s unique requirements.

Our Core Expertise:

- High-reliability PCBs for demanding applications

- Wide range of PCB technologies: HDI, rigid-flex, RF/microwave, thermal boards, and more

- Advanced manufacturing processes: high-density interconnect, buried/blind vias and more

- Fast prototype to production cycle times

- Strong engineering support from quote to delivery

Whether you need prototypes for new product development or high-volume PCB production, JHYPCB is your trusted partner. Explore our PCB capabilities for your industry below.