As a premier flexible PCB manufacturer in China, JHYPCB has extensive expertise in fabricating and assembling high-quality flex circuits. For over 15 years, we have provided advanced flex PCB solutions to consumer electronics, automotive, medical, aerospace, and defense customers.

Our state-of-the-art facilities in Guangdong enable us to produce flex PCBs in high volumes while maintaining rigorous quality control and competitive pricing. We can manufacture flex PCBs with up to 12 layers, trace/space down to 25/25 μm, and flexibility to bend radii as low as 0.1mm.

Flexible printed circuits provide many advantages over traditional rigid PCBs. They are extremely lightweight and can conform to fit mechanical designs with dynamic shape requirements. The elasticity allows for high-density interconnections in tight spaces and enables embedding electronics into irregular form factors. Heat dissipation and high-frequency signal integrity are also improved with flex circuits.

This comprehensive guide will provide key insights into the flexible PCB manufacturing process. We will cover flex circuit design considerations, fabrication techniques, emerging applications, assembly best practices, and more. We aim to help PCB designers, engineers, and procurement managers better understand the benefits of partnering with JHYPCB for their flex PCB fabrication and assembly needs.

Table of Contents

Flexible PCB Fabrication Process

Flex PCBs require specialized materials and processes compared to standard rigid PCB boards. JHYPCB utilizes cutting-edge fabrication techniques to produce high-quality, reliable flex circuits.

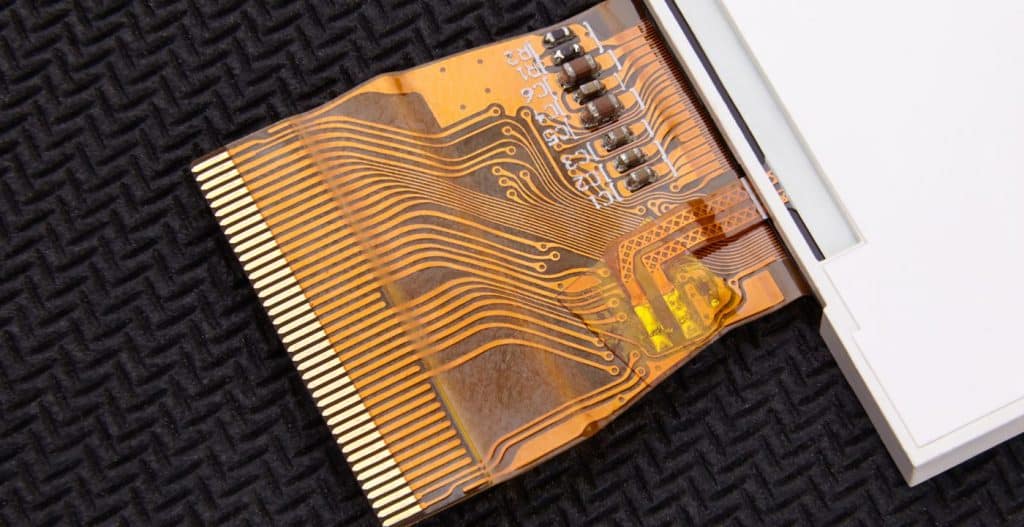

Polyimide is the most common base material used in flex PCB fabrication. The high heat resistance, chemical stability, and mechanical flexibility of polyimide films like DuPont’s Kapton make them ideal substrates. We also use flexible PET films for certain applications.

The circuitry layers are constructed using rolled annealed copper laminated to the base film. Photolithographic patterning techniques are used to etch the copper and generate trace geometries and spaces. Flex PCBs are typically single-layer or multilayer with 2 to 12 metal layers separated by adhesive dielectric films.

Our flex PCB manufacturing capabilities support sophisticated flex stackups. We produce double-sided flex using plated-through holes and microvias for interlayer connections. For multilayer flex, laser drilling forms high-density vias with diameters down to 50μm.

Compared to rigid PCB boards, flex PCB fabrication offers benefits like:

- Thinner overall construction for compact, lightweight circuits

- Dynamic flexural capability for movable/shape-changing electronics

- Improved high-frequency signal integrity at bends

- Enhanced heat dissipation with heat-spreader copper layers

- Fine line/space traces and spacing for high interconnect density

We utilize AOI and electrical testing throughout the fabrication process to ensure quality standards are met. Coupon samples are also tested for coating thickness, adhesion, solderability, and other performance metrics.

Flexible PCB Design Considerations

Proper design is crucial for manufacturing reliable, high-performing flex PCBs. Designers must account for the dynamic nature of flex circuits and make considerations for:

- Bend Radius – The minimum bend radius determines the flexibility and durability. Inside bend radii down to 0.1mm can be achieved with optimal materials and stackup.

- Board Stiffness – Polyimide films provide good flexural endurance but also dimensional stability. Selective stiffening elements like cover layers are used when needed.

- Thermal Management – Large copper planes dissipate heat efficiently. But flexing actions require thermal mitigation techniques like thermal reliefs.

- High-Frequency Layout – Controlled impedance traces, ground planes, and vias enable flex PCBs to operate at high frequencies for RF and digital signals.

- Component Selection – Low-profile SMT components withstand flexing and minimize thickness. Avoid rigid connectors, opting for flex-tail or ribbon cable connections.

- Attachment Methods – Soldering, conductive epoxy, and mechanical fastening attach components reliably. Adhesive selection is also critical.

At JHYPCB, our engineering team provides flex PCB design reviews and recommendations to identify opportunities for optimization. We have experience designing flex circuits for dynamic applications across industries.

By partnering with us early in the design process, we can help assess manufacturability, troubleshoot any issues with the planned construction, and ensure your flex PCB design is optimized for cost-effective fabrication and assembly.

Flexible PCB Assembly Techniques

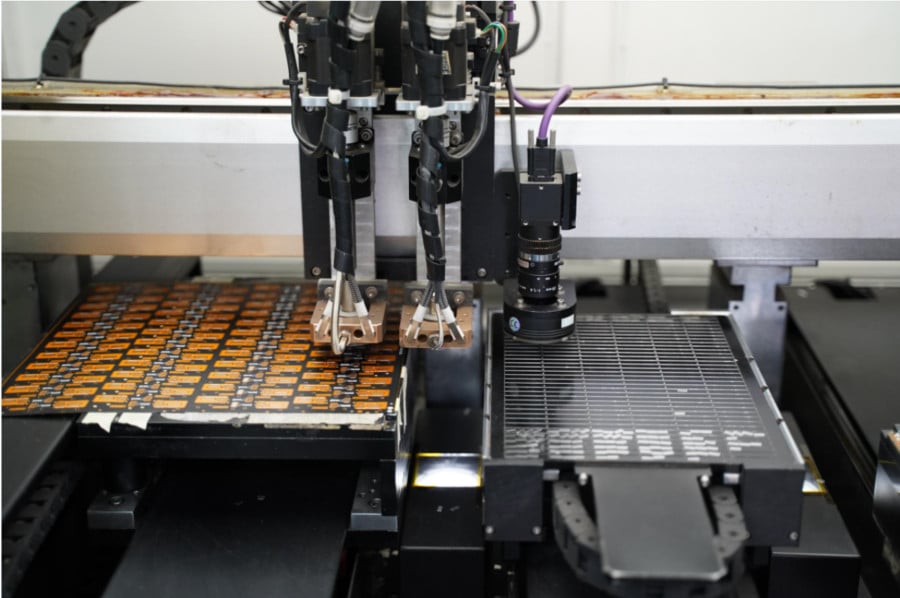

Assembly of components onto flex PCBs requires specialized techniques compared to standard rigid PCB assembly. JHYPCB has developed proven assembly processes to mount components onto flex circuits reliably.

SMT assembly is suitable for lower component counts, allowing pick-and-place and reflow soldering of chip components. For higher densities, manual assembly may be required.

Component attachment methods include:

- Solder joints – For heat-resistant components. Care is needed to avoid base film damage.

- Conductive epoxy – Provides strong mechanical bonds with electrical connection.

- Mechanical fasteners – Standoffs, screws, and clamps provide solid mounting.

- Pressure-sensitive adhesives – Adhere components while allowing rework/repair.

We select adhesives optimized for flexibility, peel strength, tear resistance, and operating temperatures. Adhesive curing methods include heat, pressure, ultrasonic energy, and humidity.

Flex PCB rework and repair present challenges due to the sensitivity of polyimide films. We utilize specialized systems and processes for component removal and replacement without circuit damage.

Our experienced PCB assembly technicians are trained on the unique requirements of flex PCB assembly. We’ve optimized our assembly processes for high yields, maximum uptime, and fast turnaround.

By leveraging our flex PCB assembly expertise, customers can accelerate their hardware development schedules and move quickly from PCB prototyping to mass production. We’re ready to discuss your specific application requirements and determine the optimal assembly process.

The unique benefits of flex PCBs make them well-suited for many emerging applications, especially wearable devices, IoT sensors, and other compact electronics.

- Wearable Devices – Flex circuits conform to the contours of the human body for devices like health trackers and smartwatches. High density interconnects fit into tight spaces.

- Internet of Things – Flex PCBs work well for embedding sensors and connectivity into irregular everyday objects to enable smart homes, offices, appliances, etc.

- Automotive Electronics – Lightweight flex circuits improve reliability of electronics in movable automotive subsystems like seats, mirrors, doors, etc.

- Medical Devices – Implantable health monitoring devices rely on thin, flexible PCBs that can withstand bodily environments.

- Robotics/UAVs – The dynamic flexing requirements in joint actuators and movable robot appendages are met by flex PCBs.

At JHYPCB, we stay on top of the latest flex PCB tech trends and are ready to support your emerging application requirements. Our technical experts can assess the feasibility of your design and identify any needed adjustments to optimize it for manufacturability.

With our capabilities in high-mix, low-to-medium volume flexible PCB production, we can help you fast-track your product development and quickly scale up to production when you’re ready.

Conclusion

Flexible PCBs provide many advantages, making them the ideal choice for electronics with dynamic shape requirements and tight space constraints. As discussed in this guide, flex circuits require careful design and specialized manufacturing processes to produce reliably and efficiently.

With over 15 years of experience, JHYPCB has become a premier flex PCB manufacturer by continuously honing our fabrication and assembly processes. We utilize the latest technologies in our ISO-9001-certified facilities to deliver high-quality flex circuits at competitive costs.

Our expertise spans the entire flexible PCB production cycle – from design review and optimization, multilayer materials selection and fabrication, precision high-density assemblies, and testing/verification. We partner closely with customers from initial concept through to volume production and maintenance.

With JHYPCB as your manufacturing partner, you can trust you’re getting a flex PCB fabricated and assembled properly to meet your technical requirements. And you’ll benefit from our guidance to avoid pitfalls and optimize your design for manufacturability.

We invite you to learn more about our capabilities by checking out the flexible PCB solutions on our website. Or contact us directly to discuss your specific flex circuit project needs. Our team of engineers and sales experts are ready to provide manufacturing expertise and deliver advanced flex PCB innovations.

Related Reading

- Custom Flex PCB:Tailored Solutions for Your Applications

- Custom PCB Fabrication in China – Prototyping & Mass Production

- Expedited PCB Services – Quick Turnaround for Your Urgent Needs

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- Rapid PCB Prototyping Services: A Comprehensive Introduction

- Introduction to Semi-Flex PCBs: Bridging Rigid and Flex PCBs

- How to Select the Right Flexible PCB Manufacturer for Your Product: A 6-Step Guide

- Layer Stackup in Rigid-Flex PCB

- What Are The Types of Flexible Circuit Boards?

- Why is Flexible PCB so Expensive?

- The Manufacturing Process Of Double-sided Flexible PCB Coverlay

- What Are The Advantages And Applications Of Rigid-Flex PCBs?

- Rigid PCB vs Flex PCB: What Is The Difference?

- How to Solder On Flex PCB?

- Flexible Printed Circuit For Today’s Packaging

- 16 Factors Affecting The Cost And Price of Flexible PCB

- Complete Introduction of Flexible Circuit Board Materials

- The terms you have to know related to the manufacture of Flexible PCB

- Knowledge of Flexible PCB Manufacturing Process Steps

- Knowledge of Plating on Flexible Circuit Board Surface

- Five factors that FPC PCB designers should know about impedance control

- Key Process Flow of Rigid-Fled PCB Production