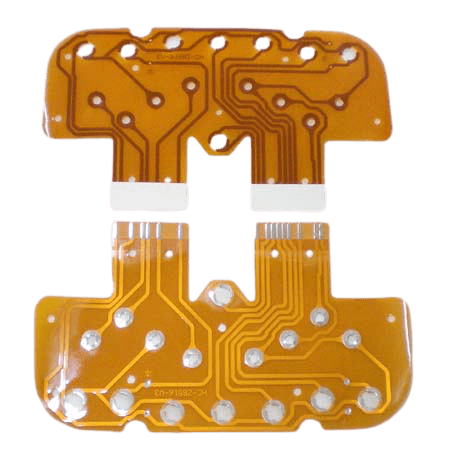

FPC flexible PCB is a highly reliable and excellent printed circuit board made of polyimide or polyester film as the base material.

FPC is the abbreviation of a flexible printed circuit board, which has the characteristics of high wiring density, lightweight, and thin thickness.

FPC is mainly used in mobile phones, notebook computers, PDA, digital cameras, LCM, and many other products. Here are some common terms related to FPC.

1、Access Hole

The Coverlay, on the surface of the flexible circuit board, is often used to attach it to the surface of the flexible PCB as an anti-welding film. However, it is necessary to deliberately expose the hole ring hole wall or square welding pad needed for welding in order to facilitate the welding of parts. The so-called “Access Hole” means that the access Hole, on the surface enables the outside world to “approach” the solder joint under the cover. Some multilayer circuit boards also have this kind of access hole.

2、Acrylic

It is a common name for polyacrylic resin, and most Flexible Printed Circuit Board uses its film.

3、Adhesive

A substance, such as a resin or paint, enables two interfaces to be bonded.

4、Anchoring Spurs

To make the hole ring welding pad have stronger adhesion on a single-sided flexible PCB, several additional finger claws can be added to the excess space outside the hole ring to strengthen the hole ring and reduce the possibility of floating from the board surface.

5、Bandability

It is one of the characteristics of Dynamic Flex Boards, such as the Flexible Printed Circuit Board, used in the Print Heads of computer disk drives, whose quality should reach a billion times of “bending test.”

6、Bonding Layer

It often refers to the film layer of multilayer PCB board, or TAB tape, or flexible circuit board, the adhesive layer between its copper skin and PI substrate.

7、Coverlay/Cover Coat

It is the outer line of Flexible PCB, and its anti-welding should not use the green paint used in the rigid PCB, because it may fall off when bending. Need to change to a soft “acrylic” layer pressed on the board surface, so that it can be used as an anti-welding film and protect the outer line, and enhance the resistance and durability of the flexible circuit board, this unique “outer film” is primarily known as the Coverlay/Cover Coat.

8、Dynamic Flex(FPC)

This refers to flexible circuit boards that need to be used for continuous exercises, such as Flexible PCB in the read/write head of a disk drive. Besides, Static FPC refers to the FPC board that no longer has any action after it has been assembled.

9、Film Adhesive

It refers to the dry flake bonding layer, which can contain reinforced fiber cloth film or does not contain reinforcement only adhesive material thin layer, such as the FPC bonding layer.

10、Flexible Printed Circuit, FPC

It is a special circuit board, which can change the shape of three-dimensional space during downstream assembly, and its substrate is flexible PI or PE. This kind of Flexible Printed Circuit Board is also like a rigid board, which can make plated through holes or sticky surface pads for through-hole insertion or surface mount. The surface of the board can also be affixed with a soft Cover Layer, for protection and anti-welding use or printed with thin anti-welding green paint.

11、Flexural Failure

Repeated bending and bending action, resulting in the fracture or damage of the material (board), is called Flexural Failure.

12、Kapton

This is the name of a DuPont product, which is a kind of “polyimide” sheet-like insulating soft material, which can be made into the substrate of FPC after Calendering copper foil or electroplated copper foil is attached.

Want to know more about PCB materials and brand suppliers? Please click here.

In fact, FR4 is one of the most used materials in the production of rigid PCBs, do you know why? Click here to learn more.

Sometimes FR4 is also used in High Tg PCBs, to learn more, please click here.

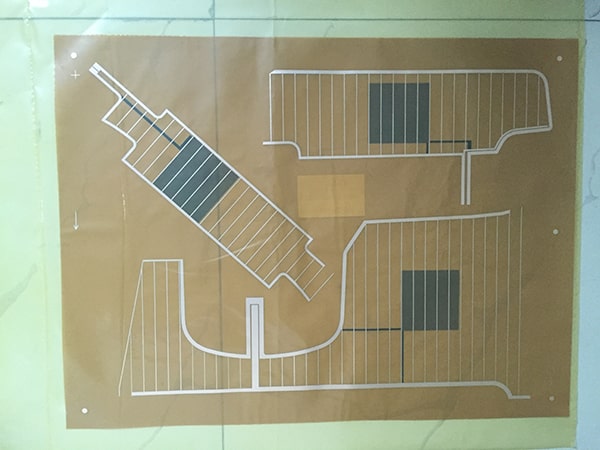

13、Membrane Switch

With the transparent Mylar film as the carrier, the SilverPastes is printed on the thick film circuit by screen printing and then coupled with the hollowed-out gasket, combined with the protruding panel or PCB to become a “touch” switch or keyboard. This small “button” device is often used in hand-held calculators, electronic dictionaries, and some household appliance remote controls, all of which are called “Membrane Switch.”

14、Polyester Films

It is referred to as the PET sheet; the most common is DuPont’s commodity MylarFilms, which is a kind of material with excellent electrical resistance. In the circuit board industry, the transparent protective layer on the surface of the imaging dry film is the same as the Coverlay on the FPC surface. It can also be used as the substrate of the Membrane Circuit, and it can also be used as the insulating layer of cables, transformers, coils, or tubular storage devices of multiple ICs in the electronic industry.

15、Polyimide (PI)

It is a kind of excellent resin polymerized by Bismaleimide and Aromaticdiamine. It was first known as Kerimid 601, a powder resin product produced by Rhone-Poulenc Company in France. DuPont made it into a sheet, called Kapton. This kind of PI board has excellent heat resistance and electrical resistance. It is not only an essential raw material for FPC and AB but also a unique board for advanced military rigid circuit boards and supercomputer motherboards.

16、Reel to Reel

Some electronic components can be produced by the retractable process of reels, such as TAB, Lead Frame of IC and some FPC, etc., which can take advantage of the convenience of rewinding and unwinding to complete their automatic online operation, to save the time of one-piece service and the cost of labor.

Related PCB and PCBA Fabrication Services

- Fast Turn Prototype PCB Service

- Low-Cost PCB Prototype Fabrication

- Rigid-flex PCB Manufacturing Service

- Fast Prototype PCB Assembly Service

- SMT PCB Assembly

- LED PCB Assembly

- Multilayer PCB Manufacturing Service

Advanced Learning: