The birth and development of FPC and PCB have created this new product- Rigid-flex PCB board; therefore, it is a printed circuit board, which combines an FPC( flexible printed circuit) with a rigid circuit board by pressing or laminating processes, and according to the relevant technical requirements to form a circuit board having FPC characteristics and PCB characteristics.

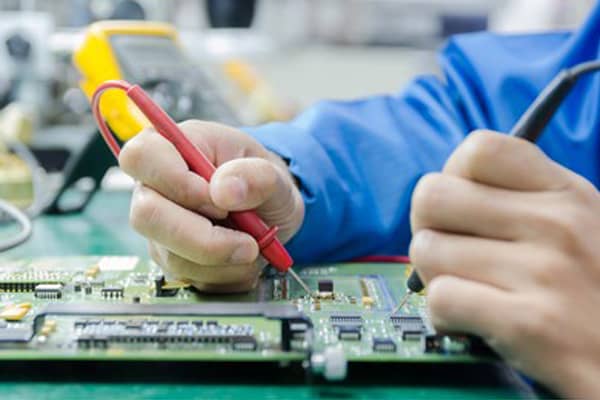

FPC Circuit Board Production

- cutting: Cut the flex PCB material(Learn more PCB fabrication material) (FCCL/cover film/pure rubber, etc.) into the PNL size we need for PCB processing.

- FPC lamination: Pressing the FPC board together with a specific temperature and pressure through a Bonding sheet to form an FPC layer stack.

- Blacking the hole: Through the black hole method, a layer of charged carbon powder is attached to the hole wall to realize the hole wall’s metallization for subsequent copper plating.

- FPC Board plating: To make the hole wall plate with a standard copper thickness to achieve electrical signal conduction between layers.

- FPC exposure: To achieve FPC graphic image transfer through the dry film/exposure principle.

- FPC etching: Acid etching is used to remove the copper layer’s FPC patterner.

- Plasma degumming: mixing a certain proportion of gas in a vacuum chamber to achieve a vacuum plasma state to meet the purpose of soft board removal or film surface roughening.

Pressing or Lamination Process

- Stick covering film: protect the copper surface of the FPC board substrate and increase the folding resistance of the FPC board.

- Fast laminating: pressing the film at a high temperature for a short period, bonding the cover film to the copper surface of the FPC board substrate to enhance the viscosity of the cover film and the FPC board.

- Browning: to roughen the surface of the copper through the chemical syrup to increase the bonding force between the FPC board and the rigid board.

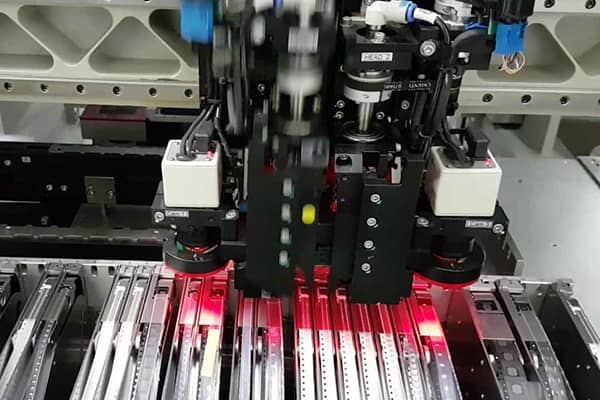

- Pressing or laminating: bonding the FPs and rigid boards together by high temperature and high pressure.

Opening Process

- Core board: The UV laser controls the deep Core board and the outer layer control depth to form the opening section to achieve the opening design.

- Routing opening slot: through mechanical forming, form a closed path with the outer layer to achieve the opening design.

- Laser depth control: open the cover of the thin cover sheet by UV laser depth control.

- Mechanical control depth: through the mechanical control depth, the outer cover of the thick cover piece is realized.

The advantages of our factory to fabrication rigid-flex PCB boards

- More than 9 years of PCB manufacturing experience, with over 8 years of experience in Rigid-flex PCB production.

- Advanced CCD hot melt equipment and automated laminating equipment, Strong manufacturing process capability of laminating.

- LDI can produce printed circuit boards with 30/30um trace width & trace spacing, precise alignment accuracy.

- The plasma and browning process can increase the bonding between FPC and Rigid PCB boards.

- With UV cutting, we can deliver quickly.

- Unique technical advantages in the opening process.

Related PCB Manufacturing Services

Related PCB Assembly Services

Related Posts

- Rigid PCB Fabrication Capability

- Flexible PCB Fabrication Capability

- PCB Fabrication Process step by step

- Double-Sided PCB Manufacturing Process

- Introduction to the aluminum PCB manufacturing process

- The Main PCB Assembly process Steps

- The Production Process and Specifications of PCB SMT stencil

- What Are The Advantages And Applications Of Rigid-Flex PCBs?