Before understanding the cost and pricing of flexible printed circuit boards (FPCs), let’s first explore what an FPC is. With their outstanding advantages, FPCs naturally come at a higher price compared to regular rigid PCBs. What are the main factors influencing the cost and pricing of flexible PCBs? Let’s examine them one by one.

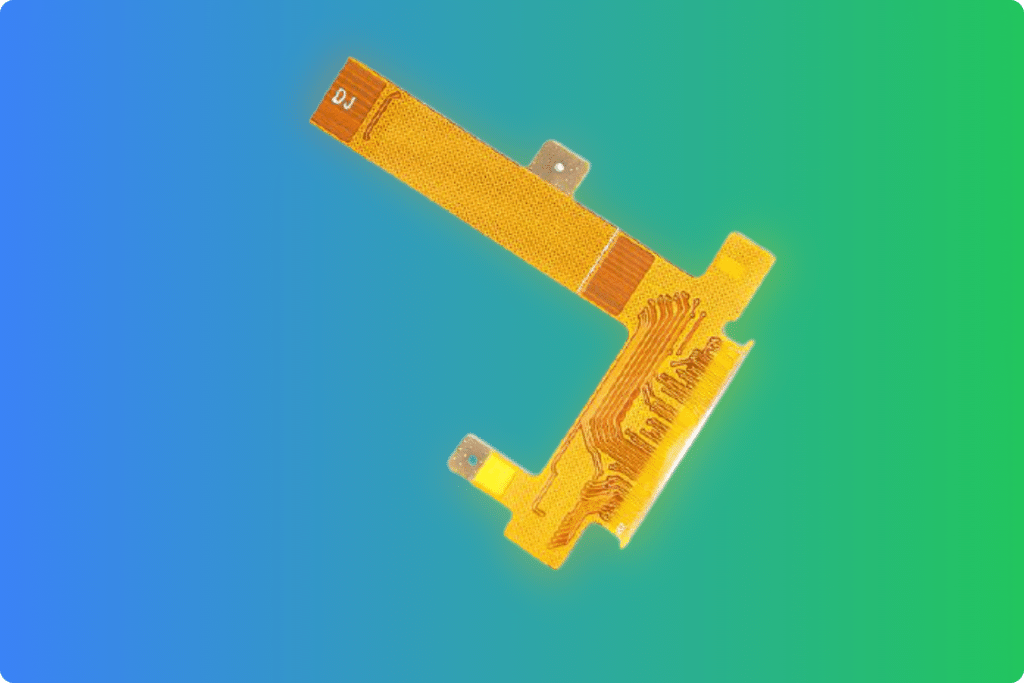

What is a flexible PCB?

Flexible PCB, also called flexible electronics; we call it FPC for short, is made of polyester film or polyester amide. Light and thin, high assembly density, high flexibility, bendable and foldable, and advantages that other circuit boards do not have. Compared with traditional interconnection technology, FPC can withstand millions of bends, is easy to install, and has good heat dissipation performance.

What are the factors that determine the cost and price of flexible PCB?

Since flexible PCB has so many advantages, its price will naturally be higher than ordinary rigid PCB. What factors make up the price of flexible PCB? Let’s discuss it together below.

1. Flexible PCB Materials

Taking a standard double-sided FPC as an example, the base materials typically include PET, PI, with thicknesses ranging from 0.0125mm to 0.10mm, and copper foil thicknesses from ⅓oz to 3oz. These material differences alone result in substantial variances in base material costs. Costs also vary between different material brands. Furthermore, reinforcement materials used in FPCs, such as steel sheets, FR4, aluminum plates, PIF CCL copper foils, etc., contribute to price discrepancies.

Advanced Learning

2. The Manufacturing Process

Different production processes lead to different manufacturing costs. Surface finish options include gold plating, immersion gold, immersion tin, OSP, etc., each with varying price points. Additionally, factors like precision shape requirements, use of silk-screened or dry film circuitry, etc., influence costs and ultimately cause price diversity.

3. Processing Difficulty Factor

Even with identical materials and processes, the inherent design and manufacturing complexity of an FPC can result in cost variances. For instance, two PCBs with 1000 holes each, one with hole diameters >0.6mm and the other <0.6mm, will have different drilling costs. Similarly, two PCBs with the same processes but differing line widths/spaces, e.g., one >0.15mm and the other <0.15mm, will have dissimilar production costs. As FPCs with higher manufacturing difficulties tend to have higher scrap rates, their costs inevitably increase, leading to price variations.

4. Panel utilization

The raw material for FPCs is copper-clad laminate, which comes in fixed sizes from the factory. FPC manufacturers calculate the panel utilization rate for a specific batch based on factors like the material, layer count, processes, and quantity of the FPCs to be produced. This utilization rate directly impacts the material cost.

5. Copper Foil Thickness

Standard copper foil thicknesses are 18um (1/2oz), 35um (1oz), 70um (2oz), 105um (3oz), 140um (4oz), etc. Thicker copper foils command higher prices.

6. The Fixtures and Test Cost

- Tooling costs – FPC prototyping and small-batch production generally don’t incur milling costs, while mass production requires dedicated fixtures, adding to expenses.

- Testing costs – These include producing and using test fixtures. Prototypes typically use flying probe testing, while mass production employs test fixtures, which is more costly than flying probe tests.

Advanced Learning

- Testing & Inspection Methods For PCB And PCBA

- Flying Probe Testing For PCB

- X-Ray Inspection In PCB Assembly

7. Dimensions

FPC manufacturers provide quotes based on the length and width specifications. Larger FPC sizes require unique materials and equipment, increasing costs.

8. Layer Count

FPCs are classified as single-sided, double-sided, or multi-layer. Single-sided FPCs are the least complex to manufacture and hence the cheapest, followed by double-sided. Multi-layer FPCs command premium pricing due to their immense manufacturing challenges. For example, a 6-layer FPC costs more to produce than a 4-layer one.

9. Acceptance Criteria

The level of customer requirements directly impacts the yield rates for PCB manufacturers. For instance, if an FPC is produced per IPC-A-6013 Class 1 standards requiring a 98% pass rate, the cost would be higher than for Class 3 with only a 90% pass rate. This variance in acceptance criteria results in different costs for manufacturers, ultimately leading to price diversity.

Advanced Learning

10. Manufacturer Capabilities

Even for the same product, costs can vary owing to differences in process equipment and technical proficiencies across FPC manufacturers.

Advanced Learning

- How to Choose the Right PCB Manufacturer and Supplier

- 6 Tips For Looking For A PCB Prototype Manufacturer

- Why Choose Chinese PCB Manufacturer

- Custom PCB Manufacturer In China

11. Payment Terms

Currently, FPC manufacturers generally adjust prices by 5-10% based on different payment methods, further contributing to pricing variations.

12. Geographic Regions

Within China itself, FPC prices tend to increase from south to north due to regional disparities. Moreover, choosing a domestic Chinese PCB manufacturer versus an overseas one also impacts the overall cost, with China benefiting from established infrastructure, a comprehensive supply chain, high production volumes, extensive experience, and relatively lower labor costs.

13. Plating Methods

Partial electroplating costs around 15% more than full electroplating.

Advanced Learning

- Knowledge of Plating on Flexible Circuit Board Surface

- Knowledge of Flexible Printed Circuit Board Processing Technology

14. Gold Finger Surface Finish

There is about a 5% cost difference between gold plating and tin plating processes for the gold finger surface finish.

15. Order Volume

The volume of FPCs ordered significantly affects the overall cost, with larger bulk orders typically qualifying for discounts or lower unit prices from manufacturers.

16. Lead Time

More urgent production schedules mean higher expedited costs have to be paid.

Pricing Examples: Impact of Specifications on FPC Costs

To better illustrate how the various factors influence flexible printed circuit board pricing, let’s look at some real-world examples with actual cost estimates:

Example 1: Material and Layer Count

- 6-layer FPC, 0.2mm overall thickness, PI material, 1oz copper Estimated Cost: $2.5 – $3.5 per unit for 5,000 pieces

- 2-layer FPC, 0.1mm overall thickness, PET material, 0.5oz copper Estimated Cost: $0.8 – $1.2 per unit for 5,000 pieces

As shown, a 6-layer PI-based FPC commands a significantly higher price compared to a 2-layer PET version, primarily due to the more costly material and increased manufacturing complexity with higher layer counts.

Example 2: Copper Thickness and Surface Finish

- 4-layer FPC, 0.4mm thick, 2oz copper, ENIG surface finish Estimated Cost: $1.8 – $2.5 per unit for 10,000 pieces

- 4-layer FPC, 0.4mm thick, 1oz copper, Immersion Gold surface finish Estimated Cost: $1.2 – $1.8 per unit for 10,000 pieces

Thicker copper foil and advanced surface finishes like ENIG contribute to increased costs, as evident from this 4-layer FPC comparison.

Example 3: Line Width/Spacing and Hole Sizes

- 2-layer FPC, 0.2mm thick, line width/spacing 0.1mm, hole size 0.3mm Estimated Cost: $1.5 – $2 per unit for 3,000 pieces

- 2-layer FPC, 0.2mm thick, line width/spacing 0.2mm, hole size 0.6mm

Estimated Cost: $0.9 – $1.3 per unit for 3,000 pieces

Designs with tighter line width/spacing and smaller hole sizes are more complex to manufacture, leading to higher pricing as seen above.

These examples highlight how even subtle changes in specifications like materials, layers, copper, finishes, line geometries can substantially impact flexible PCB costs. Careful consideration of design requirements against budgets is crucial for cost optimization.

How to reduce the cost of flexible PCB?

To summarize, the key factors influencing flexible printed circuit board pricing include materials (base, reinforcement, copper), manufacturing processes (surface finishes, precision, circuitry type), design complexity (layers, line widths/spaces, hole sizes), production volumes, quality standards, manufacturer capabilities, geographic location, plating methods, payment terms, and lead times.

Optimizing these variables through design for manufacturability (DFM) practices can help reduce FPC costs. Some recommended strategies include:

- Avoiding unnecessary multi-layer designs

- Ordering higher volumes for better pricing

- Allowing for larger minimum apertures/features

- Opting for immersion gold surface finish

- Using immersion tin for gold fingers instead of hard gold plating

- Planning production well in advance to avoid expedited costs

- Analyzing material properties and process limitations

- Reducing blind/buried vias which increase complexity

- Improving panel utilization through efficient layout

At JHYPCB, a leading Chinese PCB manufacturer, we leverage our extensive experience to provide cost-effective flexible printed circuit board prototyping, production and assembly services. Our in-depth expertise across the entire manufacturing cycle allows us to optimize designs, materials and processes to deliver high-quality, competitively-priced FPC solutions tailored to your specifications.

Whether for low or high-volume requirements, our state-of-the-art facilities and stringent quality controls ensure consistent performance. Reach out to our team today to learn how we can support your next FPC project with our comprehensive capabilities.

Related Posts

- Custom Flex PCB:Tailored Solutions for Your Applications

- Custom PCB Fabrication in China – Prototyping & Mass Production

- PCB Prototype Cost: An In-Depth Look at What Determines the Price

- PCB Assembly Cost: A Comprehensive Guide for Cost-Effective PCB Manufacturing

- How to Make Low Cost PCB Prototypes

- What Are The Types of Flexible Circuit Boards?

- Top Applications of Flexible Printed Circuit Boards in 2024

- Flexible PCB Cost: Why It’s More Expensive and How to Reduce It

- How To Reduce The PCB Manufacturing Cost?

- Rigid PCB vs Flex PCB: What Is The Difference?

- What is the defference between PCB and PCBA?

- Development and Applications of FPC Flexible PCB

- The Cheapest PCB Prototype Manufacturer-Your Best Choice

- What factors determine the price of PCB?