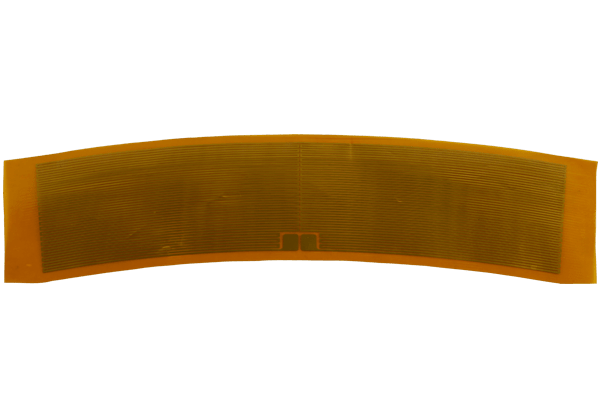

FPC(Flexible Printed Circuit Board) impedance control circuit is also known as impedance strip. When the current required to pass through the circuit is greater than the maximum that the circuit can bear, it is necessary to use impedance to control the excess flow, which is the principle of impedance control. So how to manage the value of the impedance circuit? Each aspect will affect the resistance of the impedance circuit:

1. Different Impedance Values Different Substrates

The substrate material has a significant influence on the FPC. Different materials have different resistance. Various parts of the same material even have exactly different resistance, which is the same as the principle that there are no two identical leaves in the world. Substrate materials with excellent stability are generally used in the impedance circuits on the impedance board. The materials with poor strength will lead to a massive change in material resistance; once the required impedance is exceeded, the impedance line cannot control the circuit.

2. Different Thickness of Material Results in Impedance Variation

This reason has a lot in common with the explanation of the materials above.

3. Width Spacing

The difference in width spacing between impedance circuits can change the resistance value. The impedance circuit is used as resistance, so the width of the circuit is the magnitude of resistance. What is the relationship between absorption circuit spacing? A magnetic field is generated when a current is passed between the lines. A magnetic field can also create an electric current (generator principle, this is why to shield); at this time, the current changes, which indirectly leads to inaccurate impedance control data.

4. Etching Tolerance Changes Impedance

Etching tolerance is a kind of corrosion to the circuit, which will affect the thickness and width of the circuit, so this brings us back to the contents above. Etching tolerance can only be maintained in a range, with deviations, so the change in resistance.

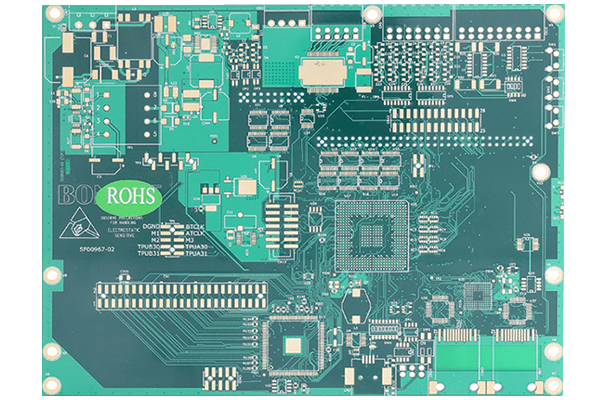

5. Copper Plating Tolerance

This effect depends on the PCB manufacturing process flow. Some processes do not affect the impedance because the plating is before the time, but most of the FPCs are etched when they are electroplated. Copper is attached to the impedance circuit at this time, which leads to the change of the resistance value of the impedance circuit.

For expert assistance in designing or producing flexible circuit boards and impedance control PCBs for your application, you can rely on JHYPCB’s expert team. Enquire now or contact us.

Advanced Learning: