Learn about the industry-adopted IPC standards that govern every step related to the design, assembly, inspection, testing, and documentation of printed circuit boards.

1. What is the norm or standard?

A norm or technical standard is a document based on science, technology, and experience approved by a national or internationally recognized body, which establishes characteristics, requirements, or specifications to achieve a product, process, or service optimal (Mintransporte, 2015). Different recognized bodies certify that products, services, or operations follow or comply with international standards.

2. What standards for designing PCBs and electronics are used in design and manufacturing, and who makes them?

For electronics, there are the standards:

- ISO (International Organization for Standardization) is more for electronics processes in designing and developing products (http://www.iso.org/).

- ITU (International Telecommunication Union) to regulate telecommunications (http://www.itu.int/).

- IEC- International Electrotechnical Commission, for testing and certification electrical, electronic, and related products (http://www.iec.ch/).

- IPC (Association Connecting Electronics Industries) for electronic boards or printed circuits (http://ipc.org/).

3. What Are IPC Standards And What are They For?

IPC is the official name of the association that produces PCB-related standards. The association was formerly called the Institute for Printed Circuits (hence the acronym “IPC”) but is presently called the Association Connecting Electronics Industries—even though it retains the IPC moniker.

IPC, itself, is an international industry association consisting of more than 4,000 member companies that make, use, specify, and design PCBs and assemblies, including:

- advanced microelectronics

- aerospace and military

- automotive

- computer

- industrial equipment

- medical equipment and devices

- telecommunications industry

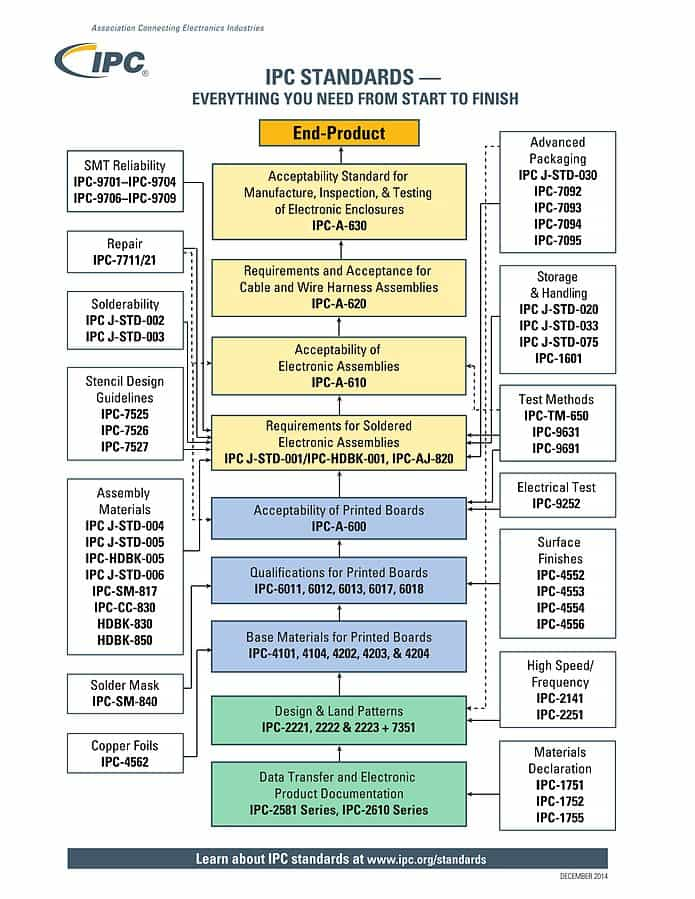

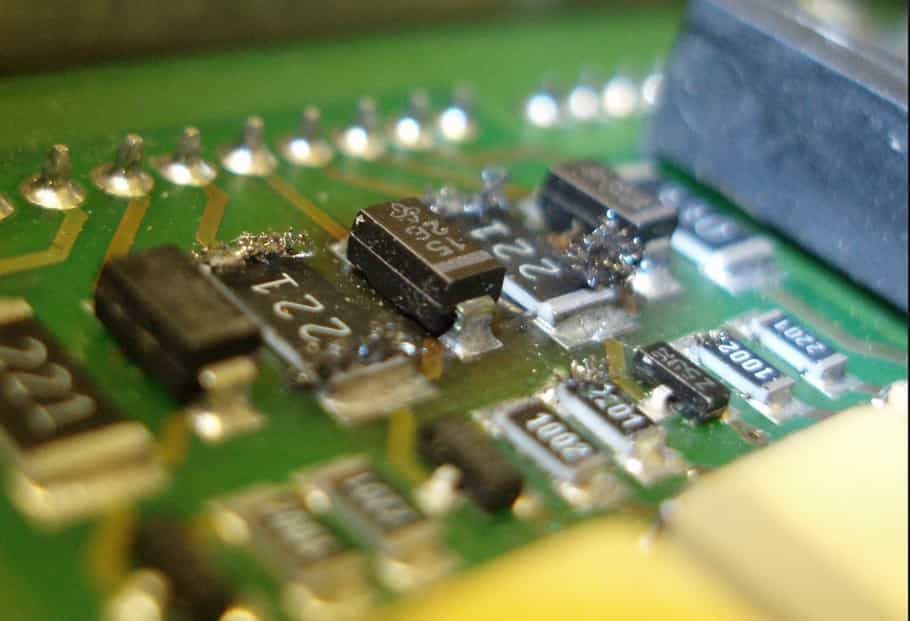

IPC standards are the electronics-industry-adopted standards for design, PCB manufacturing, and electronic assembly. There’s an IPC standard associated with just about every PCB design, production, and assembly (see Figure 1).

4. A Short History of IPC Standards

Six printed circuit board manufacturers founded the Institute for Printed Circuits (IPC) in 1957.

In 1977, its official name was changed to the Institute for Interconnecting and Packaging Electronic Circuits due to more electronic assembly companies becoming involved with the IPC Association. And by 1998, because most people in the Industry either could not remember the full name and/or didn’t agree on what the word in the title meant, the association adopted IPC as the official name and the tagline: Association Connecting Electronics Industries.

They provide fast and timely information on market and technology trends, industry advances, best practices, market research and industry reports, trade shows, technical conferences, and IPC databases.

5. An Abbreviated Timeline of Major Events for IPC and Its Standards

1958 was an eventful year for IPC as it published and sold over 25,000 copies of its book, How to Design and Specify Printed Circuits.

1964 was also an exciting year for IPC because, according to ipc.org, the first version of their IPC-A-600 standard was published. Known as the Acceptability of Printed Boards, the IPC-A-600 standard is still the primary source of visual support for the bare board acceptability requirements in the IPC-6010 series. It has been revised and updated seven times since 1964.

In 1978 London, as one of its first major international events, IPC sponsored the First Printed Circuit World Convention (PCWC). This conference brought together Printed Wiring Board (PWB) associations from around the world, with sponsors of this event including:

- IPC

- EIPC (European Institute for Printed Circuits)

- ICT (Institute of Circuit Technology UK)

- JPCA (Japan Printed Circuit Association)

- Printed Circuit Group IMF (Institute of Metal Finishing UK)

1994 marked a significant event in the history of IPC because, for the very first time, IPC offered their certification and training program based on IPC-A-610B, Acceptability of Electronic Assemblies. Again, according to ipc.org, “Today, IPC-A-610 training is conducted in many languages around the world and has a user base of more than 10,000 instructor certifications. These instructors, in turn, have trained nearly 125,000 engineers, operators, inspectors, buyers, and members of management teams. In addition, this certification program has spawned several other IPC certification efforts.”

2002 brought IPC’s highly-received and most widely-used standard: the IPC-A-620, Requirements, and Acceptance for Cable and Wire Harness Assemblies. For one, I can attest to why this standard was received so well, as I have used it often and find it very insightful.

Some of you, like myself, may have lived through the problems of adopting lead-free solder in 2008—ugh! To address lead-free solder problems during that same year, IPC teamed up with the Electronic Components Association (ECA) and Joint Electron Device Engineering Council (JEDEC) to develop the IPC-J-STD-075 standard known as the Classification of Non-IC Electronic Components for Assembly Processes.

In 2017, celebrating its 60th anniversary, the IPC worldwide membership has climbed to an all-time high with more than 4,000 member sites in 79 countries. In celebration of 60 years, IPC has created their 60th Anniversary Celebration video:

6. Why Do IPC Standards Matter?

Producing safe, reliable, high-performing PCB products requires constant attention to detail and commitment to quality throughout the production process. Adhering to IPC standards throughout the process can help companies achieve that.

Just as the production processes for PCBs take a step-by-step approach, the IPC standards all build upon one another. You can implement an IPC standard for nearly every phase of production.

To achieve high-quality, reliable products that meet customer expectations, it’s essential for companies involved in producing PCBs and the products that use them to commit to quality through IPC standards for printed circuit boards.

Complying with IPC standards can help a company improve its processes and products in numerous ways.

7. Top 6 Benefits of Joining IPC

IPC, the trade association for the electronic interconnection industry, is a member-driven organization consisting of designers, suppliers, board manufacturers, assembly companies, and government, educational, and non-profit organizations. What are the benefits of joining IPC? There are many! Let’s look at a few of them.

What are the benefits of joining the IPC besides achieving competitive excellence and financial success? As a member-driven organization and leading source for industry standards, IPC helps you in the following ways:

The PCB manufacturers must infuse quality throughout the manufacturing process to stay competitive in the marketplace. Including more than 225 active standards from design and purchasing to assembly and acceptance, the IPC standard for PCB helps you make high-quality, reliable products that meet customer expectations.

Hence, when a PCB manufacturer claims that its processes are IPC compliant, you can be assured of receiving exceptional PCB and electronic assembly services, exceeding your expectations. Now you know the importance of connecting with a PCB fabricator who follows IPC standards for PCBs, right? So, this post ends by informing you about a leading PCB designer and fabricator whose processes are IPC-WHMA-A-610 Compliant and IPC-CC-830B Compliant, and ISO 9001:2008 Certified. Creative Hi-Tech works with its clients from the start of the PCB design process to deliver boards that meet IPC standards for PCBs and ensure quality, performance, and durability.

- Stay Updated:

IPC sends its members weekly, bimonthly, and quarterly e-newsletters with current information on newly released standards, new technologies, innovative design practices, and market trends. With such timely updates, you will stay updated and can plan your business accordingly.

- Get the Information from Reliable Sources:

IPC maintains a responsive member-only website through which you can connect to experts and resolve your queries. Whether technology, environmental compliance, and management issues, the latest market trends, or simply business, you will get an accurate response from the team.

- Avail Services at Reduced Costs:

It is exclusive for the IPC members to avail 50% discount on standards and training materials. Also, IPC encourages its members to visit the IPC annual trade shows and conferences and exhibit the products.

- Marketing Opportunities:

PCB design and manufacturing is a highly competitive business these days. Hence, you can’t afford to miss any forum providing excellent marketing opportunities. By joining IPC, its members can list their products and services with a logo on the website. Since it is a platform with more than 4,800 member companies worldwide, you will surely benefit from such a listing. You can also sponsor IPC technical and management conferences, which is also one of the best ways you get noticed in the crowd.

- Improve Contacts:

IPC is the international platform that brings PCB fabricators, EMS providers, OEMs, industry suppliers, government agencies, and educational institutions under one roof. Here you can “speak the same language” and earn new contacts. You never know how the relationship may help you soon.

- Control over Quality:

As mentioned earlier, the IPC standard of PCB covers every stage of PCB design and manufacturing. By compliance with such measures, you can be assured of producing boards that offer better performance and longer life.

8. Some of IPC’s Terms and Definitions

“Shall” and “Should”… does it matter which word is used? Yes, it does!!

Under their terms and definitions sections in their IPC-A-620 standard, IPC has selected the following definitions:

Should: Reflects recommendations and is used to reflect general industry practices and procedures for guidance only.

Shall or Must: Mean that the requirement or attribute discussed is mandatory for all Product Classes.

And speaking of Product Classes, IPC has adopted the following three classes:

- Class 1 – General Electronic Products: Includes products suitable for applications where the primary requirement is the function of the completed assembly.

- Class 2 – Dedicated Service Electronic Products: Includes products where continued performance and extended life are required and uninterrupted service is desired but not critical. Typically, the end-use environment would not cause failures.

- Class 3 – High-Performance Electronic Products: Includes products where the continued performance or performance-on-demand is critical, equipment downtime cannot be tolerated, and the end-use environment may be uncommonly harsh, and the equipment must function when required such as life support systems and other critical systems.

Here are some other terms you may want to know.

- Acceptance tests: The tests required to determine whether a product is acceptable, as agreed upon by the purchaser and vendor.

- Assembly: Several parts, subassemblies, or combinations thereof joined together.

- Resist A coating material used to mask or protect certain areas of a pattern during manufacturing or testing from the action of an etchant, plating, solder, etc.

- Integrated circuit: A combination of associated circuit elements formed in place and interconnected on or within a single base material to perform a microcircuit function.

- Flexural strength: The tensile strength of the outermost fiber of a material that must bend.

- Critical operation: One procedure of an entire process that has a significant impact on the characteristics of the completed product.

In the PCB manufacturing+ industry, IPC Class II is currently the general default option. Of course, for special applications or requirements, PS Electronics will also implement the IPC Class III requirements to ensure the output of high-quality PCB or PCBA.

9. Examples of IPC Standards

There are IPC standards for almost every phase of the PCB production process. To give you an idea of what these standards entail, here are a few examples.

- IPC-2581: IPC-2581 is a generic standard used when sending information between a PCB designer and a manufacturer or assembly company. It provides a standardized format for exchanging design data that helps ensure consistent production results.

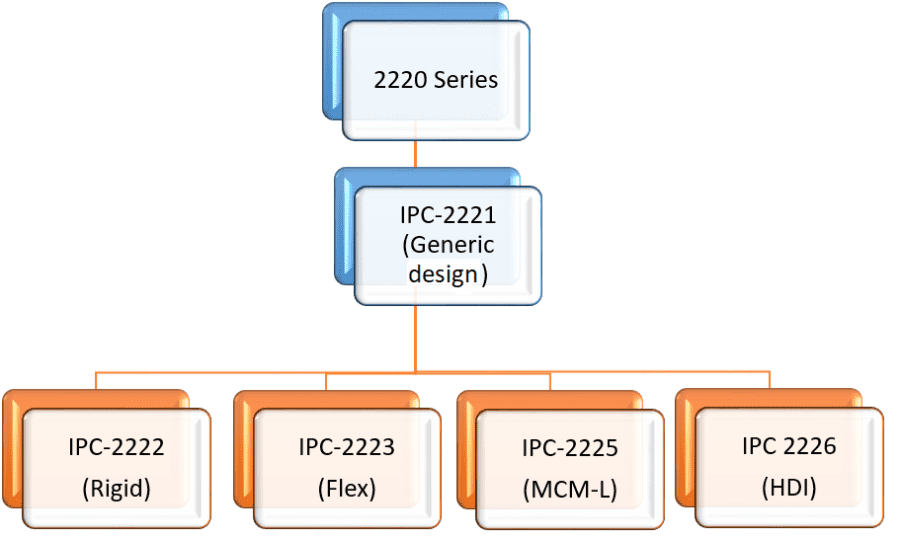

- IPC-2221: IPC-2221 is a generic standard for the design of PCBs. Within the 2220 series, there are also specifications for specific PCBs such as rigid, flex, and MCM-L. It addresses design layout, parts lists, materials, mechanical and physical properties, electrical properties, thermal management, and more.

- IPC-4101C: IPC-4101C covers requirements for base materials, typically called laminate or prepreg, primarily for use with rigid or multilayer boards. It deals with the materials used, their dimensions, and their properties.

- IPC-6012B: The specification IPC-6012B establishes qualification and performance requirements for the fabrication of rigid PCBs. It offers conditions for the various types of product classes in structural integrity, solderability, and conductor spacing.

- IPC-A-600F: IPC-A-600F sets the acceptance criteria for PCBs. It describes which observable conditions of a board are acceptable and non-conforming and the target conditions — for all parts of the PCB, from gold fingers to copper plating. It is the visual representation of the requirements put forward in other specifications.

- J-STD-001: IPC J-STD-001 describes the materials, methods, and other criteria for creating high-quality soldered interconnections. It focuses on process control and lays out requirements for a range of electronic product types.

- IPC-A-610: IPC-A-610, Acceptability of Electronic Assemblies, provides criteria for the acceptance of end products. It is the most widely used standard the IPC publishes.

- IPC-A-620: IPC-A-620 provides criteria for the acceptability of cable, wire, and harness assemblies and can serve as a stand-alone document for purchasing products.

- IPC-TM-650: IPC has also published a test methods manual, IPC-TM-650, which provides guidelines for assessing various aspects of PCBs. For example, the test method IPC-TM-650 2.6.14.1 describes methods for testing a board’s propensity for surface electrochemical migration. The test measures resistance to the flow of current across a PCB substrate surface. IPC-TM-650-2.3.25.1 describes a method for ionic cleanliness testing of bare printed wire boards, which is essential because ionic contamination can cause issues that make a PCB defective.

10. What advantages or benefits does working with IPC standards have?

- Please work with the best practices of the industry and its needs.

- Commit and demonstrate the excellence of the company and people, earn recognition.

- They are for use by designers in their work.

- They help eliminate interpretation problems between manufacturers and users.

- They facilitate the exchange of information.

- They help in the improvement of products.

- Reduce delays in product development.

- Reduce the time of the processes.

- Help to the design-oriented manufacturing environment.

- Reduce time to market.

The IPC standards are voluntary, but using them improves the product and can contribute to the robustness, reliability, and durability of the product; in addition, when used with other standards, it can reduce the levels of electromagnetic pollution and help pass the tests and certifications to which Electronic products are submitted to be sold in international markets (IEC, ISO, ITU standards and tests may be mandatory to access other markets). They serve to differentiate themselves in their own country. It also helps you design and manufacture faster and with less cost by learning from the experience of others.

11. Why do we execute IPC standards?

- IPC standards are developed with the participation of tens of thousands of industry practitioners, providing a high degree of authority and reliability, which helps us manufacturers control the quality and reliability of the final products.

- IPC standards have created a common language that the global electronics industry can follow. It has become a bridge connected to upstream suppliers and customers and has increased production efficiency.

- Every IPC standard must be strictly verified and tried. Working under IPC standards can reduce the cost loss caused by non-standard processes.

In PS Electronics, IPC standards are strictly enforced and cooperatively to meet more flexible and demanding requirements.

12. Standards for Designing PCB and Electronics

IPC standards cover every process of PCB design, production, and assembly. The most critical standards include:

- IPC-A-610, acceptability of electronic components

- IPC-A-600, acceptability of printed boards

- J-STD-001, requirements for soldering electrical and electronic components

- IPC-7711/IPC-7721, rework of electronic components/printed board and repair of electronic components and modify

Here is a description of the most used standards in the design of PCB printed circuit boards.

12.1 IPC 2220 STANDARD for PCB design- PCB Design

What is it for?: whoever wants to design a PCB, improve one there, teach design, or work in consulting this standard, you must use it.

What is it about?: IPC 2220 is a family of design standards, it is composed of the following standards:

- 2221B: Generic standard on printed circuit design.

- 2222A: Sectional design standard for rigid PCB. Used in conjunction with IPC-2221, IPC-2222 sets specific requirements for designing rigid printed circuit boards and other forms of component mounting and interconnection structures. This standard applies to single-sided, double-sided, or multilayer PCB boards.

- 2223D: Sectional design standard for flexible PCB / rigid-flex printed circuit board.

- 2224: Standard for PC PCB.

- 2225: Sectional design standard for organic multichip modules (MCM-L) and MCM-L.

- 2226: Sectional Design Standard for High-Density Interconnect Boards (HDI).

What does it contain?: The most used is IPC 2221, which defines the general requirements for PCB design and some aspects of electronic card assembly, principles, and recommendations, including the assembly or assembly of components, type THT or holes through, surface SMT. The IPC2221 standard is widely used with 7351, IPC T 50, and IPC D 325.

12.2. IPC-T-50 Terms and Definitions for Interconnecting and Packaging Electronic Circuits

It is a dictionary of Terms and definitions for Circuits, PCBs, and packaging of the entire industry, for those who need to know all the concepts and terms.

12.3. IPC-D-325 Documentation Requirements for Printed Boards, Assemblies, and Support Drawing

To professionally document a PCB or electronic design to deliver, improve, or retain experience. The guide and documentation requirements for PCBs, assemblies, and support diagrams; the “D” stands for documentation.

12.4. IPC 7351 Generic Requirements for Surface Mount Design and Land Pattern Standard

Designers who work with printed circuits with surface mount components contain appropriate geometries, features, sizes, shapes, and tolerances to ensure optimal welding, which complies with other manufacturing standards required by companies, entities, or multinationals the IPC standard. / EIA J-STD-001 or IPC A 610 for the different manual or automatic welding processes.

12.5. IPC-2252 Design Guide For Rf/microwave Circuit Boards

For advanced designers. Design Guide for RF / Microwave Circuit Boards, PCB manufacturing, and testing used in high-frequency applications (100 MHz to 30 GHz). Types of interconnections and chip mounting strategies.

12.6. IPC 2251 Design Guide for the Packaging of High-Speed Electronic Circuits

Design Guide for High-Speed Circuit Packaging. High-Speed Circuit Design Guidelines for Circuit Designers, PCB Manufacturing Engineers, and Personnel.

13. Standards for PCB Manufacturing and Assembly

13.1. IPC 600 – Acceptability of Printed Boards.

Who uses it? : For PCB manufacturers and those who in a company receive and inspect the quality of the manufacturers, of unassembled circuits, manufacturers, it serves to improve quality and communication with suppliers and customers. One of the most used standards in the world.

13.2. IPC 610 Acceptability of Electronics Assemblies (IPC A 610).

What is it for? : For PCB assemblers, welders, designers, manufacturers of electronic products, cables, repairers, who work with electronic assemblies, assembled circuits, the standard provides visual quality inspection criteria for these, it is the most widespread standard in the world electronics industry, supports design, manufacturing and maintenance activities in electronics. It contains sections of the IPC 600 and the IPC JST 001. The latest version is the IPC A 610 G (IPC-A-610 in Spanish. The letter “A” stands for acceptability or acceptance of quality.

13.3. IPC JSTD 001 Requirements for Soldered Electrical and Electronic Assemblies.

This standard is used by people or companies that work with electronic circuit assemblies, which require in-depth knowledge of the requirements for electrical and electronic connections, materials, methods, and verification criteria to produce high-quality lead-free and lead-free soldered interconnects. . Process control and electronic connection requirements. Used a lot with IPC 610.

13.4. IPC 7711/21 Rework, Modification and Repair of Electronic Assemblies

Recommended for companies or individuals who perform repairing, modifying, or reworking or assembled or unassembled PCBs for both consumer products and professional and high-reliability applications. According to the specifications, they are the electronic guide manuals of the Industry worldwide, for the removal or replacement of electronic components and the repair of circuits with the minimum impact on the quality and reliability of the product, without affecting its useful life and fulfilling the client’s requirements.

13.5. IPC 620 Requirements and Acceptance for Cable and Wire Harness Assemblies.

For those who work in cable and wire assembly for the manufacture and installation of ropes and harnesses. Visual acceptance criteria.

13.6. IPC-SM-840D Qualification and Performance Specification of Permanent Solder Mask

This specification shall define the criteria for obtaining the maximum information about and confidence in cured permanent solder mask material under evaluation with the minimum of test redundancy. This specification shall establish the requirements for:

- The review of solder mask materials.

- The conformance of solder mask material properties.

- The qualification of the solder mask via the appropriate test substrate.

- The qualification assessment of the solder mask in conjunction with the production printed board process.

13.7. IPC-4552 Immersion Gold (ENIG) for Printed Circuit Boards Surface Finished Process

The IPC-4552 standard document specifies the electroless nickel immersion gold (ENIG) surface treatment process for printed circuit boards.

13.8. IPC-4553 Specification for Immersion Silver for Printed Circuit Boards

Immersion silver and Immersion Gold are both typical PCB surface finishing processes. IPC-4553 describes the processing standards and requirements of the immersion silver process in the PCB manufacturing process.

13.9 IPC-4554 Specification for Immersion Tin Plating for Printed Circuit Boards Surface Finished

IPC-4554 specifies the requirements for immersion tin (ImSn); immersion Tin is a popular surface finishing process in PCB manufacturing. The specification calls for a minimum usable (free) tin thickness of 0.4 microns (15 µin) if the PCBs are to be soldered within 30 days.

13.10. IPC-4556 Specification for ENEPIG Plating for Printed Circuit Boards Surface Finish

The IPC-4556 specification specifies the requirements for using electroless nickel/electroless palladium/immersion gold (ENEPIG) as the surface finish of printed circuit boards. ENEPIG is a multifunctional surface finish method.

13.11. IPC-6018 Qualification and Performance Spec for High Frequency (Microwave) Printed Circuit Boards

Superseding IPC-6016, IPC-6018 covers qualification and performance of high frequency (microwave) boards.

13.12. IPC-9252 Requirements for Electrical Testing of Bare PCB Boards (Unpopulated Printed Circuit Boards)

IPC-9252 defines appropriate bare PCB board testing levels and assists in selecting the test analyzer, test parameters, test data, and fixturing required to perform the electrical test(s) on bare PCB and inner layers. Requirements for resistive and indirect continuity and isolating testing test record marking and traceability and an updated sample electrical test certificate of conformance (C of C).

For more information about the IPC standards for flexible circuit board manufacturing and materials used in manufacturing, please click here to learn more.

14. Where to Get IPC Standards

While IPC standards are not free, they can be purchased for a discount from the IPC store if you’re an IPC member. There are other online stores, such as Soldertools.net, that sell them too.

Here is an IPC PCB standard overview for free download.

Advanced Learning

- Custom Circuit Board Printing

- Quality Control of Engineering Data for Multilayer PCB

- 10 Tips To Improve PCB Design For Manufacturability

- What are PCB Design For Manufacturing (DFM) and Design For Assembly (DFA)?

- How To Search for a Reliable PCB Manufacturer

- Quick Turn PCB Manufacturer In China

- 30 Common SMT PCB Assembly Defects