The conducting paths on a PCB are made of copper and are responsible for transmitting electrical signals. Copper is an excellent conductor, but it cannot stay intact in the atmosphere; it will undergo corrosion. Consequently, the electrical properties of the PCB will degrade with time, and the circuit will not perform as expected. Thus, it is necessary to treat the surface of a PCB and make it corrosion-resistant and long-lasting.

Gold has a commendable resistance to corrosion and oxidation. It has a long life compared to copper exposed in the air. If a PCB has a surface finish of gold, it will last for a long time, and the copper underneath the surface finish will remain intact and sound. Therefore, gold is used in the surface finish to improve and maintain the performance of a PCB and offer it a long life.

When it comes to the gold surface finishing of PCB, two names come to our minds: Gold Plating and Immersion Gold. Beginners usually get confused about these two terms, and they often consider them the same. It is essential to understand the difference between these two types of surface finishes because it will help design a perfect PCB for the project. The PCB buyer needs to know which type of surface finish is suitable for the PCB, the advantages/disadvantages, and its uses.

What is Gold Plating?

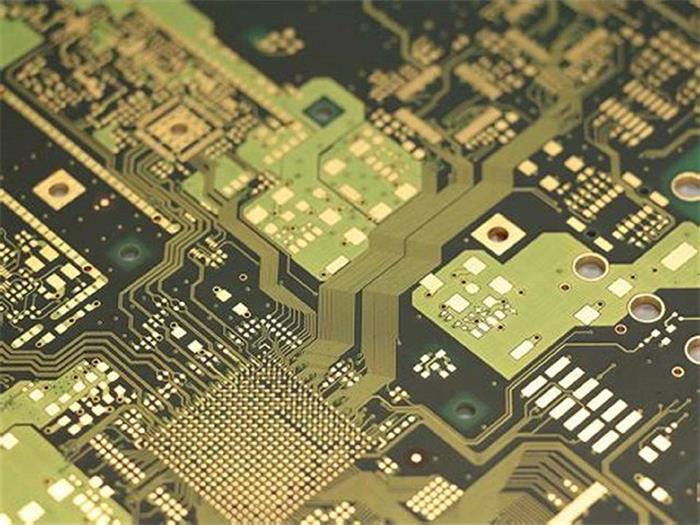

Gold Plating is when a thin layer of gold is applied over the PCB through electroplating. The important thing is the method behind it, and that is electroplating. In this method, gold is mixed with a non-precious material, usually nickel, to make it harder. This is the reason Gold Plating is also called Hard Plating.

Pure gold is quite soft; therefore, nickel or other non-precious metals are used in gold plating. It creates an alloy of gold, and it is clear that the gold used in gold plating is not pure.

What is Immersion Gold or ENIG?

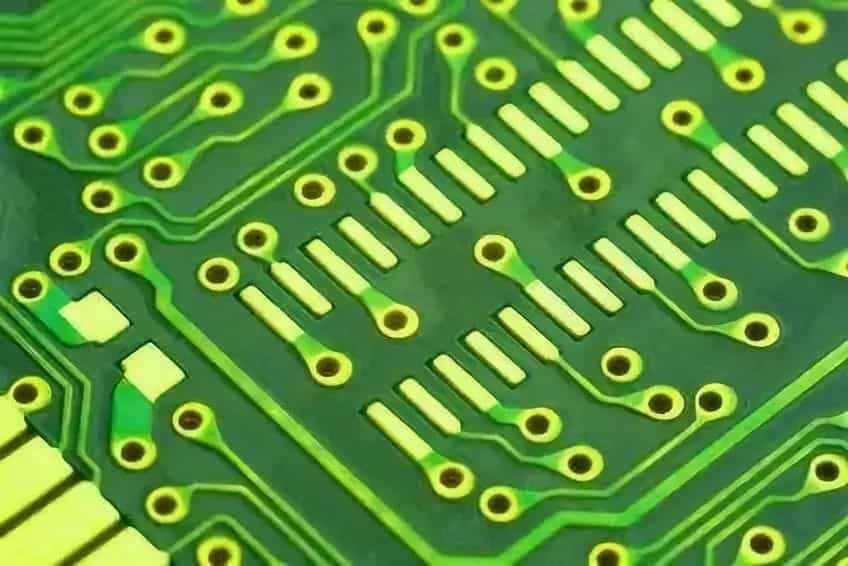

ENIG stands for Electroless Nickel Immersion Gold, and it is commonly known as Immersion Gold. Unlike gold plating, ENIG is done through a chemical reaction; there is no electroplating involved. At first, the copper is covered by a thin layer of nickel, and after that, a thin layer of gold is applied over it.

Keep in mind that the gold layer applied to the surface is pure; it is not an alloy. Thus, ENIG is a mixture of nickel and gold layers. The nickel layer protects the copper layer from oxidation and corrosion, and the gold layer protects nickel. Ultimately, there is a commendable resistance from corrosion.

Since the top layer of the ENIG treated PCB is of pure gold, it is much softer than gold plating. Therefore, it is often called soft plating.

Gold Plating vs ENIG

We have already seen the basic difference between the two types of surface finishes. That was the basic difference according to the method used in the process and hardness of gold; however, they are different in many aspects.

| performance Surface Finish | Appearance | Solderability | Signal transmission | Quality | Engineering treatment |

| Gold Plating | gold and white color | Weldability is average, occasionally poor welding. | The skin effect is not conducive to the transmission of high-frequency signals | 1. Gold surface is easy to oxidize. 2. Easy to cause the gold wire to be short 3. Solder mask bonding strength is not strong | Line width compensation and affect spacing. |

| Immersion Gold | golden yellow | Excellent | Skin effect has no effect on signal transmission | 1. Not easy to oxidize 2. No gold wire 3. Good solder mask adhesion | Line width compensation and does not affect the spacing. |

- Appearance/Color

ENIG and gold plating also differ in color. If you have these two types of surface finishes, you can guess the type by seeing the color.

ENIG is of pure gold, so it is golden yellow. It is more yellowish or golden. On the other hand, gold plating uses an alloy of gold, and nickel is usually used to make the alloy. Thus, it has a gold and white color, which has a yellow color to a lower extent; it is not as yellow as immersion gold because it contains nickel.

- Wear Resistance

Immersion gold is made of pure gold, so it is softer than gold plating. It wears if it slides over a surface. It can only be used at the parts of the PCB where sliding and movement are not expected, such as the component area.

In contrast, gold plating is much harder; therefore, it can withstand wear and tear for a long time. It remains over the surface of the PCB even if it slides on a surface a considerable number of times.

- Corrosion Resistance

The ultimate corrosion resistance is offered by immersion gold. Because of the pure gold surface, it has excellent resistance to corrosion and oxidation. Thus, even if the PCB is exposed to air, there is no need to worry about its life; it will last for a long time, and the surface will remain intact.

Gold plating is not as good as immersion gold in the case of corrosion resistance. As it has nickel and other non-precious materials, it can undergo corrosion and oxidation. Its life is less than immersion gold. But it does not mean it cannot provide protection to the copper surface. It can offer protection to the copper surface and prevent corrosion but to a lesser extent.

- Soldering

It is hard to solder on gold plating because it uses a gold alloy which causes poor soldering.

Immersion gold offers perfect soldering, and it is easy to solder components on it. Below the gold layer, there is a nickel layer that helps to create a good bond between the solder and the PCB.

- Usage

Gold plating is only used for gold fingers because that part of the PCB undergoes wear and tear. A force is applied on gold fingers, and the surface slides over another surface. Thus, gold plating is a suitable option as it is hard enough. Other than that, it has no use.

Gold plating cannot be used on the main PCB as it does not have corrosion resistance like immersion gold and is unsuitable for soldering; thus, it cannot be used where you need solder components. It is only suitable for contact surfaces. Due to these reasons, it is also called Selective Gold Plating. If the PCB does not have gold fingers, there is no need to use this type of surface finish.

Immersion gold is one of the most used and preferred surface finishes. It offers commendable corrosion resistance and excellent solderability; therefore, it is used over the whole PCB. It is expensive as compared to other types of surface finishes, but it is still used because of its qualities. The whole PCB, except the gold finger portion, can be treated through ENIG. It makes the PCB long-lasting.

Get Cheap PCB and PCBA Services Today!

JHYPCB is one solution for all your PCB and PCBA needs. We have a state-of-the-art and large facility that can handle low-high volume orders. We can manufacture all types of PCBs, including rigid, flexible, rigid-flex, HDI, metal core, BGA, impedance control PCB, and high-TG PCB. The customers can choose the desired surface finish as we offer all the available surface finishes, including HASL, ENIG, OSP, Immersion Silver, ENEPIG, ENIG + Golden Finger, Plated Gold, and Immersion Tin.

We offer quick prototypes and full turnkey assembly services. Our experts can help you make complex PCBs and also offer PCB copy services. We have the solution to all your PCB issues and requirements. We are ISO, UL, and RoHS certified, so buyers can order anything without any worries. We offer reasonable prices that are much lower than the local overseas manufacturers.

For more information and details, feel free to contact our customer service team.