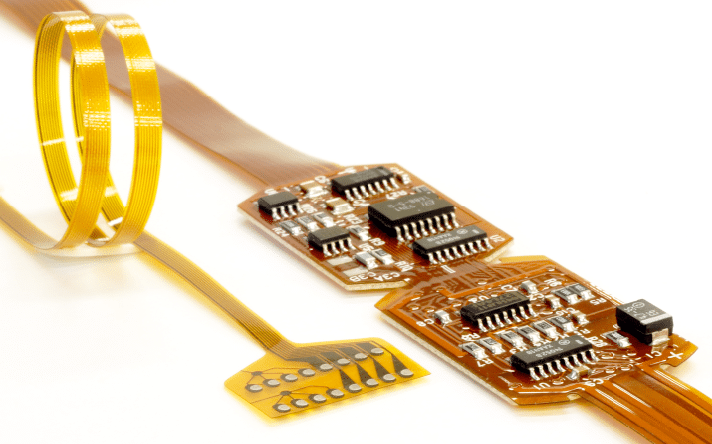

Flexible printed circuit boards (flex PCBs) have emerged as an indispensable technology enabler in the modern electronics landscape. Unlike their rigid counterparts, these flexible circuit boards offer unmatched durability, bendability and the ability to withstand repeated flexing. As electronics become more compact, portable and integrated into dynamic applications, the unique properties of flex PCBs have allowed them to drive innovation across diverse industries.

Flexible PCB Applications

Applications of Flexible PCBs in Wearable Technology

The rise of wearable electronics like smartwatches, fitness trackers and augmented reality headsets has been fueled by flexible printed circuit board technology. Flex PCBs’ ultra-thin profiles and lightweight nature allow them to conformly integrate into wearable devices and move seamlessly with the human body.

Flexible circuits in smartwatches like the Apple Watch provide vital interconnections between the display, sensors, and internal components while bending freely around the wrist. Similarly, fitness wearables from brands like Fitbit and Garmin utilize the flexibility of flex PCBs to ensure user comfort during workout sessions.

As wearable technology continues advancing towards sleeker and more compact form factors, flexible printed circuit boards will remain instrumental in enabling these innovative designs. Their unique ability to bend, twist, and withstand repeated flexing makes flex PCBs indispensable for next-generation wearable gadgets.

Applications of Flexible PCBs in Consumer Electronics

With portability and mobility becoming paramount requirements in consumer electronics, major brands have turned to flexible printed circuit boards to achieve compact, foldable, and bendable designs for their flagship devices. Flex PCBs have become the enabling technology behind many of today’s iconic smartphones, tablets, and laptops.

Take foldable smartphones like the Samsung Galaxy Fold and Motorola Razr for instance. These innovative devices utilize flexible circuit boards to facilitate the folding mechanism and routing of signals across the hinge area. The unique ability of flex PCBs to bend repeatedly without damage allows the display and internal components to function seamlessly when folded or unfolded.

Similarly, convertible laptops and detachable tablets from brands like Microsoft, Lenovo and Dell rely heavily on flexible circuits. The rigid PCBs connect to the displays and keyboards through flexible printed circuit board extensions that can twist and bend as the devices transform between laptop, tablet, and tent modes.

As consumer demand for dual-screen devices and foldable form factors grows, flexible PCBs will become even more ubiquitous inside portable electronics. Their compact nature allows flex circuits to neatly integrate into tight spaces and facilitate the mounting of components in areas too confined for rigid PCB boards. This unique flexibility ensures consumer gadgets can keep evolving into novel shapes and sizes without compromising functionality.

The fact that major tech giants like Apple, Samsung, Microsoft and others have embraced flexible printed circuit board technology is a testament to flex PCBs’ indispensable role in modern consumer electronics. Their inherent ability to bend and withstand flexing is key to realizing the portability and mobility that defines today’s iconic mobile devices.

Applications of Flexible PCBs in Medical Devices

Flexible printed circuit boards have become critical components in next-generation medical devices, enabling more compact, minimally-invasive and portable designs. The unique properties of flex PCBs allow for advanced biomedical applications both internally within the human body and externally as wearable health monitors.

One of the most widespread uses is in hearing aids and cochlear implants. The miniaturized size and conformability of flexible circuits make them ideal for integrating complex amplification and audio processing technology into the tiny ear-worn packages. Flex PCBs can neatly route electrical signals around the curves of the ear canal for optimal sound transmission.

Similarly, flexible printed circuit boards play a vital role in endoscopic and laparoscopic surgical tools by facilitating a compact, movable design. The imaging sensors, illumination and miniaturized camera components can be integrated into the long, flexible insertion tubes using flex PCBs as the interconnecting circuitry.

But the applications go beyond external devices. Implantable medical technology like pacemakers and insulin pumps leverage the unique advantage of biocompatible flexible circuit boards. These flex PCBs can withstand prolonged exposure to bodily fluids and temperature fluctuations inside the human body without compromise.

As medical devices trend towards more minimally-invasive designs to reduce patient trauma, the demand for flexible PCBs will only accelerate. Their ability to bend, flex, and interconnect components in extraordinarily compact spaces is indispensable for next-gen healthcare wearables and implants. The reliability and proven biocompatibility solidify flexible circuit boards as a trusted solution for critical life-saving applications.

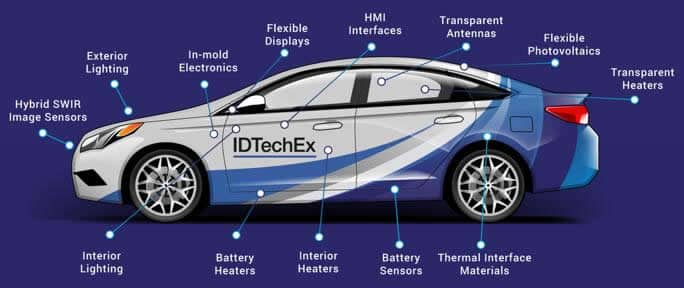

Applications of Flexible PCBs in Automotive Electronics

The automotive industry has emerged as a major beneficiary of flexible printed circuit board technology. Under the hood of today’s vehicles, flex PCBs play a vital role in enabling advanced electronics that can withstand harsh operating conditions involving constant vibration, extreme temperatures, and repeated flexing.

One key application is in connecting electronics across hinges, doors, seats and other movable automotive components. Traditional rigid PCBs would crack under constant bending stress. Flexible circuits allow vital signals and power to be routed seamlessly from the vehicle body to electronic modules mounted on parts like mirrors, sunroofs and folding seats.

Flex PCBs are also found in critical safety systems like airbag deployment units. Here, their excellent flexibility ensures the circuit board can bend as the airbag inflates rapidly without running and cracking under the explosive force.

But their uses go beyond interconnections. The engine control units, sensors, and various body control modules increasingly rely on flexible printed circuit boards as well. The thermal and mechanical durability of flex PCBs allows them to reliably function in the extreme under-hood temperatures and vibrations from the engine.

As modern vehicles become smarter and more electrified, new automotive applications are emerging for flexible circuits. The latest electric cars utilize flex PCBs to integrate battery management systems more compactly. Foldable and curved displays in next-gen infotainment systems will also leverage the unique form factor enabled by flexible printed circuit boards.

With their proven ability to withstand vibrations, temperature extremes, and enable dynamic routing, flexible PCBs have become an essential automotive technology. As cars accelerate towards higher electronics content and electrification, flex circuits will only become more pervasive under the hood.

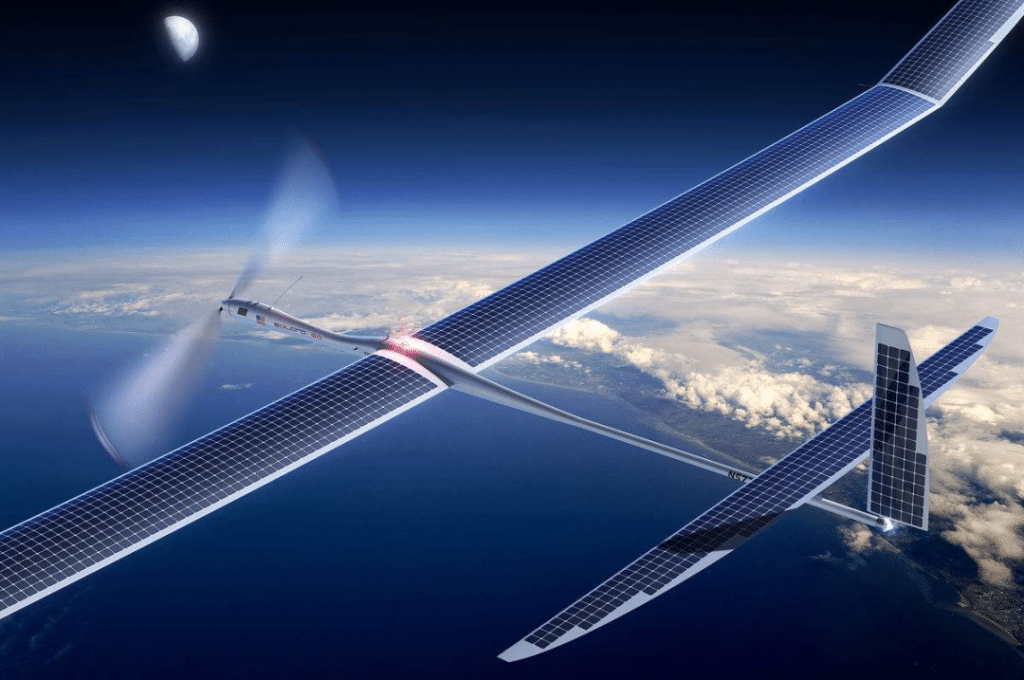

Applications of Flexible PCBs in Aerospace and Defense

When it comes to mission-critical applications in the aerospace and defense sectors, flexible printed circuit boards offer unparalleled reliability and durability. The ability of flex PCBs to withstand extreme temperatures, vibrations, and harsh environments makes them invaluable for aviation electronics and military equipment.

In the aerospace industry, flexible circuits can be found in everything from aircraft navigation systems to in-flight entertainment controls. Their flexibility allows for seamless integration around the curved fuselage surfaces and movable control surfaces. At the same time, flex PCBs can handle the intense vibrations during take-off and landing cycles.

Flex PCBs are also deployed in critical aerospace applications like jet engine control modules. Here, their thermal resistance up to 200°C allows the flexible circuits to function reliably despite intense heat from the turbines. This versatility reduces component complexity and increases operational safety.

For defense applications, flexible printed circuit boards are favored for their ruggedness and portability. Wearable military gear like night-vision goggles utilize flex PCBs to integrate electronics conformally around the soldier’s head without adding excessive bulk or weight. The dynamic flexibility ensures operability during intense movement.

Missile systems and unmanned vehicles also leverage flex PCBs extensively. Their ability to withstand high G-forces, electromagnetic pulses, and extreme cold/heat gives flexible circuits an edge in these punishing defense deployments where failure is not an option.

Across aerospace and defense, flex PCBs enable more compact packaging, ease of installation, and reduced maintenance needs – critical advantages for equipment used in mission-critical operations. As these industries push for lighter, smarter, and more resilient systems, the unique capabilities of flexible printed circuit boards will only become more vital.

Applications of Flexible PCBs in the Internet of Things (IoT)

The proliferation of the Internet of Things (IoT) and the rise of interconnected devices has been facilitated by flexible printed circuit board technology. Flex PCBs enable the flexible interconnects and dynamic form factors required for IoT gadgets to seamlessly integrate into our environments.

In the smart home sector, flexible circuits allow IoT devices to adopt curved and bendable designs for more intuitive human-product interactions. Smart speakers can utilize flex PCBs to wrap electronics around their cylindrical bodies. Smart light bulbs leverage the unique form factor enabled by flexible PCBs.

Wearable IoT technology like fitness trackers and smart jewelry rely heavily on the lightweight, low-profile nature of flex circuits. The ability to conform to the human body allows these devices to monitor health metrics discreetly under clothing.

But IoT applications of flexible printed circuit boards go far beyond consumer gadgets. Industrial IoT deployments like environmental sensors and monitoring devices use flexible PCBs to endure harsh operating conditions like temperature extremes, moisture and vibrations.

As the IoT ecosystem continues to expand, flexible circuits will be instrumental in sparking innovation. Their inherent bendability allows IoT product designers to explore novel form factors. Flex PCBs enable seamless integration of interconnects across hinges, curves and dynamically moving components.

Whether it’s a smart home automation device, a compact industrial sensor, or a new class of IoT wearable, flexible printed circuit boards provide the versatility to push boundaries. This unique technology is vital for realizing the ubiquitous connectivity and context-aware capabilities envisioned for the IoT revolution.

Emerging Applications of Flexible Printed Circuit Boards

While flexible printed circuit boards have already become indispensable across major industries, their unique capabilities continue to unlock new innovative applications driving future technologies. From robotics to flexible displays to energy solutions, flex PCBs are at the forefront of cutting-edge developments.

In the field of robotics, the flexibility and compact routing of flex circuits allow for the design of intricate robotic limbs, grippers, and humanoid structures that can mimic natural movement. Flexible PCBs enable seamless integration of sensors, actuators and interconnects across movable joints and components.

Another emerging application is flexible displays and e-paper displays leveraging flex PCBs. The inherent bendability of these circuits allows for displays that can be rolled, curved or folded into mobile devices while still functioning. This opens up possibilities for foldable smartphones, e-readers and dynamic digital signage.

The unique properties of flexible printed circuit boards are also being explored for energy applications. Solar panels utilizing flex circuits can conform to curved surfaces and movable mounting systems to maximize exposure. Flex PCBs are enabling novel battery designs and circuitry for flexible thin-film batteries as well.

As electronics become more integrated into clothing, flexible hybrid electronics combining flex PCBs with stretchable interconnects and printed components envision a future of smart fabrics. Wearables that conform seamlessly like second-skin open up new frontiers.

Looking ahead, the importance of flexible printed circuit boards will only continue to grow as technology strives for smaller, lighter, and more portable designs. Their ability to dynamically bend and withstand flexing while offering high-density interconnects is unmatched. Flex PCBs will be instrumental in realizing the ubiquitous, seamless integration of electronics envisioned for the future.

Conclusion

Flexible printed circuit boards have become a ubiquitous and indispensable technology driving innovation across a multitude of industries. From wearable devices and consumer electronics to medical equipment, automotive systems and aerospace applications – the unique capabilities of flex PCBs are enabling cutting-edge product designs previously unattainable.

Their inherent ability to bend, twist and withstand repeated flexing while offering high-density interconnects in a lightweight, low-profile package is unmatched by traditional rigid PCBs. This flexibility allows flex circuits to seamlessly integrate electronics into dynamic applications involving movement, vibrations and compact spaces.

As modern technology trends towards portability, wearability and the seamless integration of electronics into everyday life, the importance of flexible PCBs will only continue accelerating. They are vital for realizing the next generations of foldable mobile devices, compact biomedical implants, robotics, and the pervasive interconnectivity of the IoT ecosystem.

With our extensive flexible PCB manufacturing capabilities, including flex PCB prototypes, single/double-sided, multi-layer, and flex circuit assemblies, JHYPCB is well-positioned to support innovative applications across industries. We invite you to explore partnering with us to push the boundaries of what’s possible with this versatile technology.

Related Reading

- What Is Flex PCB Prototyping?

- What Is Flexible PCB Coverlay (FPC Cover Layer)?

- What Are The Advantages And Applications Of Rigid-Flex PCBs?

- Rigid PCB vs Flex PCB: What Is The Difference?

- What Are Flexible PCB Stiffeners?

- Everything You Need To Know About Multilayer Flexible PCB

- Custom Flex PCB:Tailored Solutions for Your Applications

- Introduction to Semi-Flex PCBs: Bridging Rigid and Flex PCBs

- Flexible PCB Manufacturing: A Guide to Fabrication and Assembly

- How to Select the Right Flexible PCB Manufacturer for Your Product: A 6-Step Guide

- Layer Stackup in Rigid-Flex PCB

- What Are The Types of Flexible Circuit Boards?

- Why is Flexible PCB so Expensive?

- The Manufacturing Process Of Double-sided Flexible PCB Coverlay

- How to Solder On Flex PCB?

- Flexible Printed Circuit For Today’s Packaging

- 16 Factors Affecting The Cost And Price of Flexible PCB

- Complete Introduction of Flexible Circuit Board Materials

- Knowledge of Flexible PCB Manufacturing Process Steps

- Knowledge of Plating on Flexible Circuit Board Surface

- Five factors that FPC PCB designers should know about impedance control

- Key Process Flow of Rigid-Fled PCB Production