With the upgrading of electronic products, FPC (flexible circuit board) caters to the development trend of light, thin, short, and small electronic products with its unique advantages and plays a critical cornerstone role in the electronic information industry. This paper analyzes the application of FPC in the actual application field, especially its application in the three fields of mobile phones, automobiles, and medical monitoring equipment, and makes a prospect for the future development of FPC.

What is Flex PCB?

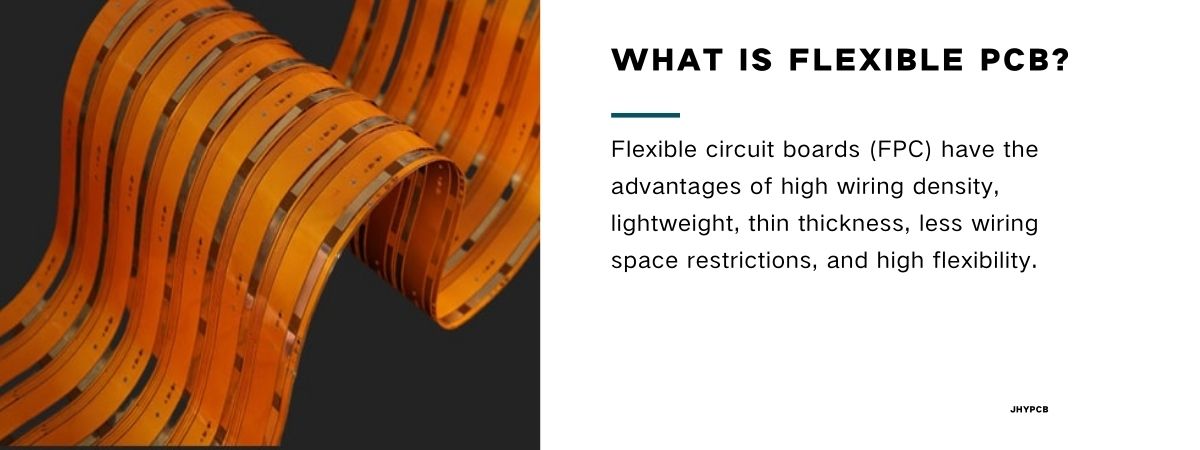

Flexible circuit boards have the advantages of high wiring density, lightweight, thin thickness, less wiring space restrictions, and high flexibility. Flex PCB is entirely in line with the development trend of light, thin, and short electronic products. It is an effective solution to meet electronic products’ miniaturization and mobile requirements. FPC can be bent, wound, and folded freely, withstand millions of times of dynamic bending without damaging the wires, and move and expand in three-dimensional space at will to achieve the integrated effect of component assembly and wire connection. FPC can significantly reduce the volume and weight of electronic products and is suitable for developing electronic products in the direction of high density, miniaturization, and high reliability. Therefore, FPC is widely used in PC and peripheral products, automotive electronics, medical equipment, communication products, consumer electronics, and other fields.

What are the advantages of flexible circuit boards?

FPCA (Flexible Printed Circuit Assembly), namely FPC assembly, is an extension of the FPC business industrial chain, and the mainstream technology in the industry is SMT. SMT (Surface Mount Technology) is the surface mount technology of electronic circuits, also known as surface mount or surface mount technology. It is a circuit assembly technology that mounts the surface-assembled components without leads or short leads (SMC/SMD for short) on the surface of a printed circuit board, then solders and assembles them by reflow soldering or dip soldering.

The application of SMT technology has the following advantages:

- The assembly density is high, and the electronic products are small in size and lightweight. The volume and weight of the patch components are only about 1/10 of the standard plug-in components. Generally, after SMT is adopted, the volume of electronic products is reduced by 40% to 60%, and the weight is reduced by 60% to 80%.

- It has high reliability, strong earthquake resistance, low solder joint defect rate, and good high-frequency characteristics.

- It reduces electromagnetic and radio frequency interference.

- It is easy to realize automation and improve production efficiency.

- Fifth, save materials, energy, equipment, workforce, time, etc.

Applications of flexible circuit board

The demand for light, thin, short, and small electronic products has caused FPC to rapidly shift from military supplies to civilian use and consumer electronic products. Almost all high-tech electronic products that have emerged in recent years have adopted many flexible circuit boards. Japanese scholar Kenshi Sakura said in the book “High-Density Flexible Printed Circuit Boards”: Almost all electrical products use flexible circuit boards, but now it is challenging to find slightly more complex electronic products that do not use flexible circuit boards.

Market prospects of flexible circuit boards

1) Mobile phone market.

Regarding mobile phones, FPCs are mainly used as parts for signal connection such as folding and rotating in mobile phones. At present, more than 3 FPCs are used in mobile phones. The popularity of multi-functional mobile phones that emphasize light, thin, short, and small also drives the demand for FPC.

FPC can be applied to mobile phone bends, LCD modules, camera modules, buttons, side buttons, antennas, and battery control.

At present, FPC is the most widely used in the Hinge Part of mobile phones. The common ones are folding, sliding, clamshell, and three-dimensional rotating bodies. Most of them are double-sided or multi-layer FPC designs, which are the output value of FPC in mobile phone applications. The biggest.

As for the button FPC, camera module, antenna, or battery FPC, it is the optional design of the mobile phone designer.

Under the situation that the above-mentioned selective functions will gradually be incorporated into the standardized design of mobile phones, it will help increase the amount of FPC. Intelligent phones’ FPC content is higher than general electronic products. Smartphones use 5-12 pieces of FPC, which is 1 to 5 pieces higher than feature phones. The FPC output value of each smartphone is about 2 to 3 times that of feature phones. Such a huge market will inevitably drive the rapid development of related fields. Smartphones’ camera modules, antennas, displays, USB cables, etc., are inseparable from FPC.

(2) Automotive electronics market.

Under the trend of automotive electronics, automotive control systems, such as dashboard displays, air quality, audio, displays, sensors, etc., require high signal transmission and high reliability to make FPC begin to show its advantages.

Under the trend of precision FPC components, coupled with the three-dimensional structure of the car body and the narrow and bending characteristics of the wiring area, the use of FPC components can better meet the design requirements. According to data from the China Association of Automobile Manufacturers, in 2014, my country’s automobile production and sales increased by 7.26% and 6.86% year-on-year. Passenger vehicle production and sales increased by 10.15% and 9.89% year-on-year, which is still the main growth force.

(3) Medical monitoring equipment.

In the past ten years, the sales scale of China’s medical device market has increased from 17.9 billion yuan in 2001 to 212 billion yuan in 2013. Excluding the impact of price factors, it has increased by 11.84 times in 13 years.

In summary, as society’s requirements for informatization and intelligence continue to increase, and it has penetrated almost all walks of life, as mentioned in the article, it is challenging to find slightly more complex electronic products that do not use FPC and FPC components. As the country further increases investment in electronic information construction in various fields, accelerating electronic information construction in the downstream field will inevitably drive the development of FPC and FPC component industries. At the same time, 4G business has been fully rolled out across the country, bringing new development opportunities for the flexible printed circuit board industry.