PCB, or Printed Circuit Board, is a substrate produced by circuit printing technology used to carry various electronic components to combine to achieve circuit functions. After core processes such as circuit film exposure, development, etching, and electroplating on the PCB copper clad board, all the copper foils are removed except for the circuits on the copper clad board to form a complete circuit layer. If electrical conduction is required between multilayer PCBs, drilling is required, and copper is attached to the holes to achieve conduction.

PCB is the basic component of electronic products. For products of different purposes, the PCBs that need to be selected are also different. Usually, we use the number of layers, substrate material, and scope of application to classify PCBs.

1. Classification of PCB Based on Layers

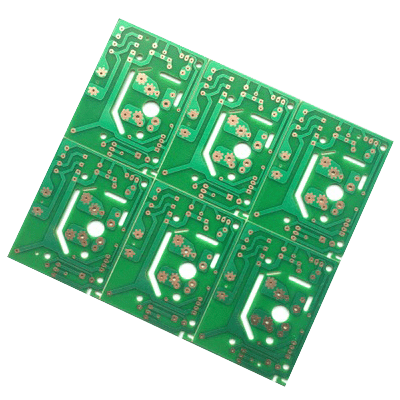

According to the number of PCB layers, it is generally divided into Single-sided Board (SSB), Double-sided Board (DSB), and Multilayer Board (MLB).

a) Single-sided PCB

A Single-sided PCB concentrates all the components on one side of the PCB board, so it is called a single-sided board. Because the single-sided PCB has a limited area, the circuit design will be relatively simple and only suitable for electronic products with simple functions.

a) Double-sided PCB

Double-sided means that there are components and circuits on both sides of the PCB board. Under the same size, it will double the designable area of the single panel, which can effectively solve the electromagnetic interference caused by the interlaced wires in the single panel. It can also reduce product volume and can be used in products with more complex circuit designs.

a) Multi-layer PCB

The multi-layer PCB is composed of single-sided and double-sided boards. The most common one is to use two double-layer boards as the inner board and then use two single-layer boards on the outside, combined into four pieces by a positioning system and insulating bonding materials. For multi-layer boards, of course, the number of layers can be increased according to the product’s design, and they are generally even-numbered. The design of the multi-layer board increases the area and density of the wiring and can make more complex circuit designs. The components of the multi-layer board are mostly SMD components, and the component layout is more precise so that the product can be lighter and small.

2. Classification of PCB Based on the Nature of Substrate

According to the nature of the PCB substrate, PCB can generally be divided into Rigid PCB, Flexible PCB (FPC), and Rigid-flex PCB.

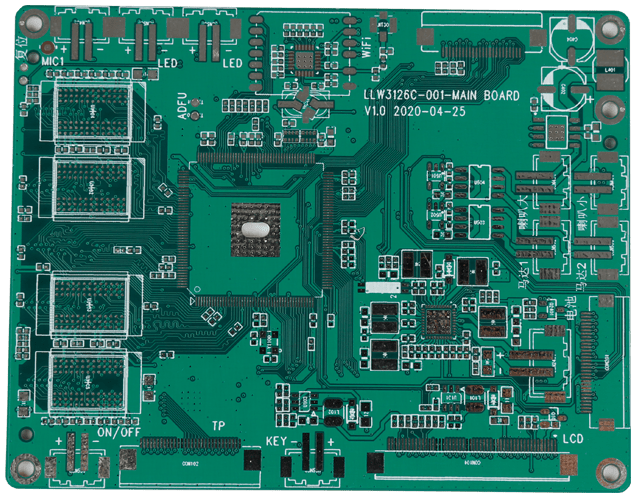

a) Rigid PCB

The primary materials of rigid circuit boards are FR-4, CEM-1, CEM-3, metal-based copper-clad laminates (mainly aluminum-based, and a few are metalcore).

i) FR-4

FR-4 is a glass fiberboard laminated with copper foil and impregnated flame-retardant epoxy fiber cloth with good mechanical processability.

More Adventures:

- Unveil the mystery of high TG PCB circuit boards Materials

- Why choose FR4 as the general material of PCB?

- Why is FR4 Used to Make High Tg PCBs?

Halogen-free sheet in FR4: Halogen-free refers to a substrate that does not contain halogen (fluorine, bromine, iodine, etc.)

Commonly used FR4 boards are yellow core and white core.

ii) CEM-1

CEM-1 is a composite substrate made of paper material impregnated with phenolic resin on the upper and lower glass fiber surfaces. The machining and electrical properties are not as strong as FR-4, but the price is low.

iii) CEM-3

CEM-3 is a composite glass fiberboard. The glass transition temperature, solder resistance, peel strength, water absorption, electrical breakdown, insulation resistance, and UL indicators have all reached the level of FR-4. But the flexural strength is lower than FR-4.

iv) Metal-based Copper Clad Laminates

These laminates are made of a metal substrate. Metal substrates have excellent heat dissipation, and they can bear high temperatures without damaging the board. They have an insulation layer placed between the metal substrate and the circuit through hot-pressing.

The typical circuit boards made of metal substrates are the aluminum substrate and copper substrate.

Aluminum Substrate: Aluminum substrate is a metal-based copper-clad laminate with a good heat dissipation function. Generally, a single panel is composed of a three-layer structure. They are the circuit layer (copper foil), insulating layer, and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is for soldering the LED pins, and the other side is the natural color of aluminum. Generally, the thermal conductive paste will be applied to the thermal conductive part. The typical application of the aluminum substrate is the LED lighting industry. Because LEDs generate more heat and aluminum substrates conduct heat quickly, the circuit boards used in LED lamps are generally aluminum substrates.

Copper Substrate: The copper substrate is the most expensive type of metal substrate, and its thermal conductivity is many times better than the aluminum substrate and iron substrate. It is suitable for high-frequency circuits and areas with significant changes in high and low temperatures and heat dissipation and architectural decoration industries for precision communication equipment.

Rigid circuit boards are generally used in electronic products. They have a certain degree of mechanical strength, and the manufactured PCB has flatness and can maintain a good overall state.

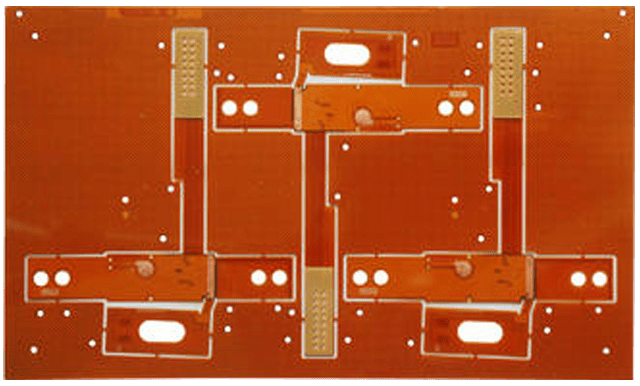

b) Flexible PCB (FPC)

FPC is made of soft layered plastics such as polyester film, polyimide film, and fluorinated ethylene propylene film. The flexible circuit board can be bent and stretched, convenient for installation according to the installation requirements.

The structure of FPC can generally be divided into single-sided, double-sided, and multilayer boards.

Single-sided circuit board structure: This structure of the flexible board is the simplest.

Double-sided circuit board structure: In a double-sided board, there are pads on both sides, mainly used for connection with other circuit boards. Although it is similar to the single-layer board structure, the manufacturing process is very different. Its raw materials are copper foil, protective film, and transparent glue.

Multi-layer board: The most typical difference between a multilayer board and a single-layer board is the addition of a via structure to connect the layers of copper foil. Generally speaking, the first processing technology of substrate + transparent glue + copper foil is to make vias.

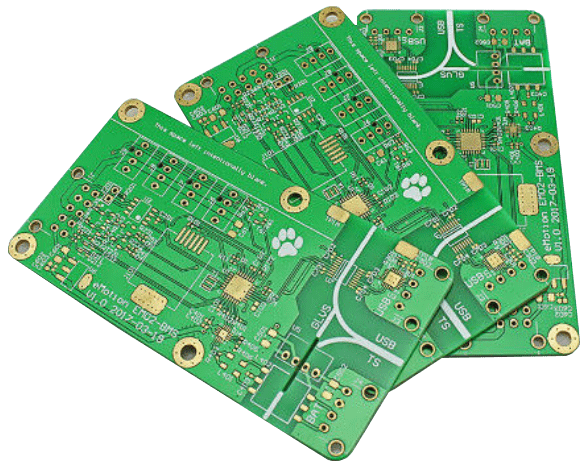

c) Rigid-Flex PCB

Rigid-Flex PCB combines the rigid circuit board and flexible circuit board-related process requirements to form a circuit board with FPC characteristics and PCB characteristics. It can be used in some products with special needs.

Advantages: The rigid-flex board has both the characteristics of FPC and the attributes of PCB. Therefore, it can be used in some products with special requirements. It has both a particular flexible area and a specific rigid area, which can save the internal space of the product. It reduces the volume of the finished product and improves the performance of the product.

Disadvantages: The production processes for the rigid-flex board are complicated. The yield rate is low, and the input materials and the workforce are more, so the price is high, and the production cycle is longer.

3. Classification of PCB Based on the Scope of Application

According to the scope of application, PCB can be divided into high-frequency and low-frequency.

The high frequency of electronic products is the current development trend. PCB high-frequency boards have been widely used in the present communication industry, network technology fields, and high-speed information processing systems. Because the dielectric constant of high-frequency boards is small, the heating efficiency and signal transmission speed are speedy. At the same time, because the material of the high-frequency board has low water absorption, it can be applied to a more humid environment. The application range is much more extensive than that of low-frequency boards.

Advanced Learning:

- Single-layer PCB vs. Double-sided PCB: How to Choose?

- What is a Multilayer PCB and What are the Advantages?

- The Application of Thermoelectric Separated Copper Core PCB in the Field of LED Heat Dissipation

- Key Process Flow of Rigid-Fled PCB Production

- Knowledge of Flexible Printed Circuit Board Processing Technology

More Adventures: