Aluminum PCB prototypes have become increasingly popular in recent years due to their superior performance and reliability compared to traditional FR4 PCB prototypes. In this blog post, we will provide you with the ultimate guide to aluminum PCB prototypes, covering everything you need to know from their definition and advantages to their applications and how to choose the right manufacturer.

Table of Contents

What is an Aluminum PCB Prototype?

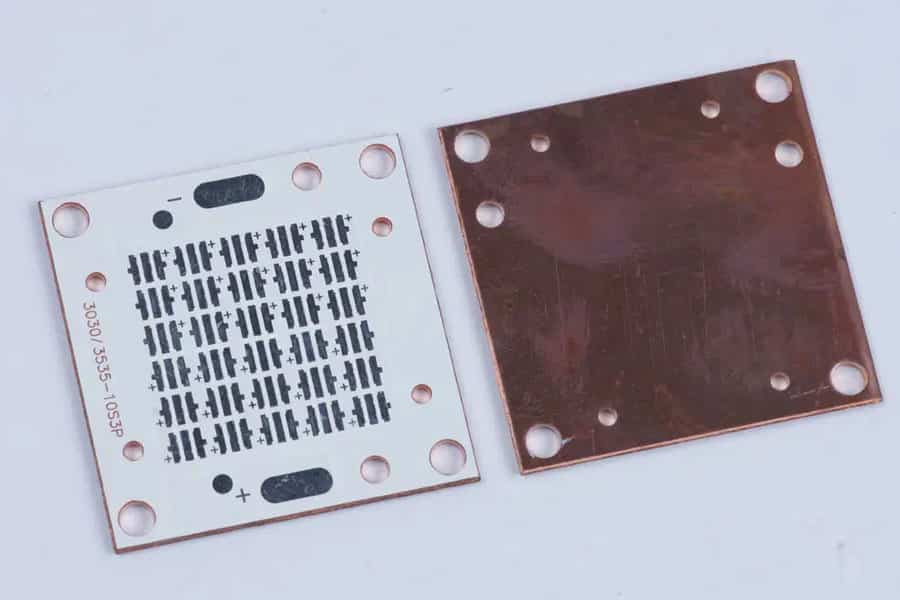

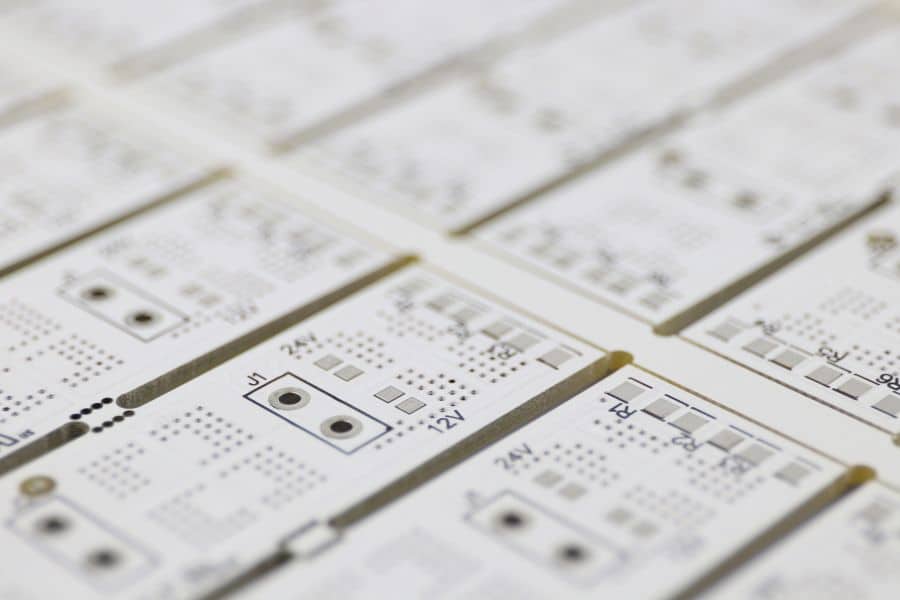

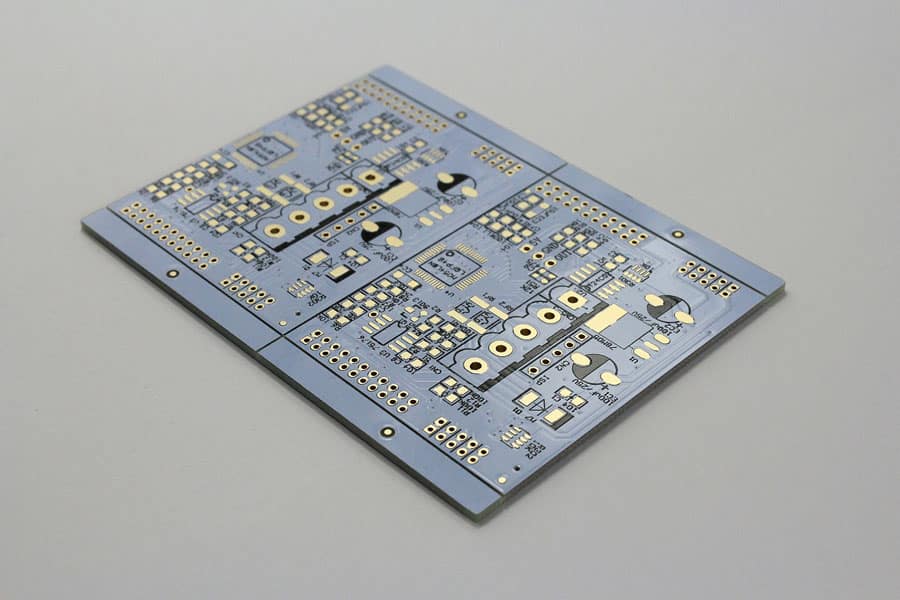

An aluminum PCB prototype is a type of PCB that uses aluminum as its base material instead of the traditional fiberglass or FR4 material. This makes aluminum PCB prototypes significantly more efficient at heat dissipation, making them ideal for high-power applications such as LED lighting, power electronics, and automotive electronics.

Advantages of Aluminum PCB Prototypes

Aluminum PCB prototypes offer a number of advantages over traditional FR4 PCB prototypes, including:

- Superior Thermal Performance: Aluminum has a much higher thermal conductivity than fiberglass or FR4, which allows aluminum PCB prototypes to dissipate heat more efficiently. This can lead to lower operating temperatures, increased component reliability, and longer product lifespans.

- Better Electrical Performance: Aluminum PCB prototypes also offer better electrical performance than FR4 PCB prototypes. This is because aluminum has a lower dielectric constant and loss tangent, which can reduce signal attenuation and crosstalk, improve signal integrity, and increase power efficiency.

- Lighter Weight and Smaller Size: Aluminum PCB prototypes are significantly lighter and smaller than FR4 PCB prototypes. This is because aluminum is a much lighter material than fiberglass or FR4. As a result, aluminum PCB prototypes are ideal for weight-sensitive applications such as aerospace and automotive electronics.

- Enhanced Durability and Corrosion Resistance: Aluminum PCB prototypes are more durable and corrosion-resistant than FR4 PCB prototypes. This is because aluminum is a naturally corrosion-resistant material. As a result, aluminum PCB prototypes are suitable for harsh environments and outdoor applications.

Applications of Aluminum PCB Prototypes

Aluminum PCB prototypes are used in a wide range of applications, including:

- LED Lighting: Aluminum PCB prototypes are ideal for high-power LED lighting applications due to their superior thermal performance and lightweight design.

- Power Electronics: Aluminum PCB prototypes are also well-suited for power electronics applications such as power converters, inverters, and motor drives.

- Automotive: Aluminum PCB prototypes are increasingly being used in automotive electronics applications due to their weight-saving benefits and ability to withstand harsh environments.

- Aerospace: Aluminum PCB prototypes are used in aerospace applications such as avionics and satellite systems due to their high performance and reliability.

- Medical: Aluminum PCB prototypes are also used in medical devices such as imaging equipment and surgical robots.

Aluminum PCB prototypes offer a number of advantages over traditional FR4 PCB prototypes, making them ideal for a wide range of applications. In the next section, we will discuss how to choose the right aluminum PCB prototype manufacturer for your needs.

Bare Aluminum PCB Prototype Fabrication

Bare aluminum PCB prototype fabrication is the process of creating a bare aluminum PCB, which is a PCB without any components soldered onto it. The process is similar to that of traditional FR4 PCB fabrication, but with some key differences.

Bare Aluminum PCB Prototype Fabrication Process:

- Material selection: The first step is to select the right type of aluminum for the PCB prototype. The most common types of aluminum used for PCB prototypes are 6061 and 5052.

- Surface preparation: The aluminum surface must be properly prepared before the copper layer can be applied. This involves cleaning, degreasing, and etching the surface.

- Copper deposition: The copper layer is then deposited onto the aluminum surface using a process called electroplating.

- Patterning: The copper layer is then patterned using a photoresist and etching process.

- Drilling: Holes are then drilled in the PCB prototype for vias.

- Plating: The PCB prototype is then plated with a protective layer of metal, such as gold or nickel.

Key Differences in Bare Aluminum PCB Prototype Fabrication:

- The use of aluminum as the base material requires different processing steps than fiberglass or FR4.

- Aluminum is more sensitive to heat than fiberglass or FR4, so care must be taken to avoid overheating during the fabrication process.

- Aluminum is more susceptible to corrosion than fiberglass or FR4, so a protective layer of metal must be applied.

Aluminum PCB Prototype Assembly

Aluminum PCB prototype assembly is the process of soldering components onto a bare aluminum PCB. The process is similar to that of traditional FR4 PCB assembly, but with some key differences.

Aluminum PCB Prototype Assembly Process:

- Component selection: The first step is to select the right components for the PCB prototype. The components must be compatible with the aluminum substrate and the assembly process.

- Solder paste application: Solder paste is then applied to the pads on the PCB prototype.

- Component placement: The components are then placed onto the PCB prototype.

- Reflow soldering: The PCB prototype is then heated to a temperature that melts the solder paste, forming a permanent bond between the components and the PCB.

- Inspection: The PCB prototype is then inspected to ensure that all of the components are properly soldered in place.

How to Choose the Right Aluminum PCB Prototype Manufacturer

Choosing the right aluminum PCB prototype manufacturer is critical to ensuring the quality and performance of your final product. Here are a few factors to consider when making your decision:

Experience and Expertise:

- Look for a manufacturer with extensive experience in aluminum PCB fabrication.

- Consider the manufacturer’s track record of success in meeting customer requirements.

- Evaluate the manufacturer’s technical expertise and capabilities.

Quality Control and Testing:

- Verify that the manufacturer has a robust quality control system in place.

- Check the manufacturer’s testing procedures to ensure that they meet your standards.

- Request samples of the manufacturer’s previous work to assess their quality.

Lead Time and Pricing:

- Get quotes from multiple manufacturers to compare lead times and pricing.

- Consider the manufacturer’s ability to meet your deadlines and budget.

- Negotiate the best possible price and delivery terms.

Customer Service and Support:

- Look for a manufacturer with a responsive and knowledgeable customer service team.

- Consider the manufacturer’s willingness to work with you to meet your specific needs.

- Evaluate the manufacturer’s reputation for customer satisfaction.

Additional Factors to Consider:

- The manufacturer’s location and proximity to your business.

- The manufacturer’s ability to provide value-added services such as design assistance and prototype assembly.

- The manufacturer’s commitment to sustainability and environmental compliance.

By carefully considering the factors outlined above, you can choose the right aluminum PCB prototype manufacturer to meet your needs. In the next section, we will provide you with some additional resources to help you in your selection process.

Conclusion

Aluminum PCB prototypes offer a number of advantages over traditional FR4 PCB prototypes, making them ideal for a wide range of applications. When choosing an aluminum PCB prototype manufacturer, be sure to consider the factors outlined in this blog post to ensure that you select the right partner for your needs.

Related Posts

- Fast and Reliable PCB Prototyping with JHYPCB in Australia

- What Is Prototype PCB Assembly?

- Fast Prototype PCB Manufacturing Services in Canada by JHYPCB

- UK PCB Prototype Manufacturing: Fast, Affordable, and High-Quality

- Introduction to Rapid PCB Prototyping Services

- How to Make Low Cost PCB Prototypes

- Gerber Files for PCB Prototyping – A Comprehensive Guide

- Fast Prototype PCB Services for US Customers

- Choosing the Right PCB Material for Your Prototype: A Comprehensive Guide

- Why Should You Consider PCB Prototyping for Your Next Project?

- The Ultimate Guide to PCB Prototype Manufacturing: Everything You Need to Know

- Exploring the Benefits and Challenges of China PCB Prototype Manufacturing

- Why Do You Need a PCB Prototype?

- What Are The Requirements To PCB Prototype Manufacturing?

- Prototype PCB Fabrication Service Price in China