Table of Contents

Introduction

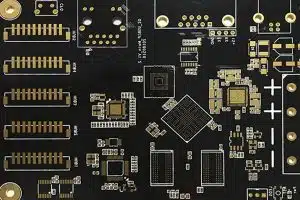

With the exponential growth of high-speed applications like 5G, autonomous vehicles, and IoT devices, printed circuit boards are being pushed to their limits to handle faster speeds and higher frequencies. This leads to increased demand for better signal integrity in PCB design using techniques like backdrilling of vias.

According to Google search data, global monthly searches for the term “backdrilled vias” have grown over 30% year-over-year. However, many PCB designers and engineers still lack a clear understanding of what backdrilling is and why it offers tangible benefits for their high-frequency PCB application needs.

As a leading PCB solutions provider catering to customers across various industries, JHYPCB recognizes the rapidly accelerating need for backdrilling services. We have made substantial investments in advanced PCB fabrication equipment and engineering expertise to offer high-precision backdrilling capabilities.

In this blog article, we provide an in-depth explainer on backdrilled vias to address the growing customer demand and search interest. We cover key topics such as:

- What are backdrilled vias

- Difference compared to regular plated through-hole vias

- Benefits of backdrilling vias

- Backdrilling considerations

- JHYPCB’s backdrilling capabilities

The goal is to help PCB designers, engineers, and procurement managers gain a clearer understanding of backdrilled vias. This enables them to make more informed decisions about incorporating backdrilling to improve signal integrity for their high-density, high-speed PCB design needs.

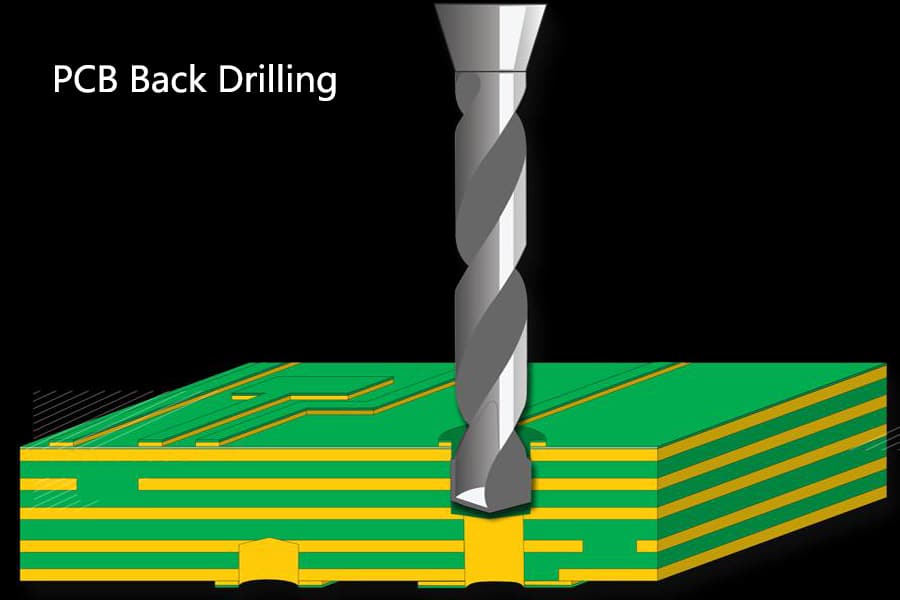

What Are Backdrilled Vias

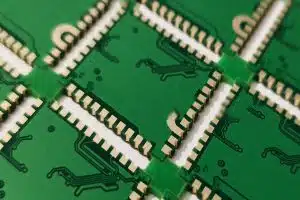

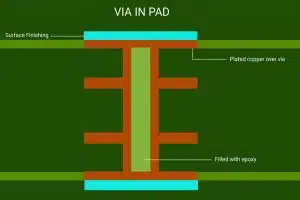

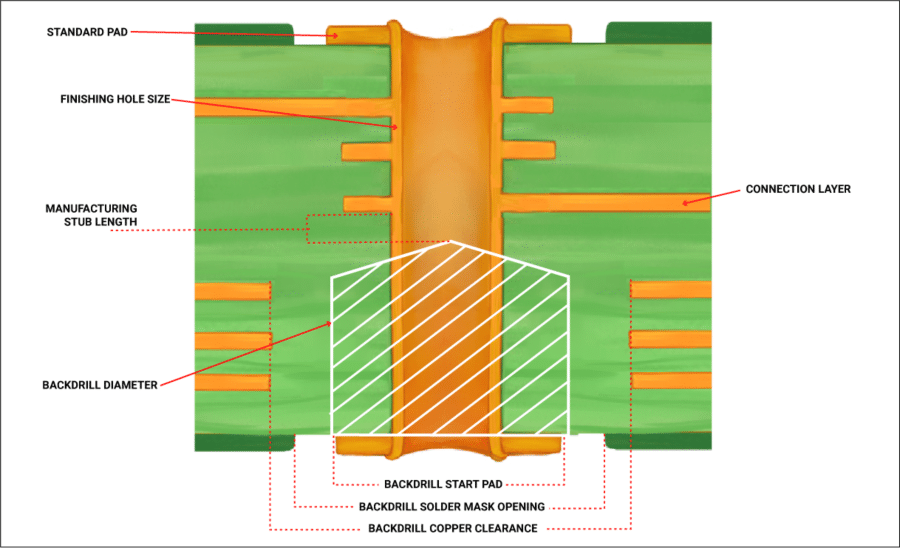

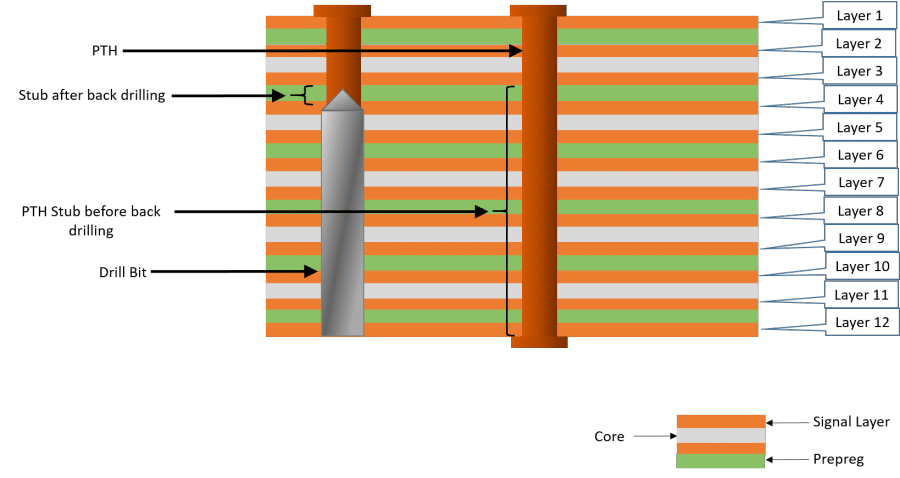

Backdrilled vias are a special type of plated through-hole vias that have the lower portion of the via “drilled away” after the PCB fabrication process.

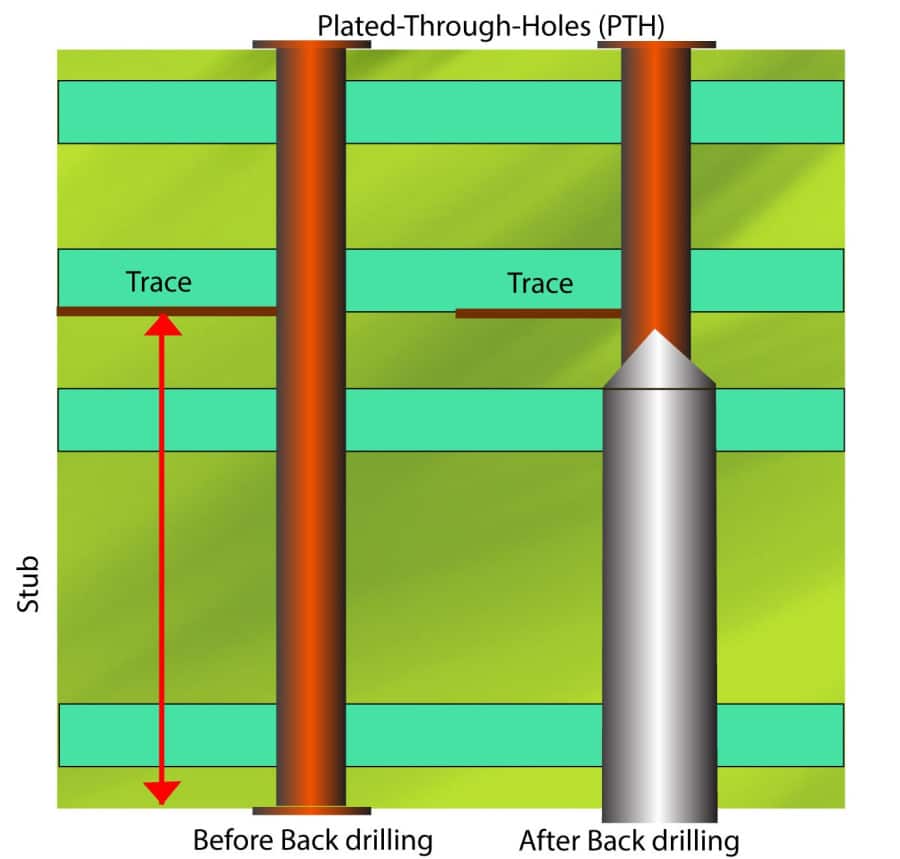

As shown in the diagram below, they look like a normal via from the top of the PCB. However, the lower half of the via barrel is removed, leaving only the connections to the necessary inner layers.

Plated through hole before and after back drilling

This contrasts with a regular via that spans the entire length from the top to the bottom layer, connecting all layers in between.

So why go through the extra fabrication steps to create these partial vias?

The answer lies in the inherent functionality of vias. As critical interconnects in multi-layer PCB boards, all vias exhibit an unavoidable parasitic effect at high frequencies known as the “via stub”. This disrupts clean signal transmission and propagation.

Backdrilling eliminates the lower stub section that is often unnecessary for signal routing between the surface and first few layers. This minimizes unwanted reflections and impedances that degrade signal integrity at high speeds.

In essence, backdrilled vias remove only the non-functional via length while retaining electrical connections between the necessary inner layer traces. This makes them ideal for high-density PCBs that require pristine signal transmission up to microwave frequencies.

Benefits of Backdrilling Vias

Backdrilling vias provides several tangible improvements in high-speed PCB performance and signal quality:

Improved Signal Integrity

- Eliminating the lower via stub minimizes unwanted impedance discontinuities and reflections that can distort signals

- This allows high-frequency signals to propagate cleanly from source to destination

Enables High-Speed Signal Transmission

- Backdrilling eliminates via stub resonances that act as bandstop filters

- This prevents attenuation at high frequencies, allowing multi-GHz transmission

Reduced Cross-Talk

- Partial removal of the via barrel decreases parasitic capacitance between the via and reference planes

- This mitigates electrical coupling and noise injection into adjacent signals

Overall, backdrilled vias are critical for meeting signal integrity and performance requirements in today’s cutting-edge applications like 5G, automotive radar systems, high-speed networking, and test and measurement equipment.

Backdrilling helps actualize the full potential of advanced PCB materials like ceramic or hydrocarbon substrates for electro-optical systems operating up to 100 GHz frequencies.

Without backdrilling, electrical engineers often hit an impasse due to excessive signal losses, reflections, or cross-talk in complex, high-density PCBs.

By offering backdrilling services, JHYPCB empowers PCB designers and engineers to keep pushing the limits for next-gen applications with pristine signal fidelity.

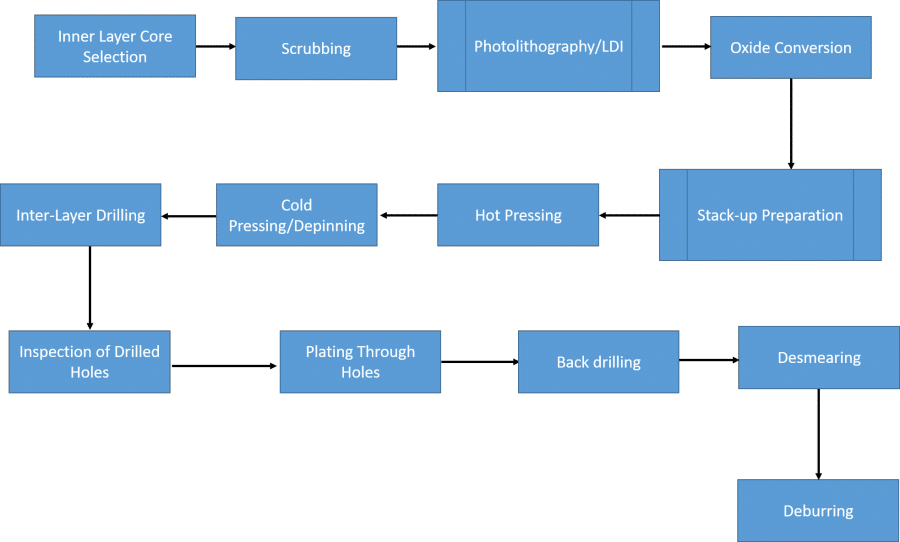

Backdrilling Considerations

While backdrilling vias enables significant high-frequency benefits, it also increases manufacturing complexity and cost compared to conventional plated through-hole vias.

As such, PCB designers should weigh various design and product factors when deciding whether to incorporate backdrilling:

When is backdrilling needed?

- For signals above 3-5 GHz to avoid stub resonance

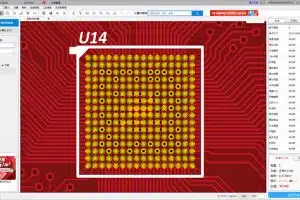

- Vias under ICs or other critical high-speed components

- High-density boards where cross-talk is a concern

Tradeoffs with backdrilling

- Additional fabrication step increases cost per board

- Tight drilling tolerances required (+/- 0.05mm)

- Generally used for HDI boards with 6-12+ layers

Evaluate product budget & life cycle

- Cost-benefit analysis for production volume

- Future-proofing for next-gen product generations

No “one size fits all” guideline exists for backdrilling vias. The optimal approach depends on PCB materials used, product lifecycle, and performance targets.

JHYPCB has extensive experience determining exactly where backdrilling is warranted based on the electrical constraints and layout for each unique design.

We work closely with customers early in their design cycle to conduct in-depth reviews. This proactive verification prevents issues from arising further downstream during prototyping or manufacturing.

JHYPCB Backdrilling Capabilities

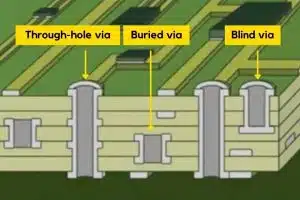

As a premier PCB solutions provider, JHYPCB houses advanced PCB fabrication equipment to offer precision backdrilling services for all via structures.

Our backdrilling capabilities include:

Backdrilling Services Offered:

- Blind & buried vias

- Plated through-hole vias

- Support for multiple drill bit sizes

Precision Backdrilling Process:

- Tight diameter & depth tolerances

- MIN hole size of 0.15mm

- Depth accuracy to +/- 0.05mm

Engineering Expertise:

- 10+ years optimizing backdrilling

- Determine best stackup configurations

- Provide design rule checks

Quality & Testing:

- Rigorous QA testing protocols

- Test point coupons on PCB panels

- Impedance profiling & network analysis

By leveraging these substantial engineering resources for backdrilling, JHYPCB customers can actualize bleeding-edge PCB innovations once considered impossible due to restrictive electrical constraints.

We enable customers to fully unlock greater functionality, speed, density, and reliability enhancements to drive their product roadmap over the coming decade.

Conclusion

As next-generation applications raise the bar for PCB performance, backdrilled vias will only increase in importance and adoption across high-speed industries. Whether for cutting-edge aerospace systems or high-throughput data centers, backdrilling is instrumental in wringing out every last drop of speed while maintaining signal integrity.

While the PCB design ecosystem scrambles to keep pace with unrelenting demands for functionality in smaller form factors, JHYPCB continues investing to lead the charge. Our holistic solutions empower customers to leverage sophisticated techniques like backdrilling with ease.

With fanatical testing protocols to ensure quality plus smooth order fulfillment globally, JHYPCB helps expedite customers’ next breakthrough innovation. We offer the agile manufacturing bandwidth to scale up reliability as customer technology transitions from R&D to volume production.

To learn more about our end-to-end PCB fabrication capabilities spanning multilayer HDI boards, rigid-flex PCBs, and metal-backed substrates using glass or ceramic, contact us today. JHYPCB aims to forge enduring partnerships with customers to bring their electrifying ideas to life and reshape the future.