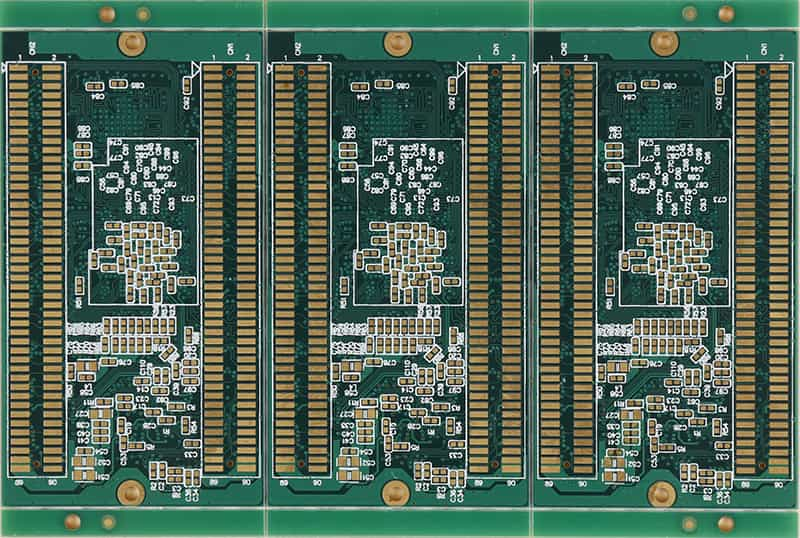

With the advancements in PCB technology, the industry has gained massive attention. Nowadays, PCBs are used in almost all types of applications. In some of the applications, the ambient temperature of the PCB is normal, which means a standard PCB would work without any problem. But if the temperature is high, then the PCB could bend and change its shape. Therefore, for such areas where the operating temperature is high (greater than 170˚C), a special PCB is needed to bear that temperature.

High Tg PCBs are special PCBs that can withstand higher temperatures. You can easily find a High Tg PCB, even if the operating temperature is 200˚C. These PCBs can bear higher temperatures without changing their shapes. They are temperature-resistant and durable. They also have a low thermal expansion coefficient, which is why they do not expand at high temperatures.

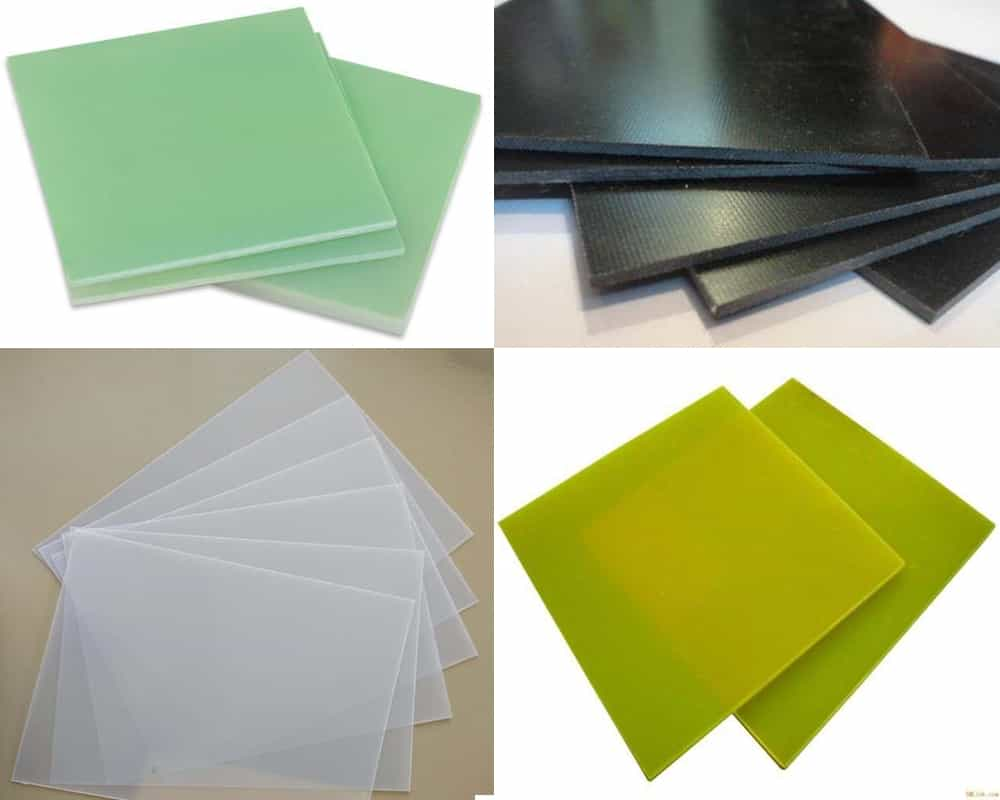

FR-4 is a very common material used for High Tg PCBs. Today, we will discuss why FR-4 is used for this purpose. No doubt, there are many materials available, so why FR-4 is still preferred. Moreover, there are metal PCBs better in temperature resistance and thermal stress, but still, FR-4 High Tg PCBs are used in most places. Stay with us, and you will get the answer to your questions.

What is Tg?

Tg stands for glass transition temperature. It is the temperature at which the PCB material changes its state. Once this temperature is reached, the PCB starts to bend and lose its rigidity. It is a mechanical property of a PCB material, which helps you choose the PCB’s right material. If the PCB is going to be used in a high-temperature environment, it should be of high Tg. The Tg of the PCB should be 20-25˚C greater than the operating temperature. If it is very near to the Tg temperature, the PCB will deteriorate or bend earlier.

Reasons for Using FR-4 for High Tg PCBs

FR-4 is used to make High Tg PCBs because of its properties. Let’s look at them in detail.

- Excellent Electrical Performance

Not only the mechanical properties of FR-4, but the electrical performance is also phenomenal. It offers optimum performance at high temperatures.

- High Temperatures Resistance

High Tg FR-4 can withstand higher temperatures, which is the most important reason for using it for High Tg PCBs. It can retain its shape at high temperatures, even over 200˚C or higher.

The FR-4 PCBs can be made in a wide range of Tg. There can be low (130-140˚C), medium (150˚C<Tg<170˚C), or high Tg (over 170˚C) PCBs. The high Tg PCBs can be used in environments having high temperatures and thermal stress.

- Ideal for Through Hole Components

It is easier to make plated through holes(PTH) in an FR-4 PCB than a metallic PCB. It has better reliability of plated through holes so that the holes components can be used in the assembly with no hassle.

- Impedance Control

FR-4 offers better impedance control. If the PCB requires strict impedance control, it is the ideal material.

- Durability and Long Life

FR-4 is a durable material and can work for a long time, even in harsh conditions. It can withstand wear and tear and high-temperature stress. It is also shockproof. Therefore, its shape and components remain intact.

- Low Cost

Cost is also an important factor in using FR-4. It is much cheaper than metals, and an excellent high Tg PCB can be prepared cheaply.

Final Words

A High Tg PCB is necessary where the working temperature is above 170˚C. You need to choose the PCB material after looking at the Tg of the PCB and the operating temperature. FR-4 is ideal because of its excellent performance, durability, temperature resistance, impedance control, and low cost. This is the reason it is preferred and widely used.

Advanced Learning: