Differences Between Single-sided PCB and Double-sided PCB

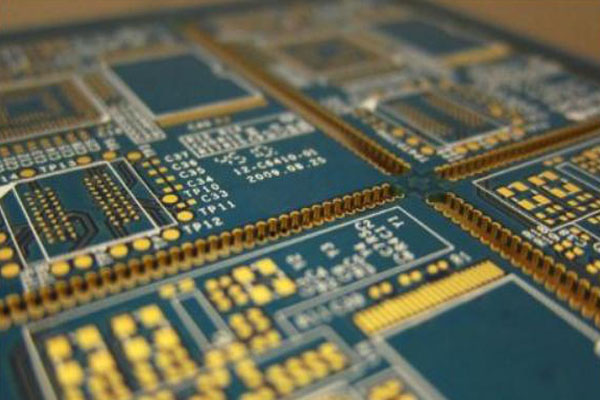

Single and double-sided printed circuit boards share identical material make-up: FR-4, a form of fiberglass mixed with epoxy. In modern manufacturing, this is usually layered with copper for conductivity and then coated in a solder mask for a professional finish. Sometimes, in a process called silk screening, industrial printers print markings and labels on the board.

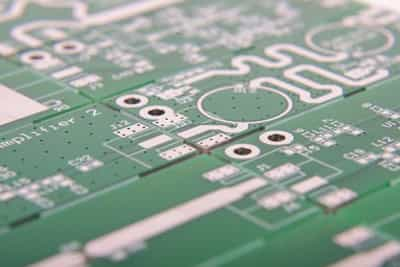

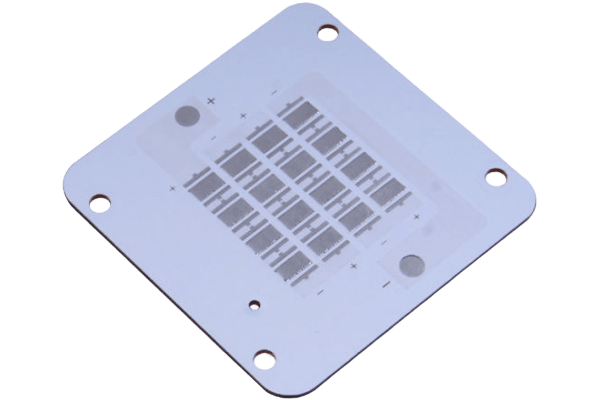

Single-sided PCBs consist of the FR4 insulating core substrate and a thin layer of copper coating on the bottom or solder side of the substrate. Through-hole components mount on the top or component-side of the substrate, with the leads passing through to the bottom side and soldered to the copper pads and tracks. Surface mount components mount directly to the solder side. The primary difference between the two boards will be in conductor placement.

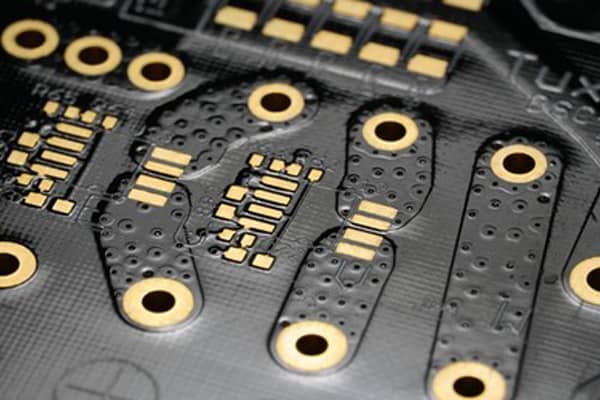

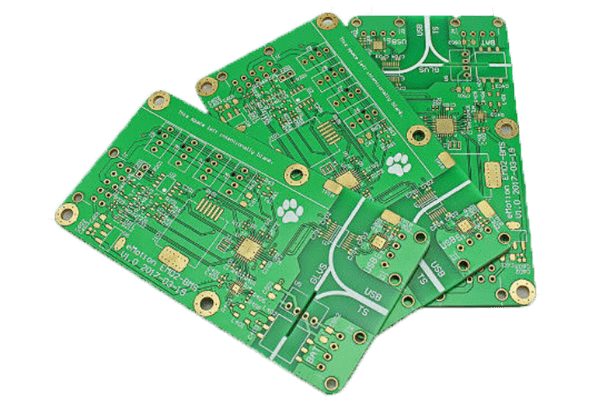

Double-sided PCB boards rely on the same core substrate but have conductors on both sides of the substrate. Very directly, a double-sided circuit board delivers twice the area for conductors. Complex routing can occur with through-hole components mounted on the top layer and surface mount components attached to the bottom layer. Plated through-holes establish “vias” or the electrical connections between the two sides.

Choose Single-Sided PCB or Double-Sided PCB?

Which PCB you pick depends on your needs and requirements. Sometimes single-sided PCBs are more suitable for project design as compared to double-sided PCBs and vice versa.

Before you pick any PCB type for your project, you must consider one thing single-sided PCB layouts are more difficult to route than double-sided PCB. Still, the following are the reasons why you should put effort into making and picking single-sided PCBs over other PCBs.

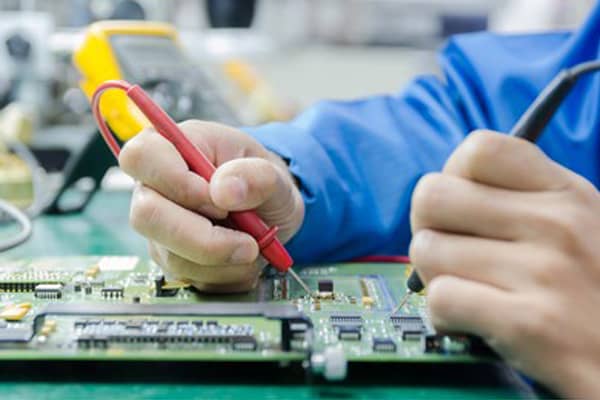

If you are a hobbyist or student and concerned about making PCBs at home, you must know, developing single-sided PCBs at home are much more comfortable than designing double-sided PCBs at home.

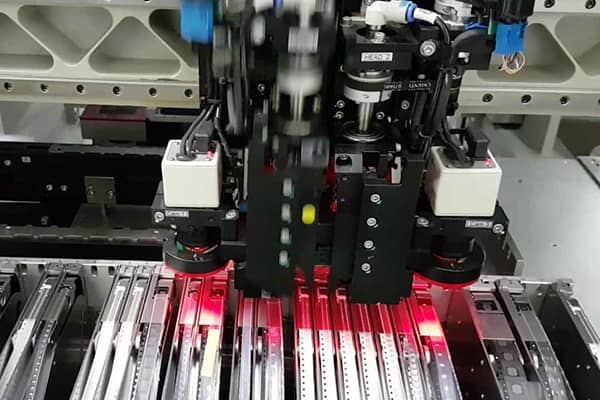

You are a manufacturer and very much interested in keeping your cost down and producing a single-sided PCB a most economical process. In terms of price, producing single-sided PCBs are more economical than having double-sided PCBs.

Almost all HVAC systems use single-sided PCBs because they are more reliable and cost-effective and don`t compromise the overall quality of the product.

Using hole technology in single-sided PCBs still has drawbacks and limitations because conductive layers, lines, and pads stay on a single side of PCB, but it still is a cheap process to combine all components in one place. Multilayer PCB is also used in many applications where single-sided and double-sided PCBs fail to fulfill the requirements.

Advanced Learning:

- Custom Circuit Board Printing

- PCB Manufacturer In China

- How To Search for a Reliable PCB Manufacturer

- Find Out Now, What Should You Do For Fast PCB Classification?

- Why Choose Chinese PCB Manufacturer

- Double-Sided PCB Manufacturing Process

- Introduction to the aluminum PCB manufacturing process

- The Benefits Of Using Double Sided PCBs