Printed circuit boards are the foundation of electronics. They provide the mechanical structure and electrical connections that allow components to function in unison. With electronics becoming more ubiquitous and integrated into all facets of life, there is an ever-increasing demand for high-quality, cutting-edge PCB solutions. This is where Shenzhen PCB assembly manufacturers have established themselves as leaders in the global marketplace.

Shenzhen has transformed itself into a powerhouse of manufacturing excellence, especially in advanced electronics like PCB assembly. Strategic government initiatives to promote manufacturing combined with private investments in infrastructure, STEM education, and incentives for innovation have made Shenzhen into a global hub for electronics.

Shenzhen PCB assembly manufacturers leverage these advantages to dominate the market worldwide. Data shows that Shenzhen accounts for the majority share of China’s massive PCB assembly output. Increasingly complex board technology is also arising from Shenzhen as local companies strive to adopt the latest techniques in HDI, rigid-flex, embedded components, and more on PCB assemblies.

With their capabilities in scalability, quality, technology adoption and connectedness to global supply chains, Shenzhen PCB assembly manufacturers reinforce their leadership position continuously. This blog post will dive deeper into how Shenzhen has earned its reputation as the premiere location for advanced, cutting-edge PCB assembly manufacturing globally.

Table of Contents

Shenzhen’s Dominance in PCB Assembly Manufacturing

Shenzhen PCB assembly manufacturers command a majority share of the total output from China, which produced over 50% of the world’s PCB assemblies in 2022. Within China, Shenzhen accounted for over 25% of the total PCB assembly manufacturing revenue alone last year. The largest PCB assembly facilities in China with thousands of daily assembly outputs are also predominantly centered in Shenzhen.

What factors contribute to Shenzhen holding such a lions share of the PCB assembly manufacturing marketplace?

Strategic government support including the creation of special economic zones, tax incentives, and policies favorable for high-tech manufacturing have given Shenzhen PCB assembly manufacturers a competitive edge. Shenzhen’s exemplary infrastructure from rapid transit systems to large sea and air freight capacities optimize transportation logistics. This enables even the most demanding customer specifications to be fulfilled by Shenzhen PCB assembly companies.

The availability of a skilled engineering workforce is another advantage. With China’s largest number of STEM graduates concentrated in the region, Shenzhen PCB assembly manufacturers can utilize cutting edge automation while retaining flexibility in human oversight over the assembly process. Investments in emerging technologies also flow freely in Shenzhen’s startup ecosystem, pioneered by PCB assembly companies constantly pushing the boundaries.

This unique combination of government support, infrastructure growth, skilled work pool, and technology investments catalyzes Shenzhen’s leadership in the global PCB assembly manufacturing space today. The numbers speak for themselves, with exports from Shenzhen significantly outpacing other Chinese regions and worldwide competitors. As demands for quality and complexity increase, Shenzhen PCB assembly manufacturers are poised to retain dominance in this key electronics manufacturing vertical.

Key Capabilities of Shenzhen PCB Assembly Manufacturers

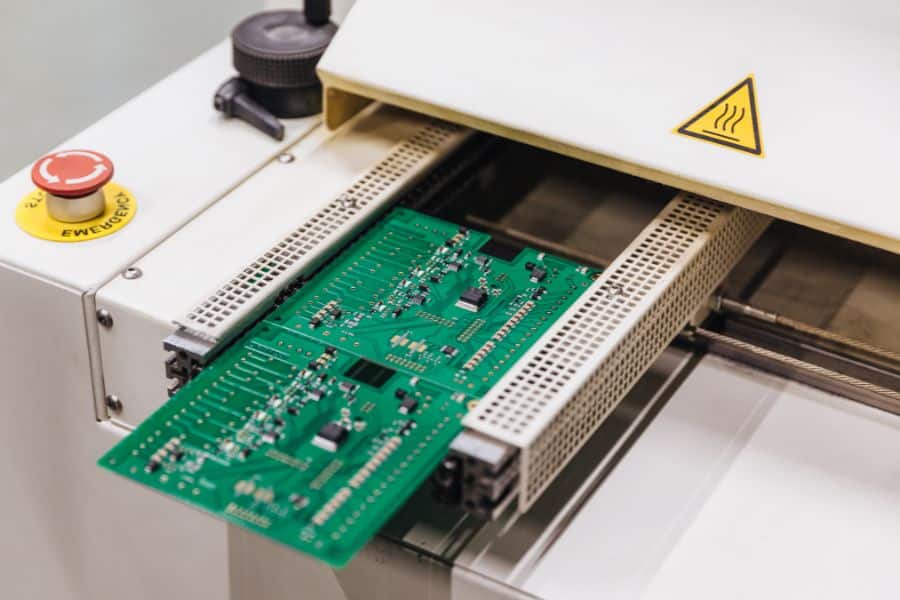

Shenzhen PCB assembly manufacturers have moved far beyond basic board assembly. They are now industry leaders when it comes to advanced manufacturing techniques for high density, flexible, and challenging assemblies.

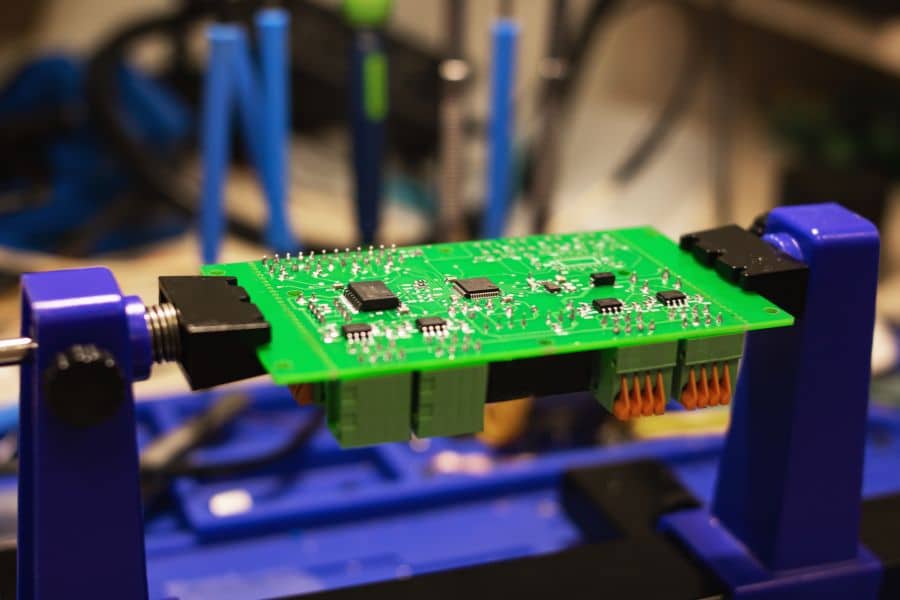

For instance, Shenzhen PCB assembly companies routinely handle boards under HDI classifications. These may incorporate microvias, stacked vias, thinner conductors, tighter pitches, buried and blind vias, and higher connection densities per unit area. Handling precision assembly with reliability for such complex designs showcases core competencies.

Many Shenzhen PCB assembly providers also offer specialized services for flexible or rigid-flex boards. These can pose unique challenges like handling thin, easily deformable PCBs and ensuring reliability across flexing cycles. In spite of that, the sophisticated machinery available with Shenzhen manufacturers makes rigid-flex PCB assembly second nature.

Of course, achieving the highest quality is paramount. Leading Shenzhen PCB assembly manufacturers regularly meet demanding industry metrics like IPC Class 2 or Class 3 certifications in their assembly processes. This covers factors spanning component selection, soldering integrity, cleanliness, inspection testing, troubleshooting, and statistical process controls.

Finally, volume and scale advantage is a key asset for Shenzhen in PCB assembly manufacturing. The production capacity available locally allows meeting orders ranging from small batches of prototypes to extremely large production runs in the hundreds of thousands. Shenzhen PCB assembly providers typically have facilities all across China adding capacity flexibility.

The sophistication evident in Shenzhen PCB assembly manufacturers extends beyond just process capabilities and available certifications too. With R&D embedded deeply in the local ecosystem, there is always emphasis on adopting the latest high-technology equipment and pushing the envelope further in terms of accuracy, miniaturization, speed, efficiency and embedding advanced functionality within PCB assembly designs.

Leading Shenzhen PCB Assembly Manufacturers

Shenzhen is home to numerous leading PCB assembly companies recognized for quality, capacity and advanced capabilities. Some of the most reputable names include:

- FastPrint: Established in 2001, FastPrint provides one-stop prototype, low-to-mid volume and mass production PCB assembly services. They are known for HDI capabilities and certifications meeting automotive grade requirements.

- RayMing: Founded in 2005, RayMing specializes in small-batch, sample-sized and prototype boards. They focus on superior quality through optimized operational controls and inspection.

- RedBoard: RedBoard provides affordable, high mix, low volume PCB assembly services since 2011. They are Shenzhen’s leading specialist supporting startups with agile small batch assembly runs.

- FS Technology: Established in 2004, FS Technology offers complete PCB manufacturing and assembly services. With facilities in Shenzhen and Huizhou, they handle everything from prototypes to large volume production, relying on state-of-the-art equipment.

- JHYPCB: Established in 2011, JHYPCB offers one-stop PCB manufacturing and assembly tailored for prototyping, on-demand production and electronics OEMs. We meet the emerging needs of Industry 4.0 with cutting-edge technical capabilities.

The ecosystem of manufacturing excellence spanning leaders like above continually catalyzes Shenzhen’s dominance as a global electronics hub. Their presence and growth trajectory validate Shenzhen as the premiere location for advanced PCB assemblies.

Why Shenzhen Leads in Advanced PCB Technologies

Shenzhen PCB assembly manufacturers are uniquely positioned to offer the most sophisticated, high technology printed circuit board assemblies globally. Three key advantages enable this – rapid adoption of advanced equipment, proximity to cutting-edge research, and startups constantly stretching the limits of innovation.

For example, Shenzhen PCB assembly companies were among the earliest worldwide to invest in and deploy advanced mount and placement machinery like high-speed chip shooters. They rapidly upgrade equipment calibrated for latest component packages. This translates into capability to reliably assemble evolving semiconductors, sensors, controllers etc. with the smallest footprints and pitches.

Academic and corporate R&D ecosystems in Shenzhen also foster constant innovation. Local universities actively focus on electronics research tie-ups. Large PCB assembly manufacturers run extensive research arms alongside production to improve techniques. Hundreds of smaller startups also experiment with pushing assembly technologies into unconventional territories.

These startups tap into the rich supply chains and manufacturing networks in Shenzhen to rapidly prototype solutions with cutting-edge PCB assembly at the core. Flexible circuits, embedded electronics, 3D packaging integration and other HDI advances often arise from such experimental origins in Shenzhen. Eventually, the expertise permeates larger Shenzhen PCB assembly manufactures who productize technologies successfully demonstrated at smaller scales.

The cycle of innovation from academic research, to startup tinkering, to large scale manufacturing expertise, gives Shenzhen unmatched leadership in stretching the boundaries of possible PCB assemblies. For any customer wanting to integrate advanced PCBs at the core of product designs, Shenzhen PCB assembly manufacturers provide the best springboard.

The Intellectual Property Advantage of Shenzhen PCB Assembly

For technology companies across sectors like aerospace, automation, electric vehicles and consumer electronics, protecting intellectual property during manufacturing is paramount. Shenzhen PCB assembly manufacturers recognize this need and provide reliable protection alongside high quality production.

IP protection spans across physical security, restricted access to confidential data and key sources codes, encrypted design data handling measures, and legal safeguards against copyright or patent infringement. Shenzhen PCB assembly providers invest heavily to ensure holistic protection against leaks, theft and unauthorized usage of provided IP.

For instance, leading Shenzhen PCB assembly manufacturing facilities feature extensive physical security protections. These include gated security perimeters, regular patrols, extensive camera surveillance, restricted access keycards or biometrics for entry, and more. Assembly floor staff only handle encrypted design data critical for production while other confidential data remains protected.

Legally binding non-disclosure agreements and IP protection contracts are standard before onboarding new clients. Shenzhen PCB assembly companies take extensive precautions while handling customer data, with encryption, isolated network storage permissions and routine external security audits. Over a decade of producing electronics innovations has streamlined these stringent IP protections as standard in Shenzhen.

In rare cases where disputes have arisen in the past allegations of IP violations by partners, the strict enforcement environment in Shenzhen ensured quick resolutions without interruptions to production quality. Overall, for any organization relying on electronics manufacturing partners to translate cutting-edge designs into high quality products, Shenzhen PCB assembly companies tick all the boxes for IP protection.

Global Connectivity With Shenzhen PCB Assembly Partners

Electronics innovations today emerge from organizations worldwide. For smooth manufacturing collaboration across geographical barriers, Shenzhen PCB assembly providers offer extensive global connectivity support bridging language, logistics and delivery requirements seamlessly.

Shenzhen manufacturers recognize English as the universal language for global business partnerships. Technical sales staff and customer service teams accordingly maintain English language fluency to interface seamlessly with international customers. Support spans world regions like North America, Europe, and advanced Asian economies where electronics R&D thrives.

The logistics infrastructure available through Shenzhen also optimizes coordinated delivery across continents. Air and sea freight capacity for reliable and cost-optimized shipping grows in line with manufacturing output. This allows meeting tight deadlines for prototype PCB assemblies, all the way to systematic dispatched of large production batches matching deployment needs worldwide.

On the whole, Shenzhen PCB assembly ecosystem offers sophisticated “soft” factors like customer service approach, communication fluency, and logistical support; which perfectly complement the “hard” manufacturing excellence Shenzhen is renowned for. Together they enable truly inclusive partnerships with customers anywhere to translate innovative electronics into deployed products through manufacturing systems calibrated for the 21st century.

With expansive expertise along the full electronics product lifecycle centered in Shenzhen, engaging a local PCB assembly partner provides the ultimate one-stop solution for making ideas reality while retaining control on IP. As ideas and inventions to advance modern life continue arising worldwide, Shenzhen PCB assembly manufacturers offer the ideal manufacturing handhold independent of geography.

Conclusion

Shenzhen has cemented itself as the epicenter for world-class PCB assembly manufacturing. The concentration of strategic advantages spanning infrastructure, engineering talent, research ecosystems, stable government backing, and entrepreneurial drive make Shenzhen home to the most future-ready PCB assembly solutions.

Whether the needs call for an initial prototype build or large volume manufacturing, Shenzhen PCB assembly partners like JHYPCB offer core competencies at globally competitive capabilities and costing. Especially for highly dense electronics or products requiring customization at scale, Shenzhen PCB assembly providers like JHYPCB bridge the gap from design inception to high-quality finished goods seamlessly.

JHYPCB itself offers complete PCB assembly services covering SMT, through hole, mixed, turnkey or complex assembly techniques. With over a decades of experience as Shenzhen PCB assembly experts catering to diverse customer profiles, JHYPCB is ready to deliver manufacturing excellence for your next electronics product.

Contact JHYPCB today to learn how our Shenzhen PCB assembly manufacturing teams can provide optimized support translating innovative product designs into reality through versatile PCB assemblies produced reliably at scale. JHYPCB eagerly awaits helping ideate, prototype and mass produce the electronics backbone powering cutting-edge innovations worldwide.