The demand for PCBs in consumer electronics, communications devices, automotive systems, and other high-tech industries continues to rise. This has led many original equipment manufacturers (OEMs) to outsource PCB assembly to contract manufacturers that specialize in SMT and through-hole assembly. Choosing the right PCB assembly contract manufacturer can improve quality, reduce cost, and speed up time-to-market.

As a PCB assembly contract manufacturer based in China, JHYPCB provides services catering to low, medium, and high-volume production needs. With in-depth expertise in SMT, THT, and mixed PCB assembly, we manufacture prototypes, small batches, and mass production orders while meeting quality standards and reliability requirements.

Whether you need quick-turn prototyping and small batch PCB assembly or a stable, high-volume SMT and THT manufacturing partner, understanding the capabilities and process controls of China’s PCB assembly contract manufacturers is key. This article outlines critical factors when selecting the optimal contract manufacturer for your PCB assembly manufacturing needs in terms of production scale, quality, and cost.

Table of Contents

Key Capabilities of a PCB Assembly Contract Manufacturer

As you evaluate potential partners for outsourcing your PCB assembly manufacturing needs in China, examining their core competencies should rank high on your priority list. Below we outline several key capabilities that leading SMT and THT assembly contract manufacturers generally possess or can customize to fulfill customer requirements.

- Types of Assembly Offered

Many PCB contract manufacturers offer a range of assembly processes, including:

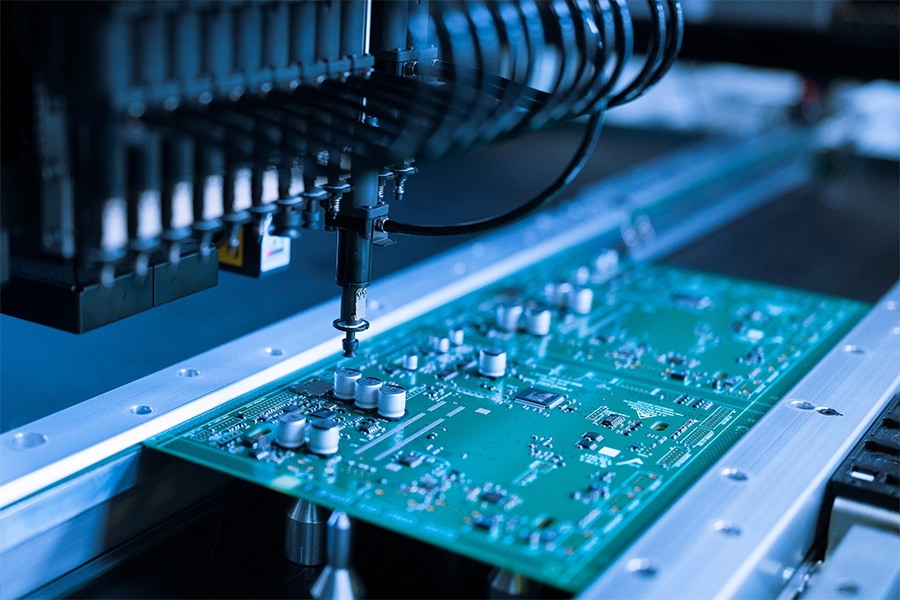

– Surface mount technology utilizing automated pick-and-place for high-volume production efficiency

– Through-hole technology which remains essential for many electronics needing leaded components or plugs/connectors

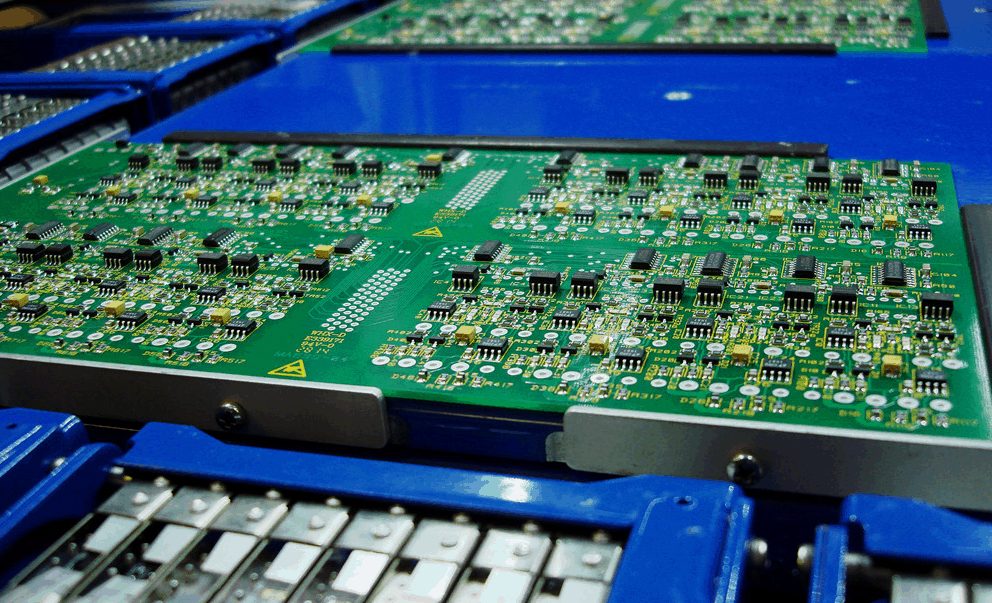

– Mixed assembly combining SMT assembly and THT processes when required

Understanding all assembly options available can help determine if a provider properly aligns with your project specifications. - Expertise with Advanced PCB Technologies

Inquiring about expertise with the latest flexible, rigid-flex, and advanced HDI PCB substrates proves worthwhile before selecting a manufacturing partner. Knowhow implementing layered designs, blind and buried vias, microvias, etc. illustrates technical competencies vital for complex assemblies. - Production Volumes Supported

Asking clear questions about operational scale and volumes supported also ranks critically. Some providers only assemble quick-turn prototypes in small batches while others accommodate mid to high-volume production mandates. Defining your forecasted volumes right away helps qualify appropriate matches. - Quality Certifications

Many leading CEMs/EMS companies obtain rigorous quality management certifications like ISO 9001, ISO 13485, or AS9100D demonstrating standardized processes, quality frameworks, and continuous improvement. Reviewing current certifications proves informative. - Specialized Testing and Inspection

Understanding available testing and inspection methods before and after assembly adds insight into overall capabilities targeting reliability and performance. Asking questions about functional testing, AOI, x-ray inspection, etc. helps qualify manufacturers. - Supply Chain Management

Vetting procedures around supply chain management and component sourcing helps reveal the working dynamics between the contract manufacturer and customers regarding BOM/material procurement. Defining who sources components and the process flexibility options based on procurement needs and inventory demands proves prudent.

Choosing the Optimal PCB Assembly Process

While evaluating the capabilities of a PCB assembly contract manufacturer, simultaneously assessing if their assembly processes align with your program requirements proves equally crucial. Key factors to examine in this regard include:

- Prototype vs. Production Assembly

The assembly process for low-volume PCB prototyping varies substantially from higher volume production. Asking clear questions upfront about the provider’s prototyping abilities, including their rapid iteration processes, small batch size capacities, flexible component sourcing networks geared for prototypes, and expedited testing and inspection cycles helps determine fit. Compare capabilities for supporting quick-turn prototypes against steady-state production. - Low vs. High Complexity Assemblies

The complexity spectrum for PCB assemblies spans simpler, low component count designs to highly dense configurations demanding advanced assembly equipment and processes. Confirming the partner’s experience with density levels and component intricacies fitting your roadmap offers prudent insight before commitments. Some specialize only in simpler assemblies while others accommodate very advanced multi-stage processes. - Standard vs. Complex Assemblies

The diversity of assembly equipment, handling and mounting techniques, and reflow processes required likewise sees broad variation depending on end configuration complexity. Providers equipped with capabilities to handle large boards, odd-form factor designs, BGAs, or microBGAs demonstrate clear competence advantages over simpler SMT component focused peers for complex builds involving next-generation component integration.

Factors Impacting PCB Assembly Cost

When researching PCB assembly contract manufacturers, cost rightfully emerges as a key consideration during vetting and budgetary planning. Below we review core variables that influence overall pricing:

- PCB Size and Layer Count

The underlying PCB raw board fabrication and materials costs correlate directly with dimensional size and layer count complexity. Larger boards with higher layer counts demand more materials, processes, and handling throughout assembly, impacting budgets. - Component Types and Sourcing

The types of components specified on the bill of materials, their operational tolerances, packaging types, lead configurations, and sourcing availability also influence pricing. Opting for readily available commodity components sees cost savings versus complex ICs or tight-tolerance specialty parts needing custom procurement. - Production Volume and Assembly Process

Higher per-unit costs apply for low-volume prototype batches compared with longer steady-state production runs leveraging optimized assembly programs. The production volume threshold where the partner transitions pricing merits consideration for total cost modeling. Per-unit pricing also differs based on assembly process (SMT vs THT) and complexity. - Testing Needs

The amount and types of testing performed during assembly and after also bears cost impact, as specialized testing adds incremental expenses. Inspecting PCB functional test coverage options and typical defect analysis testing included in base pricing makes cost forecasting easier.

Ensuring Quality and Reliability

While cost, scale, and delivery timing all weigh as important considerations when selecting a PCB assembly contract manufacturing partner, quality and reliability rank as the foremost priorities for most engineering programs. Below we explore key areas PCB assembly customers should examine when qualifying a provider’s capabilities in this regard:

- Process Controls and Quality Framework

Leading manufacturers implement rigorous quality management systems governing assembly processes. Many leverage automation and AI-powered SPC data analytics to ensure continuous visibility and control over critical process parameters. Understanding what real-time monitoring, anomaly detection, traceability mechanisms, and process control methods apply aids reliability assessments. - Inspection and Testing Capabilities

Likewise, verifying the scope of inspection and testing functionality embedded throughout the production line and after assembly completes sheds light on quality commitment. Confirming ICT, flying probe, AOI, and x-ray test application demonstrates comprehensive quality assurance targeting zero-defect deliverables. - Technical Experience and Expertise

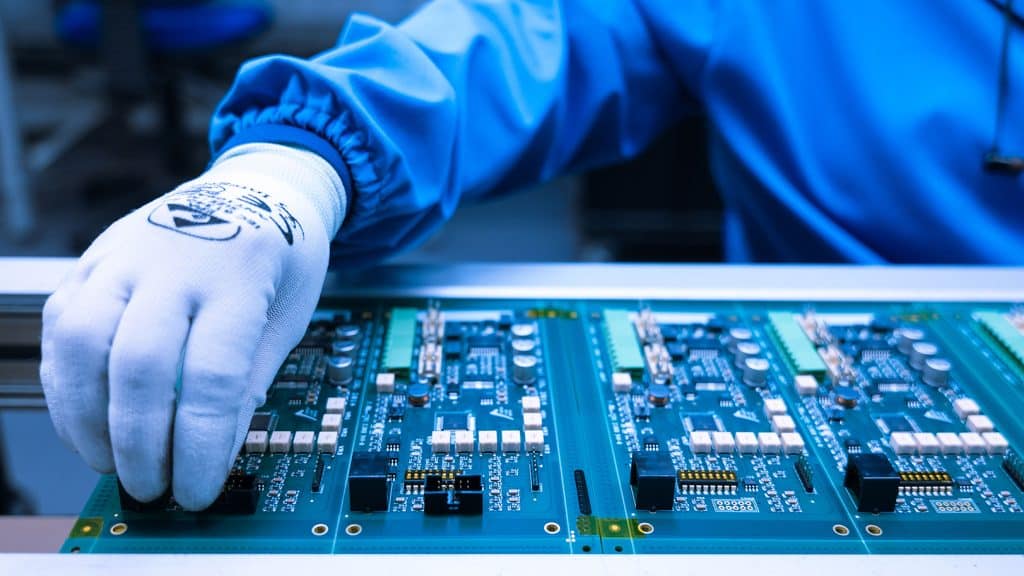

Evaluating the partner’s collective knowledge capital around PCB assembly based on years in operation, staff engineering competencies, and manufacturing best practices adoption further portends ability to deliver complex solutions reliably. Firms actively innovating around technical assembly challenges inspire greater confidence.

Conclusion

Selecting the optimal PCB assembly contract manufacturing partner involves navigating myriad factor from technical capabilities, operational management, quality framework robustness, and costs. Key questions to drive discussions start by qualifying production volume support scenarios based on your near-term prototyping and longer-term production needs. Evaluating the ability to deliver quality assemblies reliably ranks centrally as well.

We hope this guideline offers electronics engineering and sourcing teams increased clarity regarding core considerations when embarking on the PCB assembly make vs buy assessment. Please reach out with any additional questions as you quantify alternatives. Identifying the ideal manufacturing match from among China’s many PCB assembly providers begins aligning critical performance and budgetary objectives.