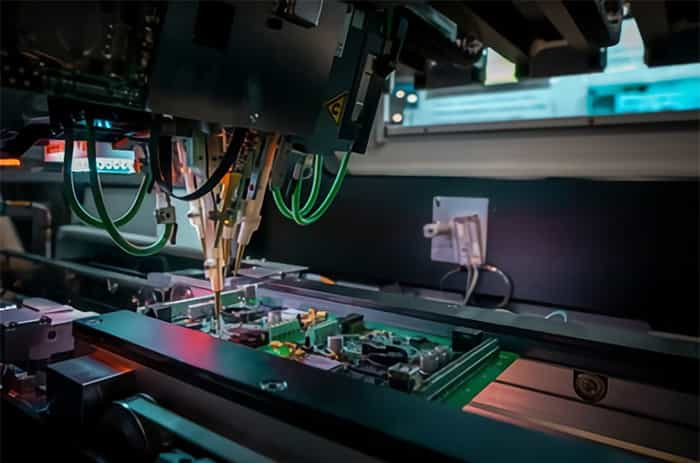

PCB/PCBA manufacturers take care of raw materials, boards, components, and everything else during the manufacturing process. They take special care and dedicate a suitable storage space to prevent any damage and harm.

After manufacturing, they store the final board or assembly with extreme precautions and take all necessary measures to keep them sound during the shipment. They understand the nitty-gritty, and they know how to keep the PCBs and PCBAs safe and intact.

After shipment, PCBs and PCBAs arrive at the destination. From here, the buyer needs to take care of their storage. Typically, these are stored for a certain time and then assembled in the product or anything else.

Buyers usually order a huge lot of PCBs and PCBAs to save money and protect themselves from the shortage of components, boards, and other issues. Therefore, PCBs and PCBAs are stored for a while and used when required.

There are certain things that the buyer needs to consider for the storage of PCBs and PCBAs. If these are not stored in optimal environmental conditions, then the components may fail, the PCB might not work as expected, and there can be several other issues. Thus, it is necessary to store them with proper precautions.

Whether you are a PCB/PCBA manufacturer or buyer, you need to know how to store PCBs and PCBAs and prevent damages and loss of money. We will discuss everything about the storage of PCBs and PCBAs in this article. We will have a look at the importance of precautionary measures, environmental conditions, precautions you need to take, and everything from the start to the end.

Before we go any further, let’s discuss why it is necessary to store PCBs and PCBAs properly.

Table of Contents

What if PCBs are Not Stored Properly?

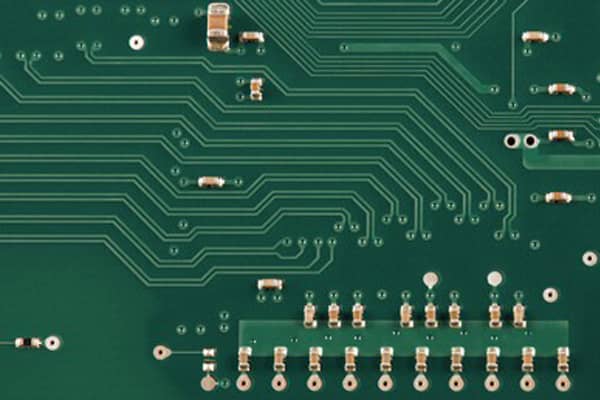

PCBs are quite sensitive to moisture and temperature changes. The copper layer over the board can undergo oxidation if exposed to air; therefore, a suitable surface finish is applied on the board. However, this surface finish is not the perfect solution because surface finishes can undergo oxidation after a certain time, so they need special care. It is important to make sure the PCB is completely safe and there won’t be any unwanted reaction on the surface.

If the surface of the PCB is oxidized, then it will not perform as expected. It cannot go for assembling. You can clean the oxidation layer chemically, and it depends on the surface layer and other factors. But after treatment, the PCB becomes more prone to oxidation. Thus, you need to prevent oxidation in the first place to ensure the optimal performance of the PCB.

It is essential to prevent moisture in the environment because it can damage the surface. Moreover, high-temperature changes are also harmful to PCBs because they can introduce cracks and various issues in the board.

What if PCBAs are Not Stored Properly?

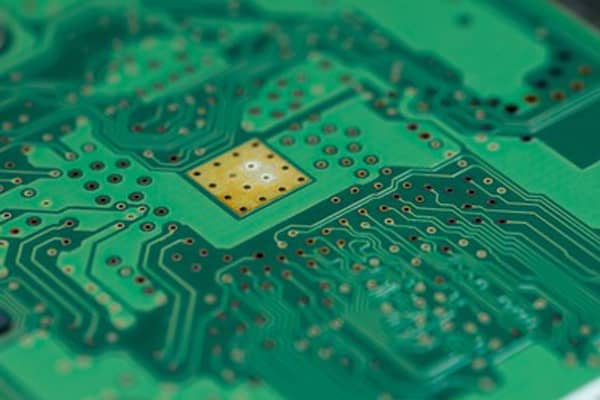

PCB assemblies need special care. They have components on them, so they are more prone to environmental conditions.

The most important problem related to PCB assemblies is Electrostatic Discharge. It can damage the components installed on the PCBA. Each component has its own susceptibility, so the components might stop working or may not offer the expected results.

Moisture is also a big problem in the case of PCBAs. During PCBA manufacturing, SMDs can absorb moisture from the environment. Later, due to a rise in temperature, the moisture expands and damages the PCB. It usually happens in reflow soldering, so manufacturers keep the environment moisture-free. Even after shipment, it is important to keep the moisture away from the board. It can damage the surface finish and badly affect the performance of the components.

High temperatures and instant changes can make cracks in the PCBAs and cause component failure. Therefore, it is essential to store a PCBA properly if you want it to perform as expected and last for a long time.

How to Store PCBs and PCBAs?

PCB/PCBA storage is a complete process. After manufacturing, the PCB goes for packaging. There are a few things that must be kept in mind. Let’s have a look at the environmental control and how PCBs/PCBAs are packed.

- Control Humidity

The first thing that you need to control is the humidity. Wherever you are storing your PCBs, you need to make sure the humidity is in control. The relative humidity of the warehouse or storage area should be less than 65-75%. Otherwise, it can affect the PCB or PCBA.

- Control Temperature

Temperature is the next important thing that must be in control. It is recommended that the temperature should be 23-25ᵒ. It is needed to maintain the temperature; high fluctuations may damage the board.

- Handling

You cannot handle PCBs and PCBAs with bare hands. It will leave sweat, oil, and marks on the board, and these can lead to various issues. The worker that is storing the PCBs must wear gloves to avoid contact with the board.

It is essential to handle the board with care; therefore, the worker needs to hold the board from the edges and carefully put it in the packaging. The board should not be rubbed against any object, and every type of mechanical damage should be avoided.

If the board is handled carelessly, there can be scratches, dust, and other particles.

- Use Suitable Packaging

For storing PCBs and PCBAs, suitable packaging is necessary. It prevents damage to the board due to moisture, electrostatic charge, and vibration. For PCBs, a vacuum package is necessary, and an anti-static vacuum packaging is used. It protects the PCBA from electrostatic discharge and provides a vacuum area to prevent moisture.

Inside the packaging, Humidity Indicator Cards (HIDs) are used. These cards indicated the humidity level inside the package. There are several circles on the card, and they indicate the value of humidity. The initial color of the circle is blue, and it turns pink when the humidity reaches that level. It gives a complete idea of the humidity inside the package, and the PCB can be baked if needed.

There are limited PCBs in every packaging, and the limit is decided on the thickness and size of the PCB. After packaging, these packages are placed in a carton along with quality certificates. The box is then sealed using packing tape.

Precautions Before Unpacking/Using PCBs

You cannot use the PCB directly when you receive it. There are certain precautions that are necessary to avoid any loss.

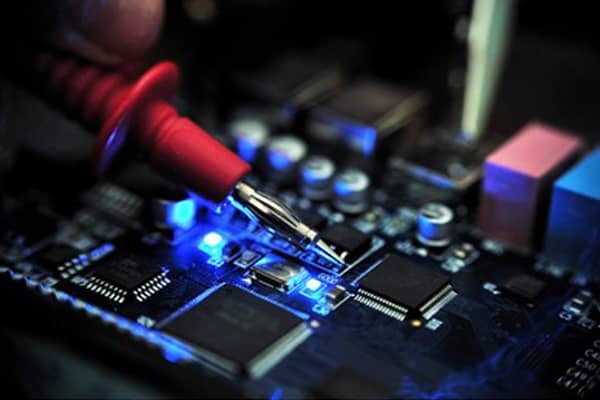

- Examination

First, you need to examine the packing. Look at it carefully and make sure it is intact. The package might get damaged during the shipment. Next, you need to look at the PCB and see any signs of oxidation, blistering, and scratches. Then, check the humidity card and see the level of humidity.

Another important thing is the date of packaging. It is usually mentioned on the package; otherwise, check the barcode. The valid storage period is only one year. After that, the valid storage period after passing the over-storage period inspection is six months. If a PCB is stored for more than two years, it is directly scrapped.

The storage of the PCB also depends on the type of PCB, its packaging, and inspection.

| PCB Type | Packaging Method | Storage Time Without Re-inspection | Maximum Storage Time |

| Heavy Copper PCB | Moisture-proof packaging | 12 months | 12 months |

| Heavy Copper PCB | Ordinary packaging | 3 months | 9 months |

| Multilayer PCB | Moisture-proof packaging | 12 months | 12 months |

| Aluminum PCB | Ordinary packaging | 6 months | 12 months |

| OSP PCB | Ordinary packaging | 3 months | 9 months |

- Drying

If there was an issue with the PCB packaging, such as damaged packaging or holes, the PCB must be dried before using it.

- Baking

If the PCB has passed the storage period inspection or the humidity level is high, baking is necessary. Manufacturers usually recommend the humidity level at which baking is required. The board is placed inside an oven for several hours at different temperature ranges. After baking, the PCB is ready to be used when cooled down to the temperature of the environment.

Temperature Range(℃) | Minimum Time (h) | Average Time (h) | Maximum Time (h) | Equipment |

105-120 | 1.5 | 2 | 4 | Convection oven |

70-80 | 3 | 6 | 16 | Convection oven |

50-55 | 1 | 2 | 3 | Vacuum oven/1torr |

PCBA Packaging and Transportation

- Cleaning and Drying

The PCBA needs to be cleaned and dried before packaging. There can be dust and other particles, and especially moisture on it. Thus, it must be cleaned and dried.

- Three-proof Paint

Three-proof paint is beneficial for PCBAs. Before storage, it is applied over the PCBA to ensure protection from dust, moisture, and oxidation. It protects the components and board and increases the shelf life. The three-proof paint is applied using a sprayer. After that, the PCBA is ready to be packed.

- Anti-static Packaging

We know the electrostatic discharge and how it can affect the PCBA. The components are prone to ESD damage, and they have a susceptibility for electrostatic charges. It is quite essential to keep the electrostatic materials away from the PCBA and use anti-static packaging to keep PCBA safe.

- Anti-vibration Packaging

During transportation, the PCBAs absorb vibrations. These can damage the PCBA. The packages are placed properly inside a carton for safety, and spacers are used between the packages. It keeps the PCBAs stable and prevents shaking.