Table of Contents

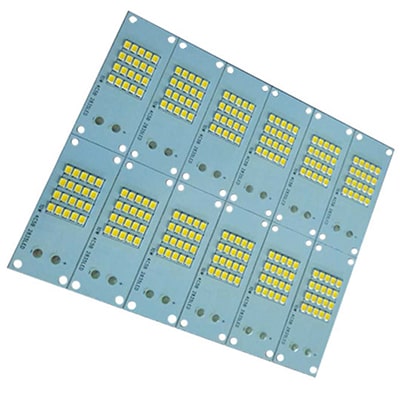

Metal Core PCBs are widely used, primarily because of their higher thermal conductivity. They can dissipate heat during operation, even if there are high-power dissipating components. FR4 and other non-metallic substrates cannot work for a long time in high heat production or high temperatures. They have a short life span; therefore, they are not preferred for applications with a substantial amount of heat generation, such as LEDs. A metal core PCB is eight times better than FR4 in heat dissipation. These PCBs use metal as the base material, which can easily transfer heat. The metal transfers the heat quickly and more efficiently. The components remain cool; therefore, they work for a long time without creating any fire hazard.

If you want a metal core PCB for your project, you need to understand a few things. Before ordering a metal core PCB, you need to know about different materials, their prototype, the manufacturing process, and the manufacturer. You need to select the correct manufacturer that can provide metal core PCBs according to your requirements. Read this article to understand everything about metal core PCBs.

Why Choosing the Right Manufacturer is Critical?

The most critical step is choosing the proper manufacturer. Every manufacturer has a limited capability of manufacturing PCBs. The manufacturer should be able to provide what you need. There are a limited number of layers, thickness ranges, types of materials, Tg range, conductivity ranges, etc. So, you need to know whether the manufacturer can fulfill your requirements or not. Once you know that the manufacturer can provide whatever you need, you can order a PCB prototype.

Metal Core PCB Prototype

The metal core PCB prototype is significant before ordering in bulk. You need to evaluate your design and make sure that the prototype is perfect before moving to bulk production. This allows you to make amendments to the design. If there is any problem with the PCB prototype, you can easily modify and order a new one. You can save time and money. You can request a PCB prototype according to your needs.

Before you order a metal core PCB prototype, make sure that you know everything about metal core PCBs and your needs. You can communicate with the manufacturer to know about the software. You need to discuss layers, board thickness, base material, copper weight, surface finish, and other essential aspects.

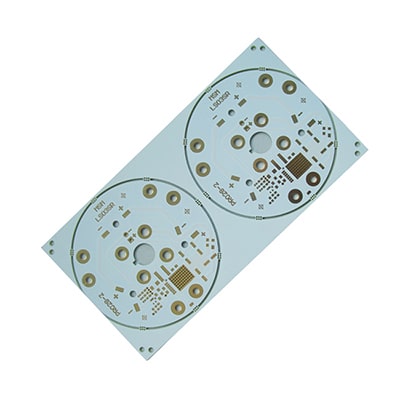

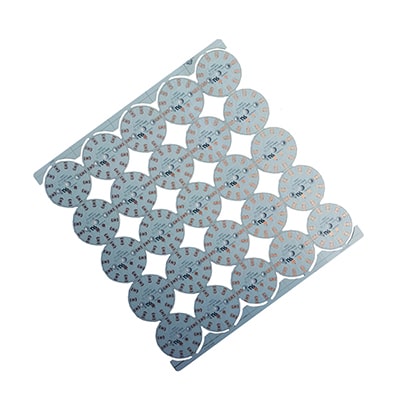

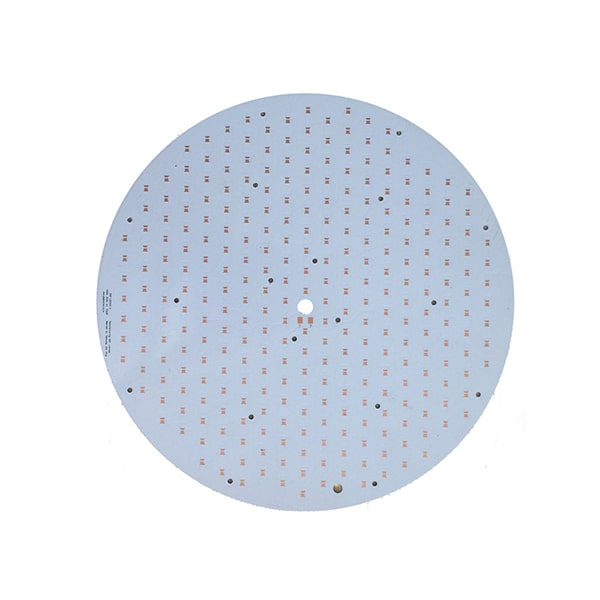

The solder mask of metalcore PCBs is usually white. Standard PCBs usually have many solder masks, but metal core PCBs mostly have a white solder mask. Metal core PCBs typically have a thickness in the range of 30-130 mil. They can be single-sided, double-sided, and multi-layered. You need to develop the required schematic design and your requirements to get a metal core PCB prototype.

Metal Core PCB Material

Metal core PCBs use metal as the base material, which can even work in high temperatures. These PCBs are made from Aluminium, copper, or a mixture of alloys. Usually, Aluminum and Copper are used as the metal core PCB material. These are the most common base materials widely used for LEDs, communication equipment, converters, power supplies, and other high-power dissipating circuits.

Keep in mind that materials have different glass transition temperatures. There can be different values of Tg, even in the same material. So, you need to select the correct type of material according to your project. You can discuss this with the PCB manufacturer.

Metal Core PCB Manufacturing Process

The process of making a metal core PCB is similar to other boards. The only difference is the material. So, the process is almost identical. Once you provide the Gerber files and all the information, the manufacturing is done according to that. There are several steps involved in the metal core PCB manufacturing process. Let’s see the essential steps to understand the process.

Drilling

After cutting the board in the required sizes, they are sent for drilling. Drilling is necessary so that the components can be connected. Drilling is also done via hole. It is done by automated machines that make the required holes. After drilling, the board is cleaned to remove the dust and particles.

Electroplating

Electroplating is done to connect the layers and make a conductive path between them. The via hole completes the path between the layers after electroplating.

Copper Plating

Copper plating is done to provide excellent conductivity. The buyer chooses the thickness of the plate. After copper plating, the photoresist is hot rolled onto the copper.

Creating and Printing of the Film

An image of the PCB, also known as ‘film,’ is required to make the PCB. A plotter printer is used for this purpose. The film is a photo negative. The negative has the exact design of the PCB with its conducting and non-conducting lines. This film is used for printing the schematic on the PCB. Once the image is printed on the PCB, there will be covered conducting lines. There conducting lines will be in black. They are hidden to keep the copper safe and sound during etching.

Removal of Excess Copper (Etching)

You only need copper in the conducting lines, so the excess copper should be removed to make the other parts non-conductive. For this purpose, different chemicals (alkaline solutions) are used to remove the excess copper. This process takes time, which depends on the amount of copper used in the PCB.

Inspection

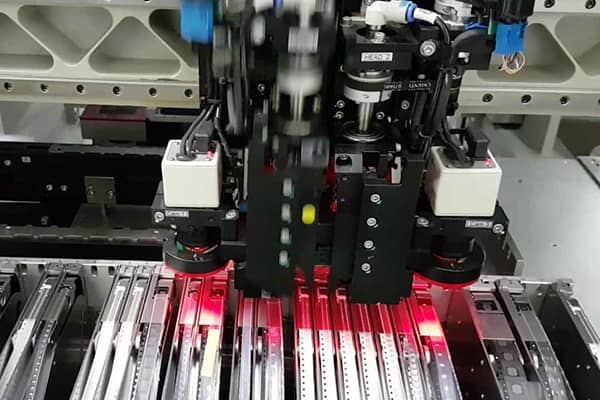

Inspection is done through automatic machines. These machines check everything in the PCB and compare it with the given file. They check for any faults.

Solder Mask and Silkscreen

A solder mask is applied to the PCB board. We know that it is usually white in the case of metal core PCBs. It is responsible for providing insulation between the conducting paths. After completing the process of the solder mask, the required color of the silkscreen is applied.

The copper on the PCB can undergo oxidation with time. Therefore, the surface finish is necessary. There are different types of surface finish, such as HASL, Immersion Gold, and OSP. You can choose anyone according to your requirements.

A flying probe tester usually does the testing. After that, experts also tested the PCB to make sure everything is according to the requirements. Now the metal core PCB manufacturing process is complete, and the PCB is ready for packing.

Metal Core PCB Price

The price of the metal core PCB depends on many aspects, such as the number of layers, size, components, quantity, and other things. Therefore, you need to ask for a quote from the manufacturer. At JHYPCB, we provide instant quotes that can be delivered within 2-24 hours. You need to provide the required information to get an accurate quote.

- Complete GERBER files

- Additional information

- Quantity

- Delivery time

- Materials requirements

- Finish requirements

Keep in mind that any change in the information can change the quote.

Metal Core PCB at JHYPCB

JHYPCB proudly provides all kinds of PCB services, including metal core PCBs, aluminum PCBs, LED PCBs, etc. We can make your metal core PCB prototype board with the minimum order of one board. We can also manufacture metal-core PCBs in bulk. You can get all kinds of PCBs at a meager cost. You can contact us for a metal core PCB price/quotation, and our team will get back to you within 24 hours. We have strict quality control, and we’re compliant with ISO 9001:2008. Our metal core PCB manufacturing process is according to international standards. Thus, we can provide you with high-quality PCBs with the on-time shipment. We also offer 24-hour online customer service. For more information, feel free to contact us.

Advanced Learning: