Quick Turn PCB Fabrication and Assembly Services in China

Quick Turn PCB China

Home » PCB Manufacturing » Quick Turn PCB Fabrication and Assembly

In today’s world, time is a crucial component. The adage “time is money” is accurate. This definition is important for having a versatile PCB with a fast turnaround time. We can see why customers will need quick-turn PCB fabrication in this situation.

Since time is such a valuable resource these days, most practices adhere to a strict guideline of conserving it. PCB fabrication and assembly is no exception, necessitating the use of fast-turn PCBs.

The customer receives their printed circuit board on time thanks to the quick turn PCB fabrication process. It means that the manufacturer completes the entire process of creating a PCB in a short amount of time.

There are many explanations why a customer will value a fast turn PCB. In brief, below are a few of these reasons:

- Delays are reduced

Fast PCB fabrication saves the PCB shoppers a significant amount of time that would otherwise be spent waiting for the printed circuit board. - Significant reduction in the time it takes to make a product

PCB fabrication steps can be a lengthy process that takes time, but thanks to quick turn PCB fabrication, the time is cut in half, allowing for quicker delivery to the consumer.

Quick Turn PCB Prototype Fabrication

As you may already know about prototype PCB fabrication, it entails developing a PCB based on a previously used pattern on a previous version. It is a procedure that is mostly carried out for inspection to make any defects or corrections as soon as possible.

The use of PCB prototypes aids manufacturers in detecting potential defects on the initial PCB to fix them early. It also allows the manufacturer to enhance the PCB’s performance and efficiency by adding more features. Changes are normally difficult to make after final manufacturing, so prototypes are so important to the manufacturer.

Quick turn PCB prototypes focus on assembling printed circuit boards just before final fabrication, with a tight deadline. As a result, the whole procedure is based on the time frame that has been set. Manufacturers provide these services to any PCB shoppers who want a fast turnaround on their PCB.

Before opting for a fast-turn PCB prototype service, the PCB shoppers should have some prior specifications for the intended PCB to ensure that the specs fit the provider’s services.

Advance Learning

Fig.1 Quick Turn PCB Manufacturing Factory

Quick-turn PCBs offer several advantages. The following are a few of these benefits:

- Reduces manufacturing costs

Using quick-turn PCBs eliminates the possibility of errors and mistakes on the initial PCB. - It saves time for the consumer

The PCB buyers will verify the PCB features via its quick-turn prototype by testing the design early enough. It allows the manufacturer to save time that would have otherwise been spent improving after the PCB has been produced. - Allows the maker to make early modifications

Since time is a valuable resource, and manufacturers constantly search for ways to cut costs and maximize profits, quick turn PCB prototypes are critical. These prototypes enable the manufacturer to get early feedback from customers and make any necessary improvements before manufacturing or fabrication.

Quick Turn PCB Assembly

You can get your PCB installed in as little as 24 hours. Time is of the essence for PCB shoppers, which is why a quick turn PCB assembly is essential. The PCB specification would also need to be fastened for the assembly phase to be completed quickly. There are many forms of assembly available:

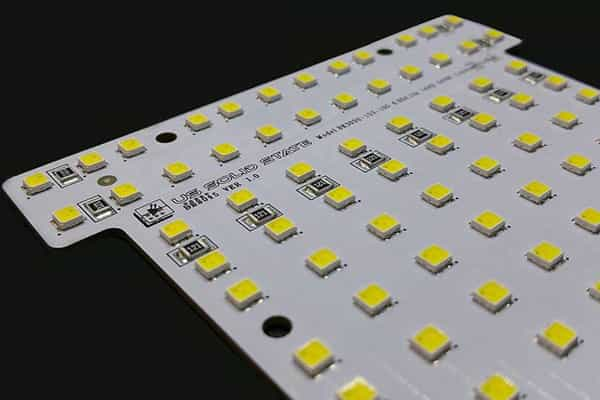

- Surface mount, or SMT Technology: Here, the electrical components are mounted onto a PCB’s surface. Learn More About Our SMT PCB Assembly Service.

- Thru-hole: It involves using leads on the components inserted into holes drilled on PCB and soldered on the opposite side by manual assembly or by using automated insertion mount machines. Learn More About Through-Hole PCB Assembly Service.

- Mixed technology: The combination of both the surface mount and thru-hole

- Single or double-sided placement: Here, the fast turn PCB board manufacturer can either place the PCB components on one side or both, counting on the customer’s needs

Quick Turn PCB Prototypes Manufacturing and Assembly Services

Fast turn Bill of Materials (BOM) of a PCB get fitted onto a board. PCB assembly can take anywhere from 24 hours to 5 days at the most. The turnaround time with JHYPCB is amazing. You will not only get good value for your money, but you will also get it in a short amount of time.

At JHYPCB, different solder types are used during the PCB assembly process. Fluxes may be leaded, lead-free, or water-free. Because of the atmosphere, non-leaded variants are normally favored over leaded ones.

Following the PCB assembly process, the PCB is carefully tested to ensure that it is functional and free of errors. Rework is done if there are any mistakes or pollution. Rework, on the other hand, is discouraged due to its inefficiency.

It results in significant losses and time waste, all of which are valuable resources. To avoid rework, manufacturers use prototypes to ensure that the initial PCB is up and running, avoiding any potential issues that might arise later in the PCB’s use.

Quick Turn PCB Fabrication

Fast PCB fabrication is quick and easy for PCB buyers, with a turnaround time of about 24 hours. Most consumers would prefer to outsource their PCBs to professional suppliers rather than doing so in-house, saving money on production and avoiding many hassles that come with it.

As a result, manufacturers need to keep up with consumer demand. It has necessitated PCB fabrication and manufacturing with a short turnaround time. Quick turn is almost always a must when it comes to PCB fabrication. After all, a quick go-to-market is a significant competitive advantage. This is precisely why, at JHYPCB, we put such a high value on timely board deliveries while adhering to all quality management procedures and certifications.

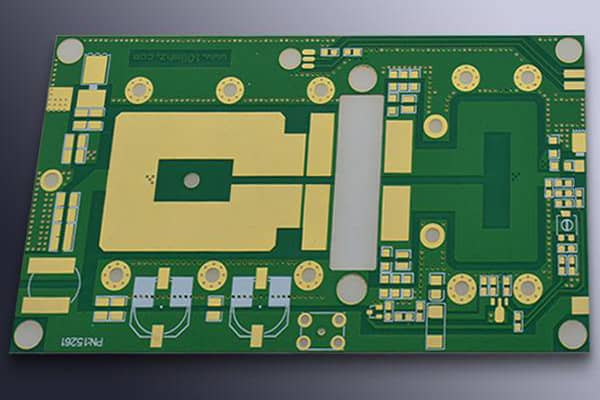

We provide quick turn PCB fabrication, quick turn multilayer PCB fabrication, quick turn rigid PCB fabrication, quick turn rigid-flex PCB fabrication, and more!

You can be assured that the standard has been authenticated when hitting the deadlines, thanks to our stringent monitoring procedures and rigorous inspection systems. We ensure that the quick turn PCB fabrication and assembly process is smooth, regardless of whether the requirement is plain or multi-layered boards.

Benefits of Quick Turn PCB Fabrication

The most significant advantage of a short processing period is that you can get to the market without delay. As a result, you’ll have a significant competitive edge, particularly if you’re in a highly competitive market.

We make sure that a lack of PCB boards doesn’t hamper the go-to-market strategy. You will go about your new introduction and campaign strategy smoothly if you have high-quality boards in place on schedule.

Applications of Quick Turn PCB Fabrication

PCB Prototypes

Quick turn PCBs are especially important for prototypes, as they provide a fast and precise indication of how the final product will work. Fast processing times are useful for assessing product effectiveness before engaging in a major production run. The idea that any improvements or tweaking will be made ahead of schedule is a bonus.

Standard Production Run

When it comes to big manufacturing lines, the most important factor to consider is delivery time. Fast turn PCBs eliminate delays, allowing device makers to meet their end-users as soon as possible. Additionally, using regular SOPs to reduce production times will result in cost optimization, a major competitive advantage.

JHYPCB: Quick Turn PCB Fabrication and Assembly Services in China

There are several reasons why JHYPCB should be your chosen partner when you need quick-turn PCBs. First and foremost, you have access to a vast body of industry expertise thanks to years of experience in fast PCB fabrication and quick turn printed circuit board manufacturing. This implies that you won’t have to invent the wheel.

Our specialist fast turn PCB producers and cutting-edge equipment ensure that you receive high-quality goods in the shortest time possible. Our customer-centric attitude ensures that you can never be left hanging, whether for personalized quotes or final product distribution.