At present, the demand for high-TG PCB circuit boards in various industries is getting higher and higher, which requires PCB substrate materials with higher heat resistance. The emergence and development of high-density mounting technologies represented by SMT and CMT have made PCBs small aperture, OK wiring, and thinning. It is increasingly inseparable from the support of the high heat resistance of the substrate.

High Tg PCB is the right choice for electronic equipment under a high-temperature environment, which can make electronic equipment play its performance better under a high-temperature environment. High Tg PCBs are also used in other top-temperature products.

We use TG150 and TG170 plates in PCB proofing manufacturing. A common question arises, “What are the advantages of these two plates as compared to TG130?” We will answer this question, but first of all, we must discuss the science behind it. We need to understand what TG is to answer the question.

What is TG?

TG refers to the glass transition temperature of the sheet material. At this temperature, the material alters its state or shape. It is usually a very high temperature. As we all know, the circuit board is generally flame-resistant; therefore, it cannot burn at a specific temperature. But it softens at a certain temperature. The temperature point at which the glass softens is called transition temperature (Tg point). This value is related to the dimensional stability of the PCB board. The higher the TG value, the better will be the temperature resistance of the sheet. Especially in the lead-free tin-spraying process, high Tg applications are more common.

What is FR4 High Tg PCB Materials

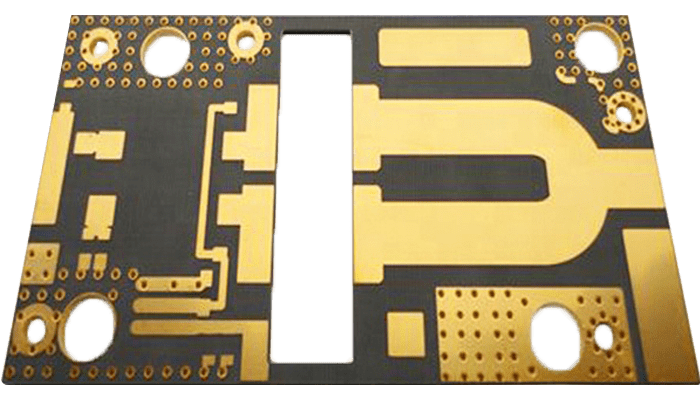

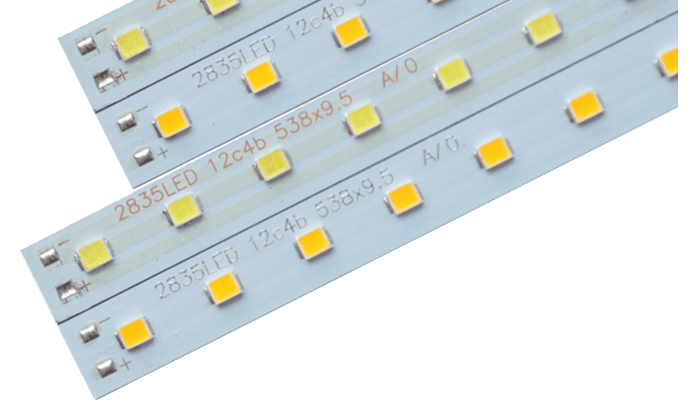

The general TG sheet is above 130 degrees, the high TG is generally greater than 170 degrees, and the medium TG is approximately greater than 150 degrees. High-TG plates are primarily used in multilayer-layer printed circuit boards (>10 layers), automobiles, packaging materials, embedded substrates, industrial control precision instruments, routers, and other fields. If the Tg of the board is increased, the heat resistance, moisture resistance, chemical resistance, stability, and other characteristics of the printed circuit board will be increased and improved accordingly.

More adventures:

Ordinary FR-4 vs. High-TG FR-4

The difference between ordinary FR-4 and high-TG FR-4 is that there are differences in the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition in the thermal state hygroscopic, thermal expansion and other conditions of the material. High Tg products are better than ordinary PCB substrate materials.

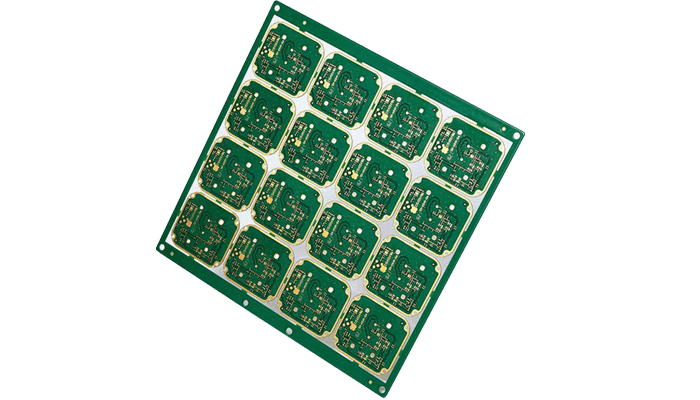

Advanced High TG PCB Circuit Boards Manufacturer in China

JHYPCB is a professional PCB manufacturer. We have sufficient raw material inventory for high-temperature PCB to deliver on time.

Hence, the performance of TG170 and TG150 must be relatively better than TG130. To provide better PCB prototyping services and meet the needs of the market in various aspects, JHYPCB provides high-quality FR-4 TG150 and TG170 plates to meet customers’ diverse PCB prototype needs. JHYPCB, a different prototype PCB Fabrication factory and supplier, specializes in unconventional boards, precision boards, special boards that others do not want to do or refuse to do. We try to meet customers’ needs in PCB proofing.

The Processing Capability of High TG Circuit Board

Layer: 1-30

Maximum machining area: 640mm*1100mm

Copper thickness: 0.5 OZ – 13 OZ

Plate thickness:

Double layer: 0.2mm–6.0mm

4 layers: 0.4mm-8.0mm

6 layers: 0.8mm-8.0mm

8 layers: 1.0mm-8.0mm

10 layers: 1.2mm-8.0mm

12 layers: 1.5mm-8.0mm

14 layers: 1.5mm-8.0mm

16 layers: 1.6mm-8.0mm

18 layers: 2.2mm-8.0mm

20 layers: 2.4mm-8.0mm

Minimum line width/spacing: 3mil /3mil

Minimum aperture of the finished product: 0.15mm

Maximum machined thick-diameter ratio: 12:1

Impedance control: +/-10%

Surface treatment: spray lead-tin, spray pure tin, Immersion gold, Immersion tin, Immersion silver,

Commonly used sheet: FR4 Tg130 / Tg170 ℃, Rogers, Arlon, Taconic, Bergquist

Special technology: buried blind hole, plate hole, plate side metallization, half-hole, metal base (core) plate.

Advanced Learning: