Table of Contents

Introduction to RoHS Standards

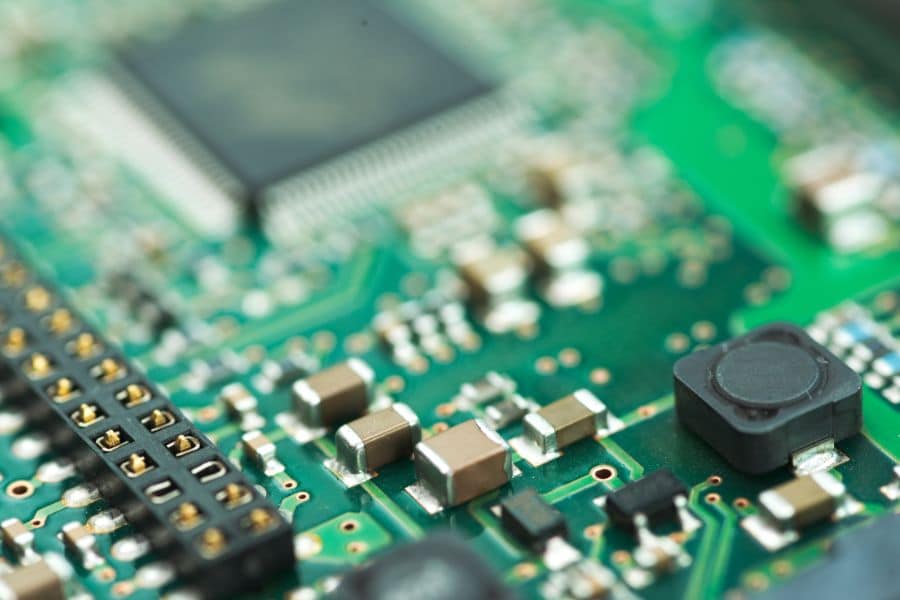

With the increasing awareness of environmental protection in the electronics industry, the RoHS (Restriction of Hazardous Substances) directive plays a vital role. RoHS restricts the use of certain hazardous materials in the manufacture of electronic and electrical equipment. This chapter will provide an overview of the RoHS standards and what they mean for printed circuit boards.

The RoHS directive was originally adopted by the European Union in 2002. The intention is to reduce the environmental and health impacts of electronics by limiting certain substances. Over the years, the restrictions and scope have evolved through recasts and clarifications. Currently, RoHS regulations apply to 10 substance categories. The 6 original restricted materials are:

- Lead (Pb)

- Mercury (Hg)

- Cadmium (Cd)

- Hexavalent chromium (Cr6+)

- Polybrominated biphenyls (PBB)

- Polybrominated diphenyl ether (PBDE)

For PCB design, fabrication and assembly, meeting RoHS compliance requirements is mandatory to access many markets. By restricting hazardous substances from PCB manufacturing and assembly processes, RoHS promotes more environmentally responsible electronics production globally.

Benefits of RoHS Compliance

Complying with RoHS restricted substance regulations for PCB manufacturing brings important benefits for both human health and the environment. Understanding these advantages will motivate more electronics producers to adopt RoHS compliant processes globally.

Reducing Harmful Substances

RoHS helps minimize the amounts of heavy metals and brominated flame retardants used in PCB fabrication and assembly. These substances have raised health concerns due to toxicity, accumulation in nature, and difficulty breaking down chemically. By limiting concentrations in RoHS compliant PCBs, risks posed to workers and communities can be reduced.

Promoting Environmental Responsibility

Adoption of RoHS guidelines also makes the PCB industry more ecologically responsible. Substitutes have been developed for harmful materials subject to restriction. Companies like JHYPCB use more environmentally friendly practices for engineering, sourcing, production, testing and even waste treatment of RoHS compliant printed circuit boards.

Access to Global Markets

With RoHS compliance now mandatory for selling electronics in large markets like the EU, adhering to maximum thresholds for restricted substances allows access that non-compliant manufacturers miss out on. Partnering with reliable RoHS compliant PCB producers like JHYPCB ensures products meet import requirements.

RoHS Restricted Substances for PCB Materials

Understanding which hazardous substances are covered by RoHS requirements is important for PCB manufacturers and partners. Restrictions apply to maximum concentrations of the following 10 material categories in homogeneous materials of finished RoHS compliant PCBs:

Lead (Pb)

Lead can accumulate in the environment and living things causing health damages. The maximum concentration limit is 0.1% by weight.

Mercury (Hg)

Mercury exposure poses risks to the brain, heart, lungs, immune system and other organs. RoHS restricts mercury to 0.1% maximum.

Cadmium (Cd)

Cadmium is toxic with a half-life of over 20 years in humans. The RoHS limit for cadmium is 0.01% by weight.

Hexavalent Chromium (Cr6+)

Chromium VI compounds can cause cancer via inhalation and skin contact. Concentrations cannot exceed 0.1% for RoHS compliance.

Polybrominated Biphenyls (PBB)

PBBs are brominated flame retardants that persist in the environment and living tissues. The RoHS threshold is 0.1% for these hazardous chemicals.

Polybrominated Diphenyl Ethers (PBDE)

Similar to PBBs, PBDEs bioaccumulate and pose toxicity concerns for liver and thyroid function. RoHS sets the same 0.1% limit.

| RoHS Restricted Materials | |

| Banned Substance | RoHS LIMIT: MCV* PPM |

| Lead (Pb) | 1000 |

| Mercury (Hg) | 1000 |

| Cadmium (Cd) | 100 |

| Hexavalent Chromium (Cr+6) | 1000 |

| Polybrominated Biphenyl (PBB) | 1000 |

| Polybrominated Diphenyl Ether (PBDE) | 1000 |

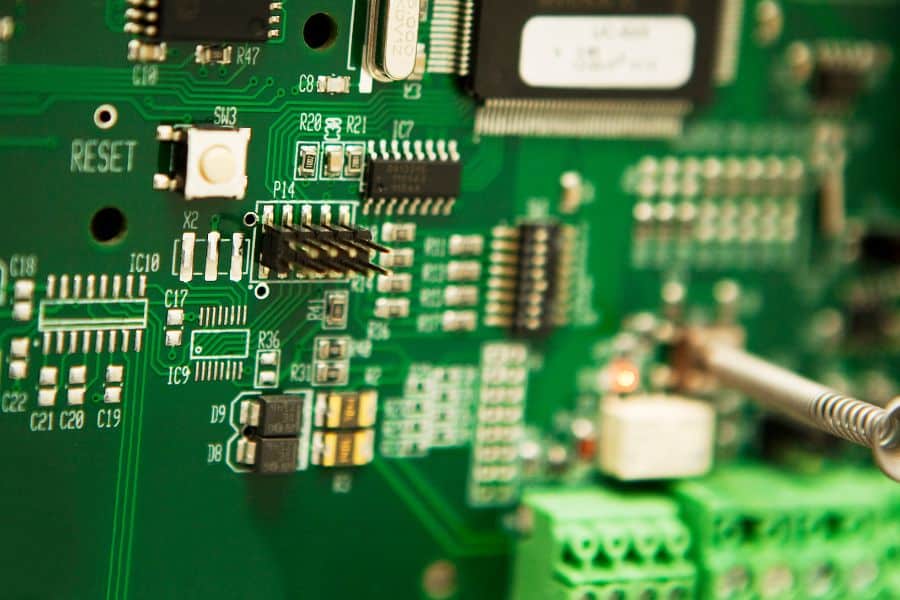

Manufacturing RoHS Compliant PCBs

Manufacturing fully RoHS-compliant printed circuit boards requires specialized materials and environmentally responsible processes that restrict the use of hazardous substances.

RoHS Compliant Raw Materials

We source certified RoHS-compliant base materials from dependable partners for PCB fabrication. Substrates like FR-4 laminates, solder masks, and other components are verified to not exceed the maximum concentration values for restricted substances.

RoHS Compliant Fabrication Processes

Our PCB manufacturing facility utilizes processes specifically designed to be ecologically sustainable by eliminating the use of lead, cadmium, hexavalent chromium and other harmful materials banned under RoHS directives.

Restriction of Hazardous Substances

All equipment and methods used in PCB fabrication are optimized to fully comply with RoHS standards by keeping restricted heavy metals and brominated flame retardants out of the manufacturing process while delivering the same quality and function.

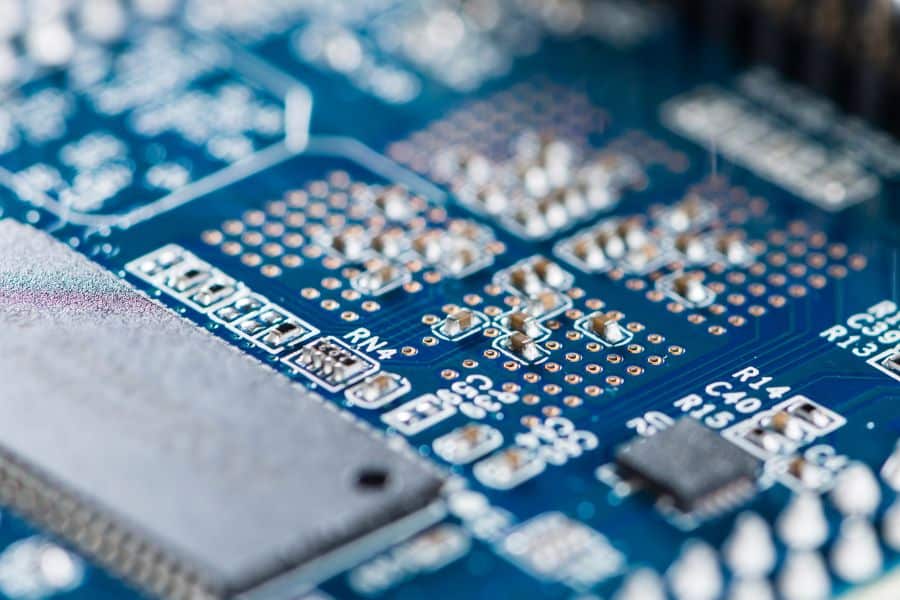

RoHS Compliant PCB Surface Finishes

In addition to restricting hazardous substances from board materials and production processes, choosing an ecologically responsible surface finish is also key for fully RoHS compliant PCBs:

Common Finishes

Immersion silver, immersion tin and organic solderability preservatives (OSP) are frequently used PCB surface finishes that comply with RoHS directives.

Lead-Free and Non-toxic

These non-lead surface finishes do not employ any of the banned toxic heavy metals or flame retardants on PCB surfaces, maintaining board compliance.

JHYPCB utilizes all applicable eco-friendly RoHS compliant PCB finishing processes to deliver boards without comprising performance or reliability.

Some of the finishes available to customers include:

| Surface Finishes | Shelf Life | Co-Planarity |

| ENIG | 12+ Months | Yes |

| Immersion Silver | 6-12 Months | Yes |

| Immersion Tin | 3-6 Months | Yes |

| Lead Free HASL | 12+ Months | Moderate |

| OSP | 6-12 Months | Yes |

Assembling RoHS Compliant PCBs

In addition to RoHS compliant manufacturing, we also provide PCB assembly services that adhere to hazardous substance regulations. This includes using verified components and lead-free solder.

RoHS Compliant Components

All electronic components used in our RoHS compliant PCB assembly operations, like integrated circuits, resistors, capacitors etc. are sourced from trusted partners and verified to meet restricted material limits.

Lead-Free Soldering

Our production lines utilize specialized lead-free solder pastes and wires containing tin, copper, and silver alloys instead of traditional tin-lead solders. This ensures no lead contamination during PCB assembly.

Fluxes Meeting RoHS Requirements

We use RoHS compliant fluxes that are free of heavy metals and brominated materials. Flux residues are also cleaned properly after soldering using eco-friendly processes.

Partnering with JHYPCB for complete PCB assembly ensures your finished boards meet all global RoHS hazardous substance regulations.

Testing and Certifying RoHS Compliant PCBs

Verifying PCBs meet RoHS restricted substance requirements is crucial for manufacturers and customers. At JHYPCB, we utilize rigorous testing and provide detailed RoHS compliance certification reports.

RoHS Testing Methods

Our quality control team extracts base material, solder, paste and component samples from PCB production runs and has them analyzed by accredited testing laboratories using methods like ICP-AES and GC-MS to accurately detect banned substance levels.

RoHS Certification Standards

We assess all test results against maximum concentration standards for the 10 RoHS restricted materials categories. Only PCBs passing and receiving RoHS certification are shipped to customers.

Obtaining RoHS Compliance Reports

Buyers can request full RoHS testing reports from our team to document the PCB compliance certification process. Reports detail test methods, specifics on samples analyzed and final verification that RoHS limits on hazardous substances were met.

Advantages of Using a RoHS Compliant PCB Manufacturer and Assembler

Partnering with leading RoHS compliant PCB manufacturers and assemblers like JHYPCB brings significant benefits for customers focused on hazardous substance restriction:

Environmentally Responsible

Our use of green materials, lead-free processes and waste control ensures your PCB production has minimal ecological footprint. Both manufacturing and assembly are designed for sustainability.

Access to Global Markets

Since our production processes comply with substabce limits and reporting requirements, the PCBs JHYPCB supplies can access import markets like the EU where RoHS guidelines are mandatory.

High-Quality Production

Leveraging decades of electronics engineering expertise and by staying at the forefront of ecological trends for the industry, we deliver exceptional RoHS compliant PCBs without compromising on quality, functionality or durability.

Difference Between WEEE, REACH and RoHS

While aiming to reduce hazardous electronic waste, RoHS differs from WEEE and REACH regulations in key aspects:

WEEE Directive

Focuses on e-waste recycling and recovery requirements once products reach end-of-life stage. Sets collection, reuse and landfill diversion targets.

REACH Regulation

Aims to improve security of chemical substances by assessment and authorization processes. Applies to all industrial sectors utilizing chemicals.

RoHS Directive

Specifically restricts 10 hazardous materials used in electrical and electronic equipment manufacturing processes to reduce toxicity risks.

Key Points on RoHS Standards for PCBs

Adhering to hazardous substance regulations like RoHS is crucial for the electronics industry to reduce environmental and health impacts. For PCB manufacturers and partners, meeting RoHS requirements should be a priority.

As discussed in this guide, RoHS standards restrict 10 materials categorized as toxic heavy metals, flame retardants or otherwise ecologically damaging at end-of-life. By limiting concentrations in production processes and finished PCBs, as well as properly reporting and certifying compliance, the risks posed by these substances can be minimized.

Choosing a reliable, RoHS compliant PCB producer like JHYPCB ensures your boards meet the world’s toughest restrictions on hazardous substances. You can be confident our manufacturing, assembly and testing protocols satisfy all major market regulations while delivering exceptional quality and function.

Partner with us for RoHS compliant PCBs manufactured and assembled responsibly!

Related Posts

- Choosing the Right Metal Core PCB Manufacturer is Critical to Your Success

- How to Get a Quote and Order PCB Assembly?

- Fast Prototype PCB Manufacturing Services in Canada by JHYPCB

- Applications of Different Types of PCBs in Major Industries

- Shenzhen – The Global Hub for High-Quality PCB Assembly Manufacturing

- Choosing the Right PCB Assembly Manufacturer for Your Needs