For LED grow lights, the most important part is the PCB board, which carries the LEDs and needs to dissipate heat quickly, so it is usually made of aluminum with high thermal conductivity. If you are developing LED grow lights or want to customize LED grow lights for your farm or indoor planting, as a one-stop professional printed circuit board manufacturer, JHYPCB can provide you with high-reliability custom LED PCB, grow light manufacturing, and assembly services.

What are LED Grow Lights?

Grow lights are artificial light sources, usually electric, designed to stimulate plant growth by emitting an electromagnetic spectrum suitable for photosynthesis. Grow lights are used in applications where there is no natural lighting or supplemental lighting is required. Example: In winter, when possible daylight hours may not be sufficient for desired plant growth, lights extend the time plants receive light.

LED plant growth lamp is a kind of lamp that uses a light-emitting diode (LED) as the light source and replaces sunlight with light according to the law of plant growth to create a plant growth and development environment. LED plant growth lights help to shorten the growth cycle of plants. The light source is mainly composed of red and blue light sources, using plants’ most sensitive light bands. Red light wavelengths use 630nm and 640-660nm, and blue light wavelengths use 450-460nm and 460-470nm. These light sources can make plants produce the best photosynthesis to get the best growth state.

The necessity of supplementary light in the greenhouse

With the accumulation and maturity of knowledge and technology, the plant grow lamp, regarded as a symbol of modern high-tech agriculture, has gradually entered people’s field of vision. With the gradual deepening of the research on the spectrum, the research has found that different wavelengths of light have different effects on the growth stages of plants. The greenhouse’s interior lighting is important to extend enough light intensity in a day.

How to choose plant grow lights?

Only by choosing the light source scientifically can we better grasp the speed and quality of plant growth. When using artificial light sources, we must choose the natural light closest to the conditions for plant photosynthesis. Measure the photosynthetic luminous flux density PPFD (Photosynthetic PhotonFlux Density) produced by the light source on the plant, grasp the rate of plant photosynthesis and the efficiency of the light source, and the light quantity of photosynthetically active photons initiates the photosynthesis of plants in the chloroplast: including light reaction and subsequent dark reaction.

Features of plant grow lights

- Highly efficient conversion of electrical energy into radiant energy.

- High radiation intensity in the effective range of photosynthesis, especially low infrared radiation (thermal radiation)

- The bulb’s emission spectrum meets plants’ physiological requirements, especially in the effective spectral region of photosynthesis.

Application of grow lights

Grow lights are used for indoor gardening, plant propagation, and food production, including indoor hydroponics and aquatic plants. While most grow lights are used industrially, they can also be used in the home.

- Marijuana cultivation

- Industrial Plant

- Farm

- Mini garden

- Hydroponic Growing

- Anywhere planting Flowers, Succulents, Fruits and greenhouse, etc.

LED Grow light vs. Normal LED, What is the difference?

Many indoor growers wonder if they can use any old LED light as a grow light. They thought these two types of LED lights had no difference as they could both emit human visible light.

However, we cannot use ordinary LED lights as grow lights because their principles differ.

Regular lights only provide illumination; that is to say, they are engineered as an artificial light source in order to lighten your dark spaces. They are comprised of narrow spectral wavelengths and usually do not have the proper spectrum of light to support photosynthesis.

On the other hand, grow lights are specifically designed to generate the right amount of light so plants can photosynthesize.

Many ordinary lamps generate a lot of heat, but the unique design of the plant growth lamp can dissipate heat quickly.

The average lifespan of regular lights is only 750 hours, but many premium LED grows lights last about 50,000 hours, depending on wattage.

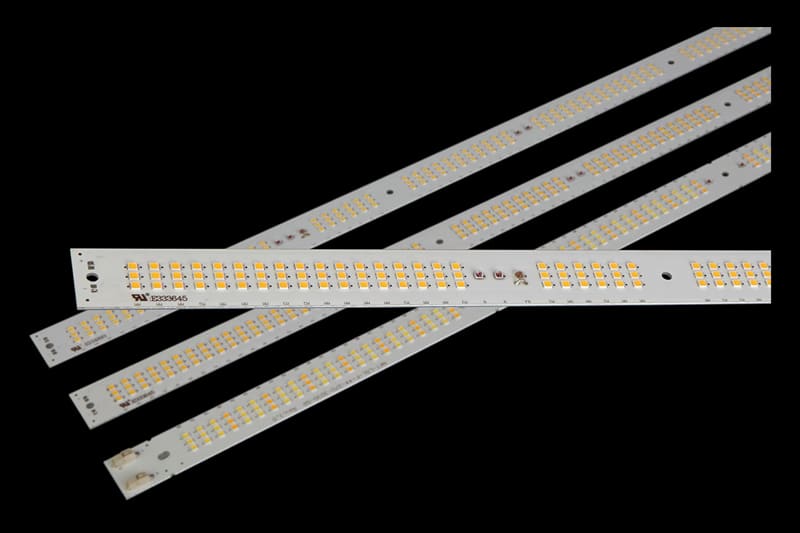

LED Grow Light PCB

The PCB used in most LED grow lights is aluminum based. Because LED light will generate heat, aluminum-based PCB has a thermal conductivity of 1W/mK to 9W/mK, which can play a good heat dissipation effect.

Aluminum PCB for LED grow lights can be single-sided, double-sided, flexible, or multi-layered.

Of course, in addition to aluminum, you can also choose FR4, copper, metalcore, or ceramic as the substrate of the grow light PCB. Ceramic PCBs have better heat dissipation capabilities than aluminum PCBs.

LED Grow lights PCB structure

The aluminum-based copper-clad PCB is a metal circuit board material composed of copper foil, a thermal insulation layer, and a metal base plate. Its structure is divided into three layers:

Circuit Layer: It is equivalent to the copper-clad plate of ordinary PCB, and the thickness of the circuit copper foil is from 1oz to 10oz.

Dielectric Layer: The insulating layer is a heat-conducting insulating material with low thermal resistance. Thickness: 0.003 “to 0.006” inch is the core technology of aluminum-based copper-clad plate, which has been UL certified.

Base Layer is a metal substrate, generally aluminum or optional copper: aluminum-based copper-clad laminates and traditional epoxy glass cloth laminates.

LED Grow Lights PCB Manufacturing Capability

At JHYPCB, we have offered PCB solutions using many different materials for more than ten years. We provide LED PCB manufacturing, component sourcing, and assembly under one roof. We are flexible and can work with you to develop the best metal core PCB – customized for your specific requirements. Our LED PCBs are all made with a thermal aluminum clad layer to dissipate heat, keep the PCB components cool, and improve your products’ performance.

We take pride in our 99% customer satisfaction rating and our reputation for being known as a PCB solutions provider. We offer quality PCBs to businesses and have a fast turnaround time. The table below shows our LED PCB manufacturing capacities.

| Quality Offered | Standard IPC Class 2, IPC Class 3 |

| Layers | 64 Layers |

| Board Size | Min 6*6 mm, Max 610*610 mm |

| Board thickness | 0.5-8.0mm |

| Copper thickness | 1-3oz |

| Thermal conductivity | 1.0-4.0W/m K |

| Breakdown voltage | 2-8KV |

| Min.Line Width | 0.15mm |

| Min.Space | 0.15mm |

| Min.Hole Size | 0.15mm |

| Min.BGA PAD | 14mil |

| Impedance control PCB | ≤50Ω ±5Ω |

| Solder mask | White, Black, Green, Blue |

| Profile Routing | V-CUT, Punch |

| Surface Finishes | HASL, HASL (Lead-free), Immersion gold/Tin, OSP |

| Min Track / Spacing | 4 mil / 4 mil |

| Test | 100% test, flying probe testing |

| Monthly capacity | 30000 square meters |

LED Grow Lights PCB Assembly Service

If you have already designed the PCB for your LED grow light and want to verify it, you can use our PCB prototype manufacturing service; if you need mass production, you can also choose us. Our high-quality, high-efficiency PCB manufacturing services will leave you satisfied.

Established in 2011, JHYPCB is an advanced PCB manufacturer and assembly service provider with two large PCB manufacturing and PCB assembly factories. We provide one-stop LED plant grow light PCB manufacturing, assembly, LED procurement, component sourcing, conformal coating, testing, and other services.

Conclusion

If you want to manufacture LED grow lights or are looking for a one-stop turnkey LED grow light PCB manufacturing and assembly service that can provide you with from prototype to mass production, please don’t miss JHYPCB, which has rich experience and absolute advantages.