As electronics companies race to meet growing market demand amidst supply chain uncertainties, leveraging turnkey PCB assembly manufacturing partners provides assurances when outsourcing production. Turnkey PCB assembly providers offer end-to-end services spanning fabrication, component procurement, SMT and THT assembly, testing, and even fulfillment/logistics support under one roof.

This consolidates the entire value-chain for creating fully assembled PCBs or electronics units ready for distribution and sale. Working with an expert turnkey assembly partner reduces effort spent coordinating multiple suppliers and contracts. It also compresses timelines compared to separately orchestrating board fabrication, component sourcing, inspection, assembly, testing, etc.

As demand volatility persists across consumer IoT, automotive electronics, 5G infrastructure, and other industries, original design manufacturers stand to gain by examining expanded outsourcing opportunities with turnkey PCB assembly manufacturers. This post examines the benefits, tradeoffs, and provider qualifications to guide decision making.

Table of Contents

Capabilities of a Turnkey PCB Assembly Provider

The core value proposition of turnkey PCB assembly partners hinges on the breadth of integrated manufacturing capabilities under one business entity. Key offerings to assess span:

- Full Assembly Services

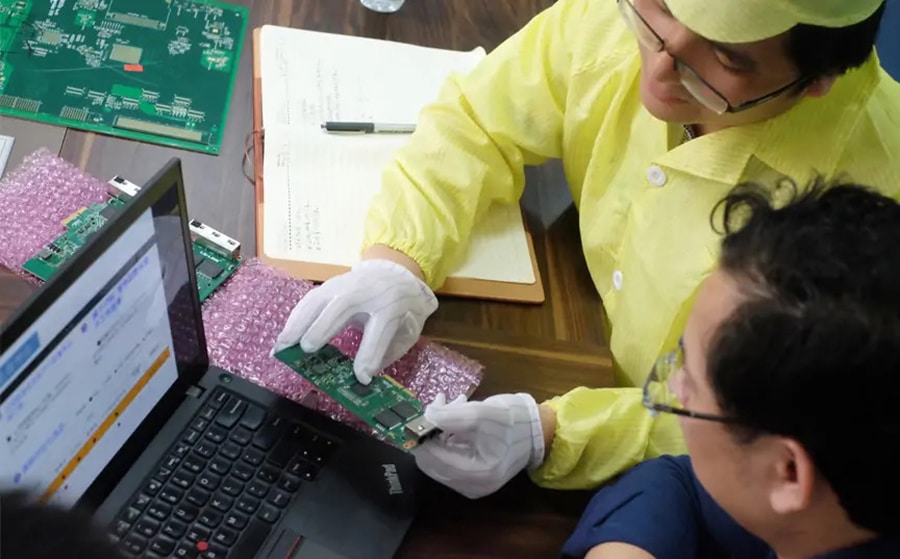

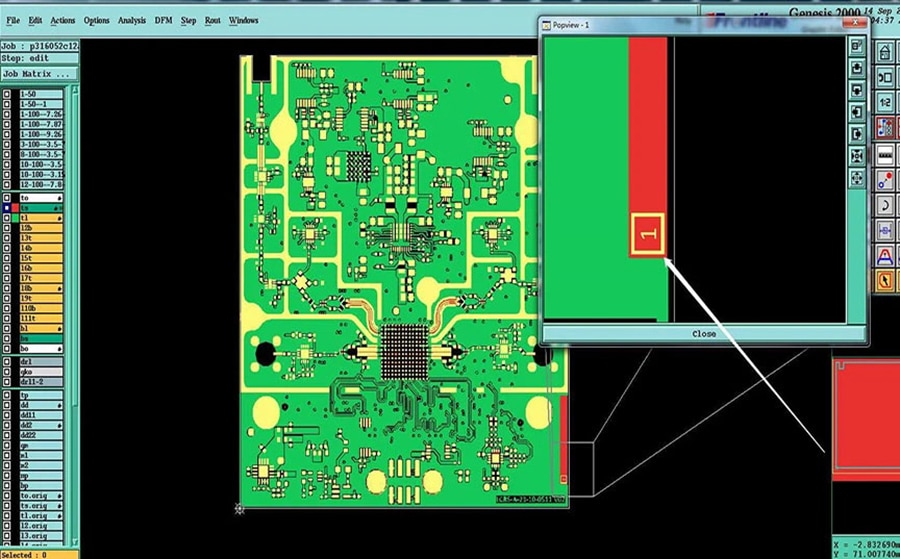

A qualified turnkey provider manages all assembly processes spanning SMT population, through-hole insertion, manual assembly, cleaning, AOI, etc. This consolidates the entire workflow reducing customer burden. - In-House PCB Fabrication

Combining PCB manufacturing and assembly proves essential for rapid prototyping, accelerating new product launches. On-site fabrication bolted to assembly lines ensures smooth material flow. - Component Procurement

Take rate of supply chain functions like procurement, inventory management, and qualifying BOMS merits review. The less customers directly handle upstream, the faster products productionalize. - Logistics and Fulfillment

End-to-end oversight optionally extends to outbound functions like order fulfillment, warehousing/storage, global shipping, and forward stocking hubs helping products reach markets quicker.

Streamlined and Simplified Process

Beyond quality manufacturing functions, working with turnkey PCB assembly partners simplifies engagement models for customers through:

- Single Point of Contact

Consolidating all manufacturing and supply chain expertise under one account team allows for unified project oversight, instead of collaborating with disparate suppliers and fragments of organizations. - Reduced Procurement Overhead

With the partner managing procurement, inventory planning, production scheduling, and shipping logistics, effort otherwise spent coordinating various vendor contracts lightens. - Expedited Time-to-Market

Turnkey orchestration compresses manufacturing lead times by sequencing fabrication, assembly, inspection, test, fulfillment seamlessly sans delays between hand-offs among subcontractors.

The streamlined coordination through an integrated provider boosts speed by curtailing excess administrative activities. This allows engineering customers to focus innovation resources on core product development and market launch.

Expertise and Technology

Beyond efficient operational integration, leading turnkey PCB assembly manufacturers further differentiate through:

- Specialized Equipment and Capabilities

Top tier providers continuously invest in advanced machinery including high-speed SMT mounters, automated optical inspection (AOI) systems, expanded testing functionality, and smart storage to bolster quality and output. - Industry Knowledge

Seasoned players develop specialization around customer verticals most actively innovating like consumer electronics, automotive, industrial automation etc. This translates to tailored solutions. - Process Engineering Depth

Engineering prowess matters immensely for evolving complex designs reliably. Seasoned turnkey partners wield decades of process engineering institutional knowledge around PCB assembly optimization, yield improvement, and output innovation.

The depth of expertise and technology infrastructure determine ultimate production ceiling and robustness for more intricate electronics critical to emerging segments.

Scalability

A key advantage of leveraging turnkey PCB assembly manufacturing services involves the scalability to adjust output volume spanning:

- Support Diverse Volume Needs

Leading providers accommodate low, medium, and high-volume production scenarios making them invaluable for volatile consumer device demand fluctuations where forecasting proves tricky. - Prototype to Mass Production

The under-one-roof integration readily adapts for seamlessly transitioning pilot prototypes to larger pre-production ramps through high-yield mass manufacturing with aligned quality procedures across the continuum. - Global Manufacturing Footprint

Geographic diversity of manufacturing centers across North America, Europe, and Asia provides localized assembly options closer to target markets helpful for international supply continuity and expedited fulfillment requirements.

This volume flexibility coupled with global infrastructure better equips engineering customers to scale intelligently as market adoption dictates while meeting regional compliance needs proactively early in product lifecycles.

Conclusion

As engineering teams weigh make vs buy tradeoffs amidst turbulent component supply ecosystems, partnering with vetted turnkey PCB assembly manufacturing providers offers strategic relief. Their integrated fabrication through post-production support bridges capability gaps companies face trying to stay nimble solo long-term.

Key aspects to drive alignment center on verifying production scale readiness globally, component procurement adaptability, quality consistency during ownership transfers, and retaining enough internal engineering bench strength for sustaining differentiated innovation as outsourcing ratios rise. Finding the right balance hinges on honest business assessment of core vs contextual strength.

Turnkey assembly partners equipped as flexible capacity amplifiers help buffer unpredictability companies will continue facing. We welcome any additional questions technology firms have regarding optimizing manufacturing strategies.